Patents

Literature

300results about How to "Improve assembly work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

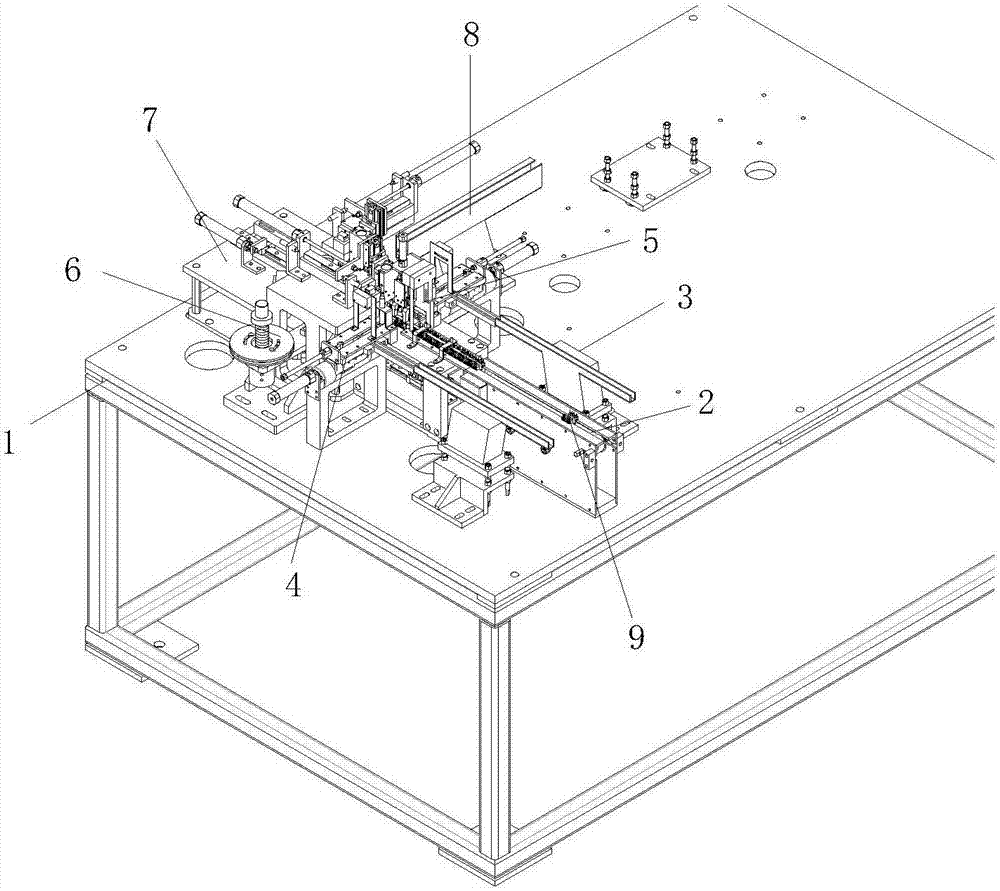

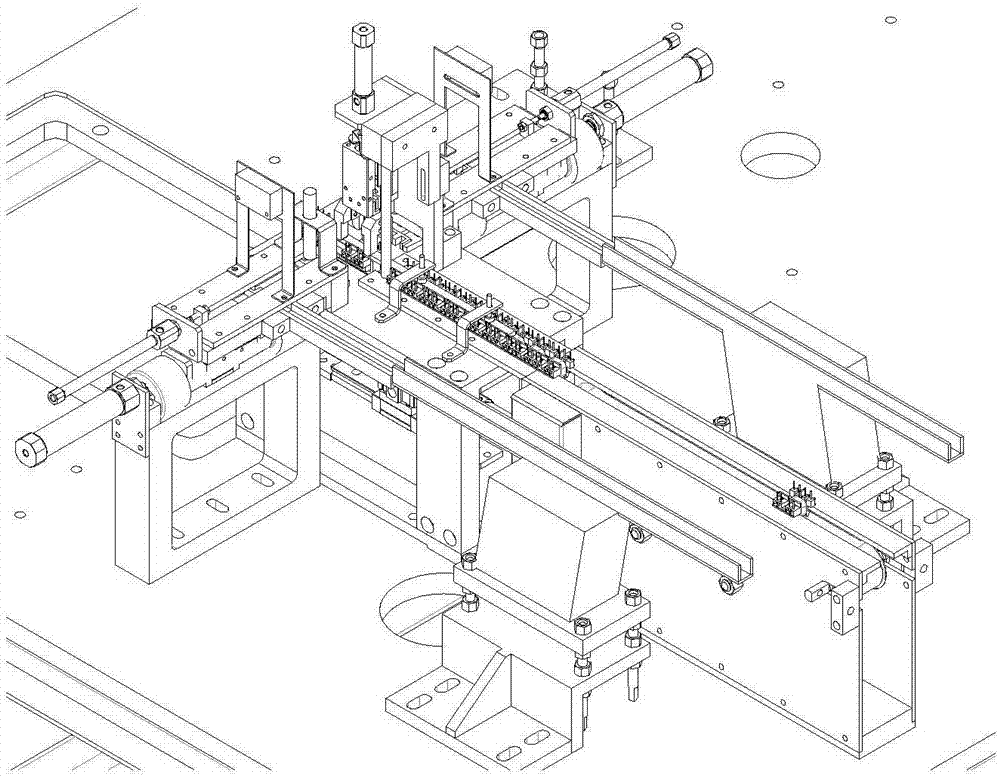

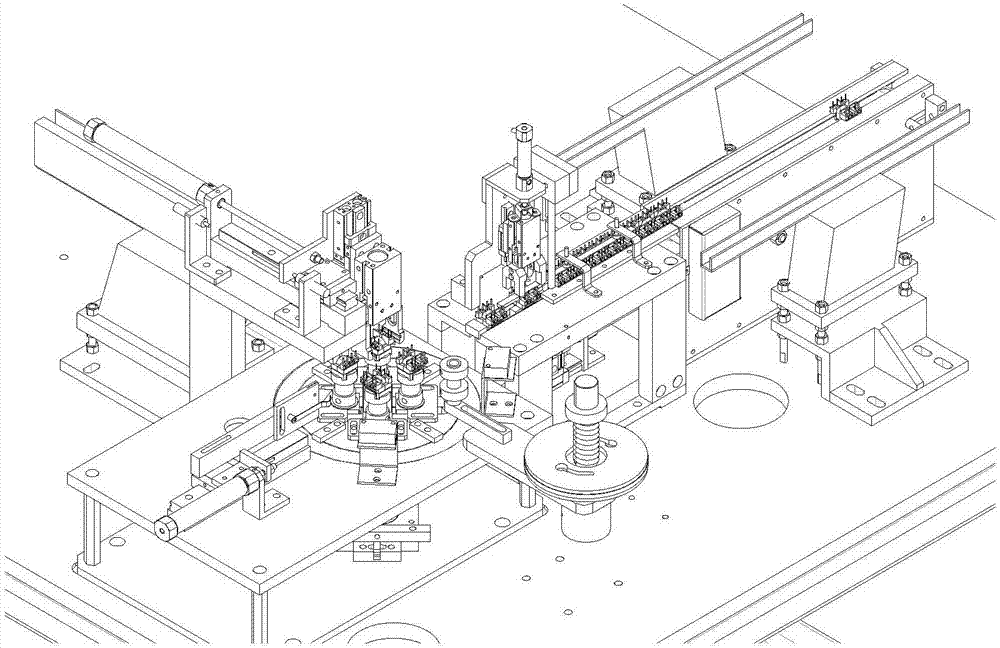

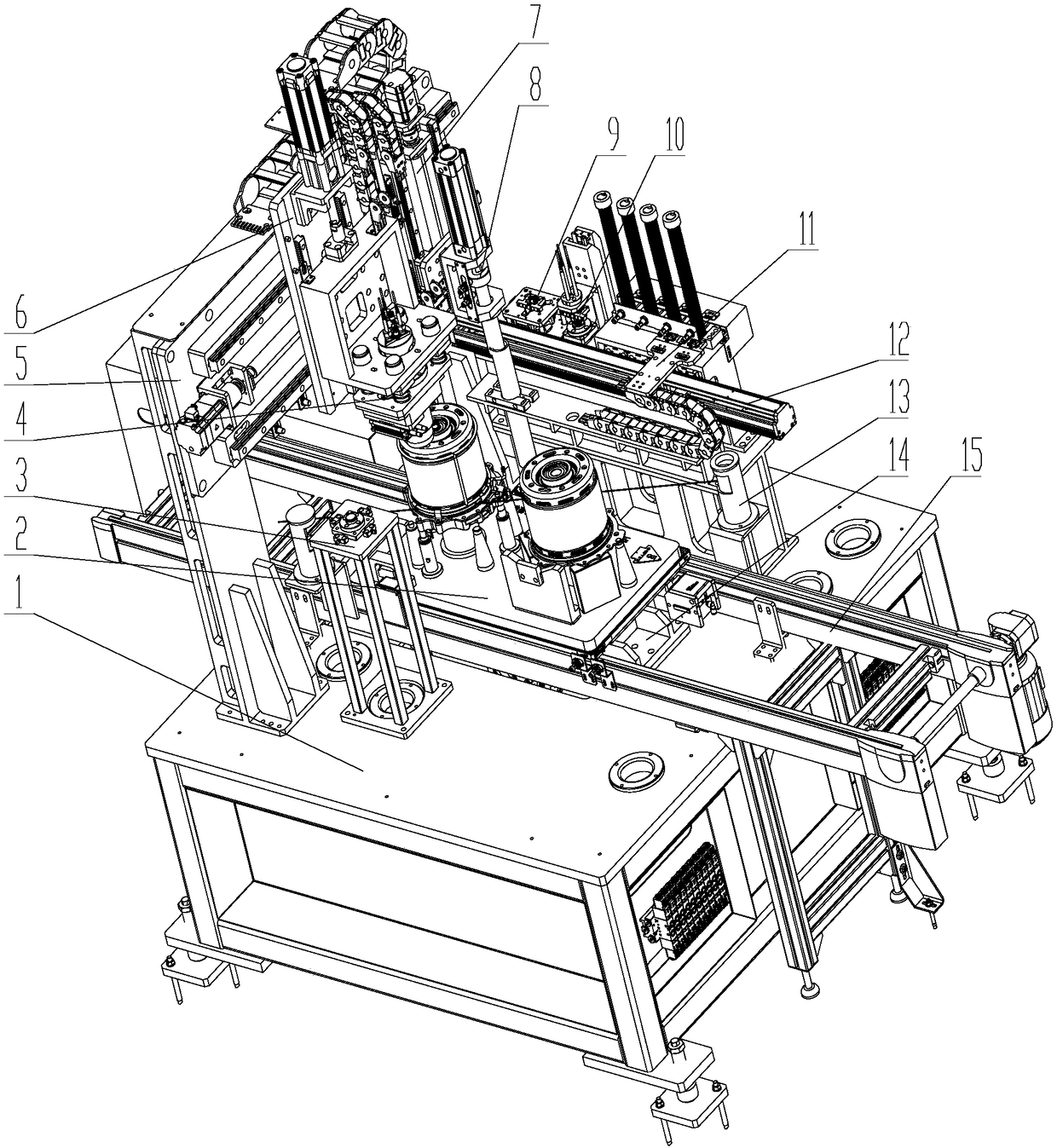

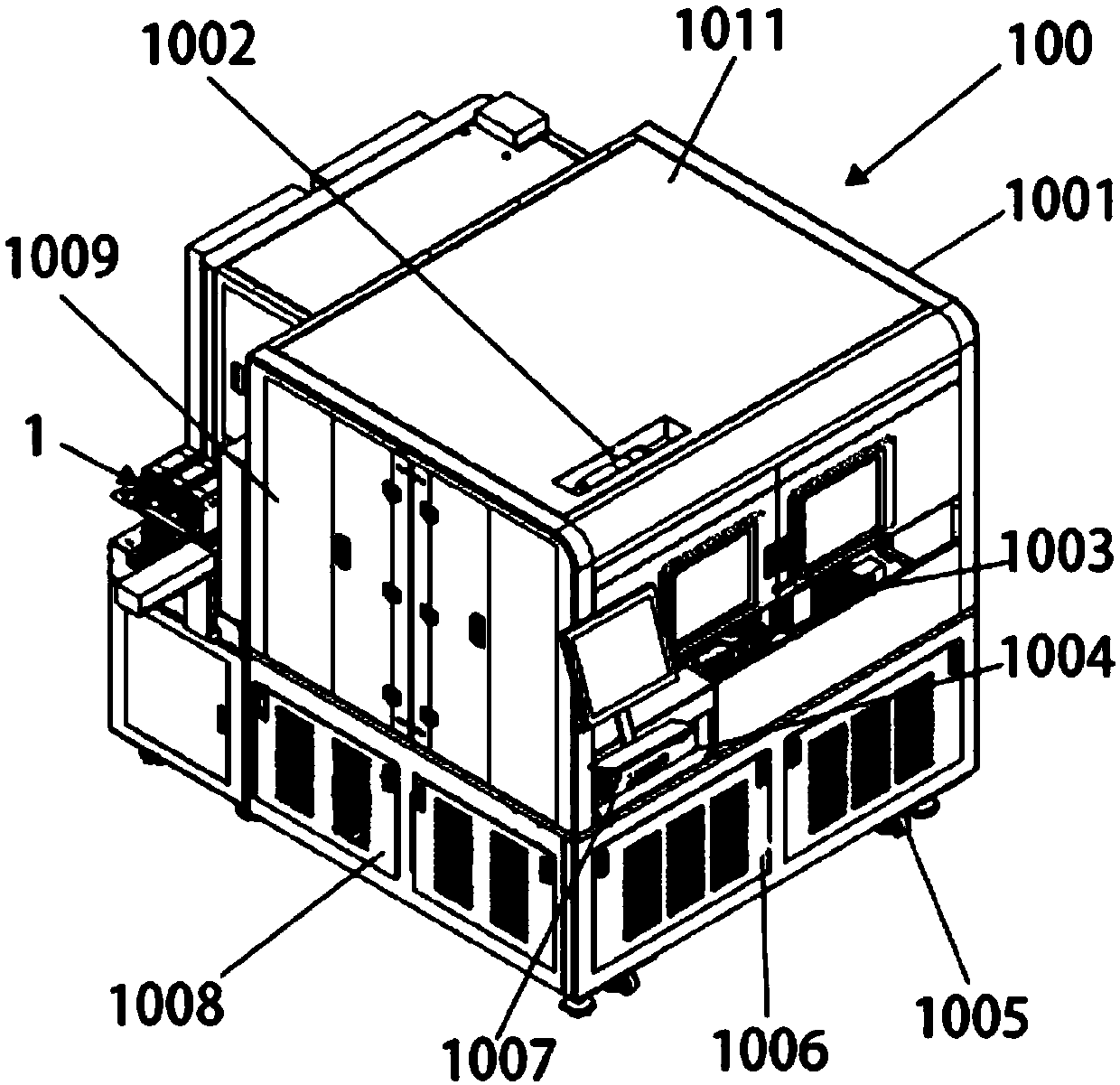

Household electrical appliance product transformer assembly assembling system

ActiveCN106876128AImprove assembly work efficiencyAchieve windingAssembly machinesInductances/transformers/magnets manufactureButt jointAdhesive

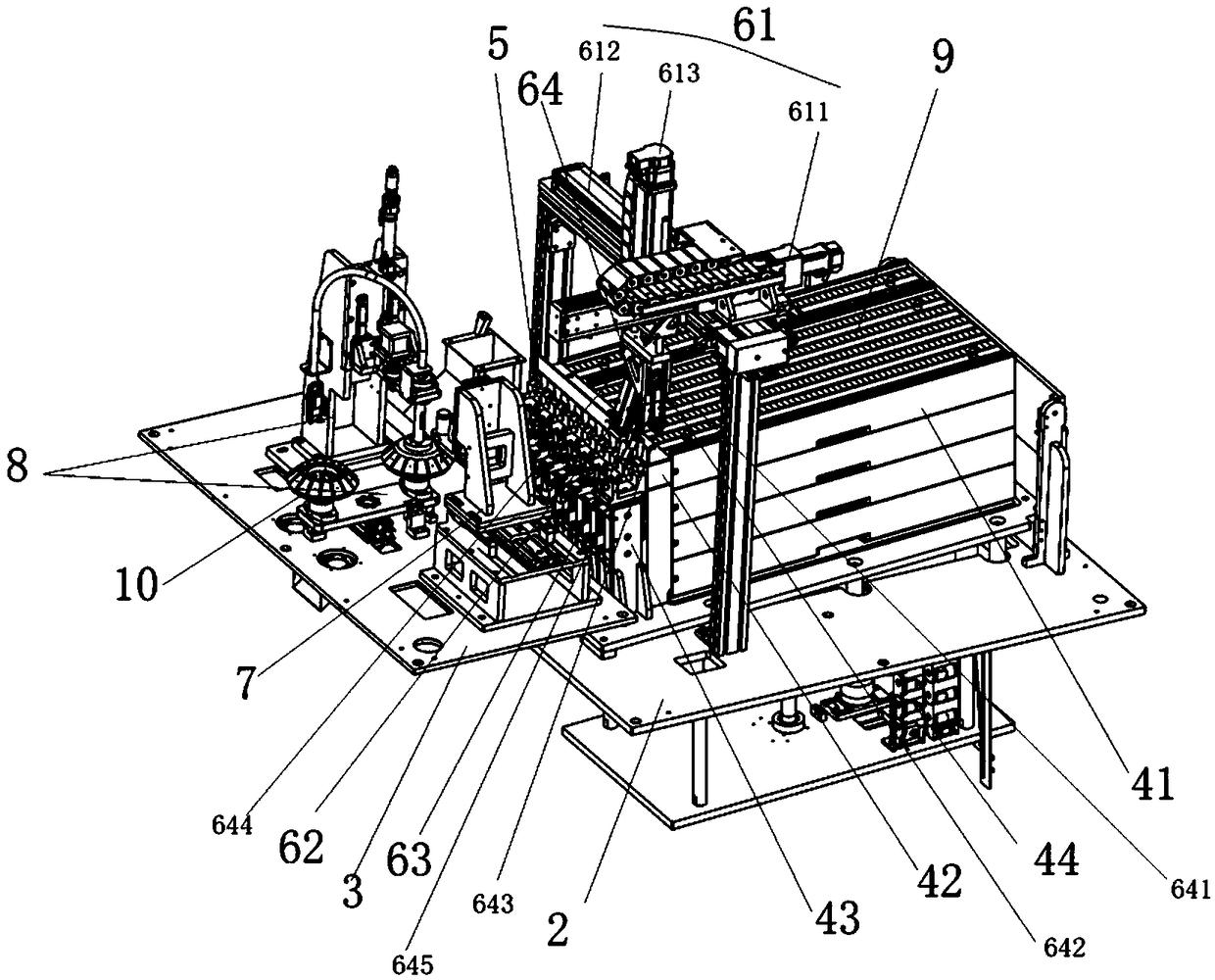

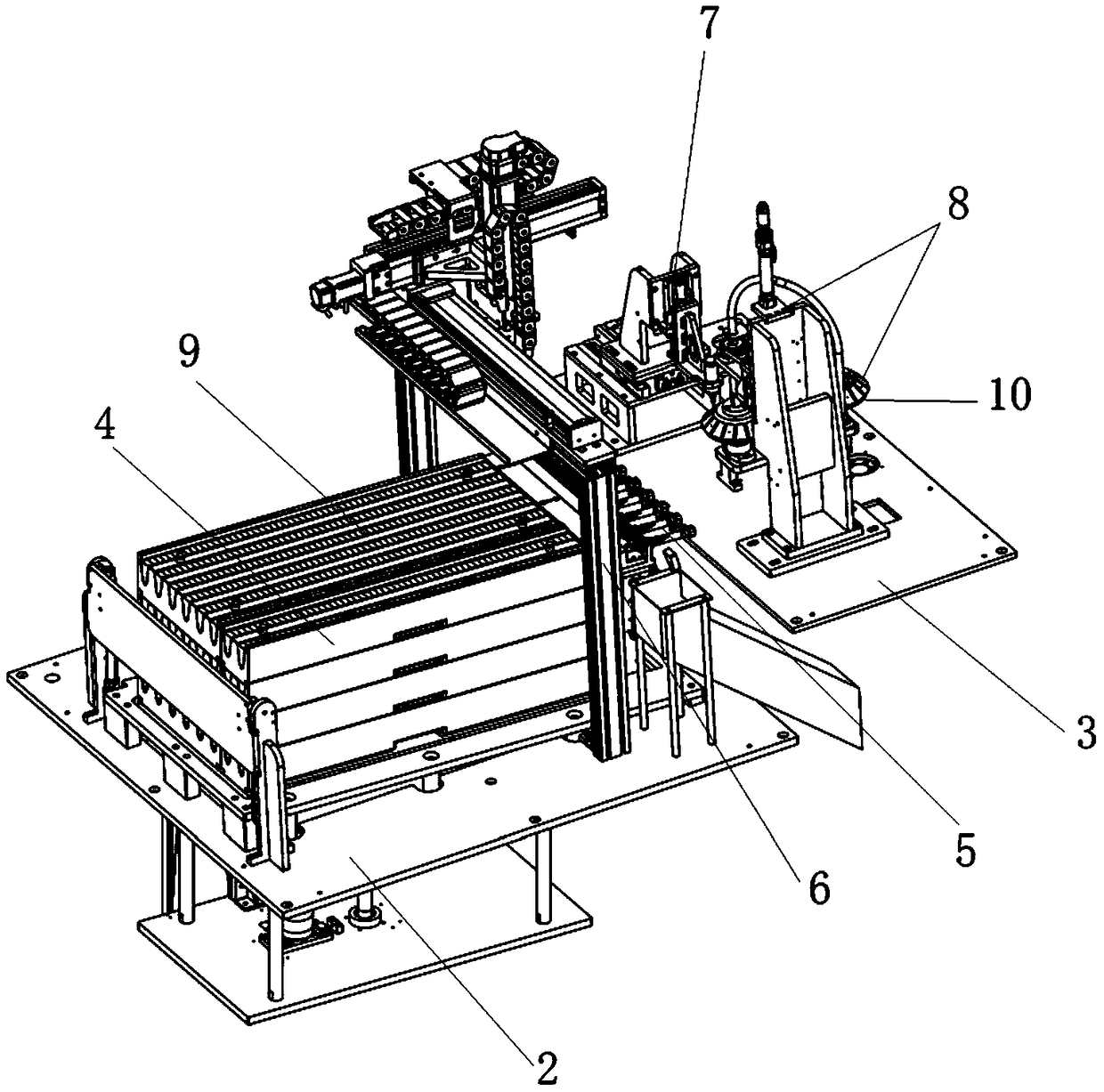

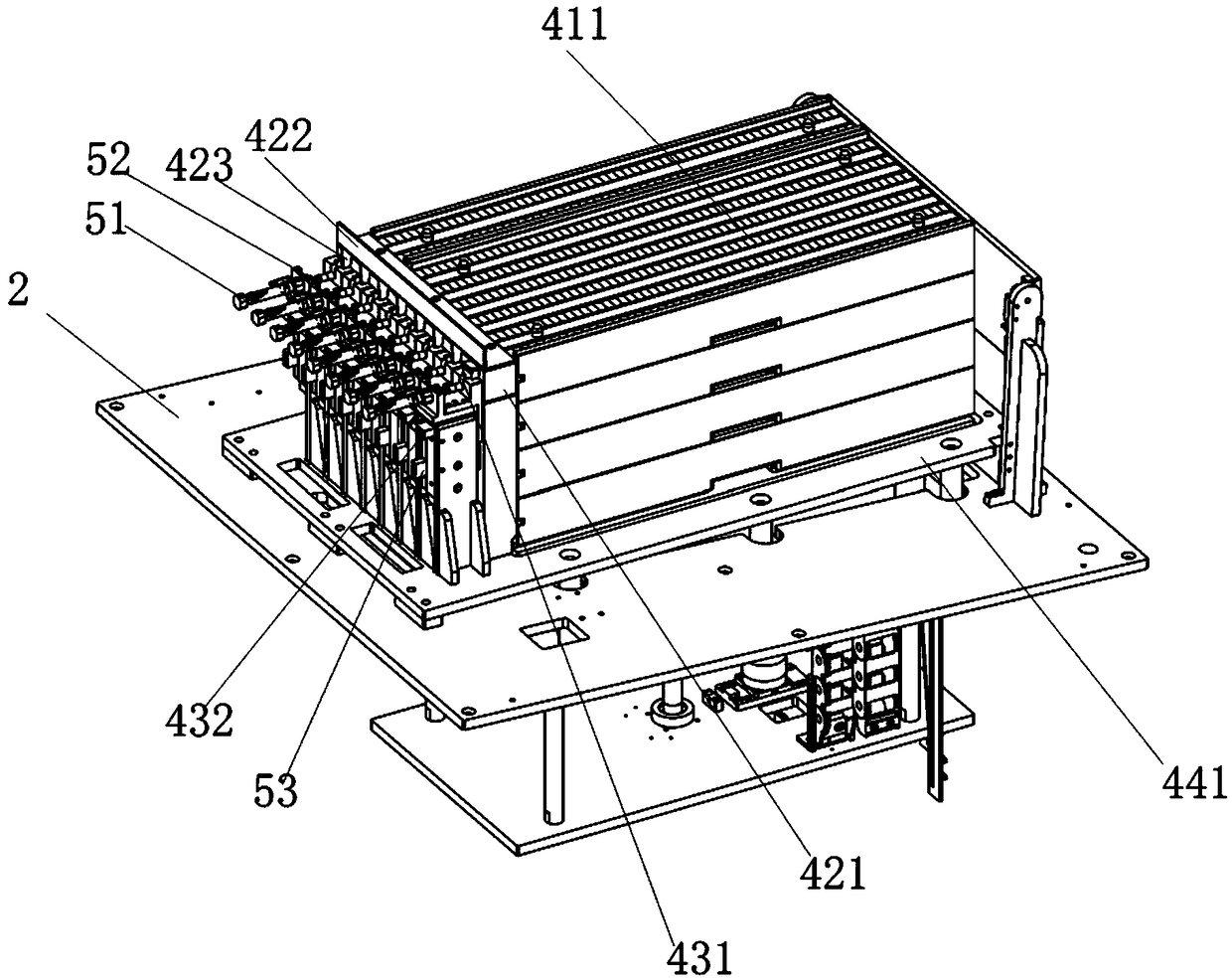

The invention discloses a household electrical appliance product transformer assembly assembling system. The household electrical appliance product transformer assembly assembling system includes a rack and a workbench arranged on the rack; a first conveying mechanism, a second conveying mechanism, a third conveying mechanism, an assembly magnetic core inserting positioning mechanism, magnetic core inserting mechanisms, a feeding and grabbing mechanism, an adhesive tape conveying mechanism, a rotation adhesive tape winding mechanism, and a discharging grabbing mechanism are arranged on the workbench, wherein the first conveying mechanism, the second conveying mechanism and the third conveying mechanism are used for conveying a transformer assembly to be assembled; a discharging end of the first conveying mechanism is in butt joint with a feeding end of the assembly magnetic core inserting positioning mechanism; the magnetic core inserting mechanisms are arranged on two sides of the assembly magnetic core inserting positioning mechanism; feeding ends of the magnetic core inserting mechanisms are in butt joint with a discharging end of the second conveying mechanism for conveying a magnetic core; and the feeding and grabbing mechanism is correspondingly arranged on a discharging end of the assembly magnetic core inserting positioning mechanism. The household electrical appliance product transformer assembly assembling system is reasonable in structural design, can achieve rapid inserting and rapid winding of the magnetic core, can achieve continuous assembly production, and can greatly improve the assembly working efficiency.

