Method for manufacturing heat exchanging tube of heat exchanger

A manufacturing method and heat exchanger technology, applied to heat exchange equipment, indirect heat exchangers, tubular elements, etc., can solve problems such as difficult welding, difficult control of gaps, and reduced heat exchange efficiency, so as to eliminate false welding and assembly work Efficiency improvement, effect of improving heat exchange efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

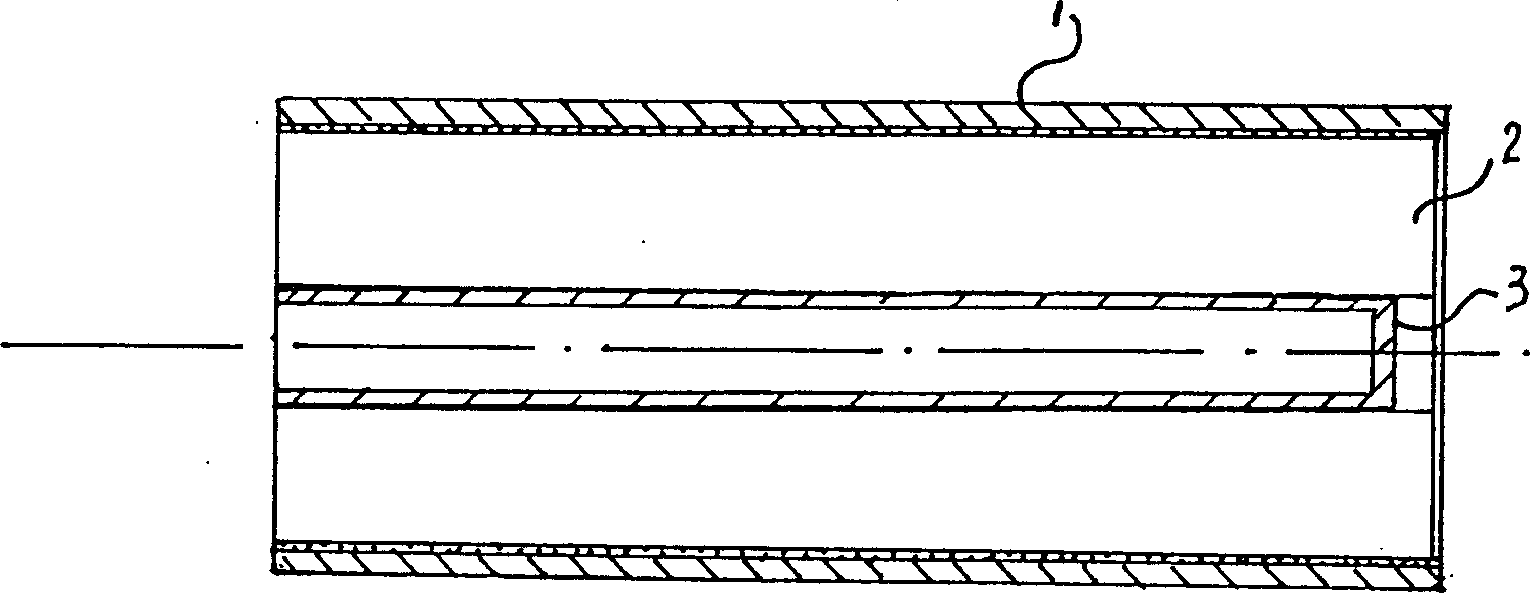

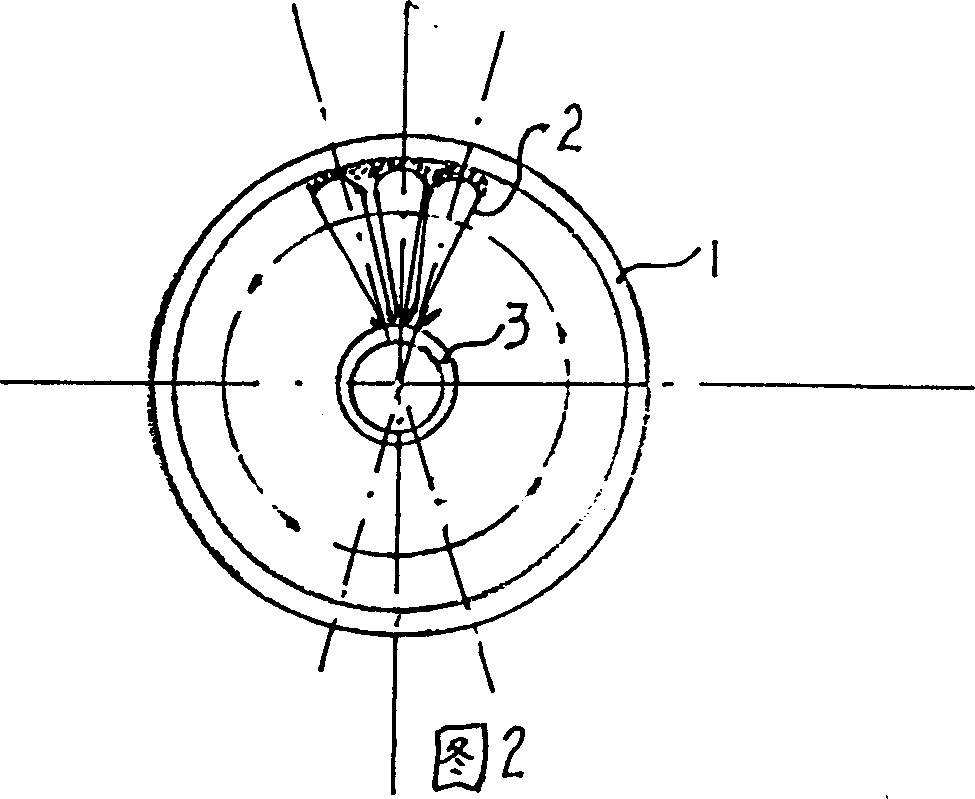

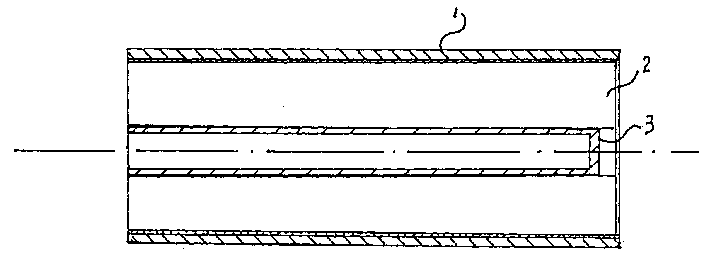

[0011] As shown in the figure, the manufacturing method of the present invention includes the following steps: (a), cutting the outer tube 1, the fin tube 2 and the core tube 3; (b), penetrating the core tube 3 into the wing (c), the outer surface of the finned tube 2 is hung with solder and then fitted into the lumen of the outer tube 1 in a dynamic fit manner; (d), the outer tube 1 end is pre-shrunk for a length and penetrates into the shrinking mold, and the inner diameter of the shrinking mold is set to be smaller than the outer diameter of the outer tube 1 by 1 mm; (e), one end of the outer tube 1 is placed in a lathe chuck for clamping, and the other One end is tightened with the head of the tailstock of the lathe, and corrected so that the axes of the chuck, the outer tube 1 and the head coincide, and the shrink film is fixed on the large carriage of the lathe; (f), the lathe is opened, and the drive chuck The disk drives the outer tube 1 to rotate, and the moving of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com