Owner:浙江预立兴川机器人技术股份有限公司

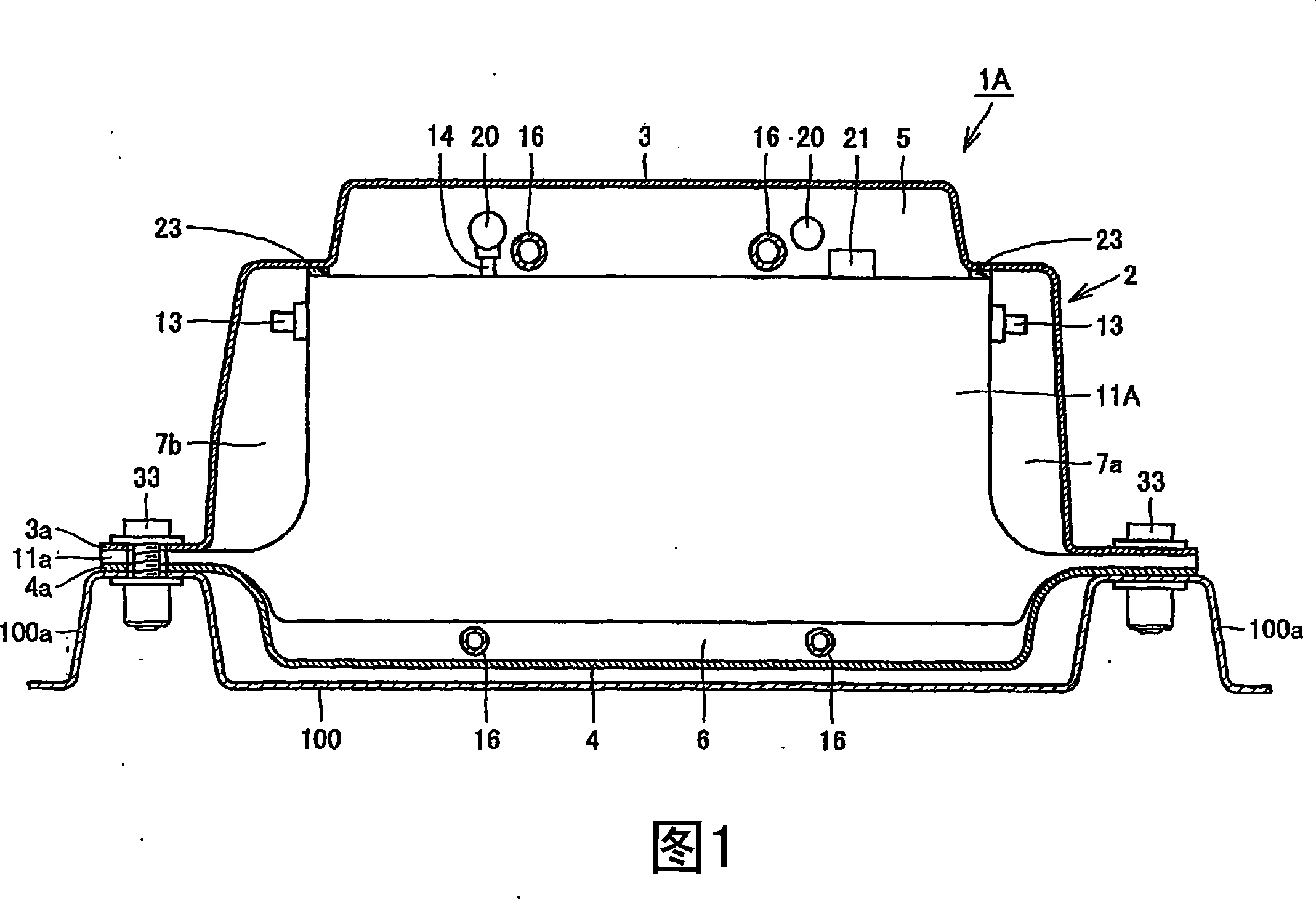

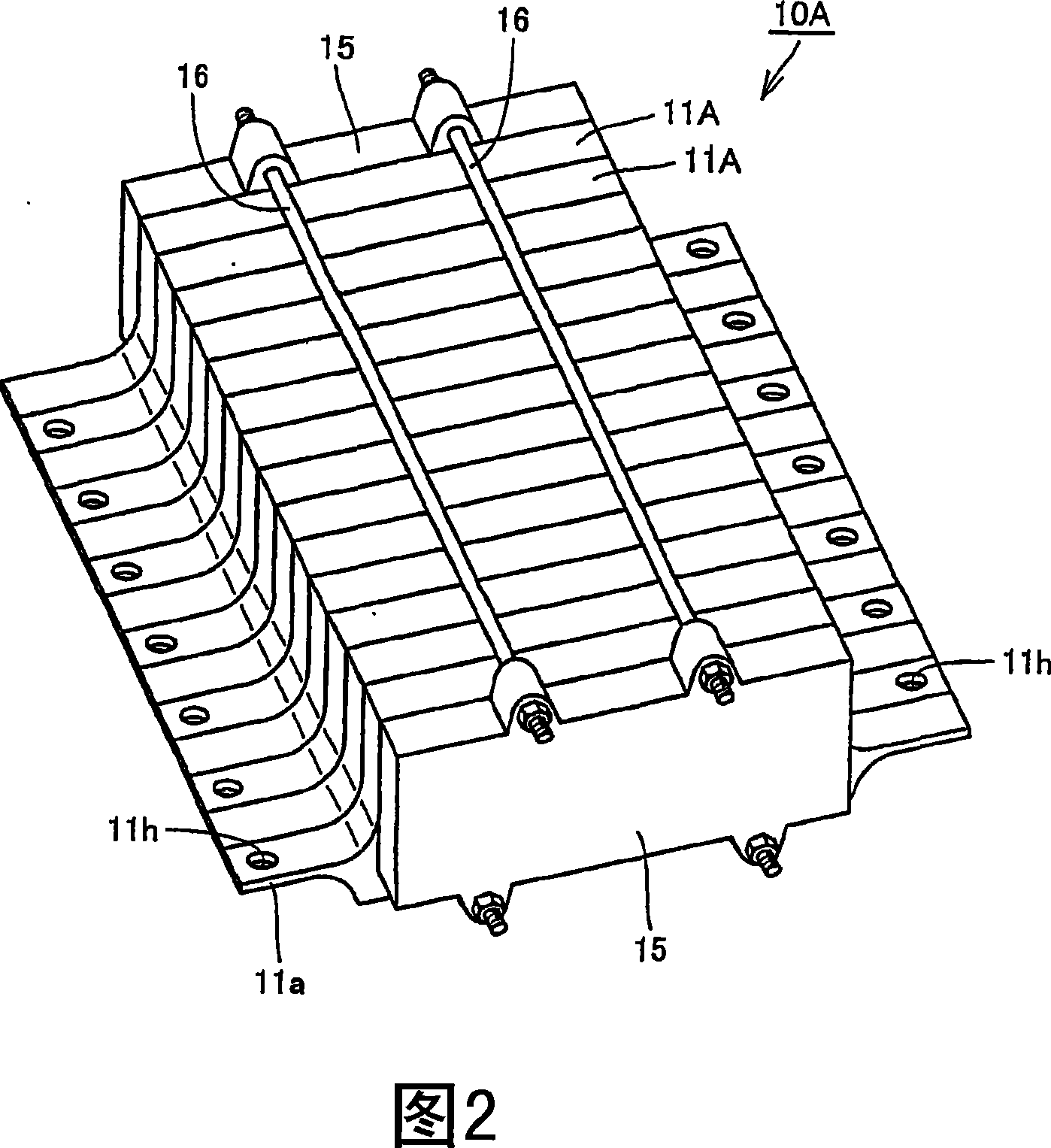

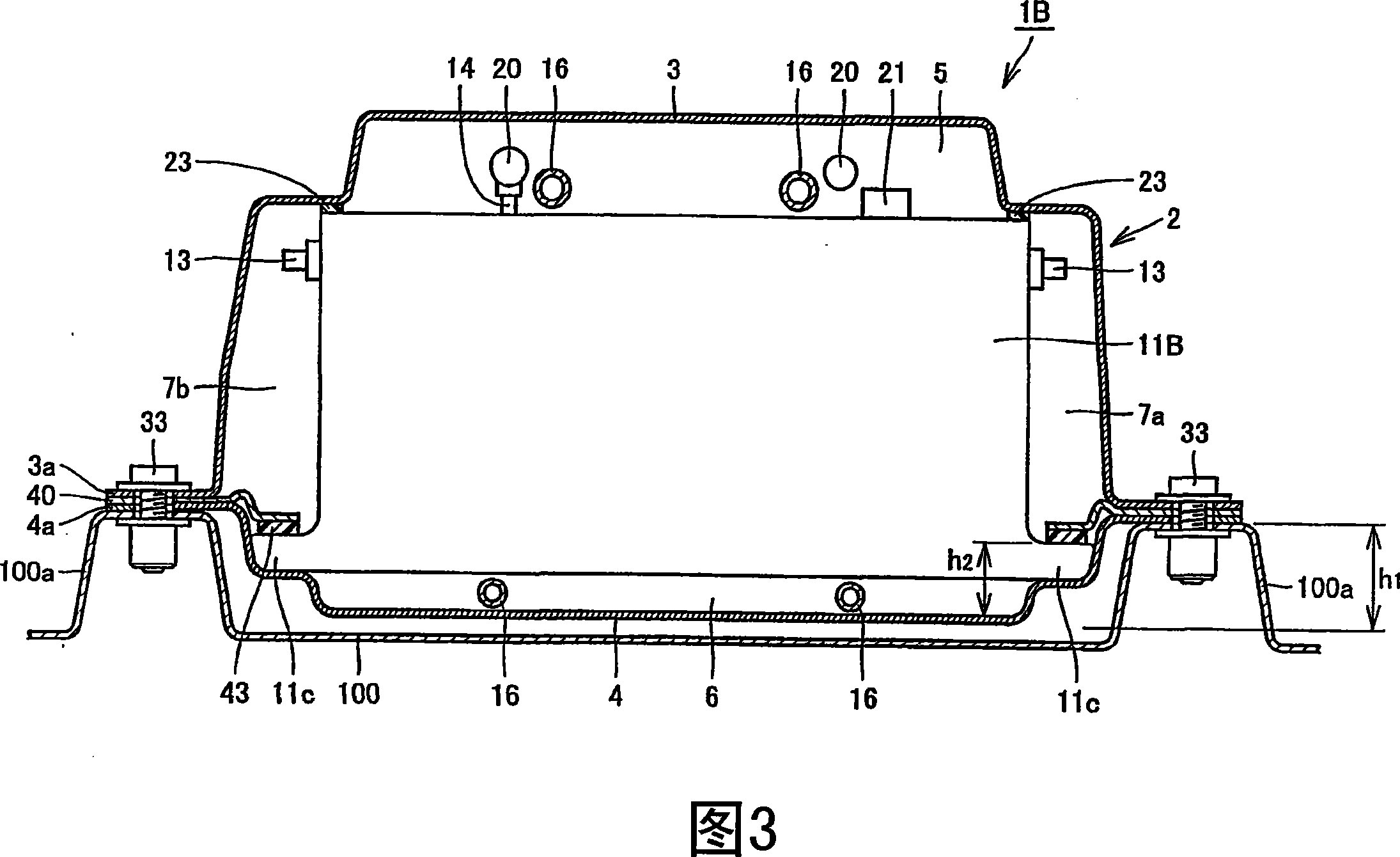

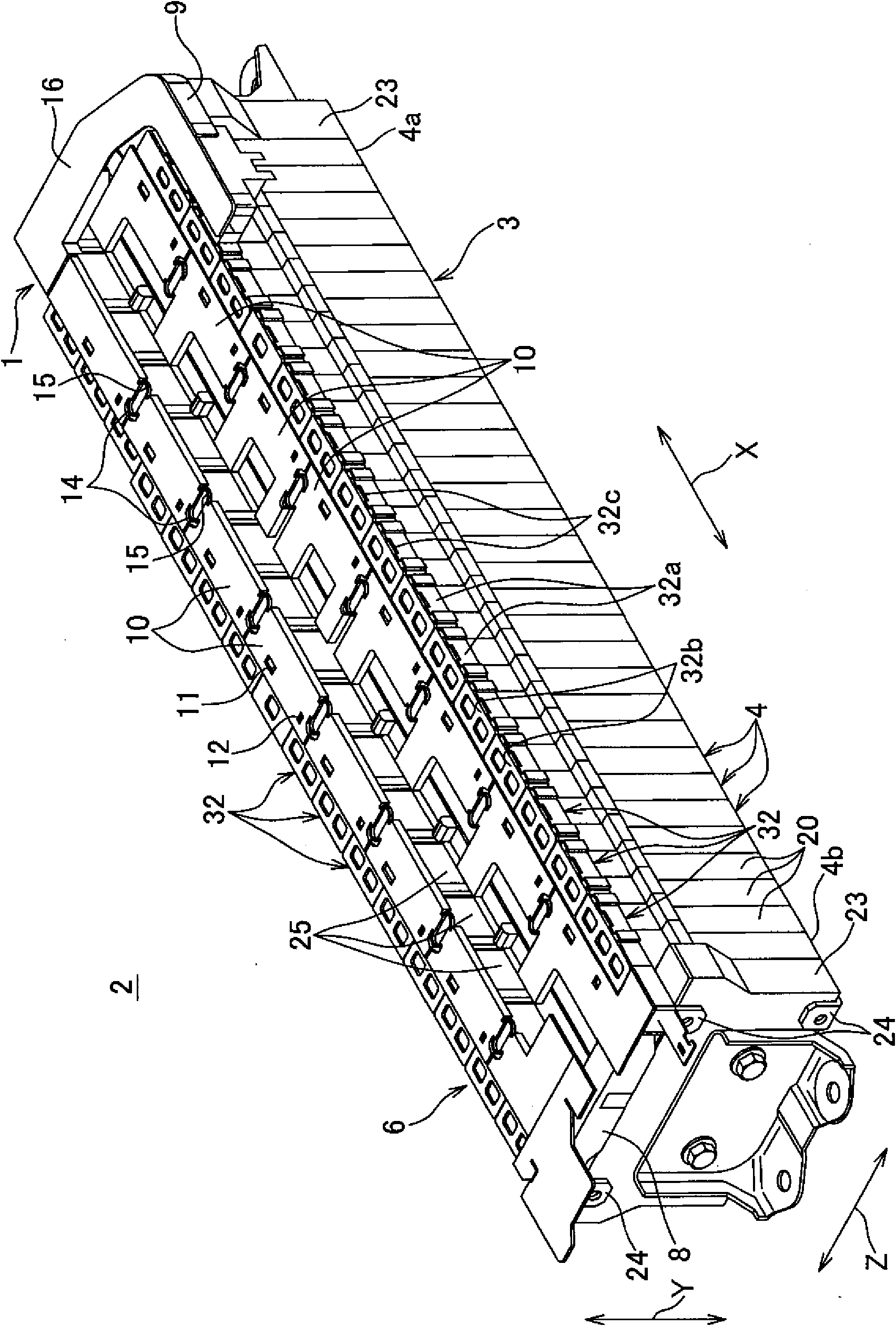

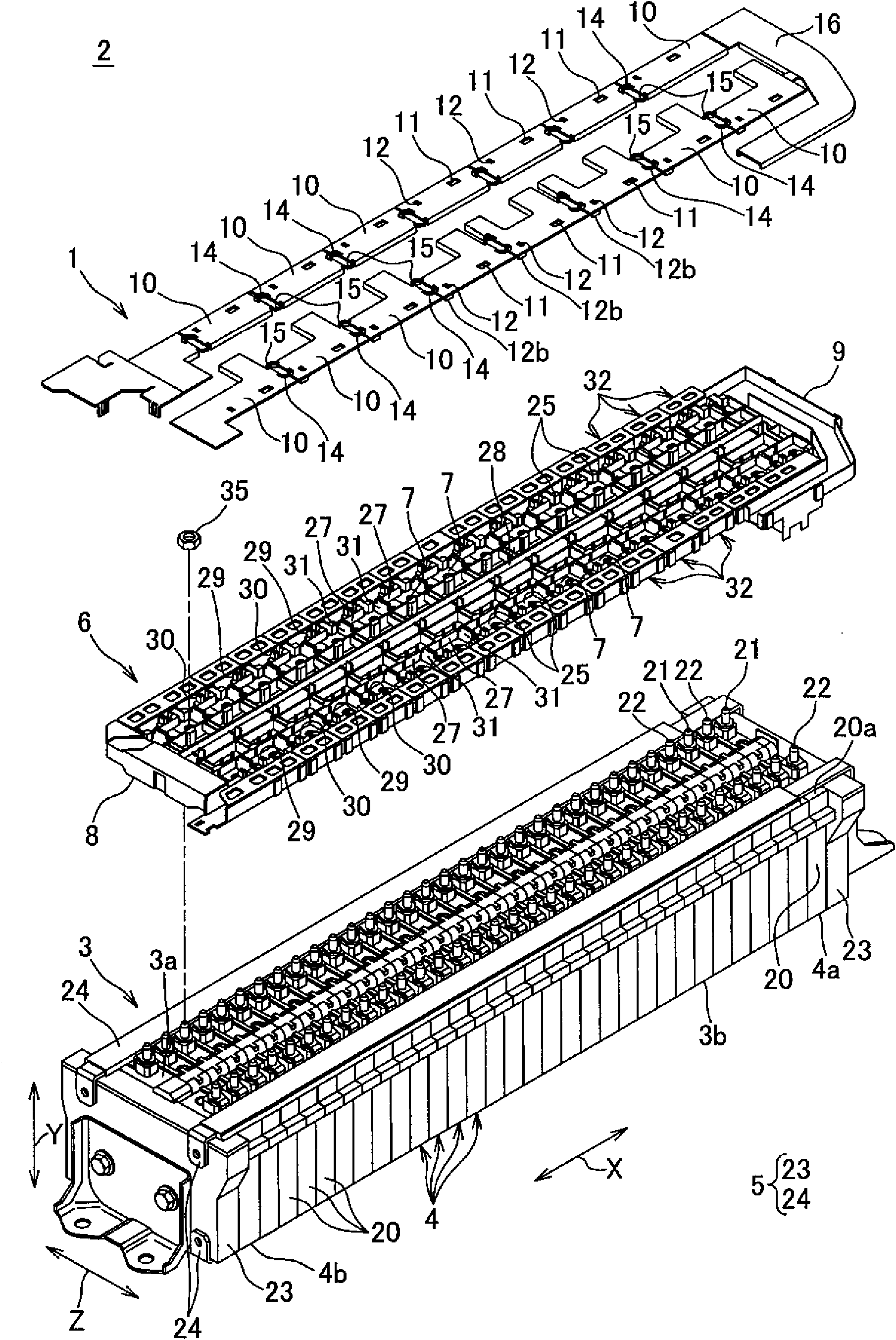

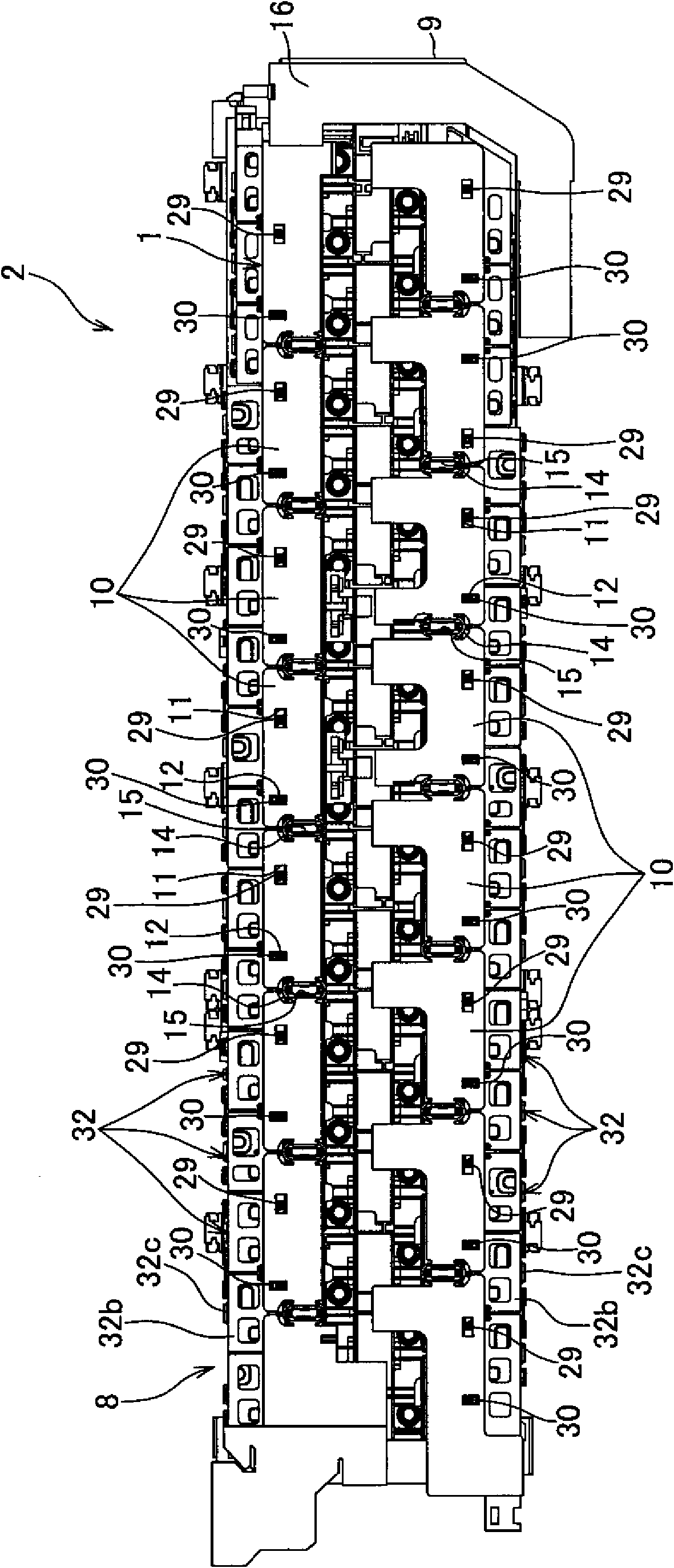

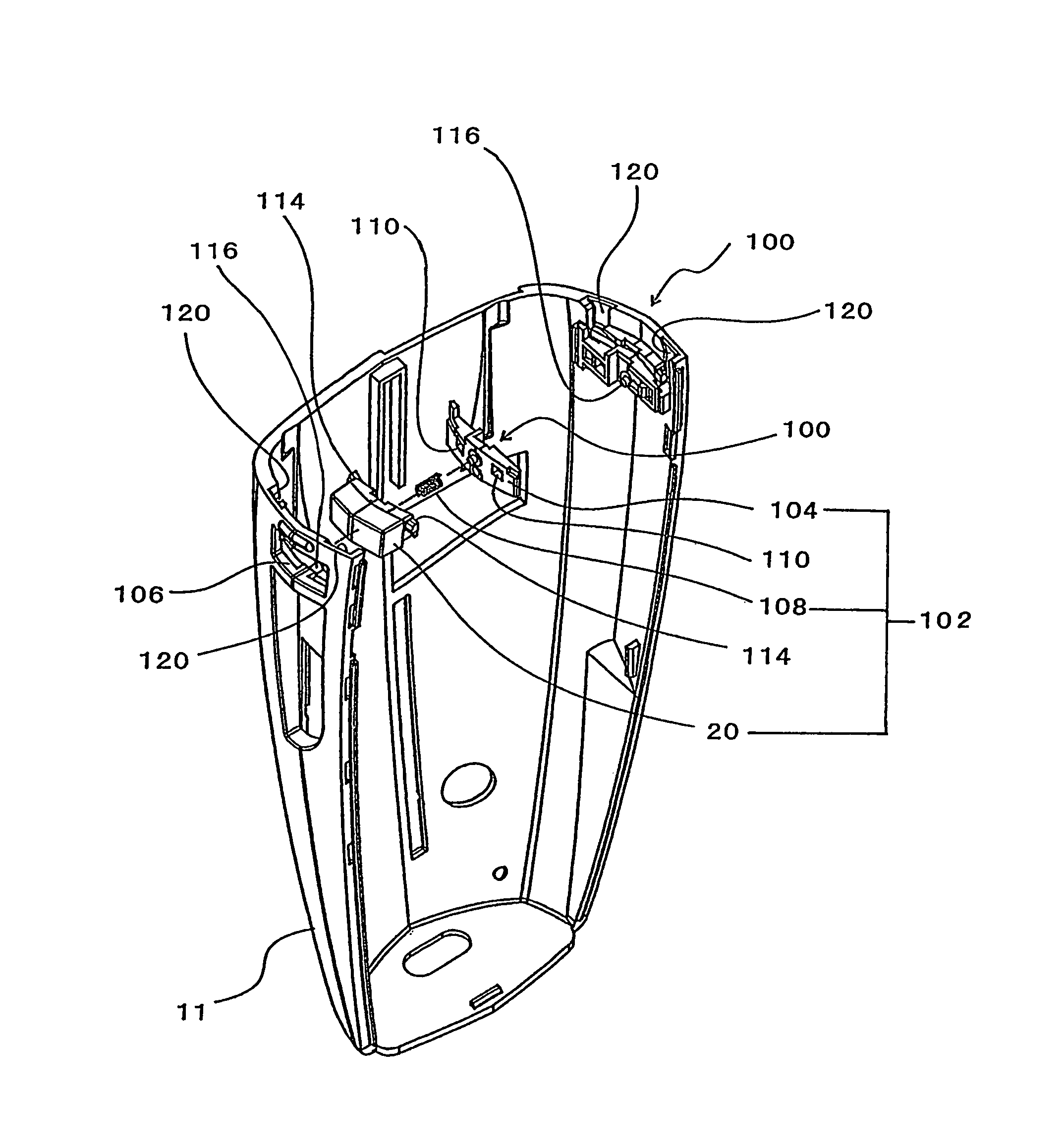

Battery pack

InactiveCN101128946AImprove assembly work efficiencyReduce in quantitySecondary cellsCell lids/coversEngineeringBattery pack

In a battery pack, battery pack flange portions (11a) are provided at opposing sides of a battery assembly (10A) along a stacking direction of battery modules (11A), so as to project laterally. The battery module flange portions (11a) are interposed between an upper case flange portion (3 a) and a lower case flange portion (4a) when the upper case flange portion (3 a) and the lower case flange portion (4a) are overlaid, and fastened and fixed concurrently by bolts (33). The bolts (33) are also used in fixing the battery pack (1A) to a vehicle (100). With this configuration, a battery pack that can reduce assembly steps with the bolts and the like to improve efficiency in the fastening work can be provided.

Owner:TOYOTA JIDOSHA KK

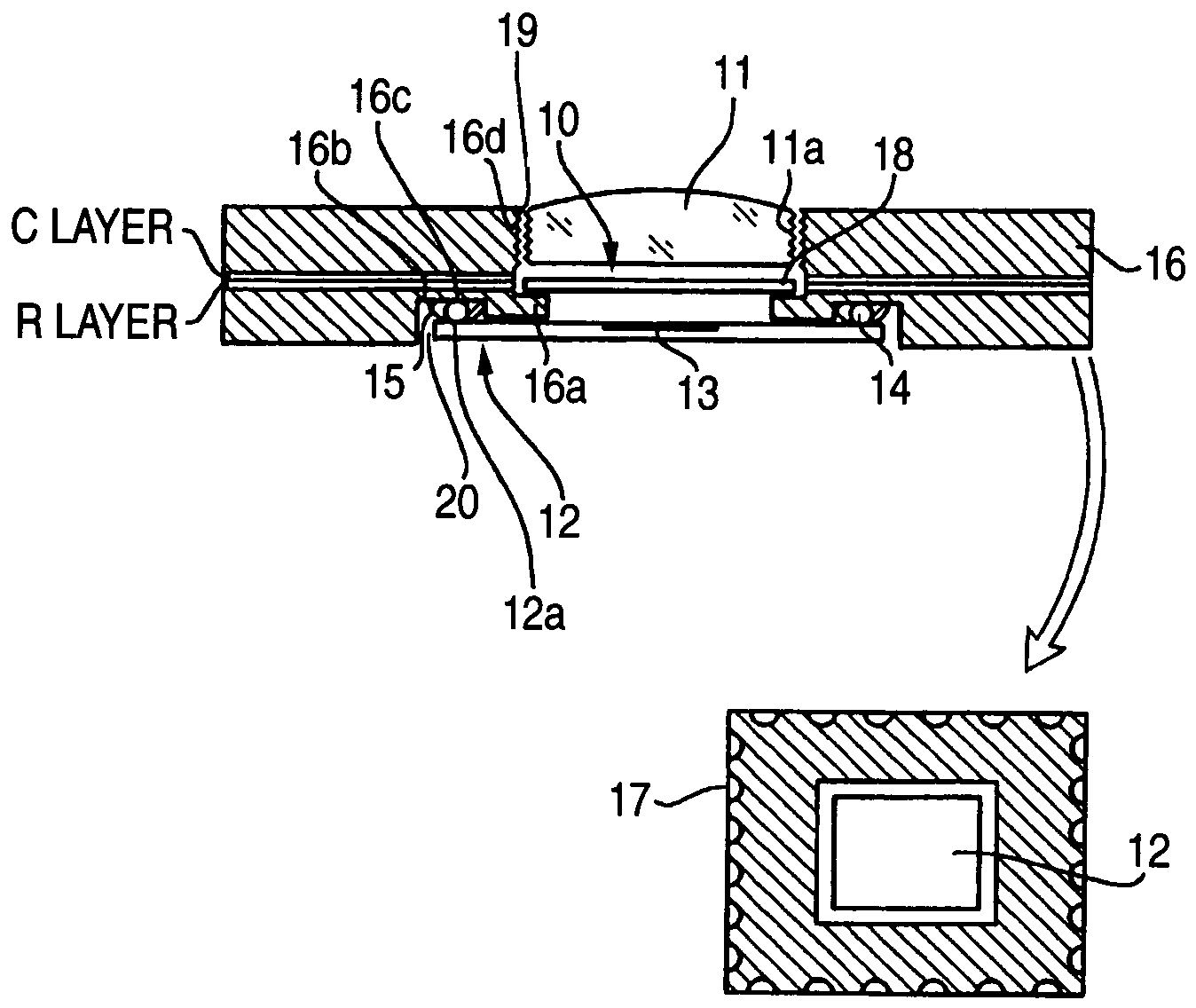

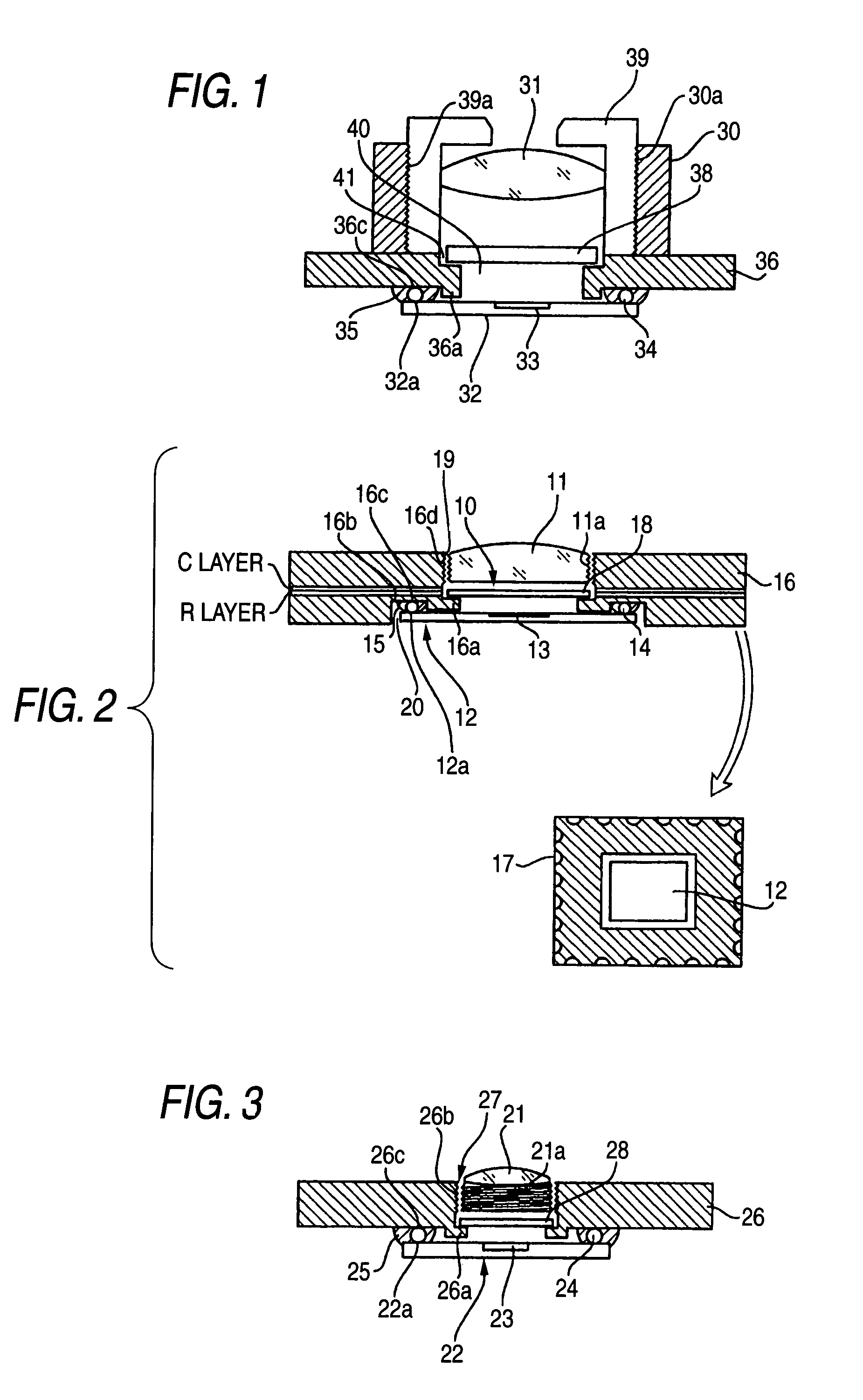

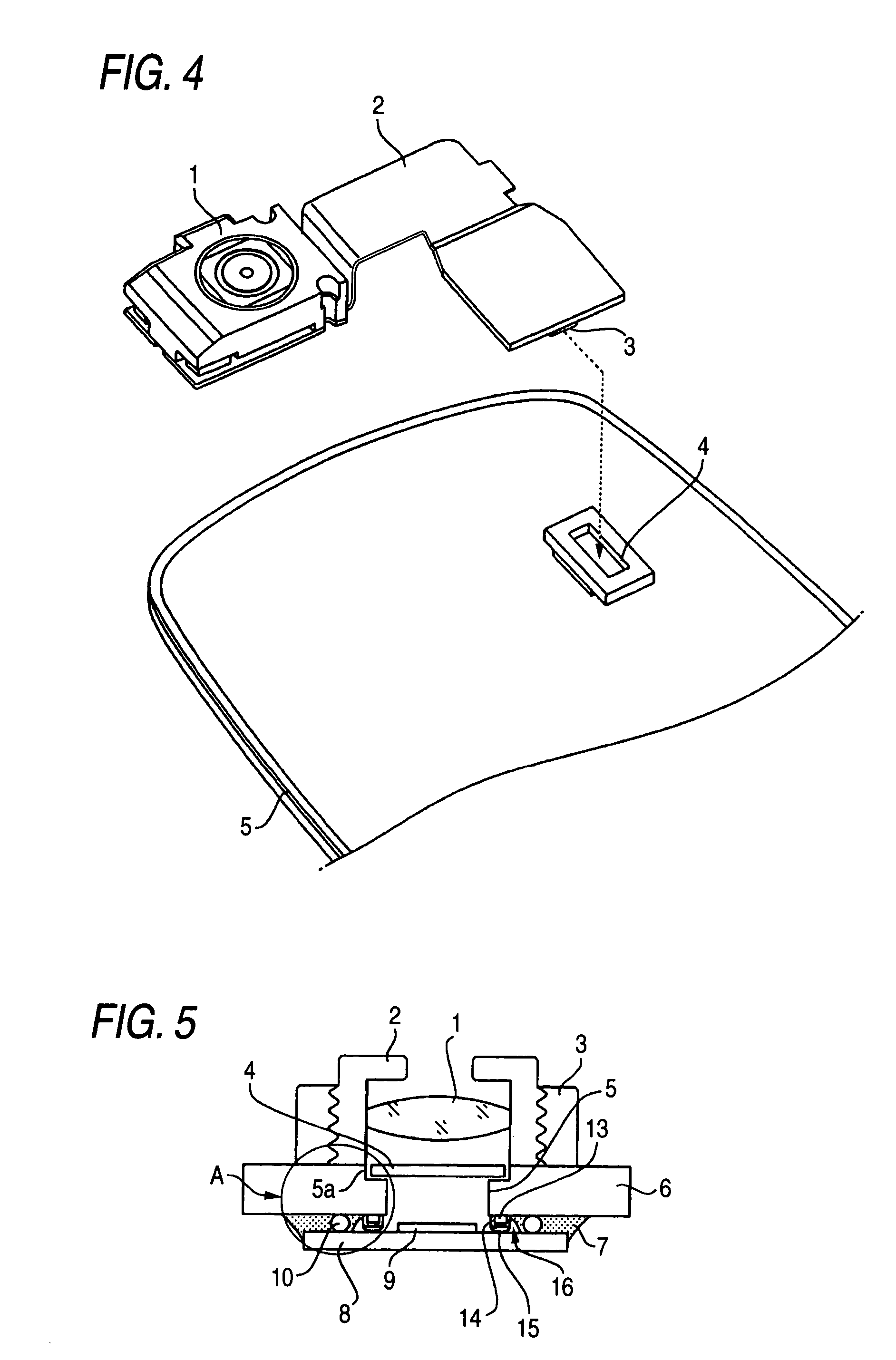

Imaging device package camera module and camera module producing method

InactiveUS7583309B2Improve signal-to-noise ratioImprove assembly work efficiencyPrinted circuit assemblingTelevision system detailsFlat glassCamera module

An IR cut-filter is fitted into a support portion within the optical-system containing portion of a ceramic board and a lens 11 is mounted in the ceramic board by screwing the lens.In an imaging-device containing portion, an imaging device with a light receiving portion arranged therein is mounted outside the support portion by flip-chip packaging. Further, the vicinity of the flip-chip packaging portion is sealed with resin.Additionally, on the base of the imaging-device containing portion of a ceramic package, the lands of an imaging device are so positioned as to correspond to the respective land positions of a ceramic package and patterns are electrically connected by melting a gold bump, whereby the imaging device is mounted by bare-chip packaging. The land portion is filled with an underfill agent and then sheet glass is mounted on a through-hole 5b and sealed with a sealing agent, so that the through-hole 5b for containing a light receiving portion is sealed up.

Owner:KYOCERA CORP

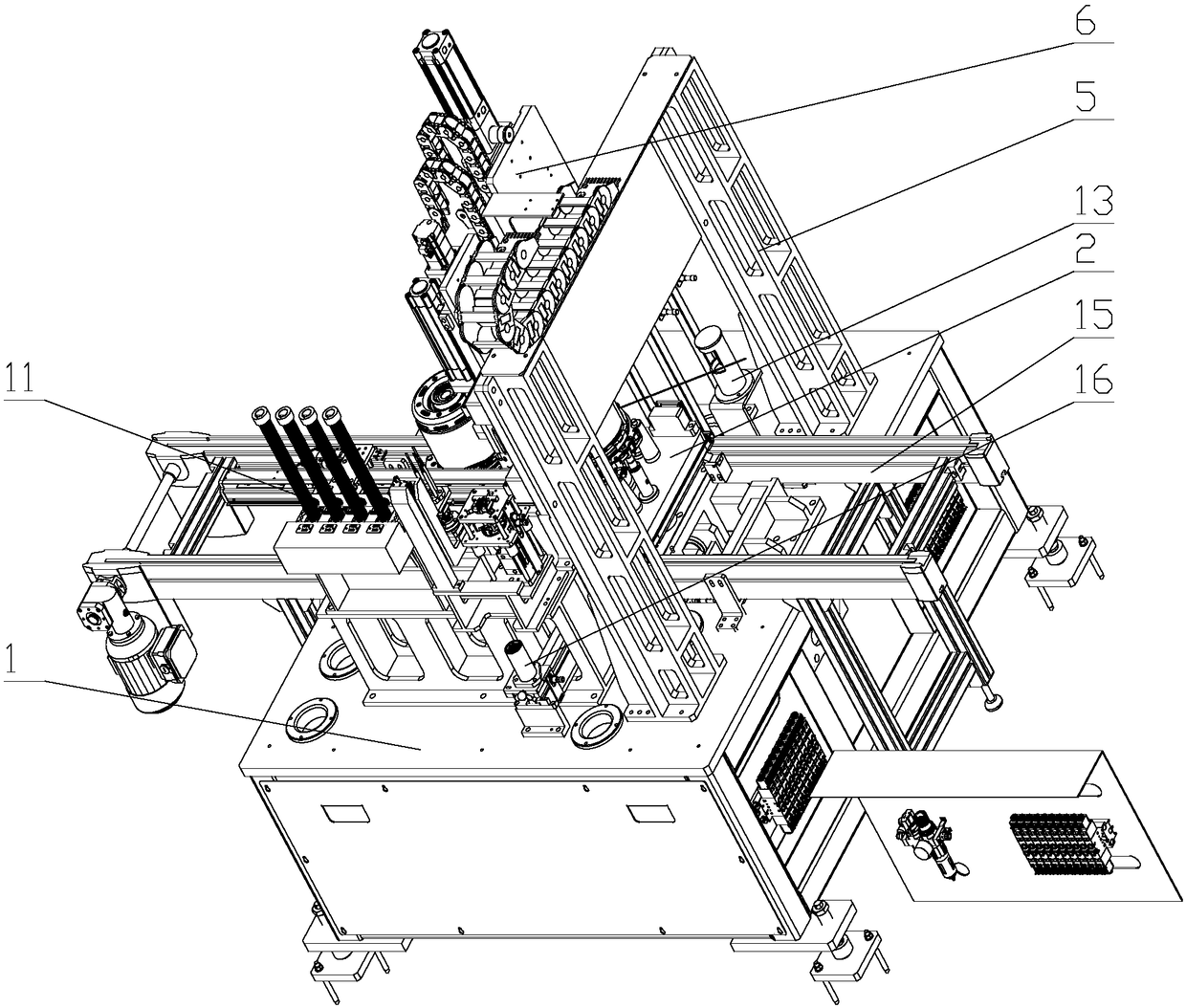

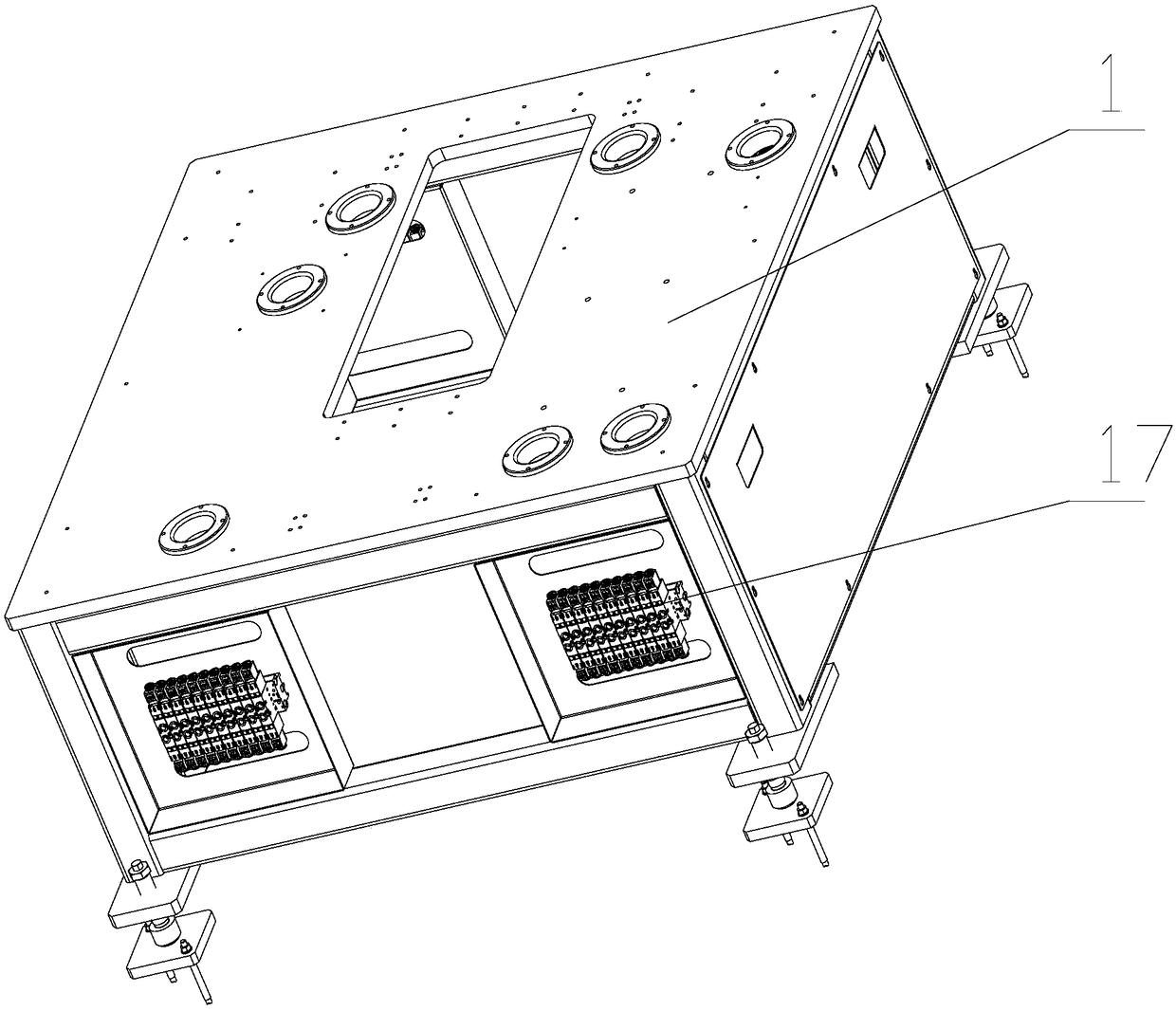

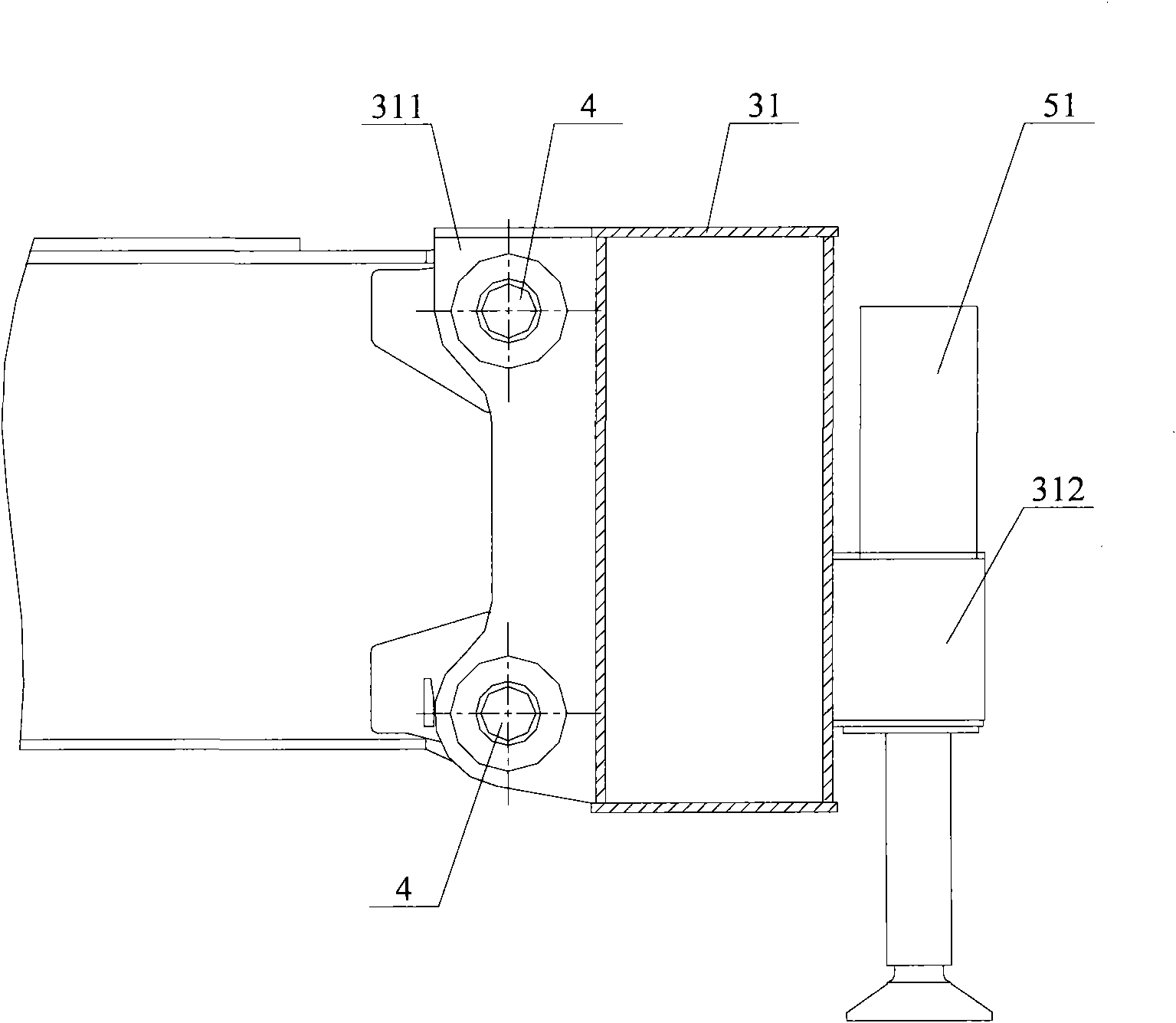

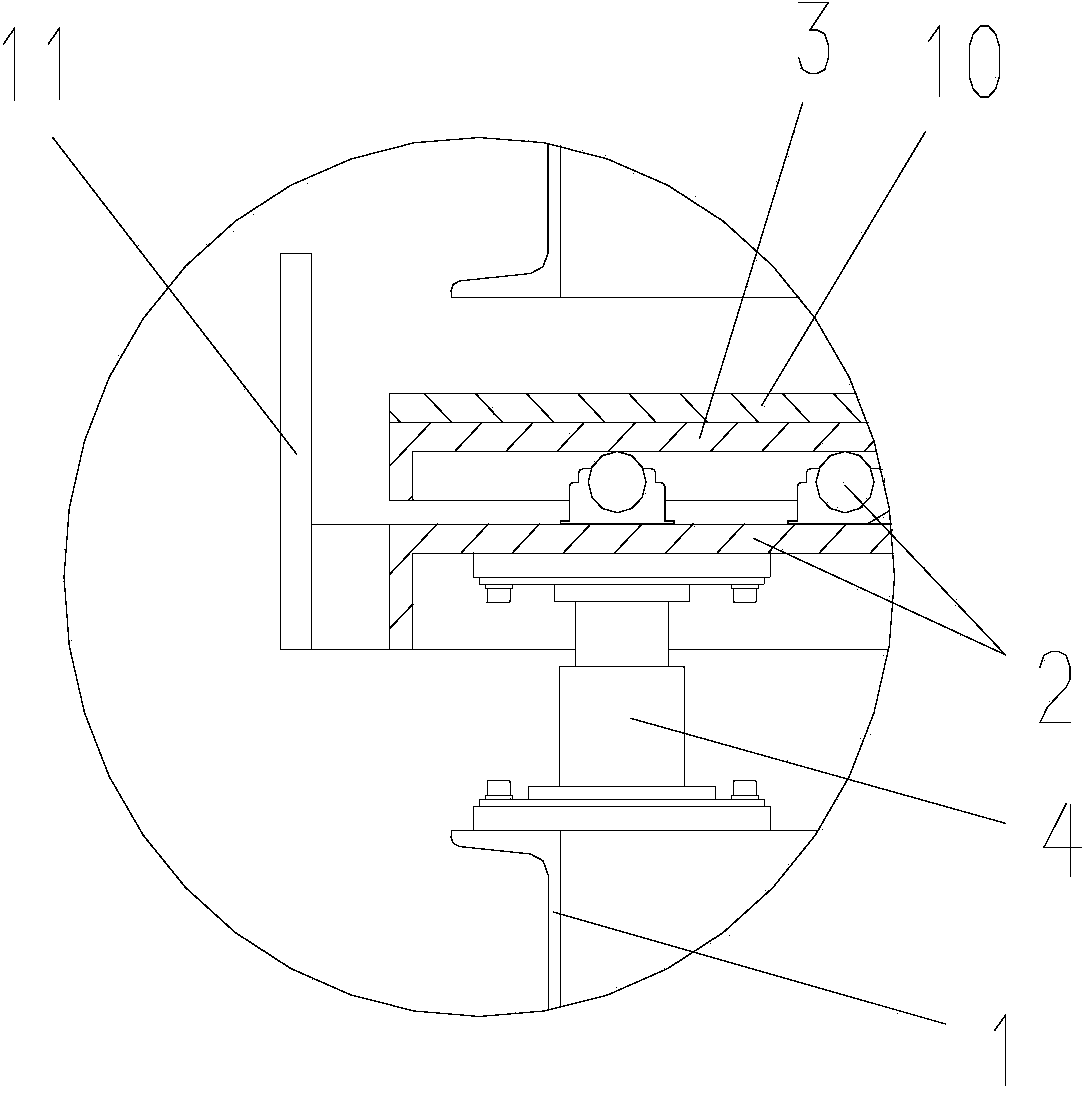

Shaft ringshield mounting device

PendingCN108262599AExquisite structureEasy maintenanceMetal working apparatusEngineeringMechanical engineering

The invention discloses a shaft ringshield mounting device and relates to automatic selective assembly equipment, in particular to a measurement selective assembly portion of the automatic selective assembly equipment. Conveying rails stretch across the upper portion of a base; a workpiece tray is conveyed along the conveying rails; a clamp ring measuring and calibration device is mounted on one side of the conveying rails; a clamp ring rolling-out device, a clamp ring recheck device, a clamp ring feeding device and a clamp ring transfer device are assembled on the other side of the conveyingrails through supports; a servo horizontal moving device stretches across the conveying rails; a clamp ring measuring device is mounted on the servo horizontal moving device through a clamp ring measuring and lifting device, and a clamp ring pressure head device is mounted on the servo horizontal moving device through a pressure head servo lifting device; and a secondary positioning and jacking device is mounted on the base and is located on the lower portion of the workpiece tray. The shaft ringshield mounting device has the characteristics that the structure is novel, detection is automaticand accurate, assembling is automatic, the accuracy rate is increased, the assembling working efficiency is improved, and the labor cost is lowered, and the shaft ringshield mounting device is a novelshaft ringshield mounting device integrating the economical efficiency and practicability.

Owner:DALIAN ZHIYUN AUTOMATION

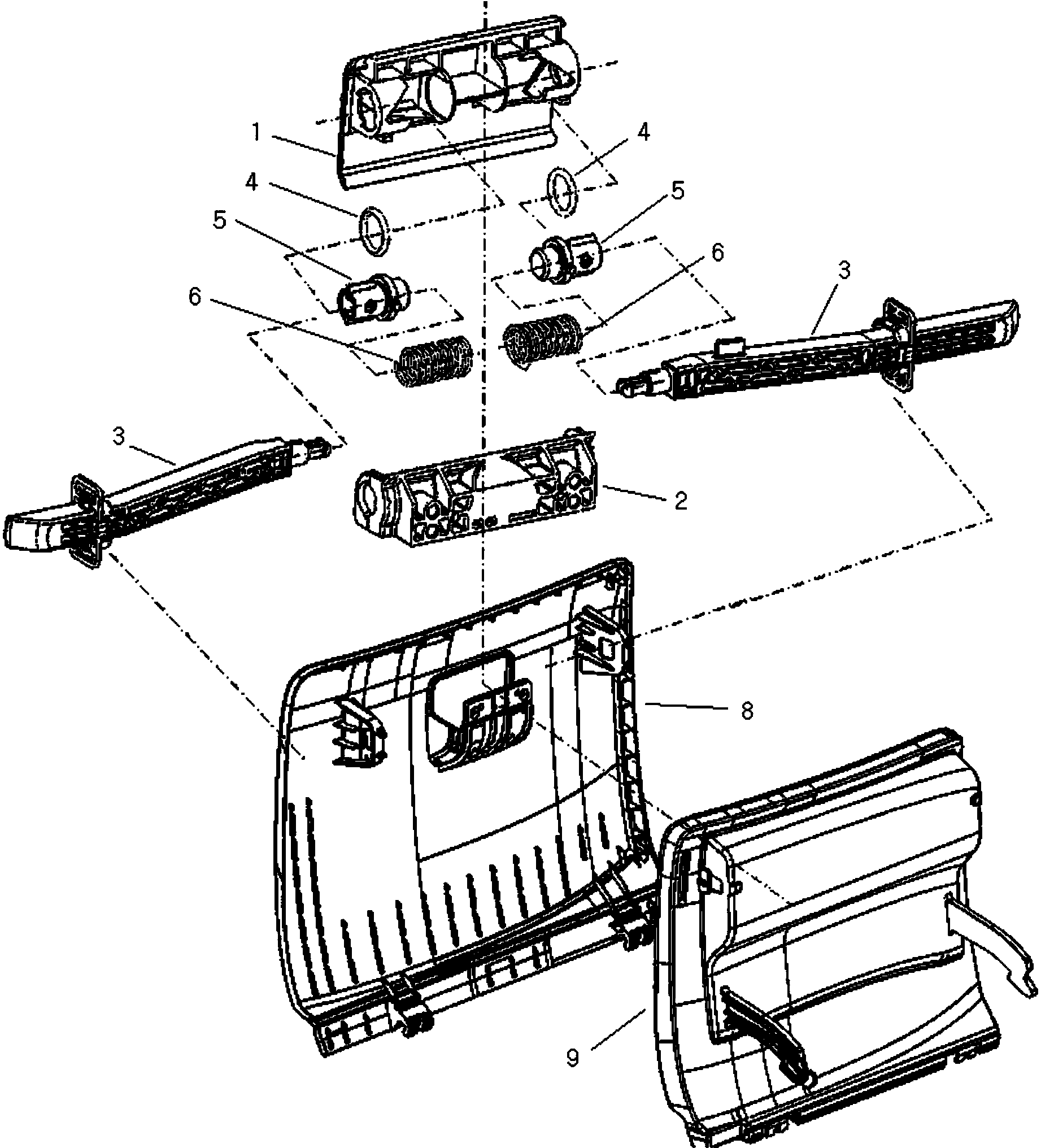

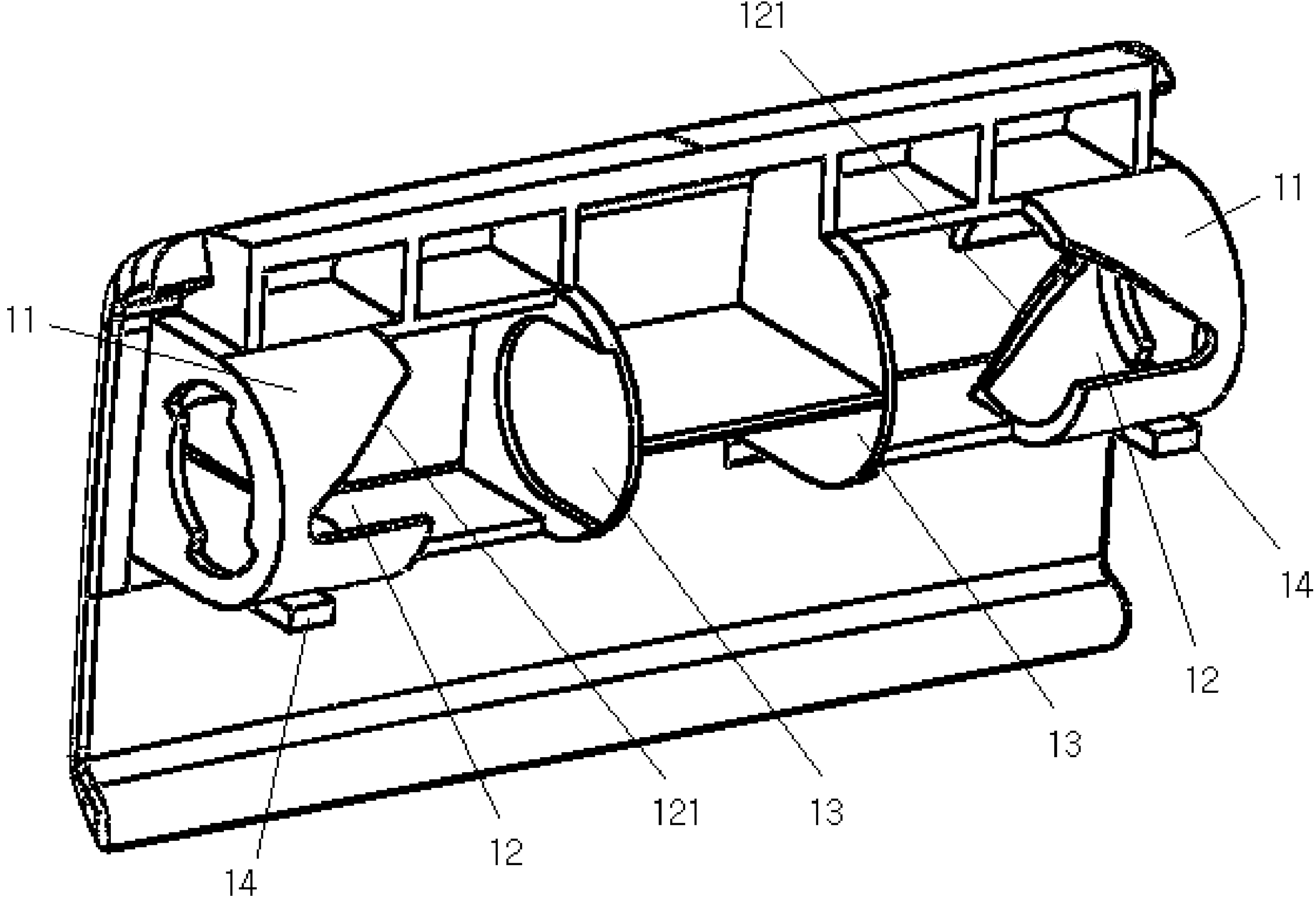

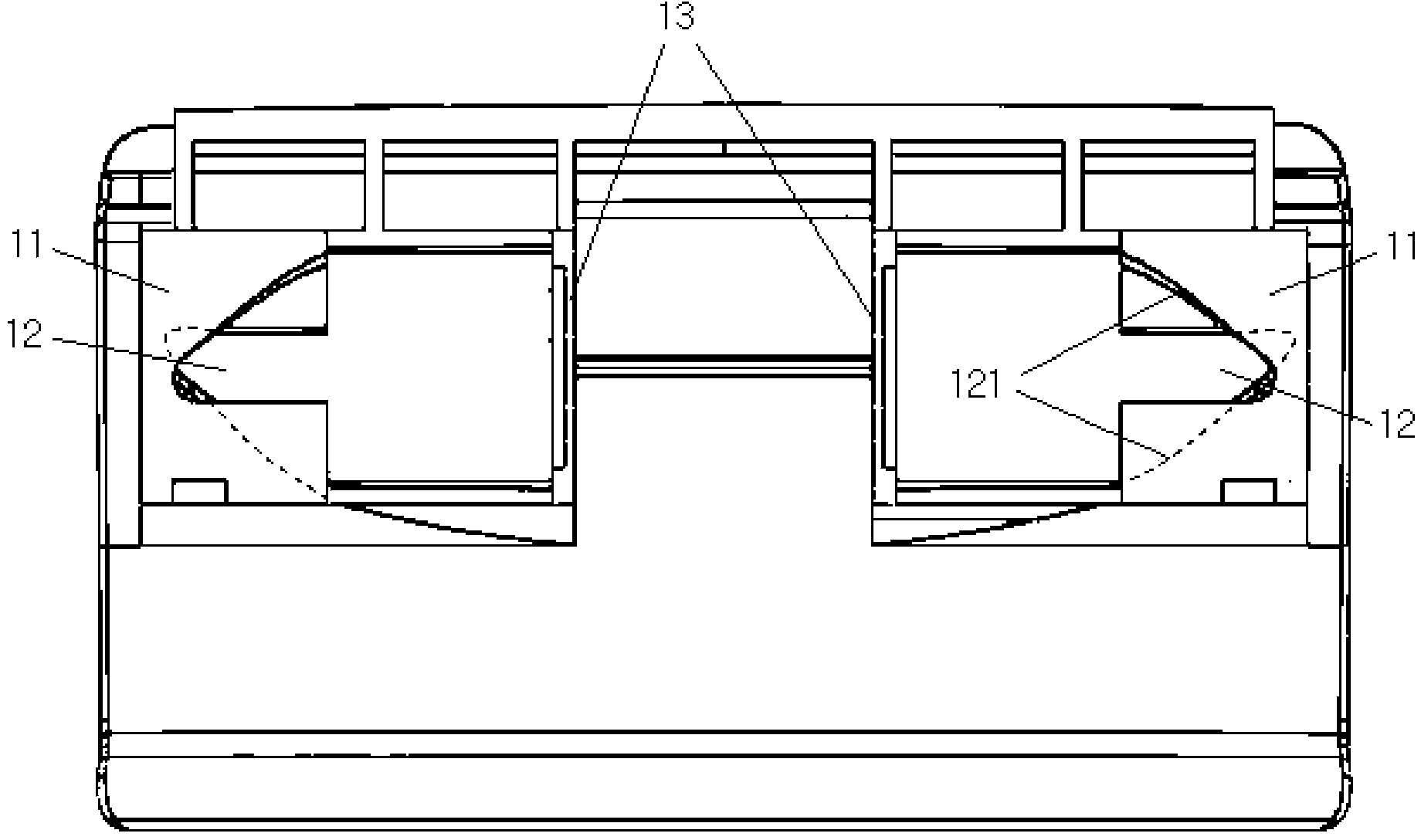

Bilateral locking device

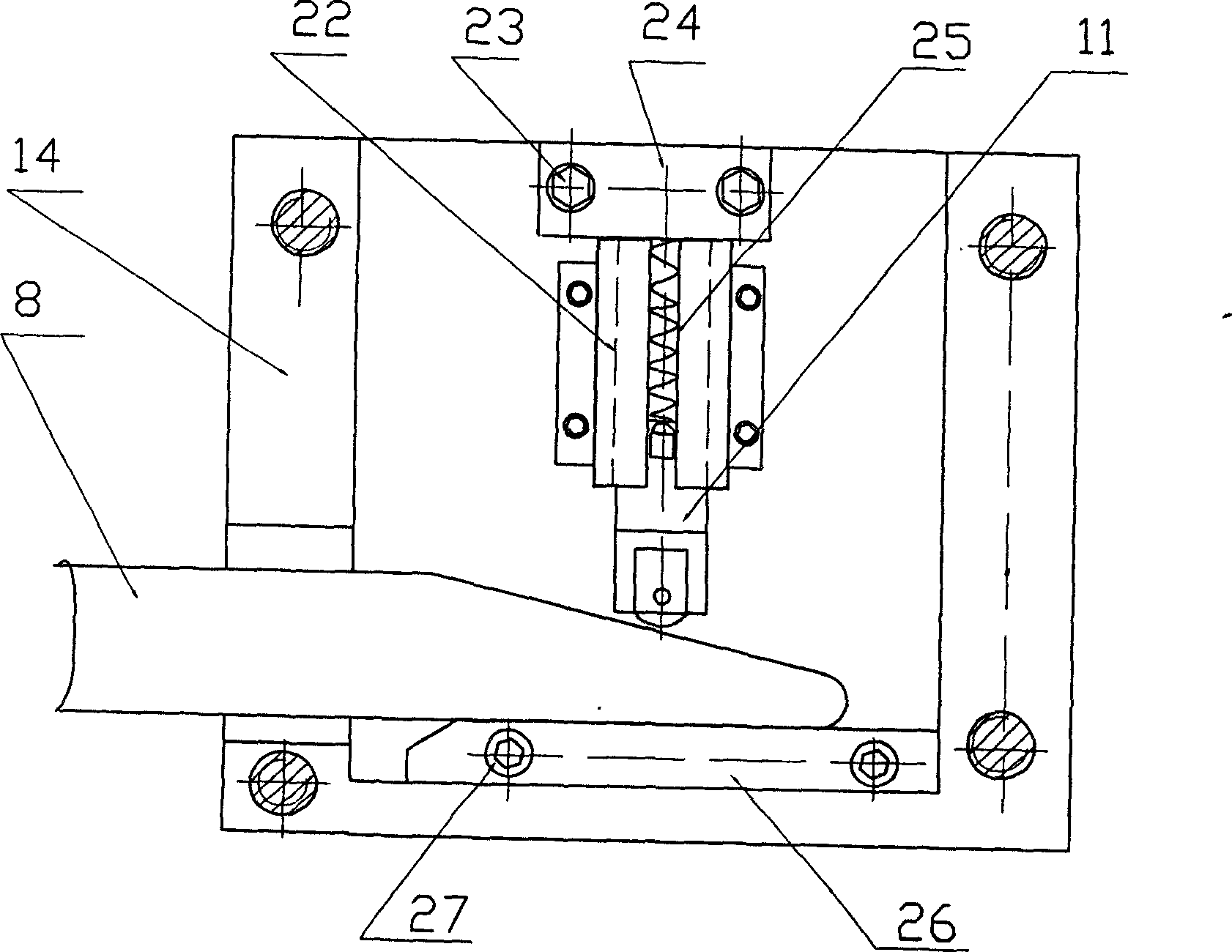

InactiveCN103867052AEasy to disassembleAvoid damageNoise-prevention/anti-rattling lockingPulp and paper industry

The invention relates to a bilateral locking device, relates to the technical field of locksets and aims to solve to the technical problems of inconvenient maintenance and low assembling efficiency of an existing device. The device comprises an outer cover plate, a main-body part and a handle, wherein the main-body part is fixedly arranged on the outer cover plate, and the handle is pivoted with the main-body part; a left sliding-shaft barrel and a right sliding-shaft barrel are respectively and fixedly arranged at the back of the handle, a sliding shaft is arranged in each sliding-shaft barrel, and the two sliding shafts are respectively driven to extend and retract through the matching of the shaft-barrel guiding ports and the sliding-shaft pins of the two sliding-shaft barrels and the sliding shafts in the barrels; a shaft hole is formed in the clamping end of each sliding shaft, two disassembling holes are formed in the hole wall of each shaft hole, and a stop block is fixedly arranged in each shaft hole; the left side and the right side of the main-body part are respectively provided with a locking rod, the hook end of each locking rod is inserted into the shaft hole of the corresponding sliding shaft, and the stop block in each shaft hole is hooked after two elastic clamping hooks at the hook end of the corresponding locking rod penetrate through a clamping hole in the corresponding shaft hole. The device provided by the invention is suitable for being used as the box cover of an automobile glove box.

Owner:上海琦天汽车科技有限公司

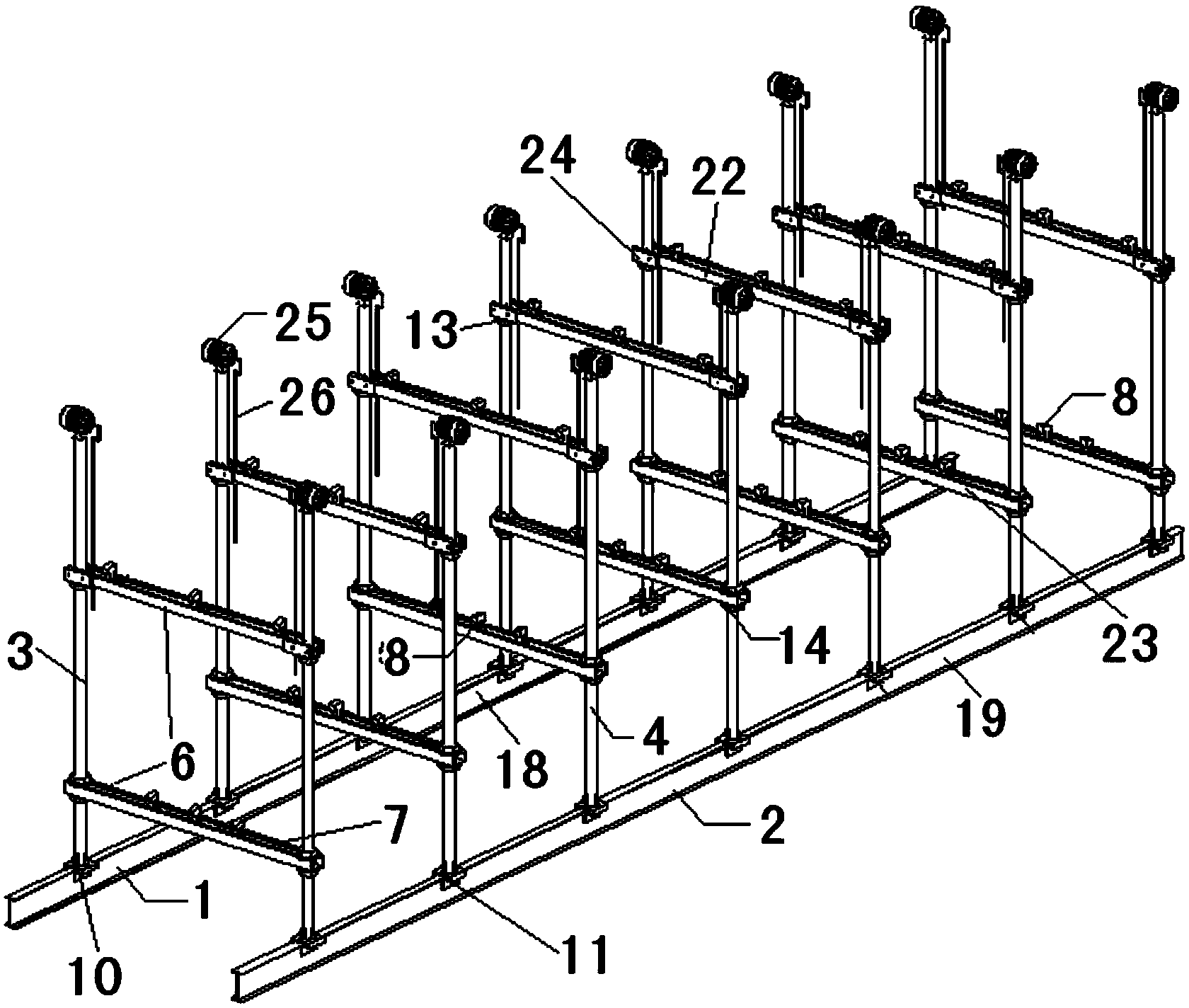

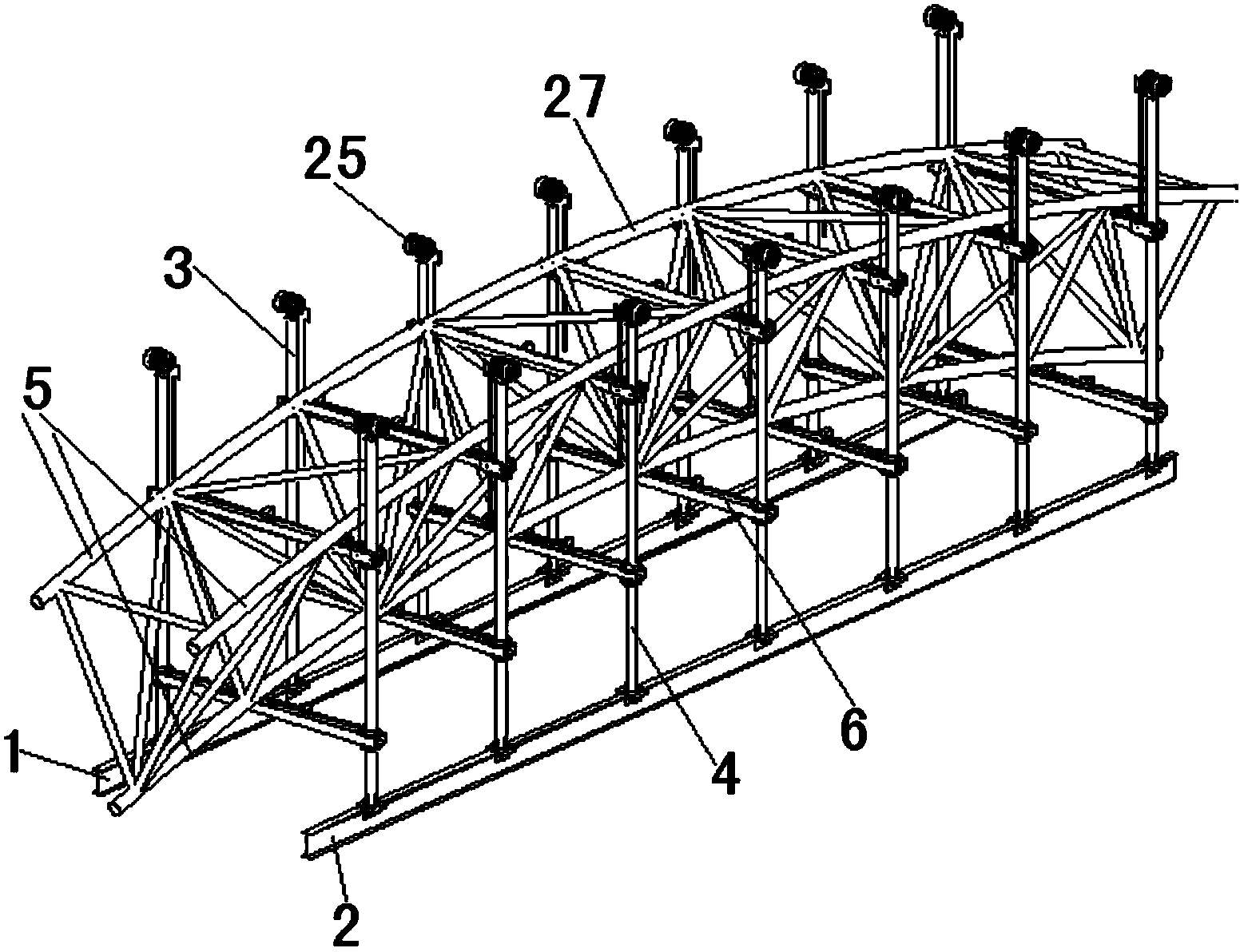

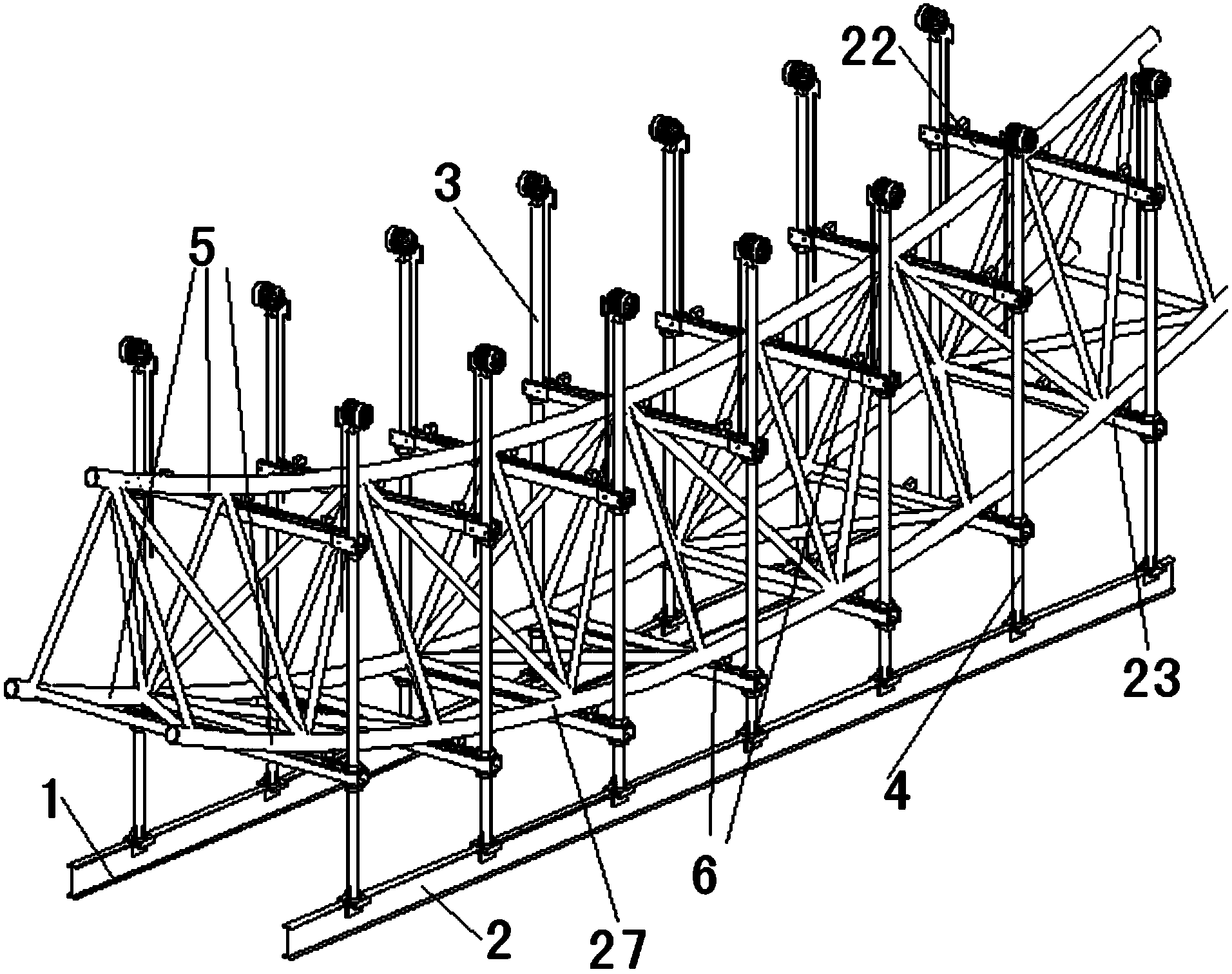

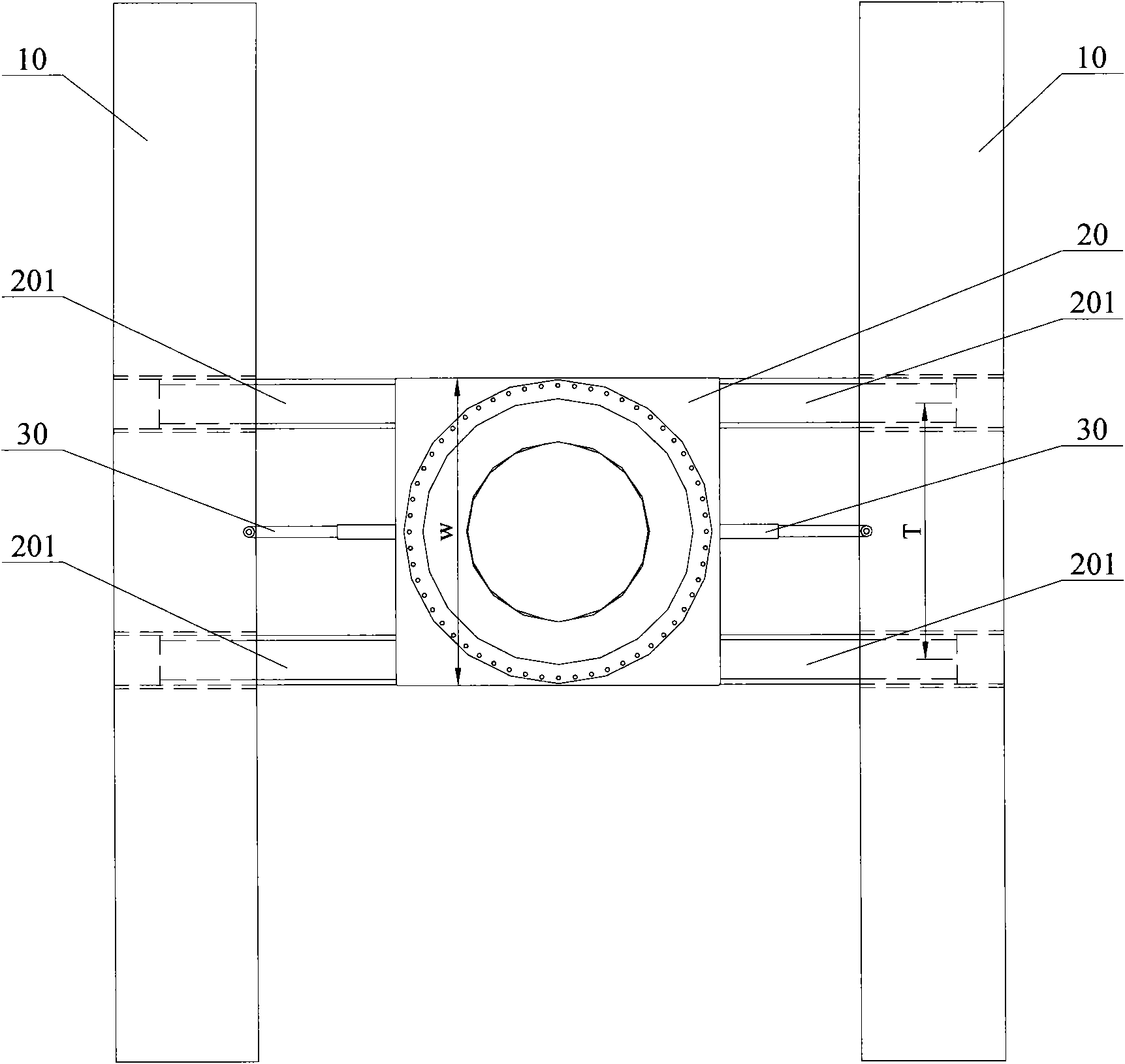

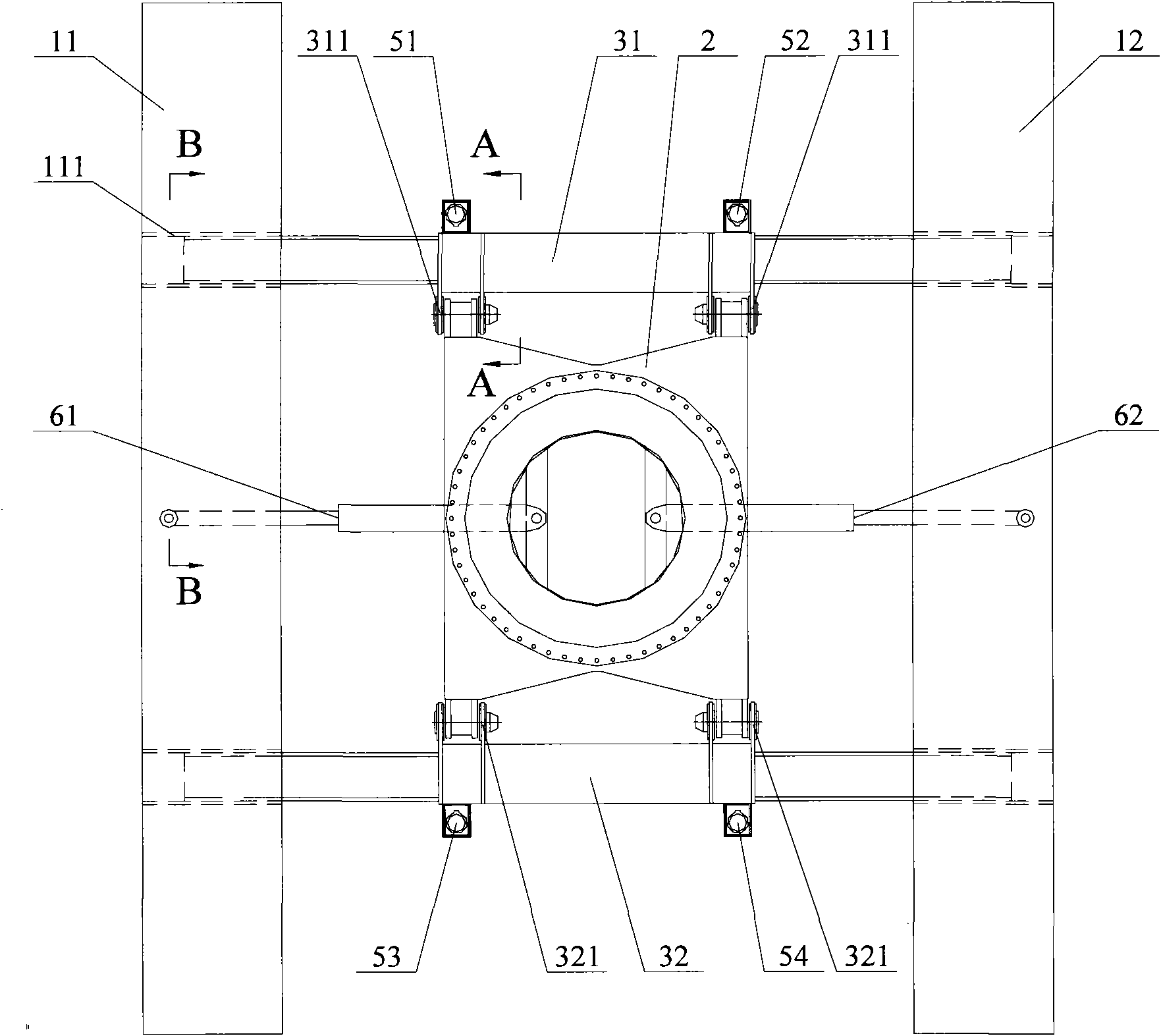

Jig frame structure for truss assembling and method for assembling truss with jig frame structure

Owner:ANHUI HANGXIAO STEEL STRUCTURE CO LTD

Crawler chassis and engineering machine with same

InactiveCN101607574AImprove rigidityMeet the external dimension requirementsEndless track vehiclesCranesStress conditionsEngineering

The invention discloses a crawler chassis which comprises an underframe, two crawler frames and two connecting crossbeams, wherein the two crawler frames are symmetrically arranged at the right side and the left side of the underframe; the two connecting crossbeams are symmetrically arranged at the front side and the rear side of the underframe; the ends of the right side and the left side of the two connecting crossbeams are respectively connected with the crawler frames at the right side and the left side; the front connecting crossbeam is provided with an auxiliary seat extending backward, and the rear connecting crossbeam is provided with an auxiliary seat extending forward; and the auxiliary seats on the two connecting crossbeams are detachably and fixedly connected with the underframe. The crawler chassis meets the design requirements through the length of the auxiliary seats and can meet the requirement of external size for transportation while guaranteeing working stability, thereby greatly improving the stress conditions of all parts of the crawler chassis and enhancing the rigidity of the chassis. In addition, the external size and the weight of the underframe are effectively reduced to further facilitate transportation and installation of a whole machine. On the basis, the invention also discloses a crawler crane with the chassis.

Owner:ZOOMLION HEAVY IND CO LTD

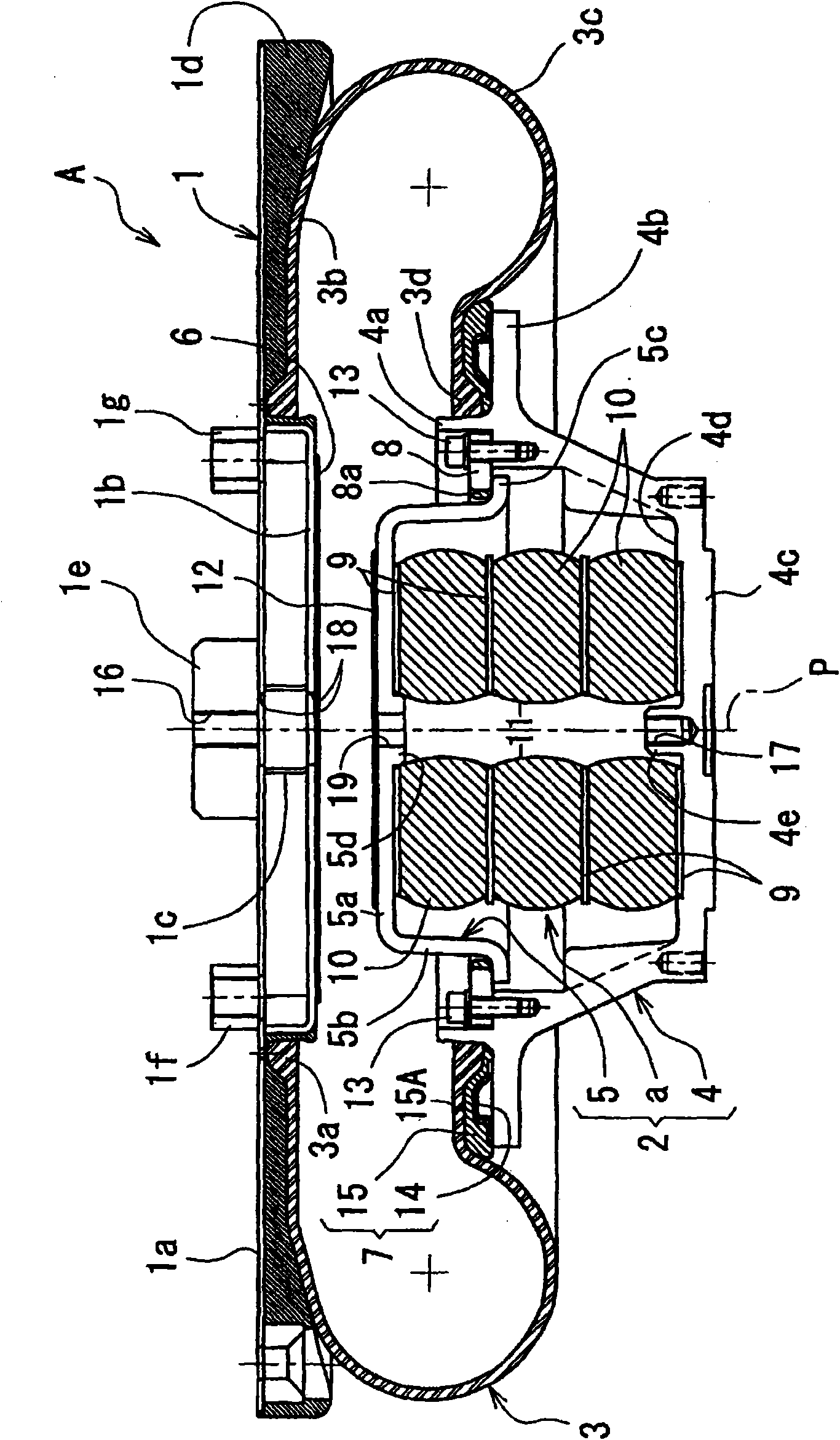

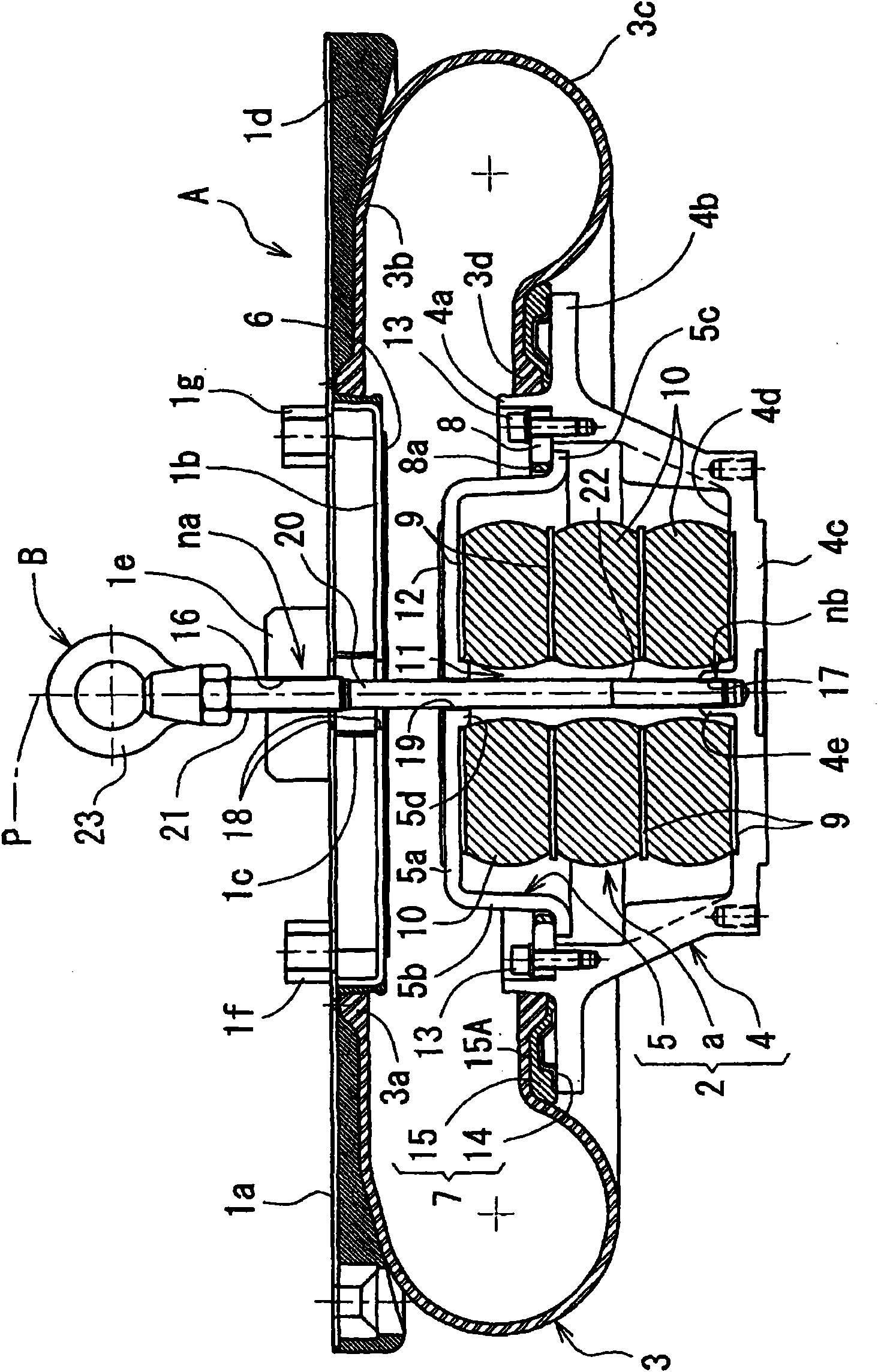

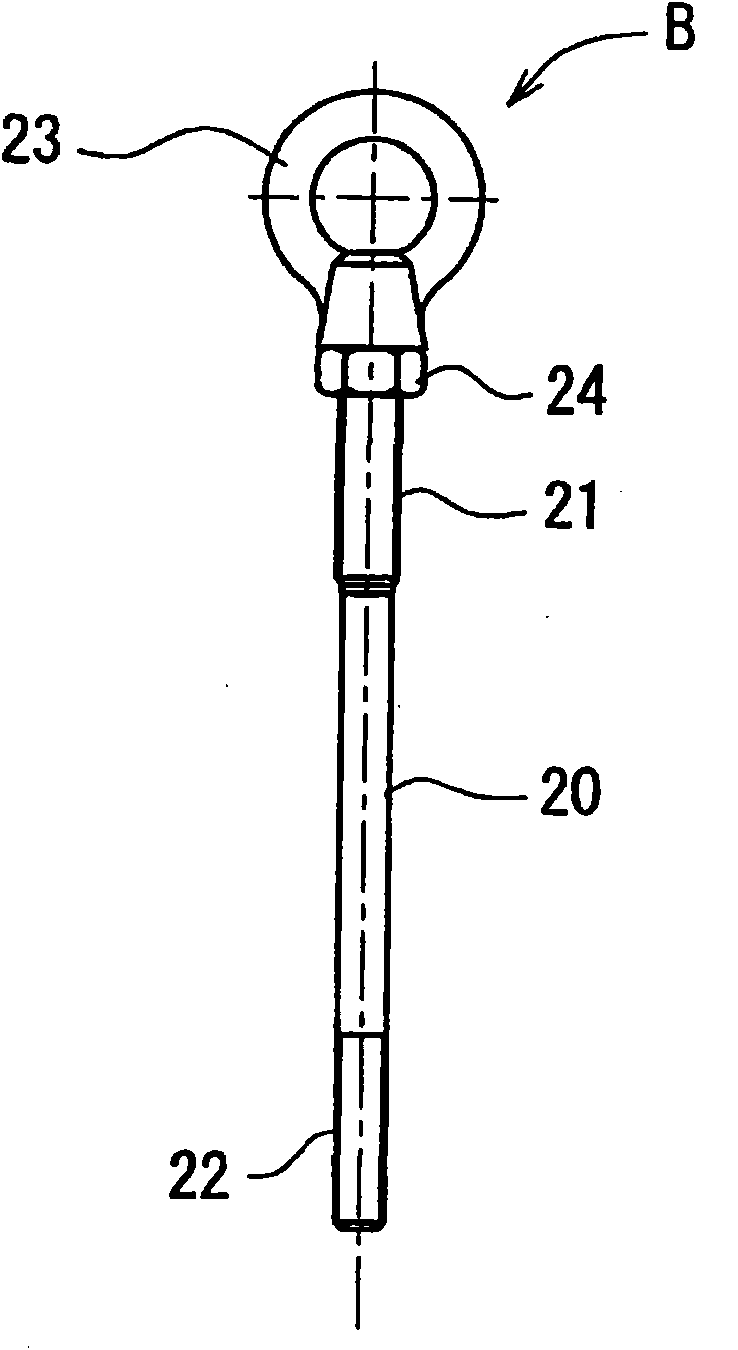

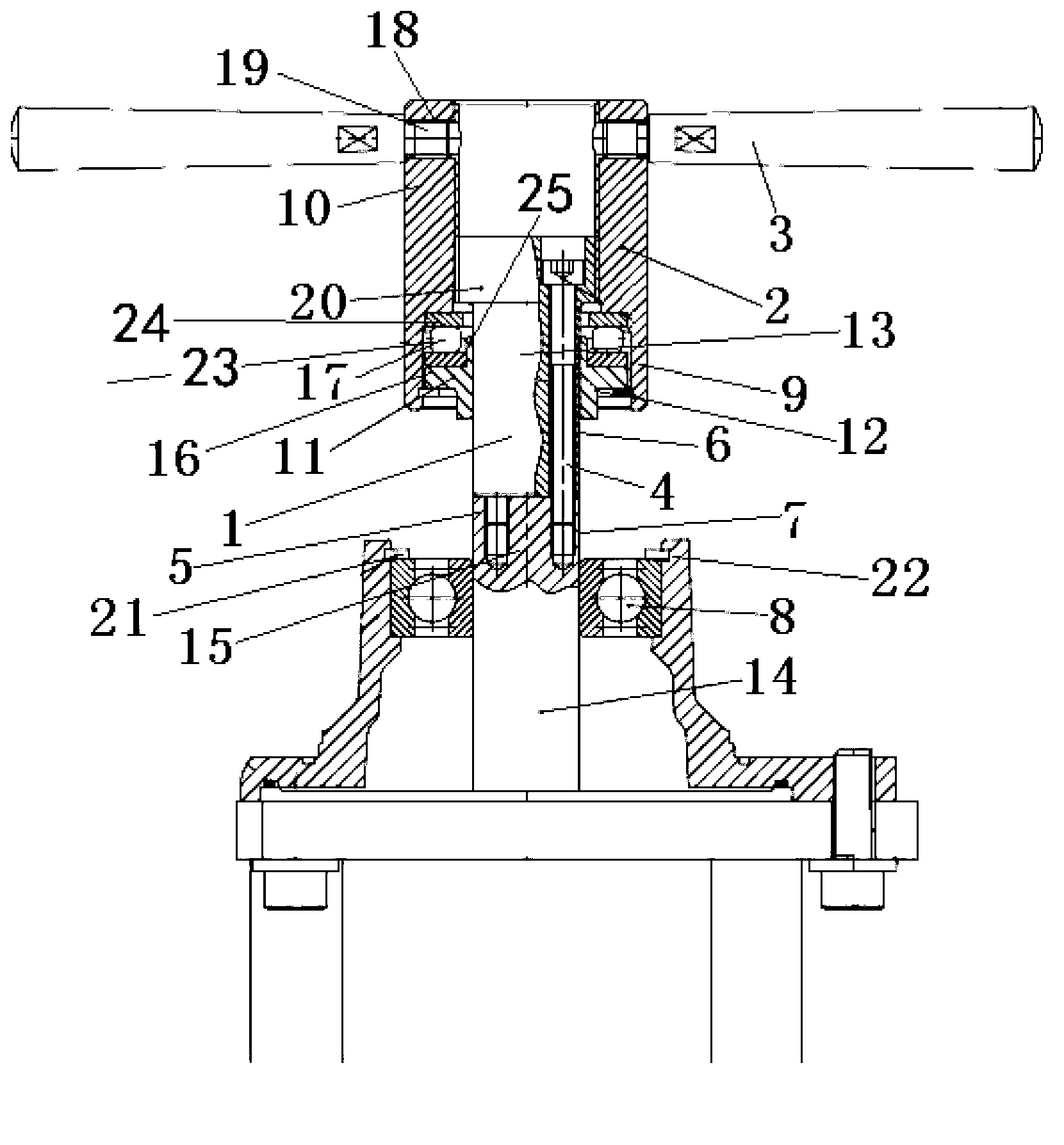

Air spring for vehicle and hanger mounting method thereof

InactiveCN101956779ASuitable for mobileEasy to carryGas based dampersBogie-underframe connectionsAir springAir suspension

The invention provides an improved air spring for a vehicle. The air spring can be provided with a hanger convenient for carrying, meanwhile does not produce the butting problem of an upper supporting part and a lower supporting part caused by a hanging structure thereof, is suitable for hanging movement and is favorable for the durability of a stop dog. A rubber diaphragm (3) is arranged in the air spring for the vehicle in a mode of crossing the upper supporting part (1) on the vehicle body side and the lower supporting part (2) arranged on the chassis side below the upper supporting part (1), the upper supporting part (1) and the lower supporting part (2) are provided with female threads (16, 17) with a common longitudinal axis (P) respectively, and the female thread (17) of the lower supporting part (2) is constructed to screw with a lower male thread (22) formed at the lower end of the roughly bar-shaped hanger (B) for hanging the air spring. The female thread (16) of the upper supporting part (1) is constructed to screw with an upper male thread (21) positioned in the hanger (B) and spaced from the lower male thread (22) on the upper part, and meanwhile, the female thread (16) of the upper supporting part (1) is set in a state that the lower male thread (22) can pass.

Owner:TOYO TIRE & RUBBER CO LTD

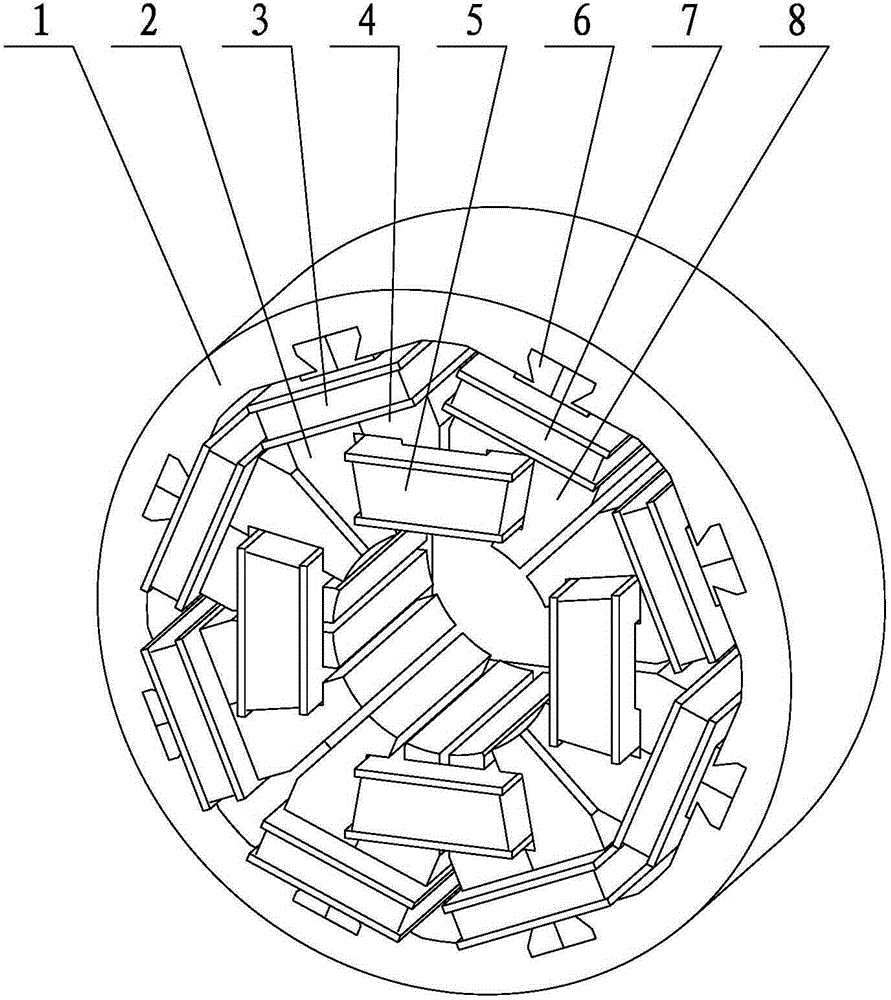

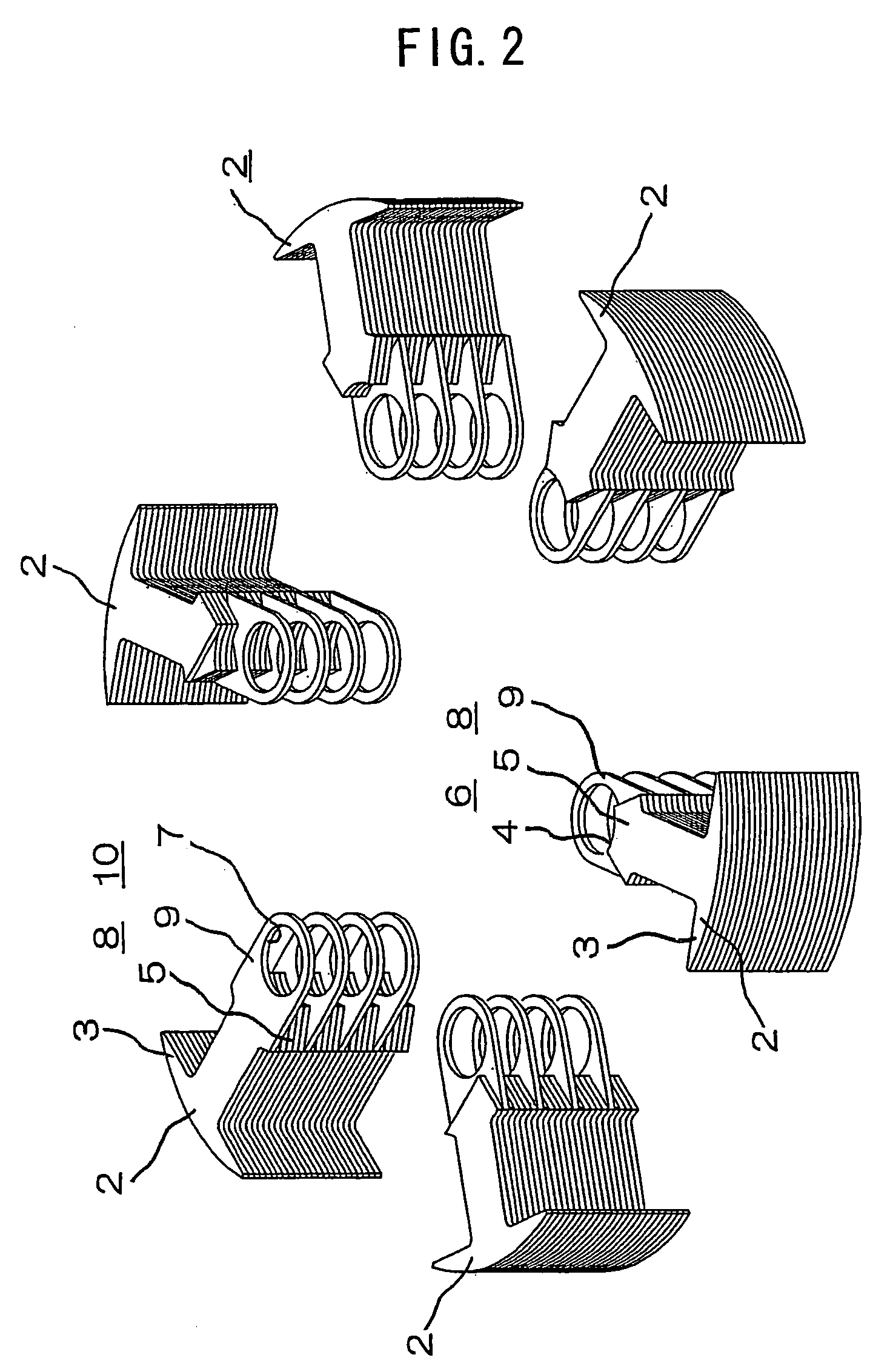

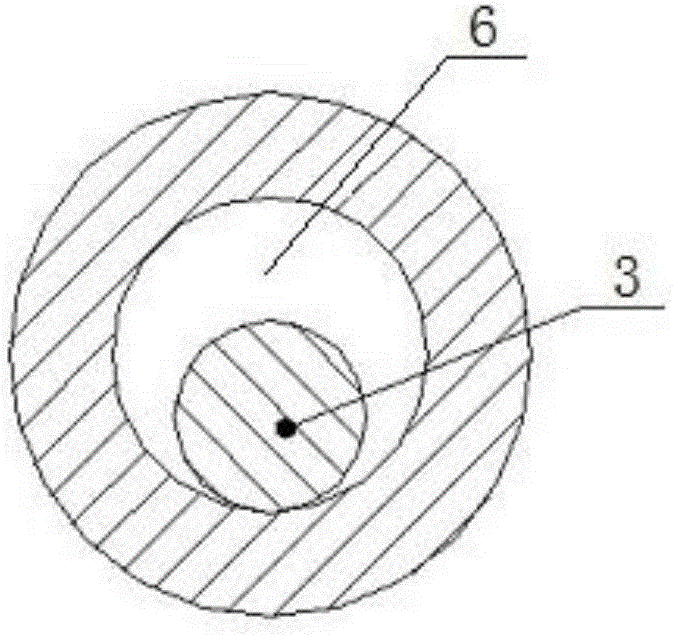

Assembling type pole changing stator iron core and winding

ActiveCN104682585AImprove assembly work efficiencyIncrease productivityMagnetic circuit stationary partsEmbedding prefabricated windingsEngineeringMechanical equipment

The invention provides an assembled type pole changing stator iron core and winding and relates to a motor stator iron core and winding. The assembled type pole changing stator iron core and winding mainly comprises a stator magnet yoke and a plurality of stator insert parts; in an assembling process of the assembled type pole changing stator iron core and winding, a working winding and a starting winding are wound firstly, then the working winding and the starting winding are assembled in the stator insert parts, then the plurality of stator insert parts are arranged at the inner side of the stator magnet yoke, a traditional method that a lead wire is embedded in a stator line slot through manual marking and line pressing in the stator winding inserting process is not required, the assembling efficiency of the assembled type pole changing stator iron core and winding is high, and the production efficiency can be improved and the cost is reduced due to the adoption of mechanical equipment.

Owner:重庆市美庆科技有限公司

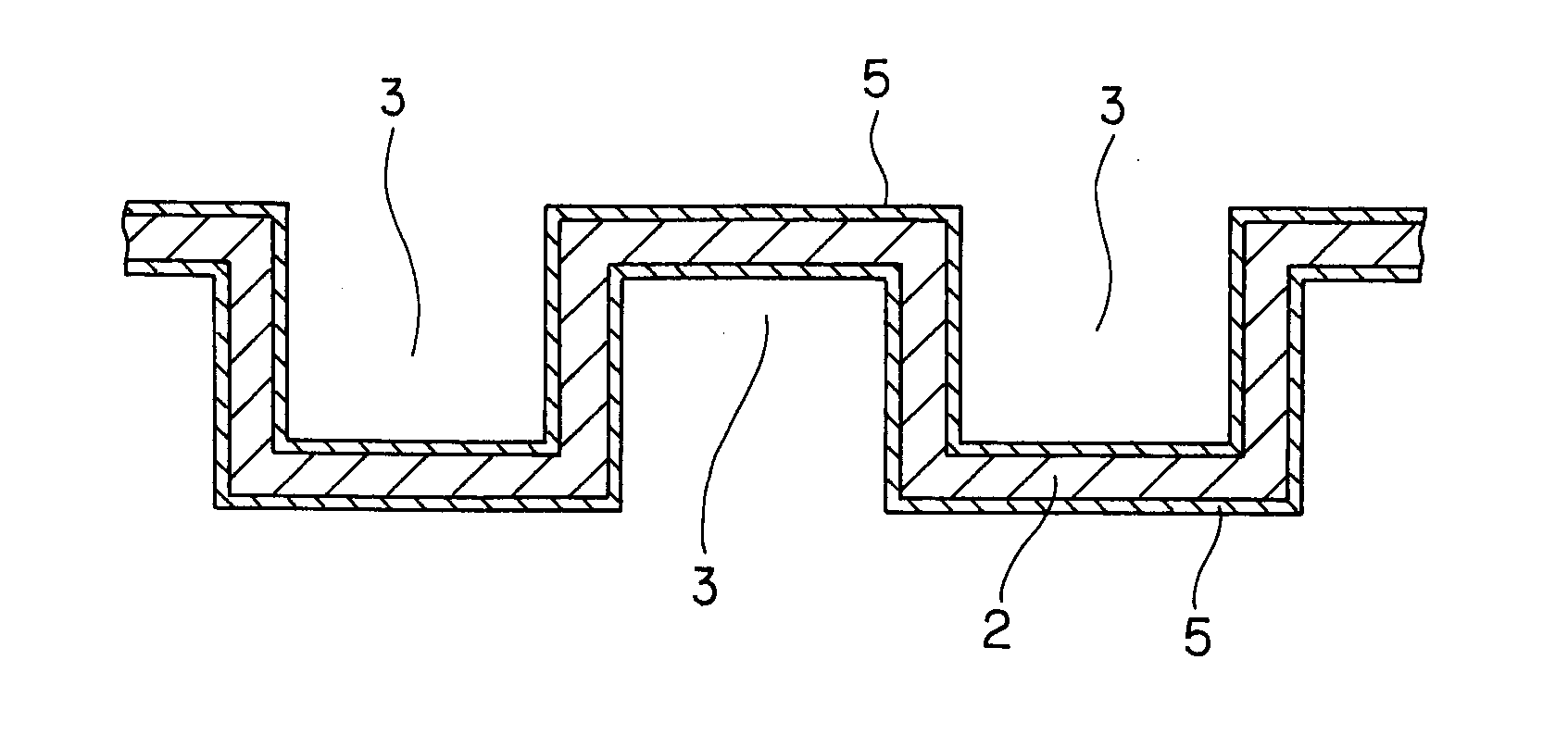

Separator for fuel cells

ActiveUS20070238005A1Easy to assembleImprove corrosion resistanceFuel cells groupingElectrode carriers/collectorsFuel cellsEngineering

The object of the invention is to provide a separator for fuel cells which is of improved strength and corrosion resistance and facilitates the assembling of unit cells. The separator comprises an electrically conductive resin layer formed by electrodeposition in such a way as to cover a metal substrate and a gasket component. The resin layer contains an electrically conductive material. The separator of the invention has thus an enhanced corrosion resistance, makes some considerable improvements in the assembling work efficiency of unit cells, and makes sure higher strength because of the use of the metal substrate.

Owner:DAI NIPPON PRINTING CO LTD

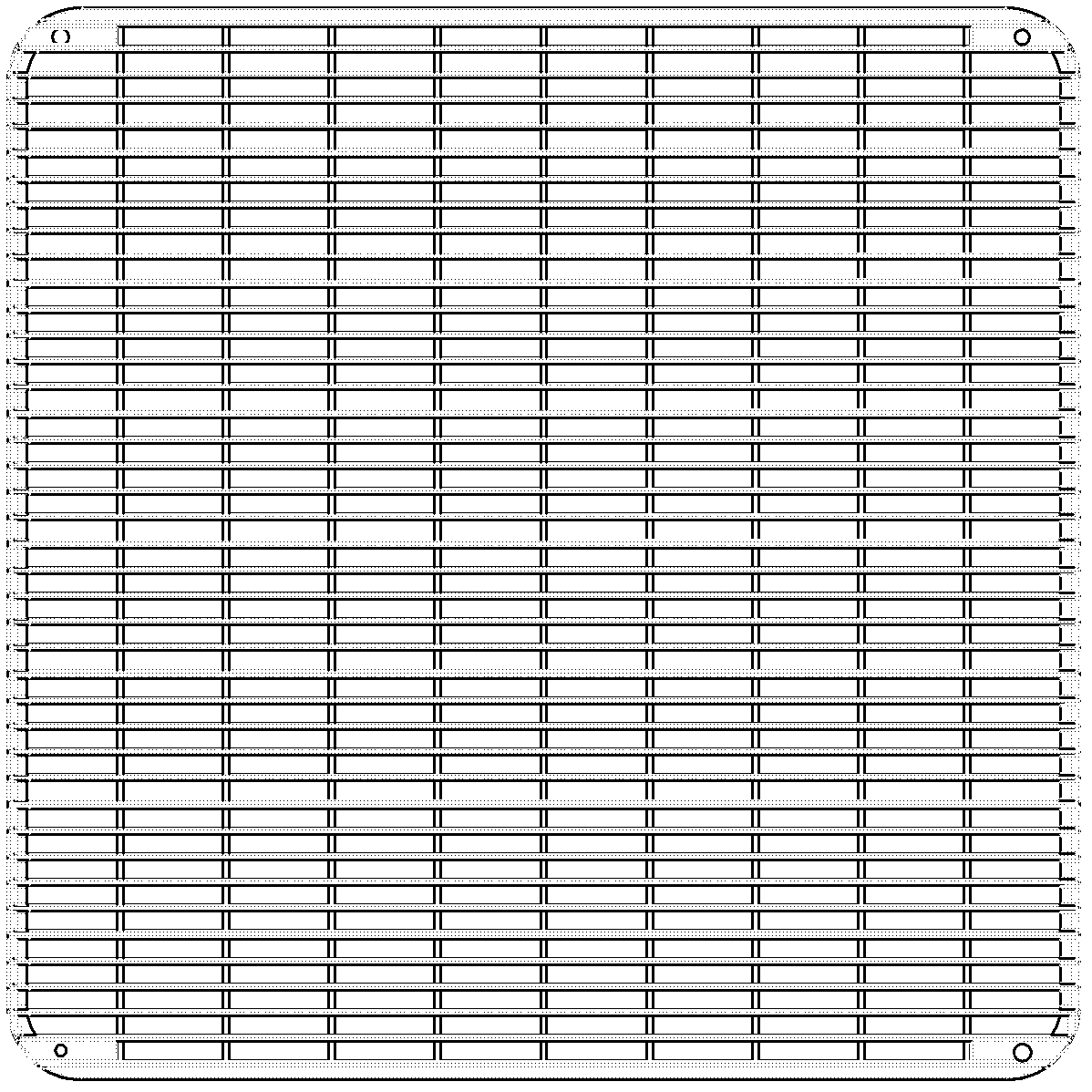

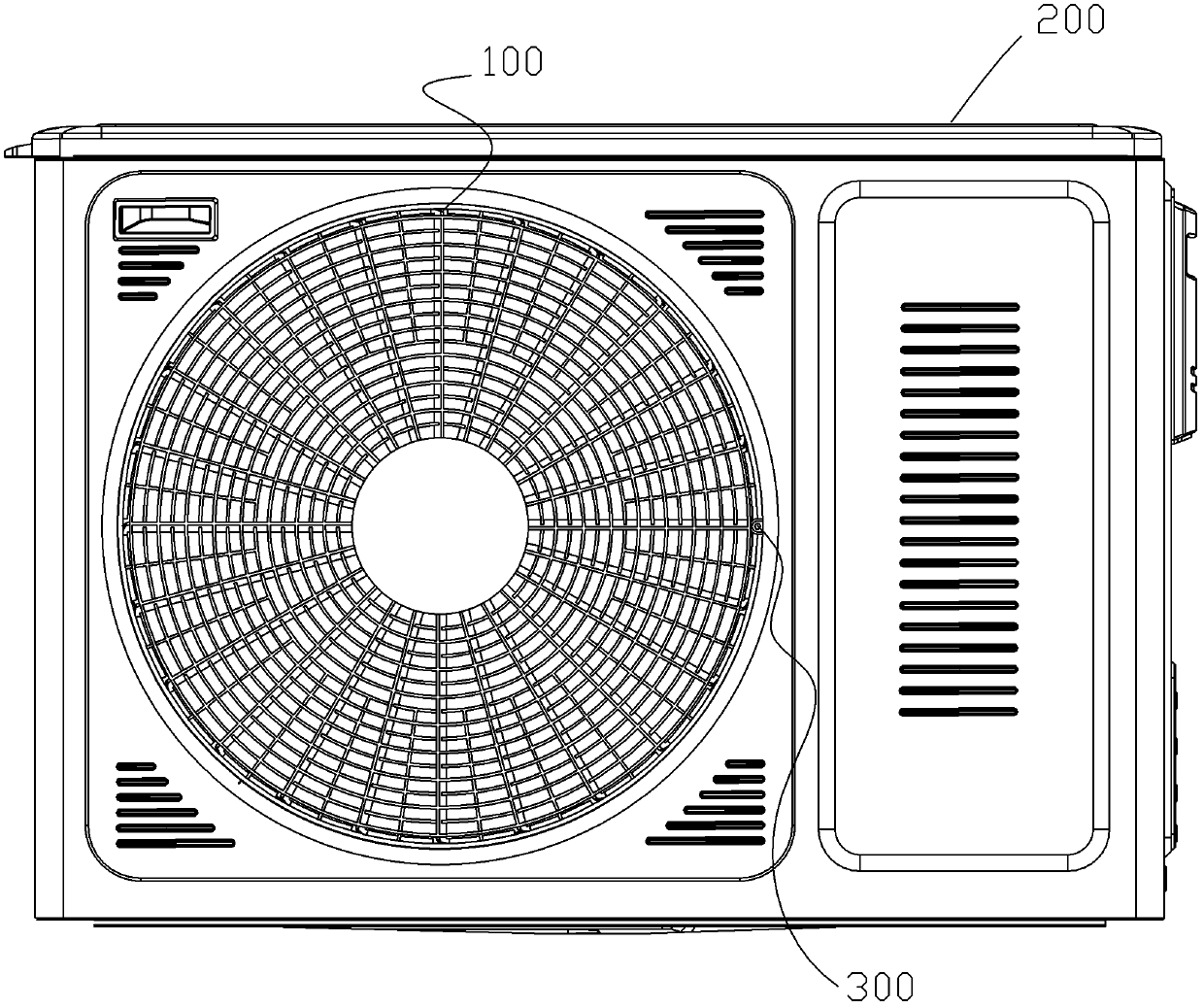

Air-out device of air conditioner outdoor unit

ActiveCN103375854AFirmly assembledEasy to fixLighting and heating apparatusAir conditioning systemsEngineeringFace shield

The invention provides an air-out device of an air conditioner outdoor unit. The air-out device comprises a face shield and a disc-shaped air-out grid, the face shield is arranged on a case of the air conditioner outdoor unit, and the air-out grid is assembled on the face shield. An air outlet is formed in the surface of the face shield, and the disc-shaped air-outlet grid covers the air outlet. Fastening devices and fixing devices are arranged on the edge of the circumference of the air-outlet grid. Fastening grooves and positioning devices respectively matched with the fastening devices and the fixing devices are arranged on the surface of the face shield. Each fastening device of the air-outlet grid is clamped into the corresponding fastening groove in the face shield and fastened with the same, and each fixing device of the air-outlet grid is fittingly fixed with the corresponding positioning device of the face shield. By the air-outlet device, the air-outlet grid can be further firmly assembled on the air conditioner outdoor unit; looseness, sliding and the like can be effectively avoided; quick positioning of the air-outlet grid in assembling is realized, efficiency of the assembling is greatly improved, the air-outlet grid is convenient to disassemble and replace, and actual operation is facilitated; use of fasteners is decreased, and thereby cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

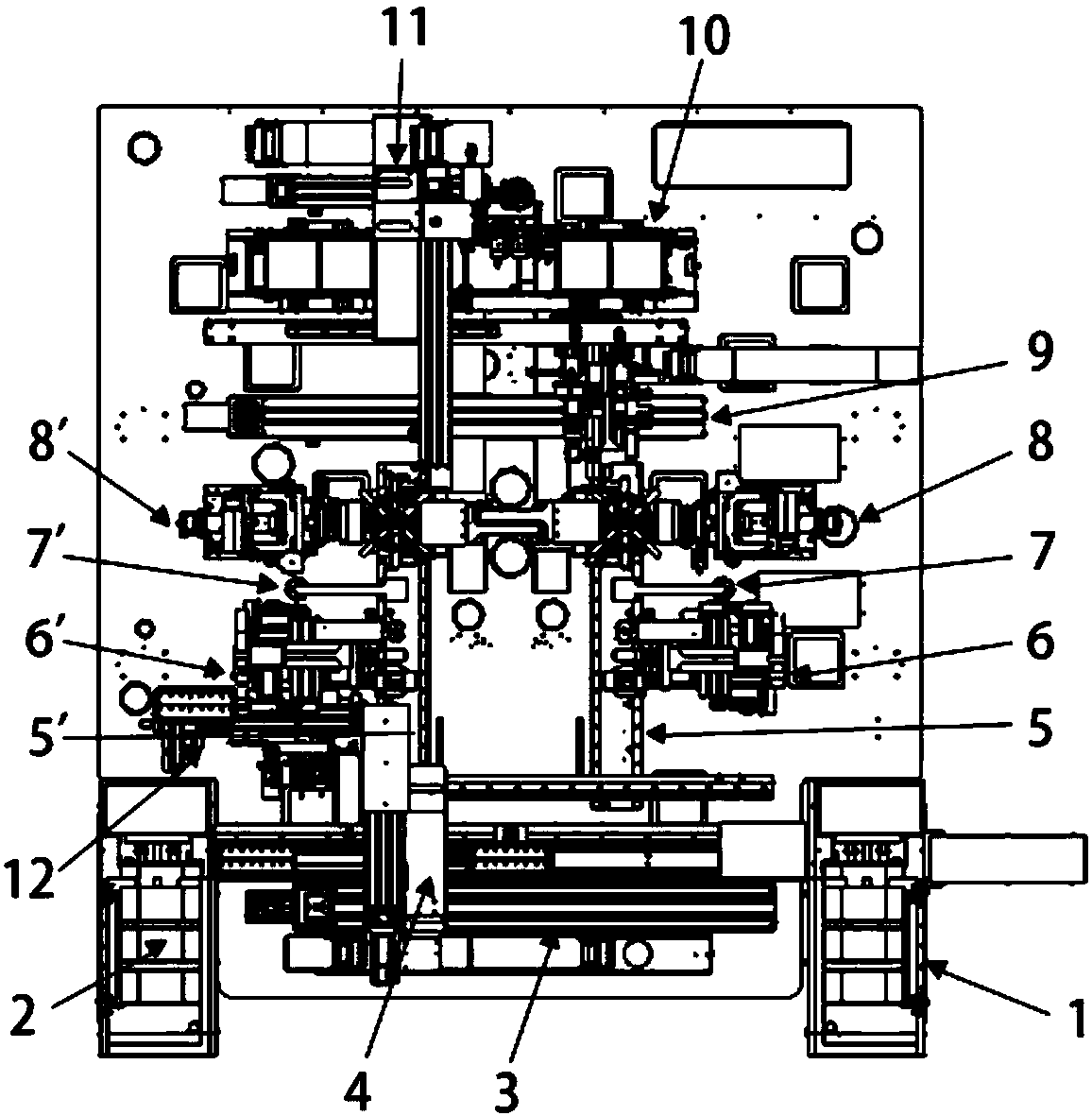

Dual-camera module assembling device

ActiveCN107682593AIncrease productivityHigh degree of mechanizationTelevision system detailsMaterial gluingCamera moduleEngineering

The invention discloses a dual-camera module assembling device, which comprises a circuit board feeding unit, a circuit board transmission unit, two groups of circuit board pickup units, two groups ofsix-axis transmission units, two groups of dispensing units, two groups of detection units, two groups of adjusting and fixing units, a motor transmission unit, a motor group feeding unit, a motor pickup unit and a module output unit. Thus, two cameras and lenses at two sides which are integrated can realized AA aligning and assembling at the same time; as a two-working position and four six-axismode is adopted, complete and automatic aligning of the dual camera modules can be realized, the operation speed during the aligning process is quick, the aligning precision is high, and the output ratio of the aligning module is high and is 1.5 to 2.5 times that of an ordinary base.

Owner:NINGBO SUNNY OPOTECH CO LTD

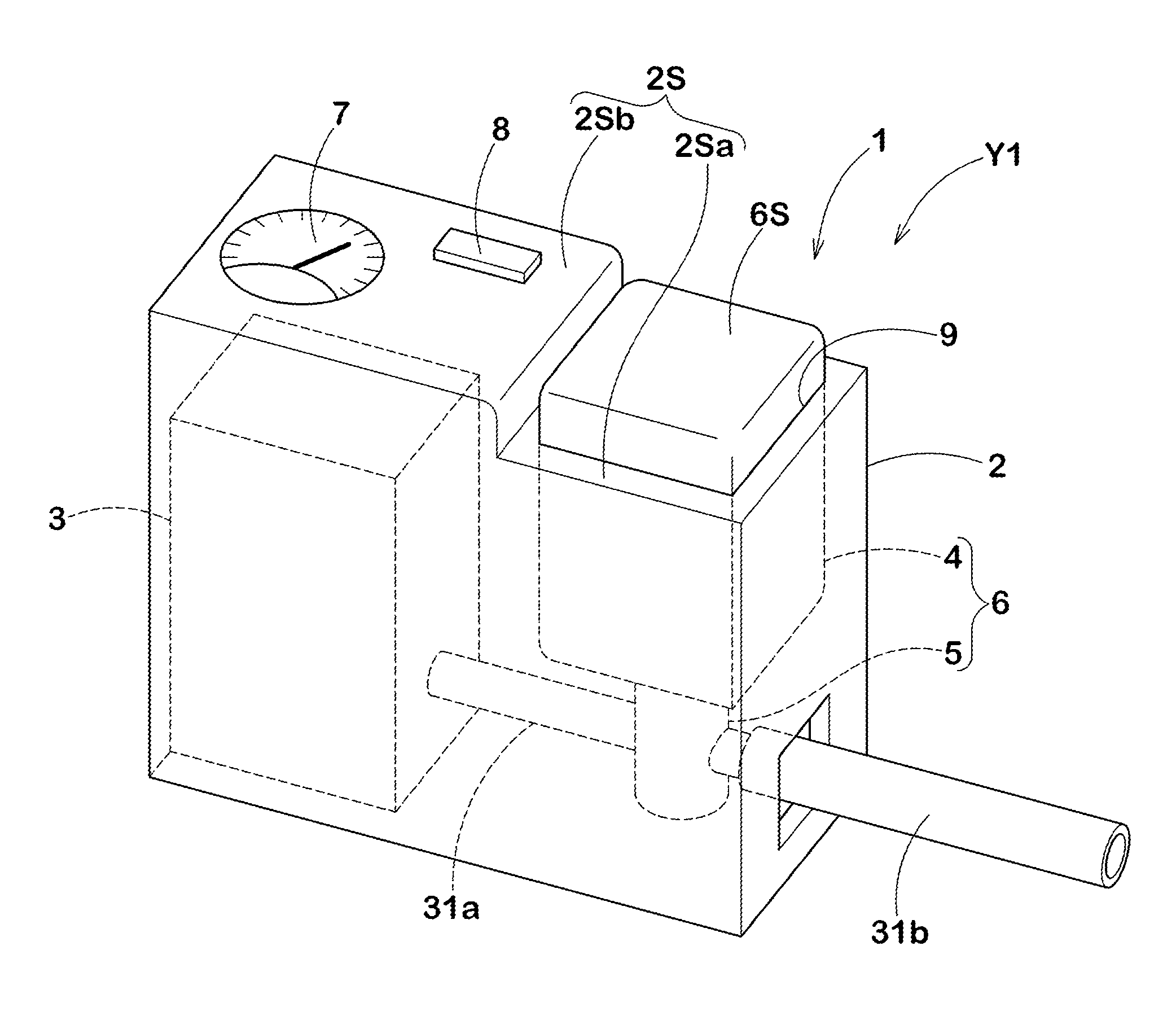

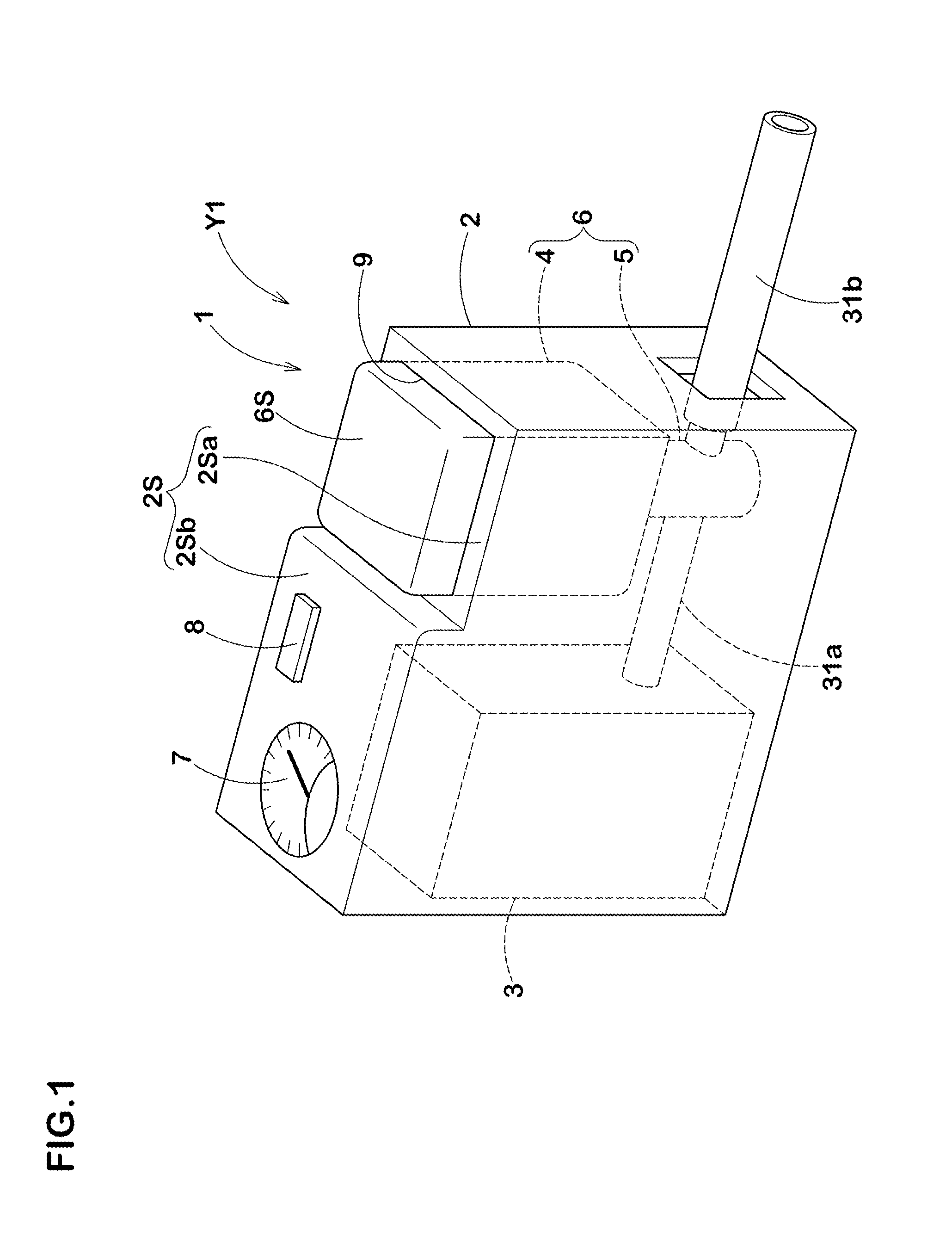

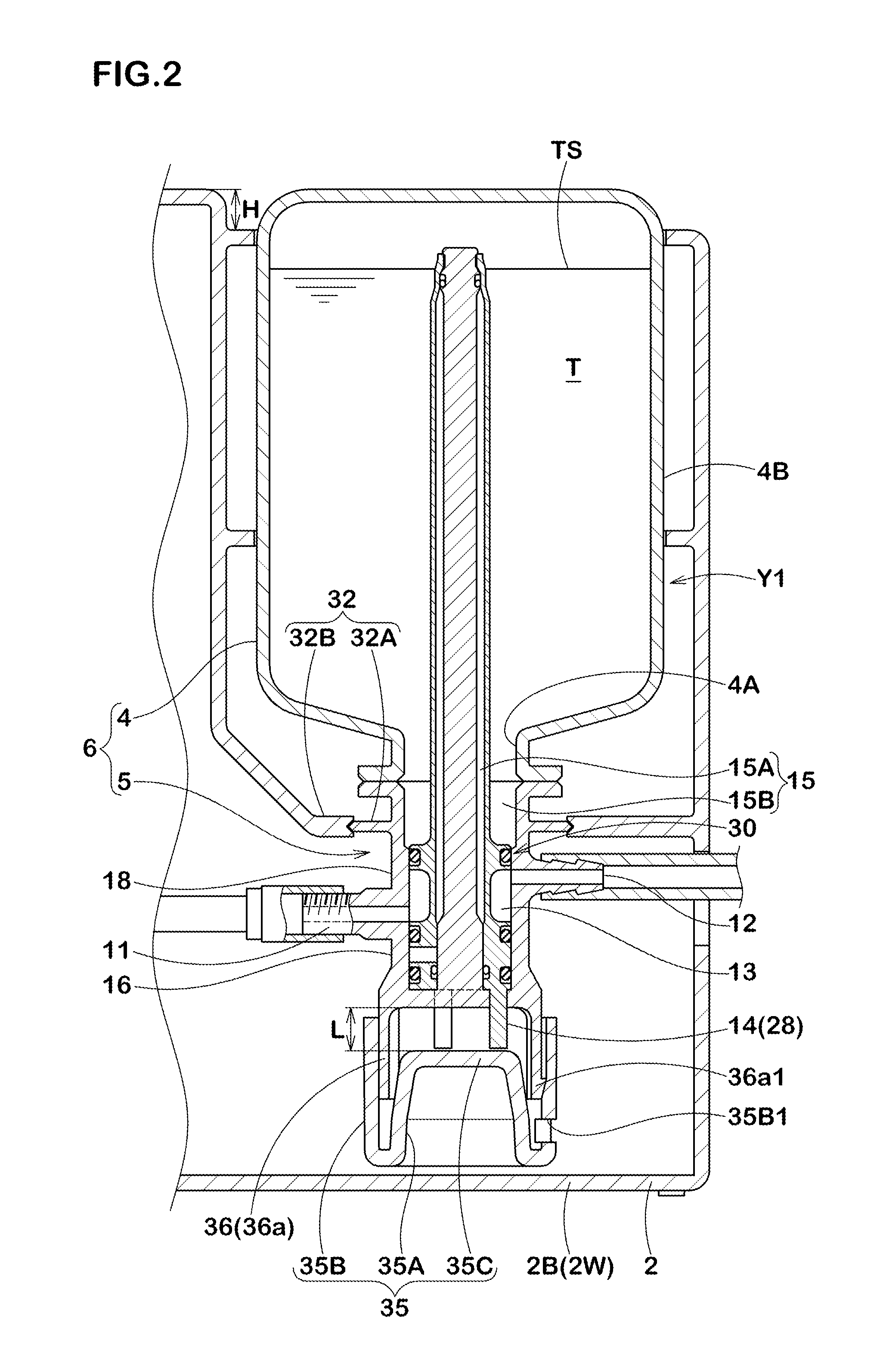

Integrated puncture repair kit

InactiveUS20140366981A1Simplify piping and structureSimplified piping and structureTyresVehicle servicing/repairingEngineeringBottle

An extraction cap of an integrated puncture repair kit is provided with: an intake unit for taking compressed air coming from a compressor into the extraction cap; an outlet unit for taking the intaken compressed air or both compressed air and a puncture repair solution to outside the extraction cap; a dedicated air flow path that ordinarily connects to the intake unit and provides conduction from the inlet unit to the outlet unit without passing through a bottle container; a dedicated puncture repair flow path comprising a first flow path section that is connected by a switching means to the intake unit instead of the dedicated air flow path and providing conduction from the intake unit into the bottle container, and a second flow path section providing conduction from inside the bottle container to the intake unit; a first on-off valve that is interposed in the second flow path section and ordinarily closes the first flow path section; and the switching means, which is actuated by downward pressing of a bottle unit and connects the intake unit switching from the dedicated air flow path to the dedicated puncture repair flow path, and also releases the first on-off valve to close the second flow path section.

Owner:SUMITOMO RUBBER IND LTD

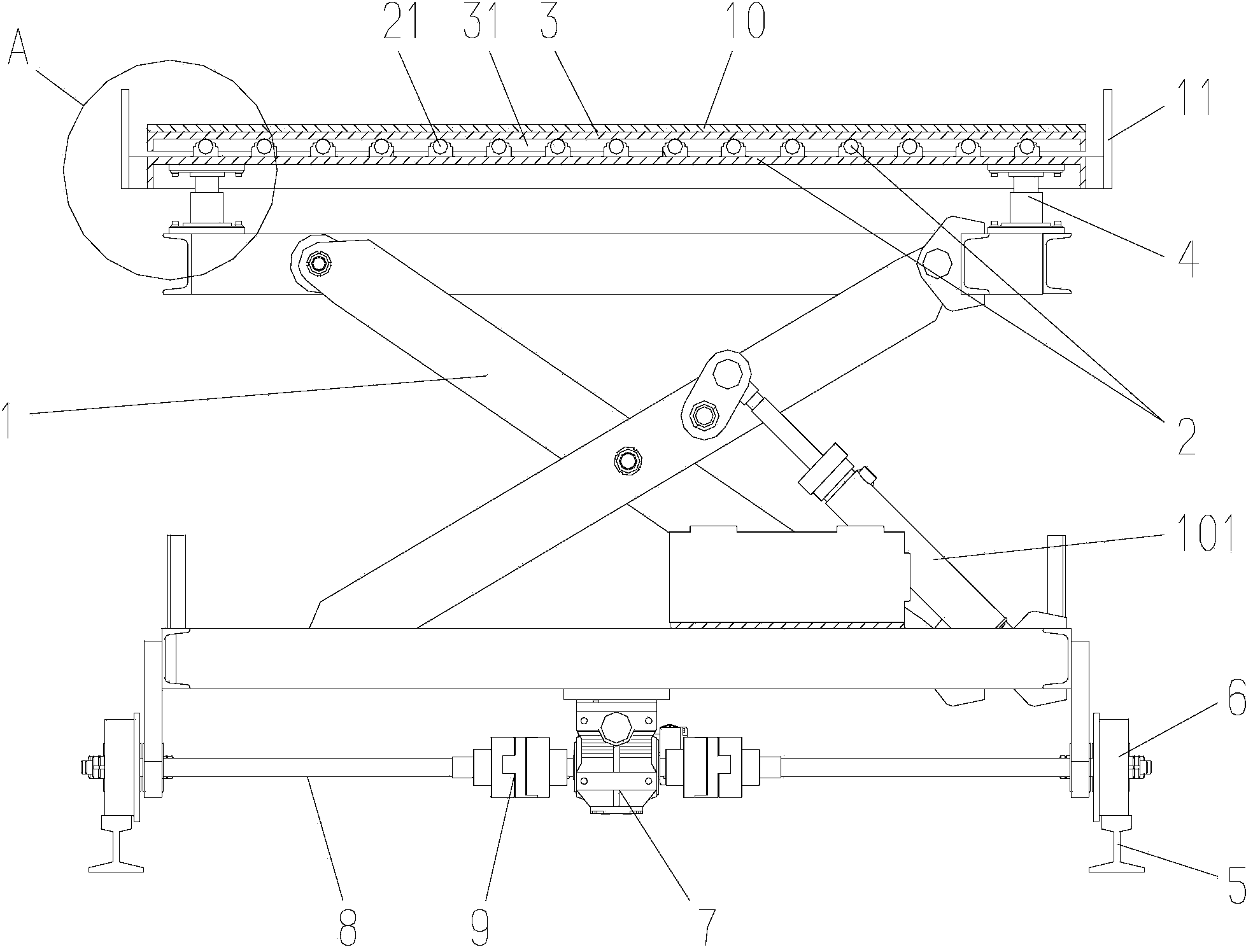

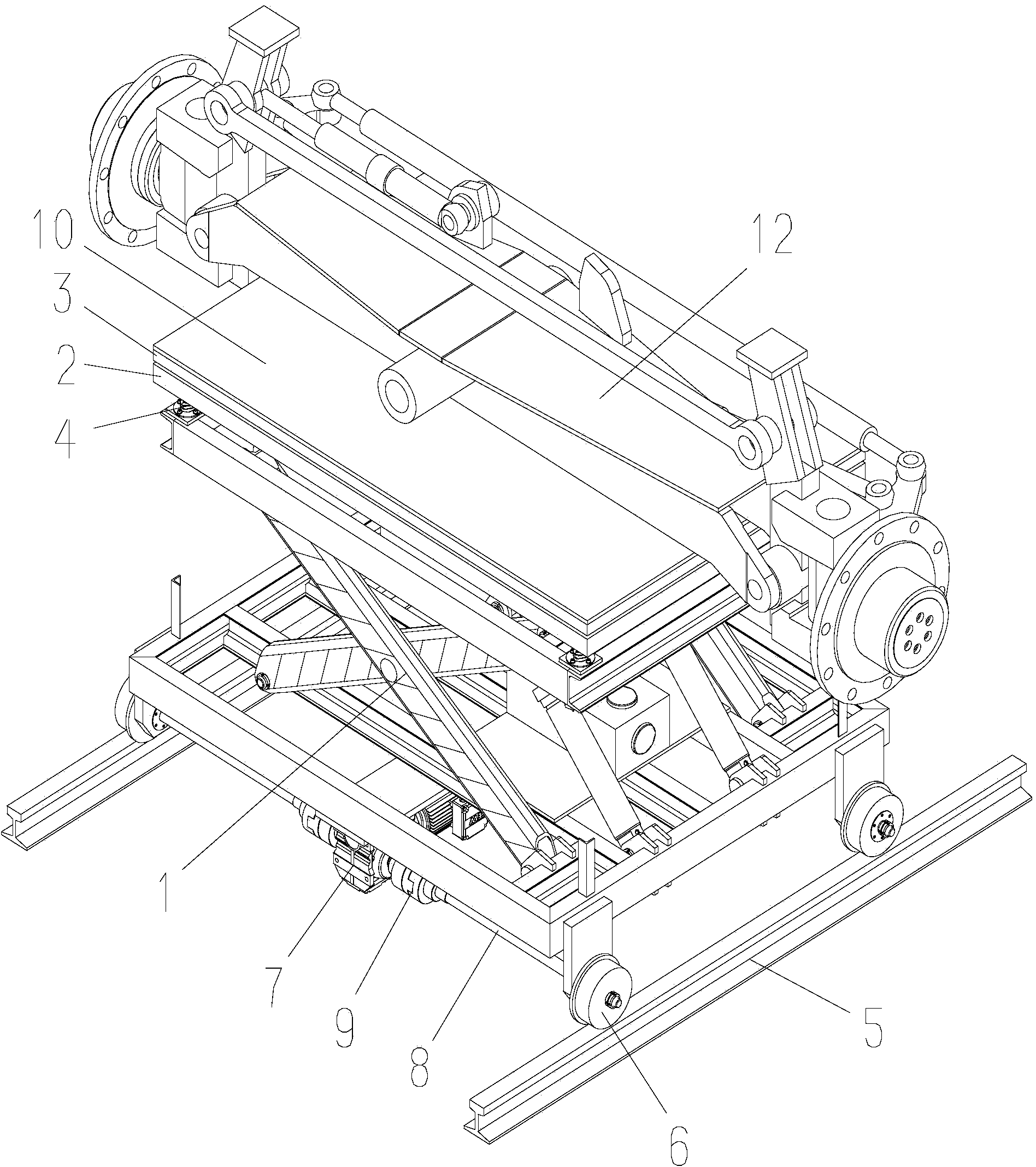

Floating conveying assembling vehicle

InactiveCN103708378AEasy to adjustQuick assemblyLifting framesMechanical conveyorsEngineeringUltimate tensile strength

The invention discloses a floating conveying assembling vehicle which comprises a lifter, a universal ball platform and a workbench placed on the universal ball platform. The universal ball platform is arranged on the upper portion of the lifter in a supporting mode through a spring support. During assembling, a workpiece is placed on the workbench, the workbench is placed on a universal ball of the universal ball platform so that the workpiece can be easily pushed to move freely in the horizontal plane, meanwhile, due to the fact that the universal ball platform is arranged on the spring support, the gravity of the workpiece and the gravity of the universal ball platform are balanced through a spring, an assembling operator can adjust the position of the workpiece in a fine mode easily in the up-down direction, accordingly, the assembling position of the workpiece can be easily adjusted through the assembling vehicle, quick assembling is achieved, assembling working efficiency is improved, labor is saved during assembling operation, labor intensity is low, a track is arranged, long-distance conveying and alignment assembling integrated automatic working can be achieved, the automatic degree is high, and meanwhile the floating conveying assembling vehicle has the advantages of being simple in structure, convenient to maintain and the like.

Owner:CMCU ENG

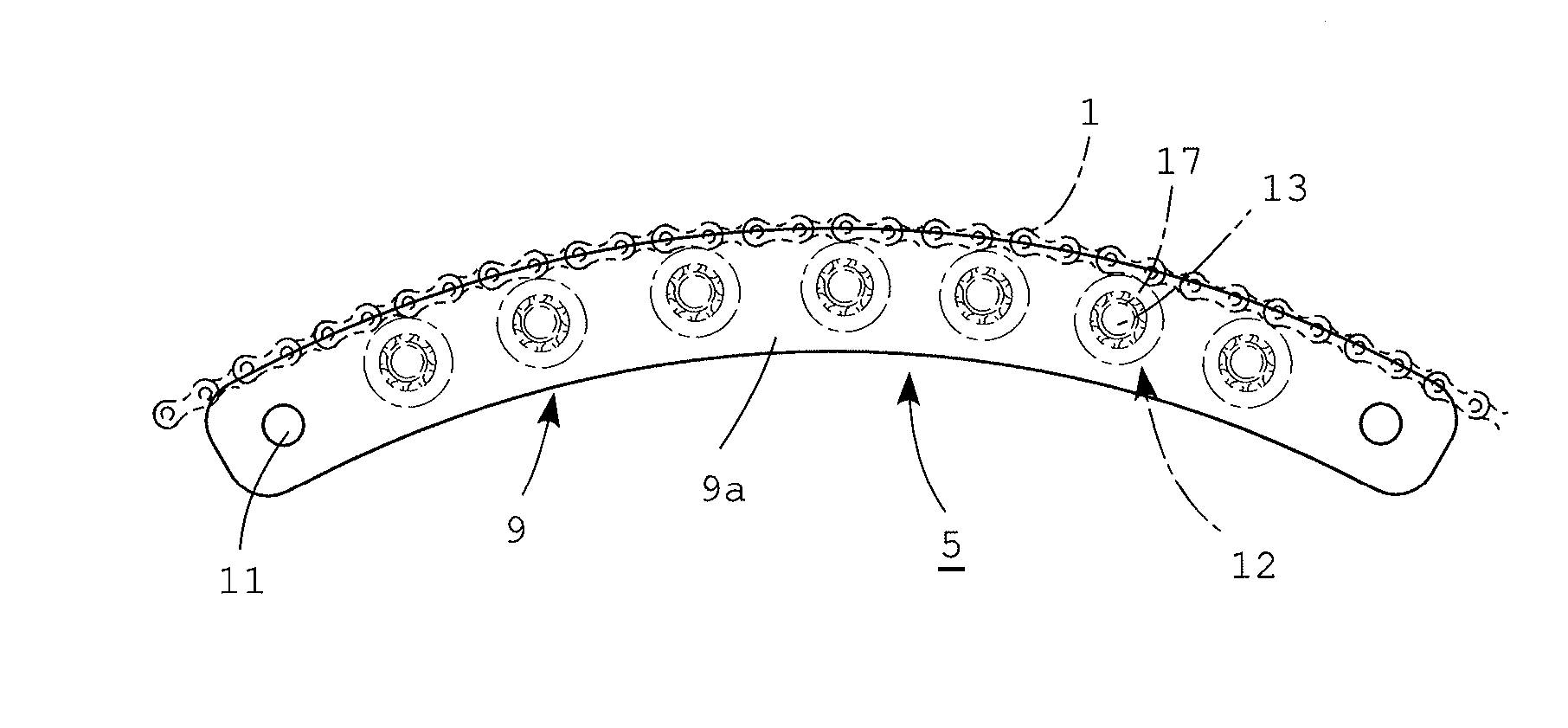

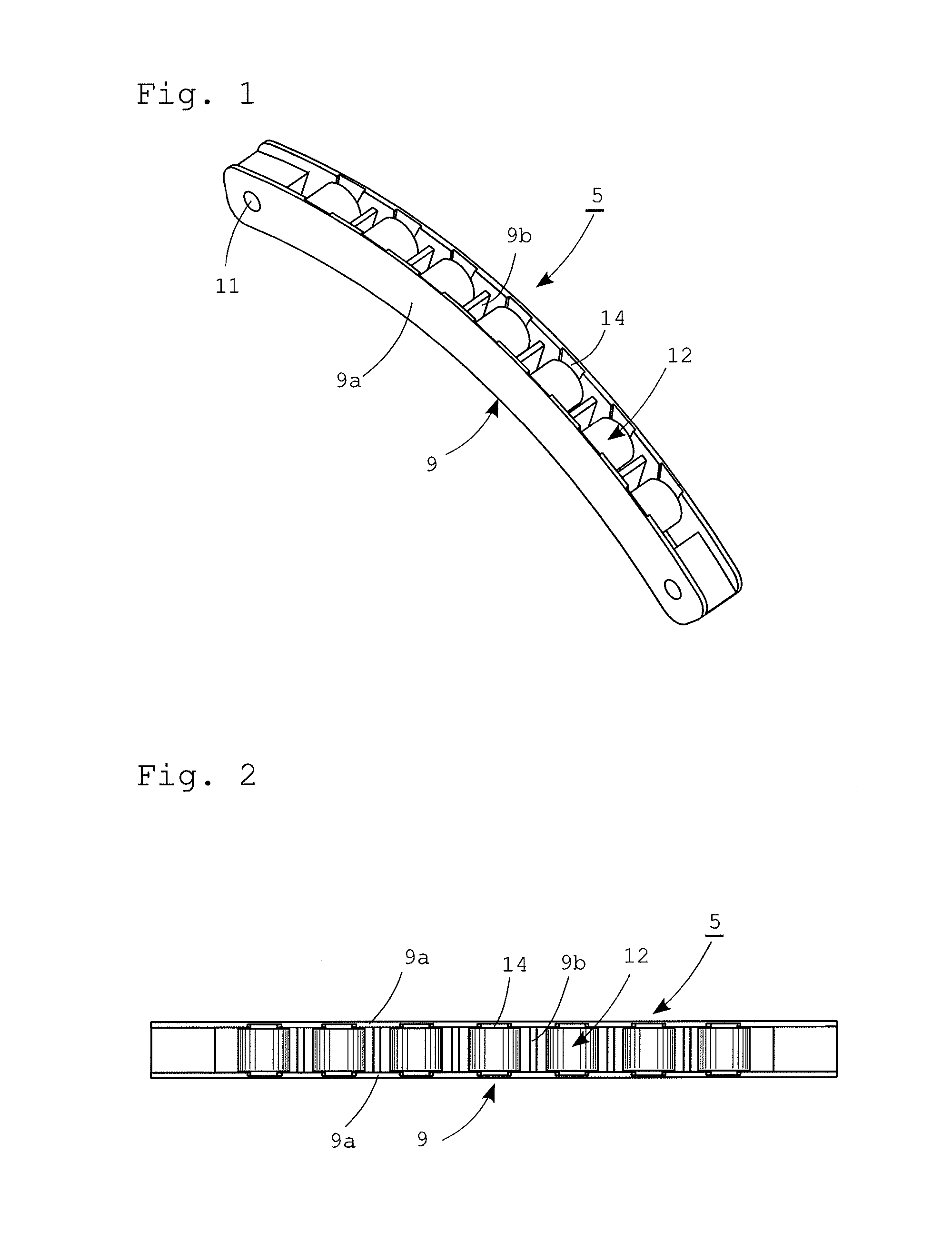

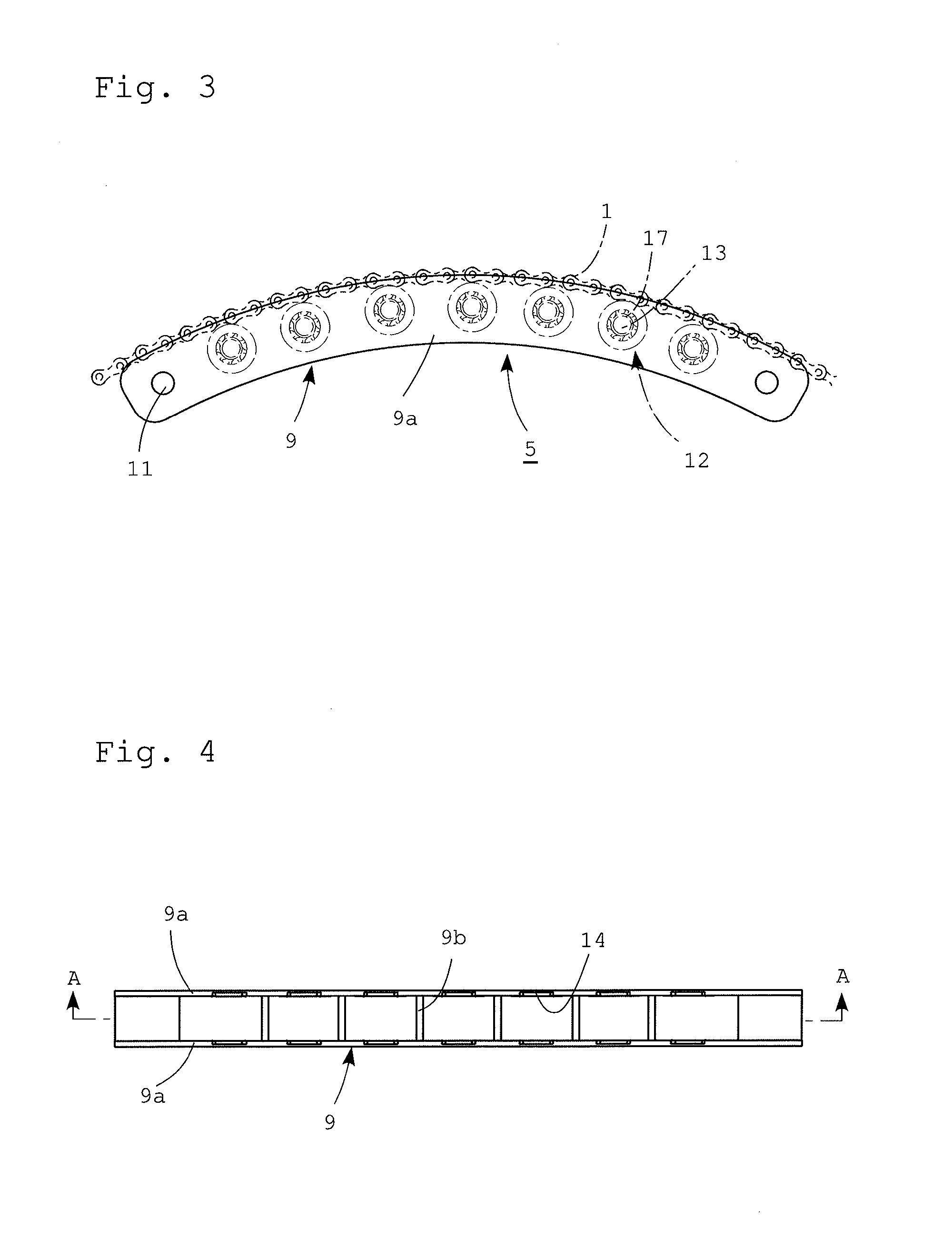

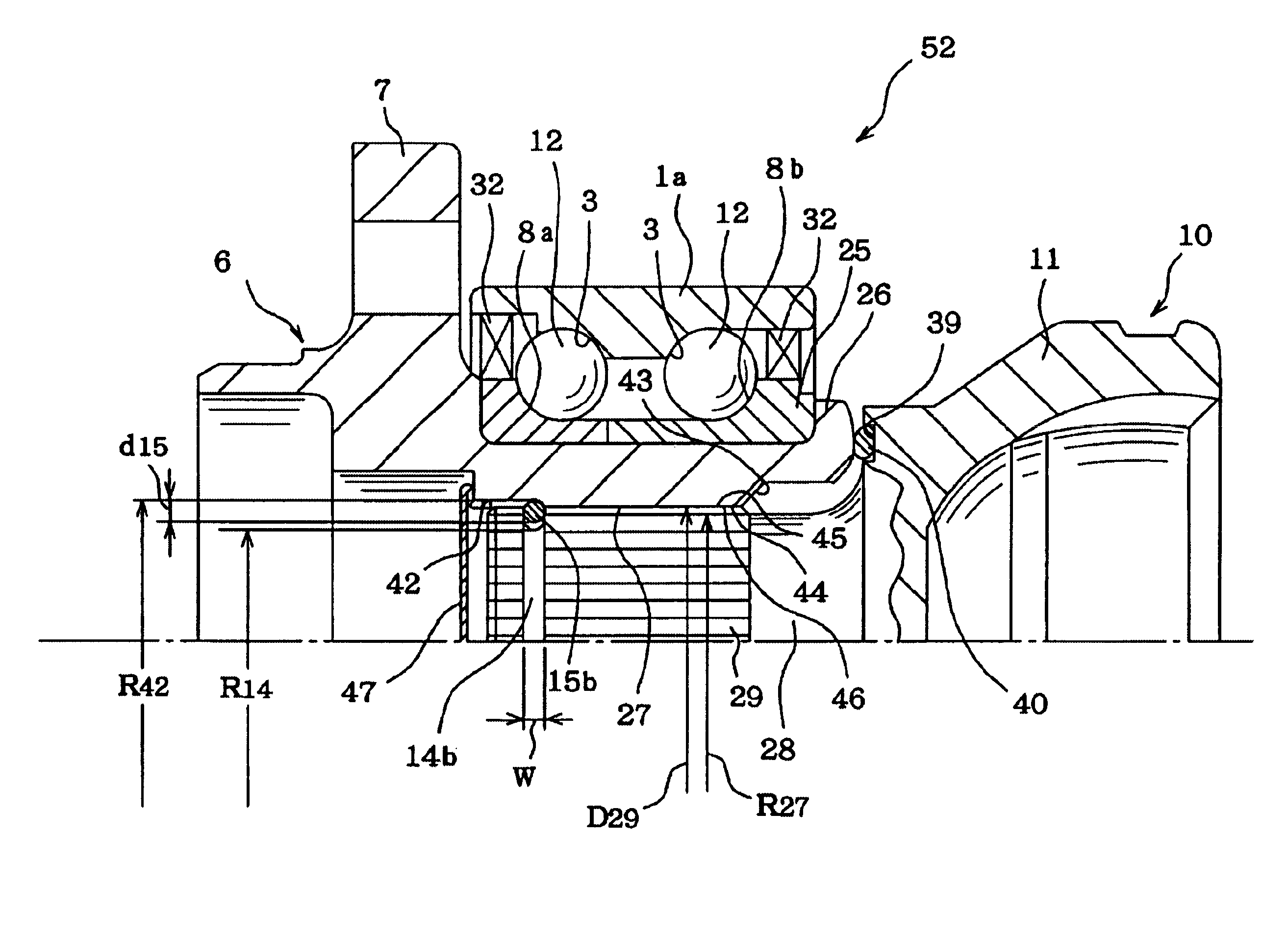

Chain guide and chain tensioner device

InactiveUS20130331211A1Improve assembly work efficiencyHigh mechanical strengthGearingEngineeringChain link

A chain guide and a chain tensioner device using the chain guide. A roller, brought into contact with a chain, comprises a support shaft supported by an opposing guide base provided along the running direction of the chain, and roller bearings each having a steel outer ring on the outer peripheral surface of the support shaft so as to be brought into contact with the chain. The roller is also configured to be assembled by inserting opposite ends of the support shaft into support recesses on facing wall surfaces of the guide base. The roller, has a vibration damping material between the support shaft and the support recess of each of the plate members.

Owner:NTN CORP

Cover member and power supply device equipped with this cover member

ActiveCN102576843AEasy to installEasy to processCell lids/coversElectrical and Electronics engineeringEngineering

In a power supply device, there has been a problem that when a bus bar module to which batteries are connected varies in length, it becomes difficult to attach a cover member. The bus bar module (6) comprises: a plurality of bus bars for connecting adjacent batteries in a battery assembly body to each other, the battery assembly body being formed by stacking a plurality batteries; a main body portion (8) having the bus bars attached thereto and being stacked on the battery assembly body; a plurality of alignment projections (29) provided on the main body portion; and a plurality of locking portions (30). The cover member (1) is installed adjacent to the bus bar module along the stacked direction (X) of the batteries and comprises: a plurality of cover portions (10) for covering each of the bus bars; and an elastic deformation portion (14) for coupling the adjacent cover portions so as to be able to be mutually displaced. Each of the cover portions comprises: an alignment opening (11) into which each of the alignment projections is inserted; and a locking receiving portion (12) by which each of the locking portions is locked. The alignment opening is shaped so as to be able to be inserted even when the positions of the alignment projections move along the direction (X), thereby solving the above problem.

Owner:YAZAKI CORP

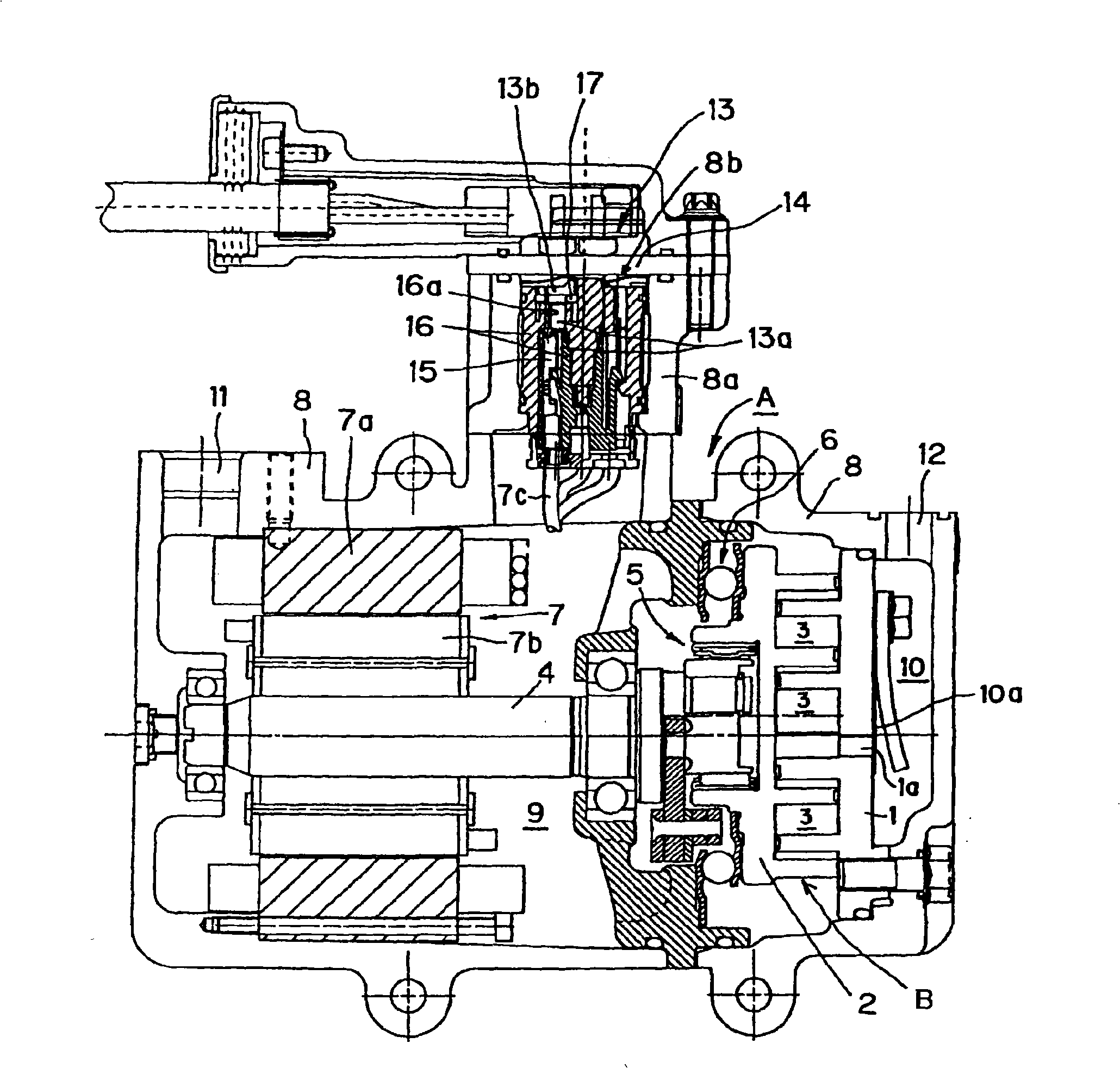

Electric compressor

InactiveCN101356366AImprove assembly work efficiencyPositive displacement pump componentsCoupling device detailsElectric motor

An electric compressor having a compression mechanism, an electric motor for driving the compression mechanism, and a housing for receiving the compression mechanism and the electric motor. An opening formed in the housing is closed with a lid member to which a sealed terminal is attached, and an electroconductive pin of the sealed terminal is fitted in a socket connected to a lead wire of the electric motor. The socket is embedded in an insulative member, and the electroconductive pin of the sealed terminal is inserted in a hole formed in the insulative member and is fitted in the socket. An insulation section and the insulative member that surround the base of the electroconductive pin hold a ring member that is formed from an insulative elastic material and surrounds the electroconductive pin, and the portion held is sealed and insulated by elastic deformation of the ring member. Pouring and curing of resin for insulation, which have been necessary for a conventional structure, are not necessary, so that the electric compressor has high assembling efficiency and whose sealed terminal can be reused.

Owner:SANDEN CORP

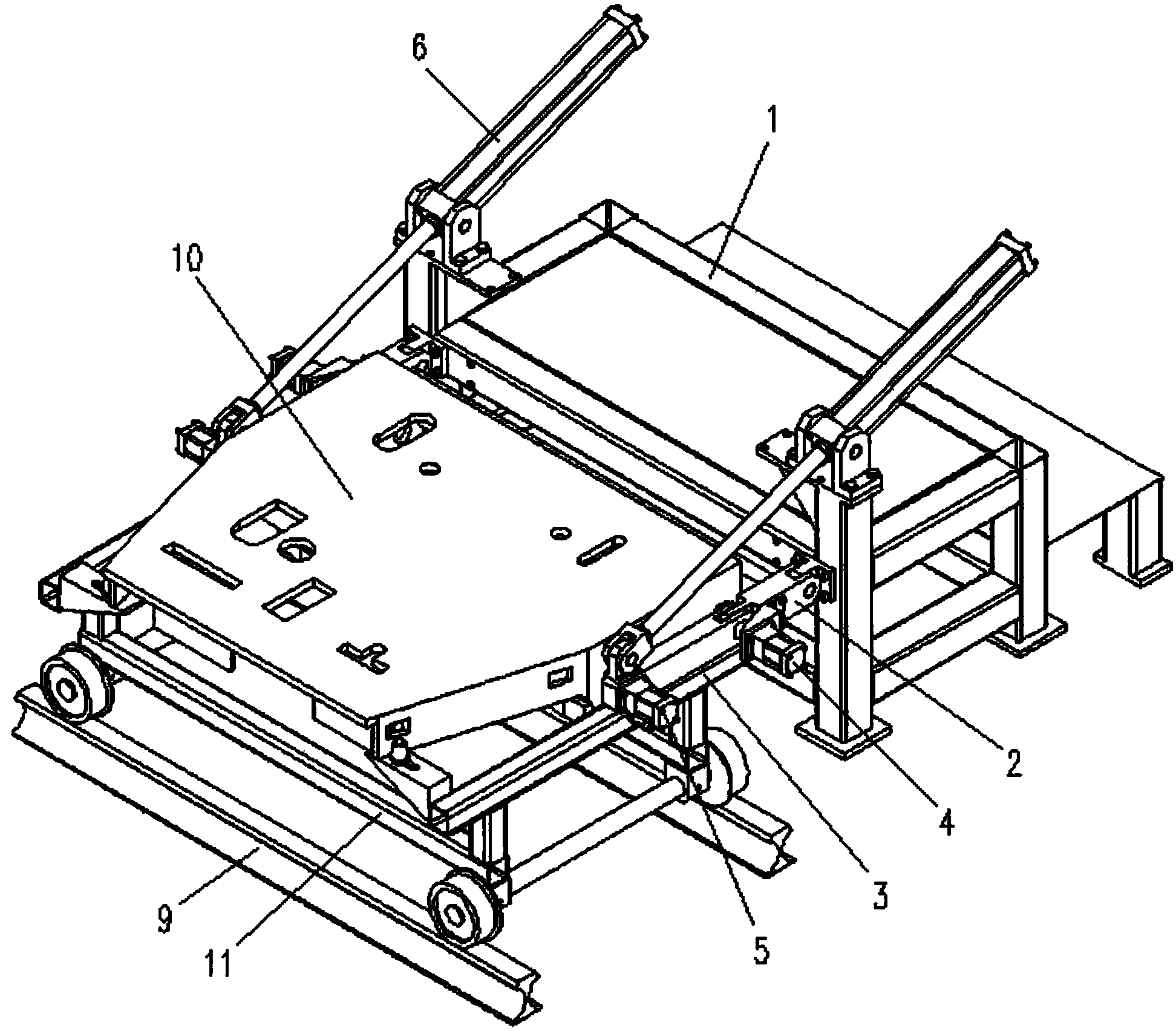

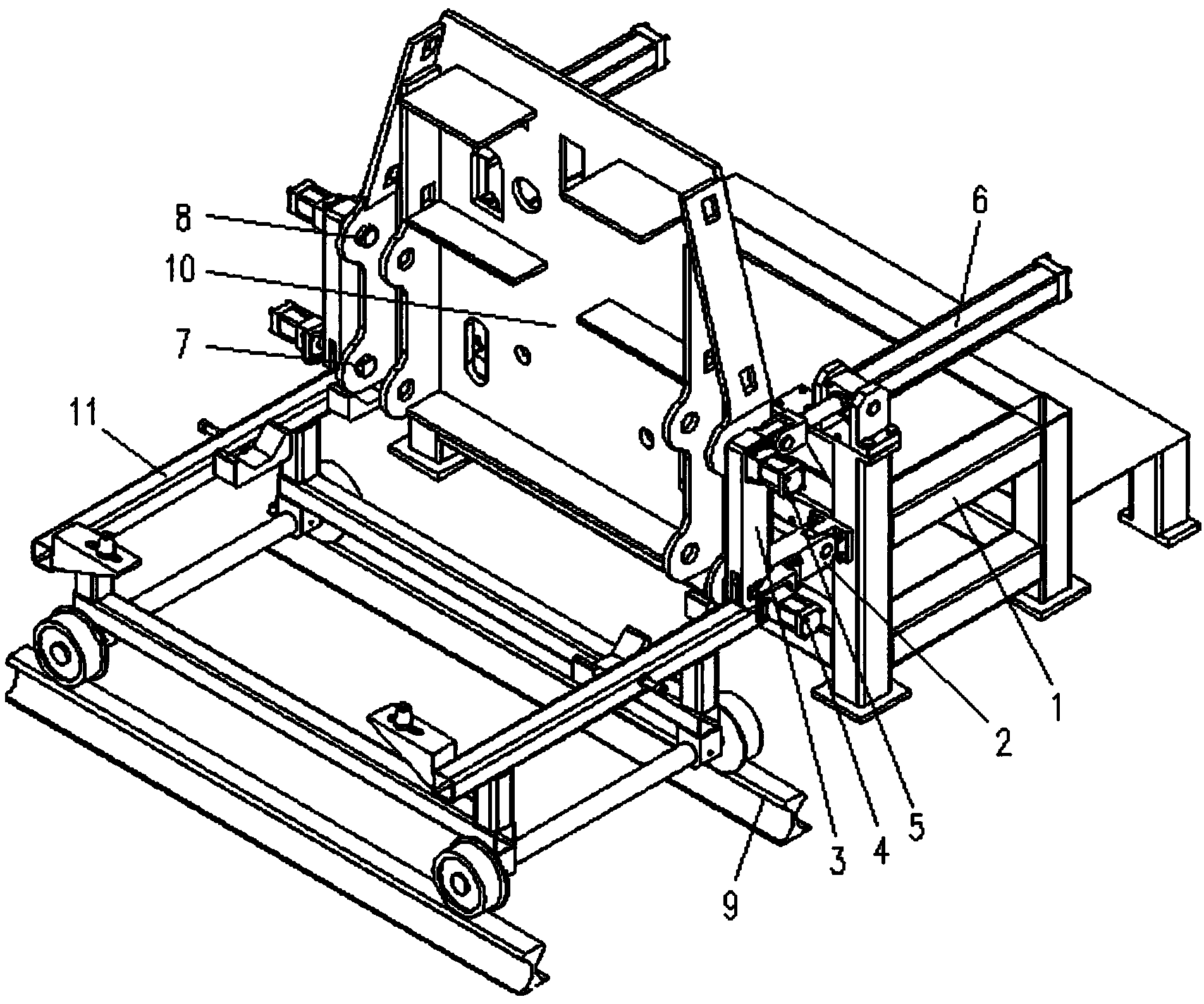

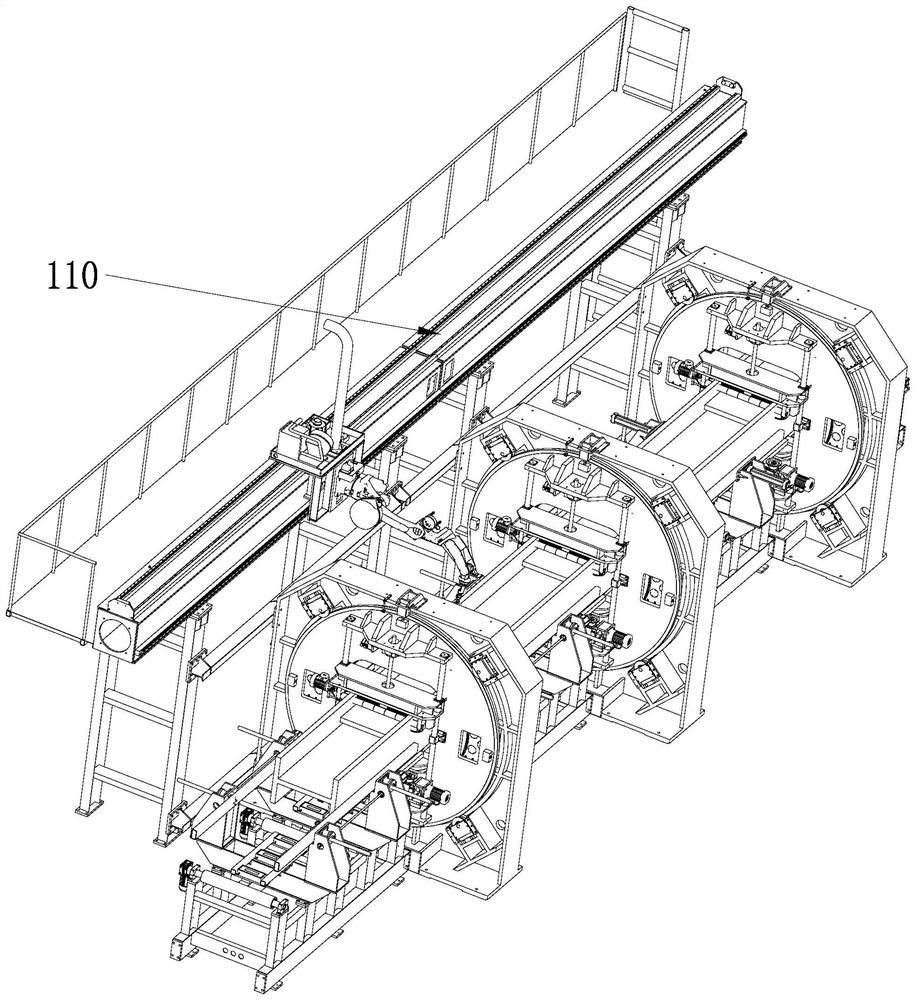

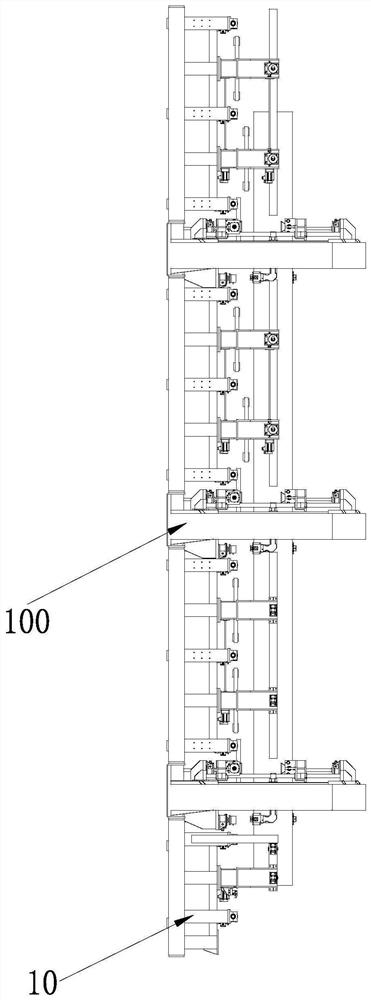

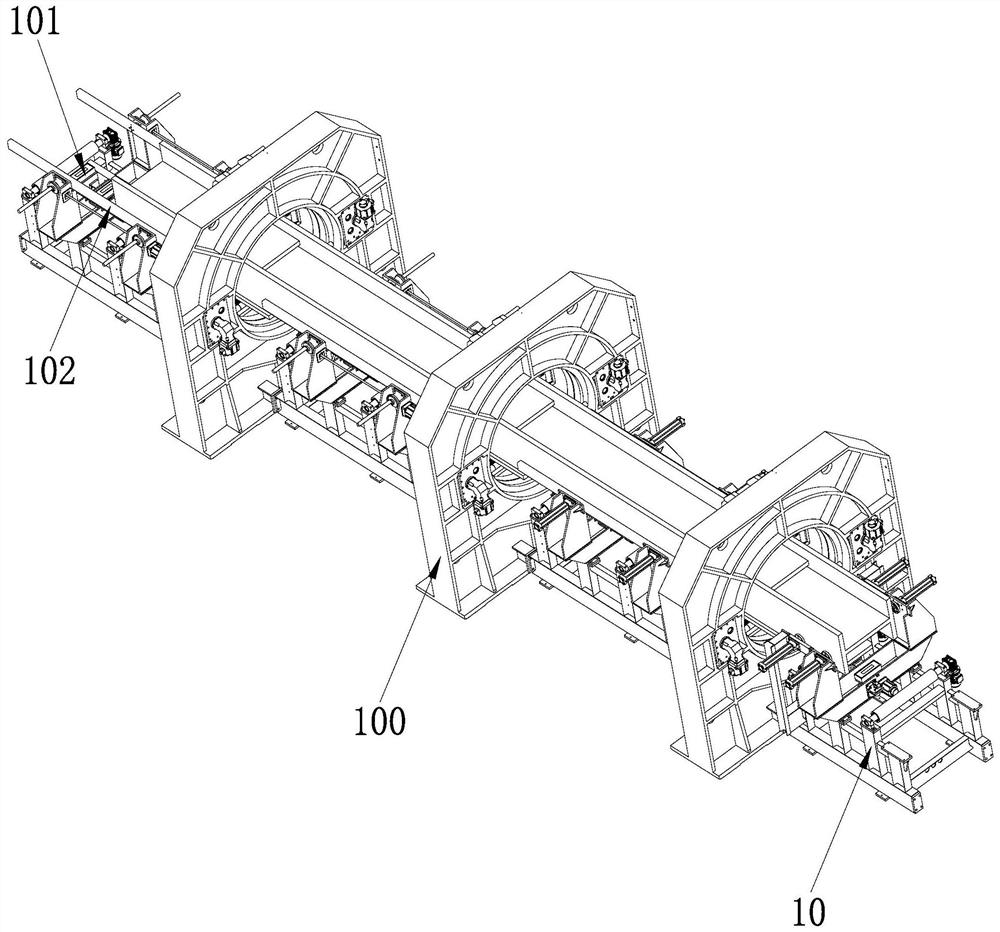

Turnover machine for assembling and base assembling device for engineering machinery

ActiveCN103707034AImprove work efficiencyEasy flipAssembly machinesWork benchesHydraulic cylinderHigh volume manufacturing

The invention discloses a turnover machine for assembling. The turnover machine comprises a machine seat and a pair of turnover manipulators arranged on the machine seat, wherein the turnover manipulators comprise turnover arms, turnover elbows, first insertion pin cylinders, second insertion pin cylinders and turnover hydraulic cylinders. The invention also discloses a base assembling device for engineering machinery. The base assembling device for the engineering machinery comprises vehicle rails and a transporting vehicle which is arranged on the vehicle rails and is used for transporting a base of the engineering machinery. According to the turnover machine for assembling and the base assembling device for the engineering machinery, taking and arrangement of a workpiece to be turned over are realized by controlling insertion pins to be inserted into and released out of the workpiece by the insertion pin cylinders; the turnover elbows and the turnover arms are controlled to integrally rotate around a hinge center, and the turnover arms are controlled to be fixed and the turnover elbows are controlled to rotate independently, so that the turnover machine can catch up and put down the workpiece and enable the workpiece to randomly rotate between 0-90 degrees; a large-size workpiece can be turned over conveniently through the turnover machine; the working efficiency for assembling parts on the upper surface and the lower surface of the large-size workpiece is improved; the assembling work is high in safety; the turnover machine is applicable to large-batch production.

Owner:CMCU ENG

H-shaped steel overturning, welding and forming device

ActiveCN112059456AImprove assembly accuracyImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to an H-shaped steel overturning, welding and forming device. The H-shaped steel overturning, welding and forming device comprises a welding robot moving mechanism, a steel plateconveying mechanism, and a plurality of clamping and overturning mechanisms arranged in the length direction of the steel plate conveying mechanism, wherein a web jacking mechanism and a wing plate jacking mechanism are further arranged on the steel plate conveying mechanism. The H-shaped steel overturning, welding and forming device is simple in structure, ingenious in design and suitable for welding of H-shaped steel components of various types, and ensures the welding quality and the welding precision; spot welding is performed through an electric welding machine; and the assembling precision, machining efficiency and automation degree of the H-shaped steel are greatly improved; the H-shaped steel can be directly assembled through the H-shaped steel overturning, welding and forming device with no need for a traveling crane and a large amount of auxiliary manual work; and the the H-shaped steel overturning, welding and forming device has high assembling operation efficiency, saves labor force and operation time, is safe and convenient, and improves the production efficiency of products.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

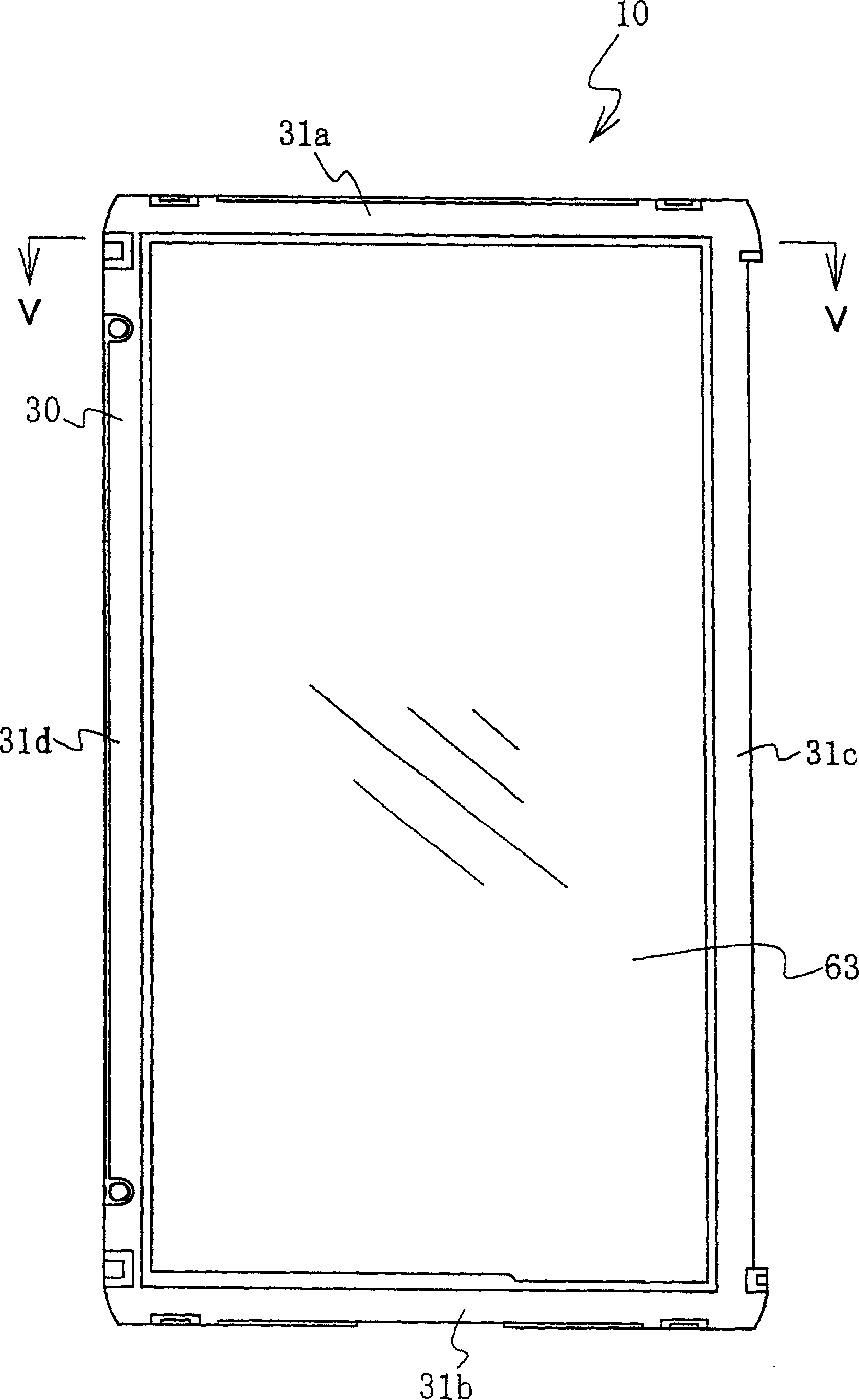

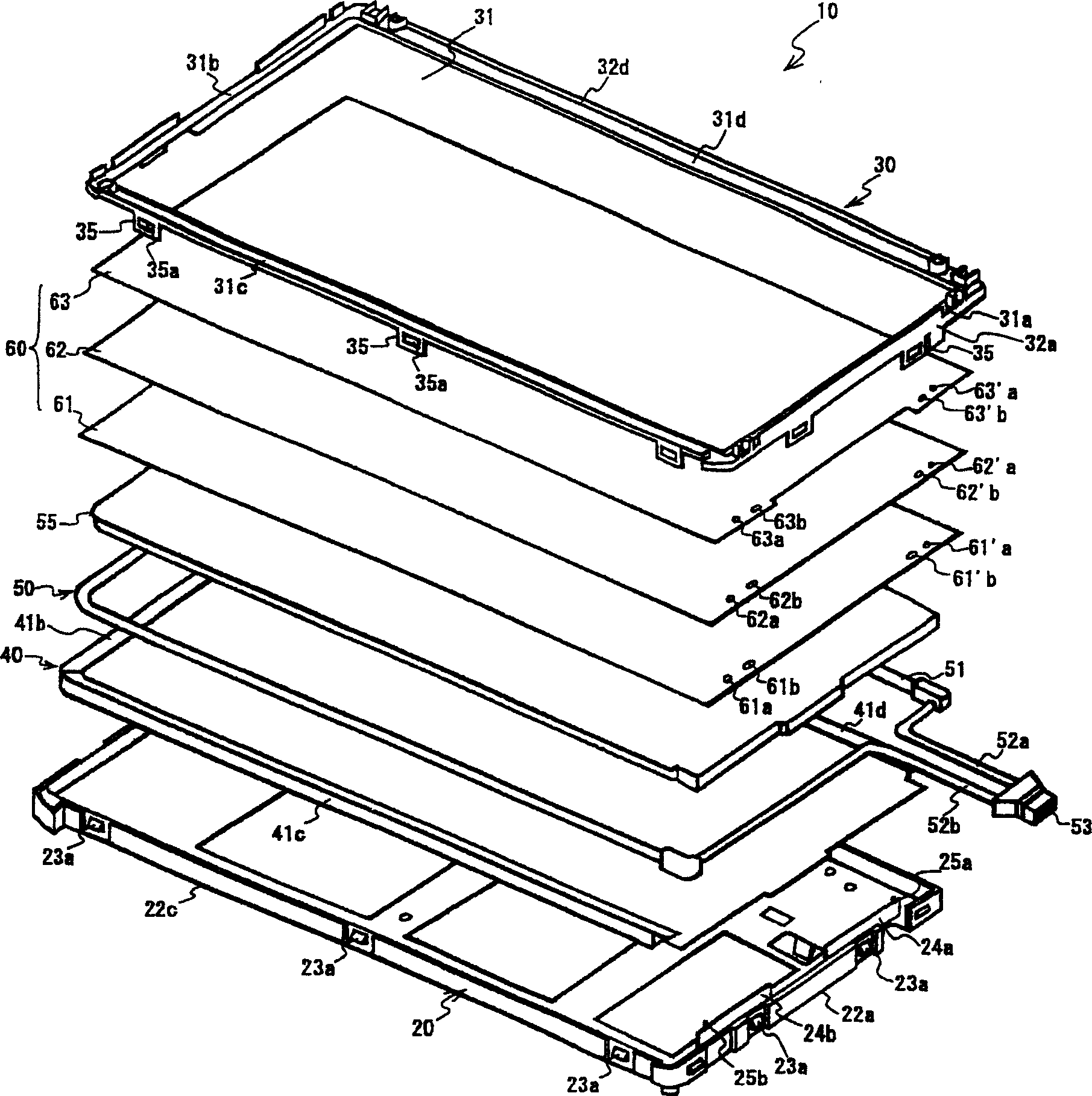

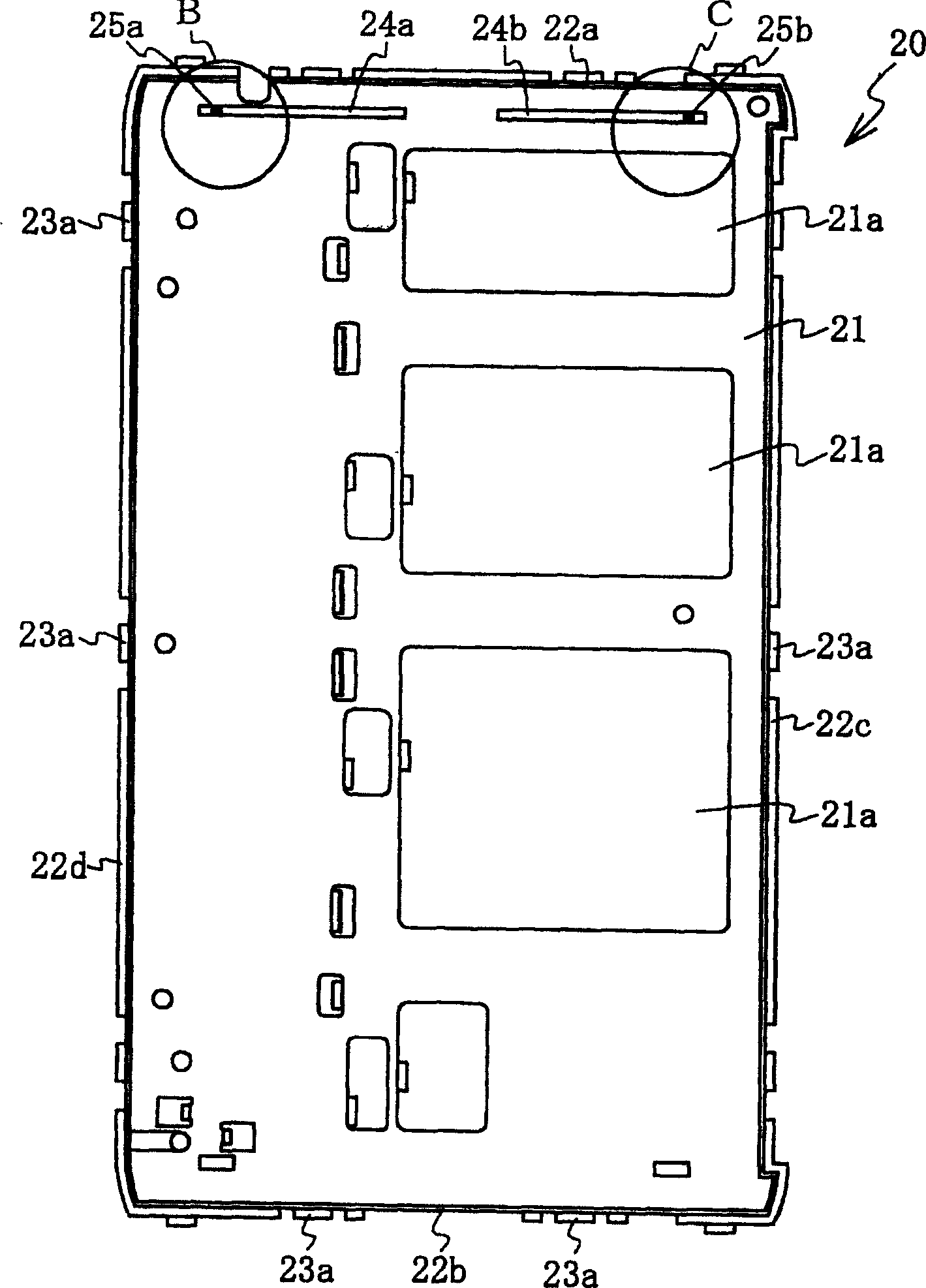

Liquid crystal display device

ActiveCN1598664ALarge displayAvoid wrinklesStatic indicating devicesOptical light guidesLiquid-crystal displayEngineering

A liquid crystal display device (10) includes a liquid crystal panel, at least one optical sheet (60) substantially rectangular in shape, where first (61a,62a,63a,61'a,62'a,63'a) and second (61b,62b,63b,61'b,62'b,63'b) openings are formed at the opposite ends of one side of the optical sheet at a predetermined interval, a main frame (20) in which the optical sheet(s) are placed, and a sub-frame (30) arranged above the optical sheets and the main frame, in which the main frame is provided with first small protrusions (25a,25b) jutting upward corresponding to the first openings at the top surface, while the rear surface of the sub-frame is provided with second small protrusions (33a,33b) jutting downward corresponding to the second openings, thereupon the first small protrusions are inserted into the first openings of the optical sheet(s) and the second small protrusions are inserted into the second openings to connect and install the sub-frame to the main frame, and the optical sheet(s) are then aligned and fixed. Accordingly, the optical sheets are aligned better and firmly fixed to achieve larger display screens and thinner liquid crystal display devices and wrinkles are prevented from occurring in the optical sheets.

Owner:JAPAN DISPLAY INC

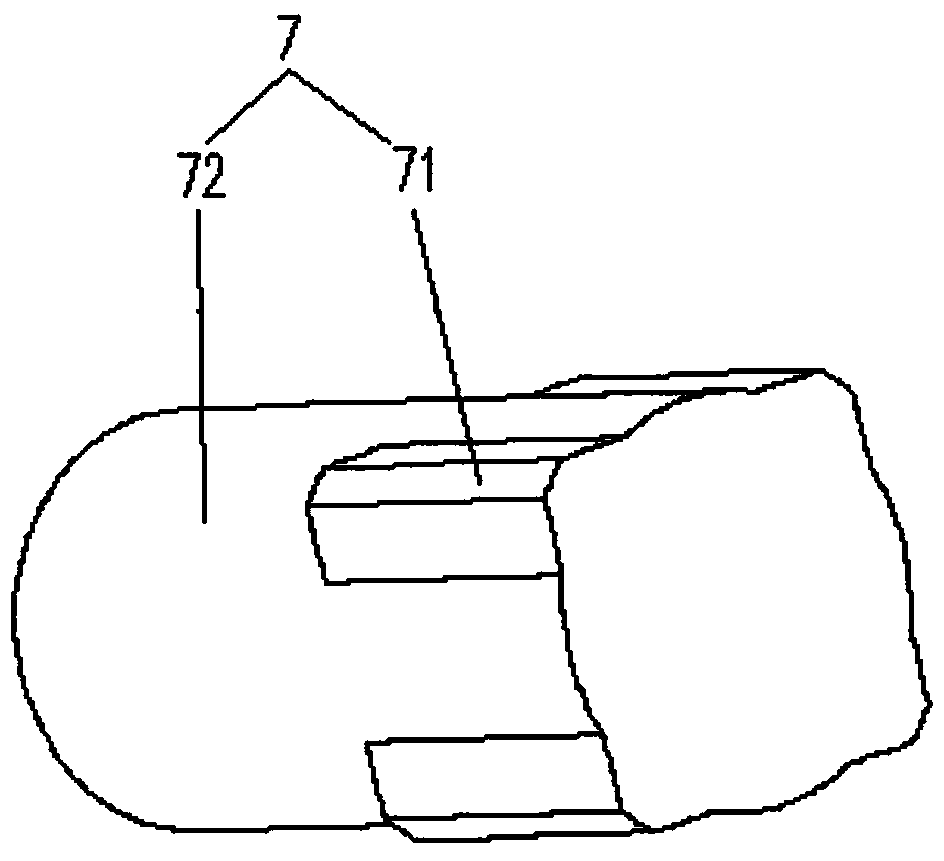

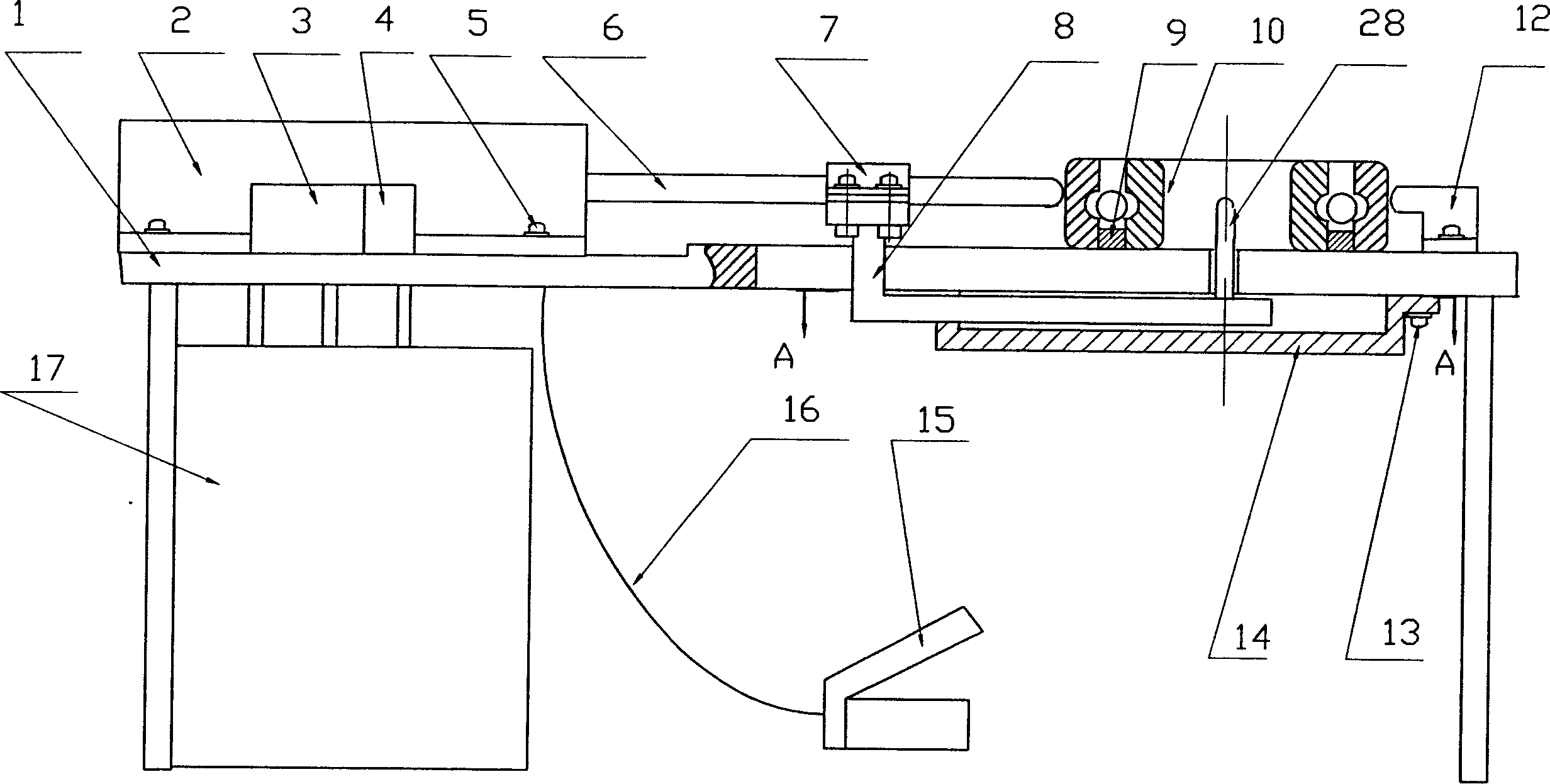

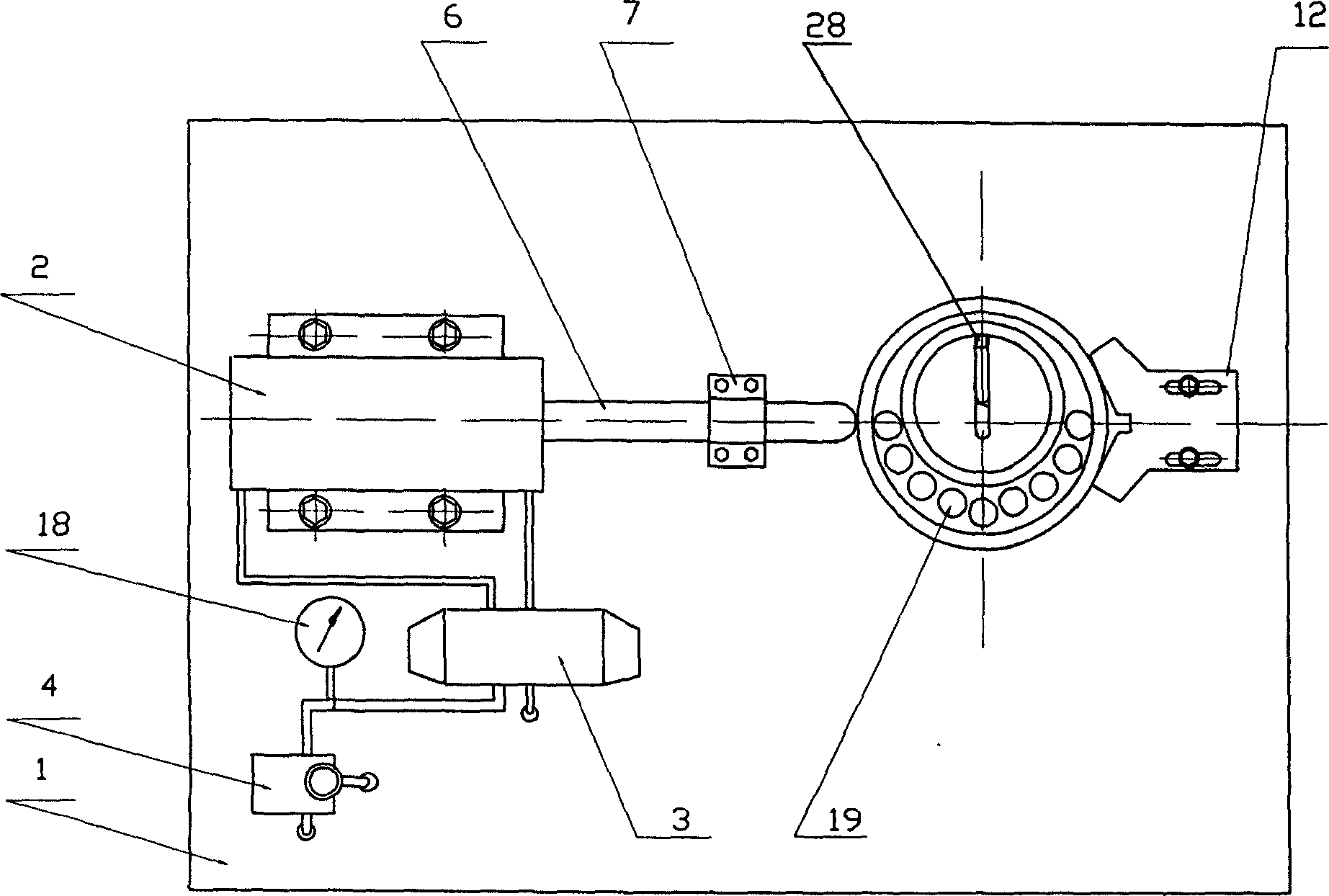

Low-noise and bearing-assembled ball feeder

A low noise shaft assembling device, to add balls into the shaft through the shaft's ferrule, comprises platform, a pressure input device fixed on the platform and a shaft supporter. Two piston rods put pressure on the inner ferrule and outer ferrule of the shaft to make it elastic deformation and add balls into the shaft.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Mounting tool for mounting bearing of shaft head of motor

The invention provides a mounting tool for mounting a bearing of a shaft head of a motor. A vertical column (1) of the mounting tool has a circular rod structure; one end of the vertical column (1) is connected with a shaft head end (5) of a motor shaft head (14) through a bolt (4); a pushing sleeve (2) has a hollow structure; the pushing sleeve (2) is screwed with a thread tooth part at the other end of the vertical column (1) through a thread part distributed on an inner cavity of the pushing sleeve (2); and a handle (3) is connected with the pushing sleeve (2). Under the condition that the bearing cannot be mounted according to a hot sleeve method, the mounting tool for mounting the bearing of the shaft head of the motor provided by the invention can be used for cold-pressing the bearing through a manual mounting tool and quickly and conveniently mounting the bearing on the shaft head of the motor. Meanwhile, by using the mounting tool provided by the invention, the interior structures of the bearing and the motor are not damaged by knocking inner and outer rings, so that the mounting tool is portable and convenient, the assembling efficiency is increased and the bearing and the bearing and encoder in the motor are effectively prevented from being damaged.

Owner:EFORT INTELLIGENT EQUIP CO LTD

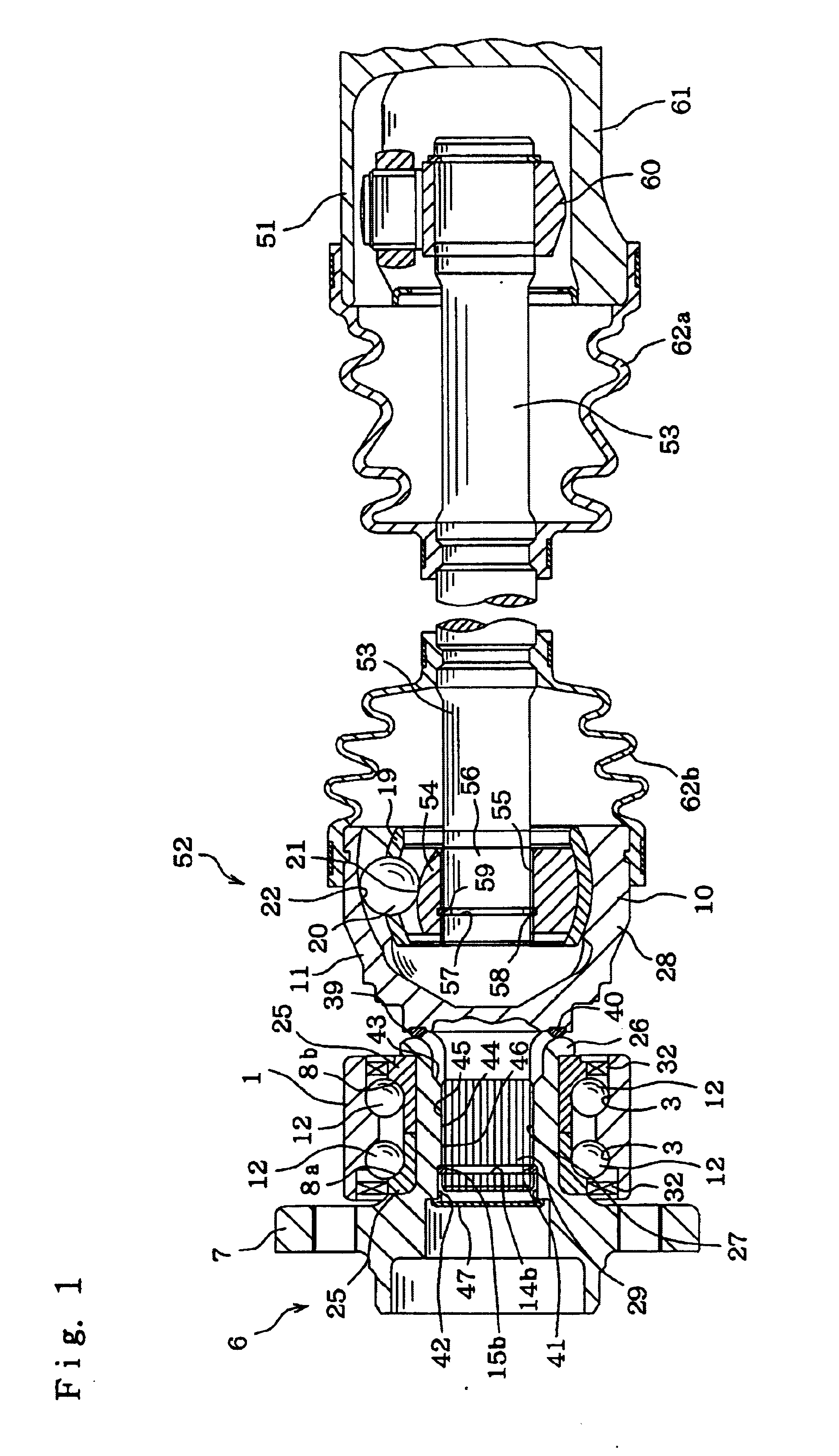

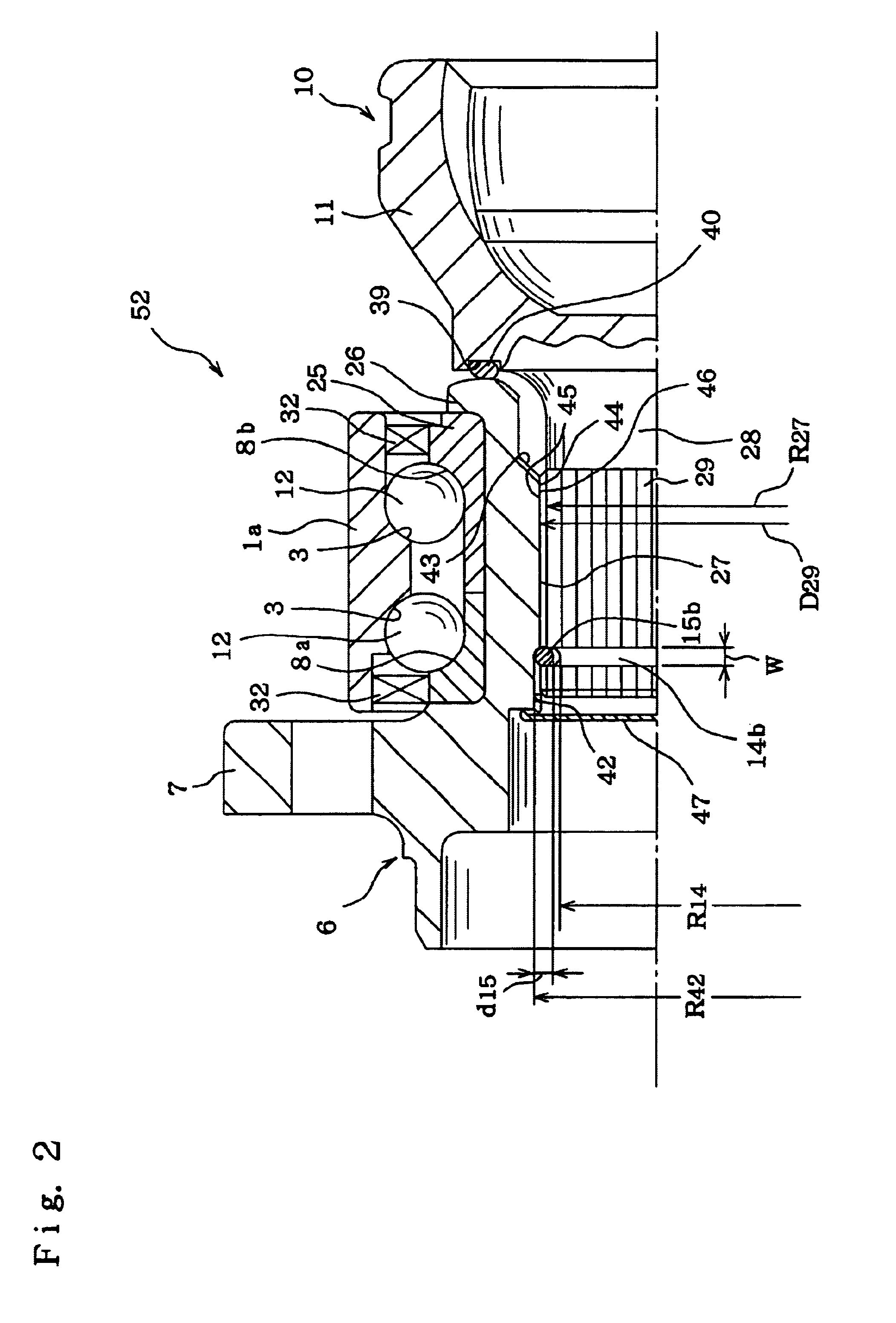

Drive unit for wheel and assembly method for the same

InactiveUS6851866B2Improve assembly work efficiencyAvoid noiseYielding couplingRolling contact bearingsEngineeringFlange

A combination of a constant-velocity joint and an axle unit for wheel-drive which comprises an outer race having an outer-ring raceway and being not rotatable even during use, a hub having an installation flange for supporting the wheel near the outside end, a first spline section and an inner-ring raceway near the inside end facing the outer-ring raceway, a drive member having a second spline section facing the first spline section, and a housing section forming an outer ring of the constant velocity joint, a plurality of rolling bodies between the outer-ring raceway and inner-ring raceway, the hub being engaged with the drive member by way of a spline connection with a pitch circle, and a coupling member adapted to freely deform elastically in the radial direction and located between and engaged with the first engagement section and the second engagement section so as to position the hub and drive member in the axial direction, wherein the clearance width in the circumferential direction on the pitch circle is controlled within the range of 0.001 mm to 0.10 mm.

Owner:NSK LTD

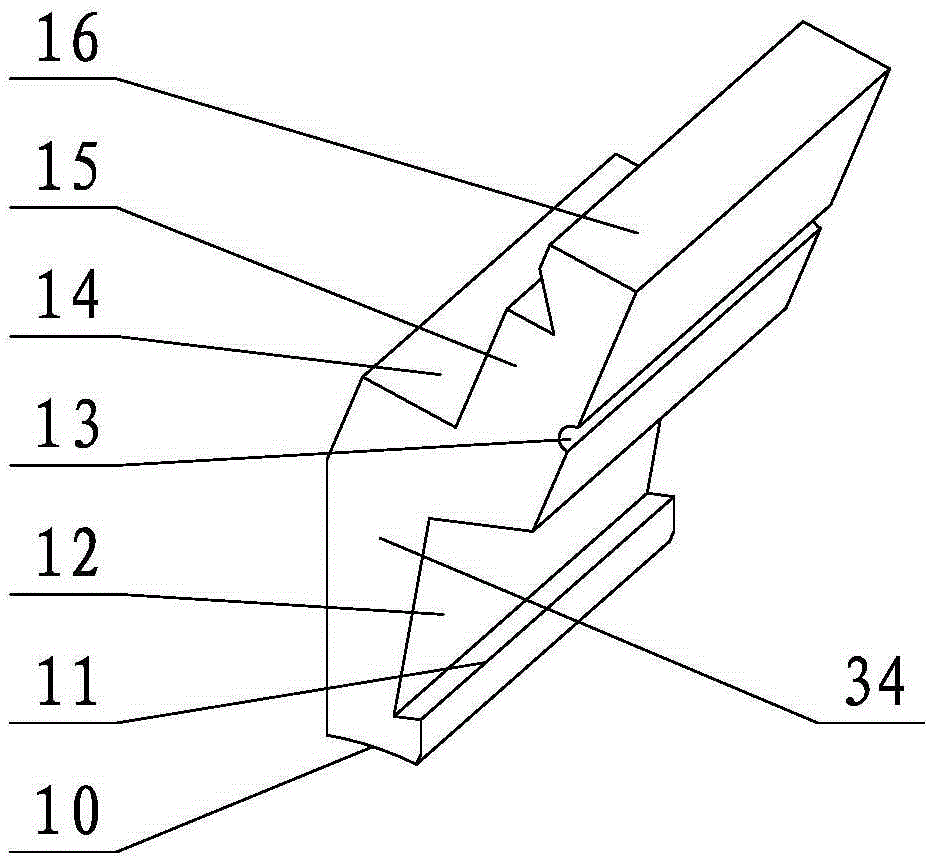

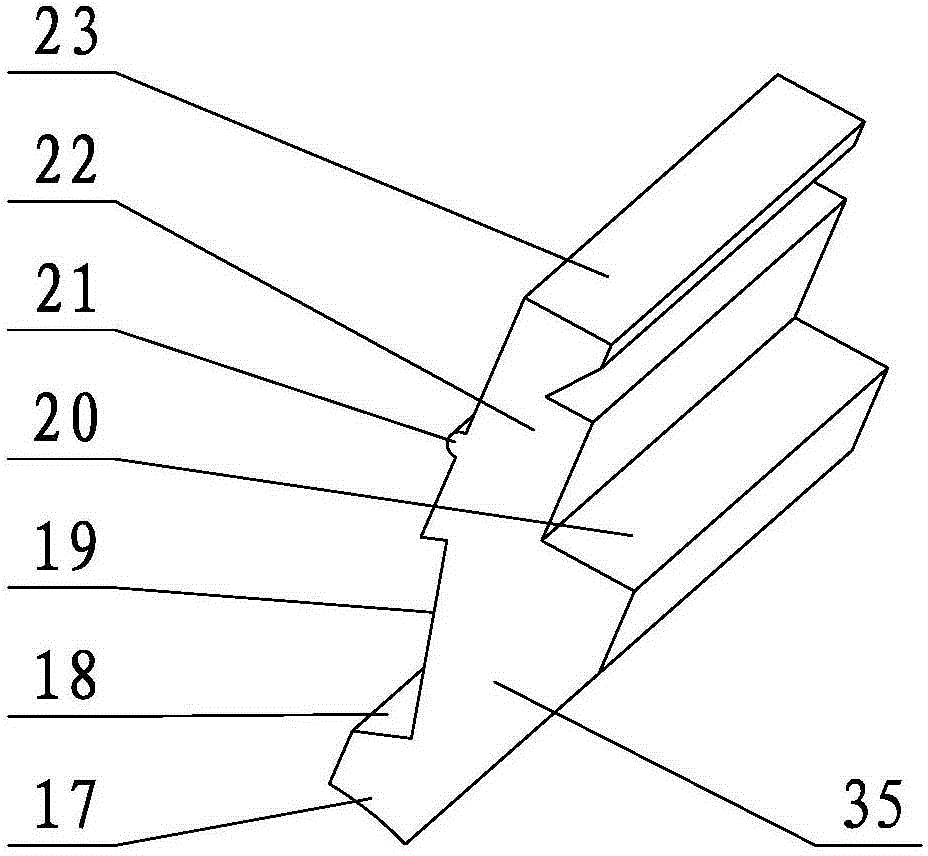

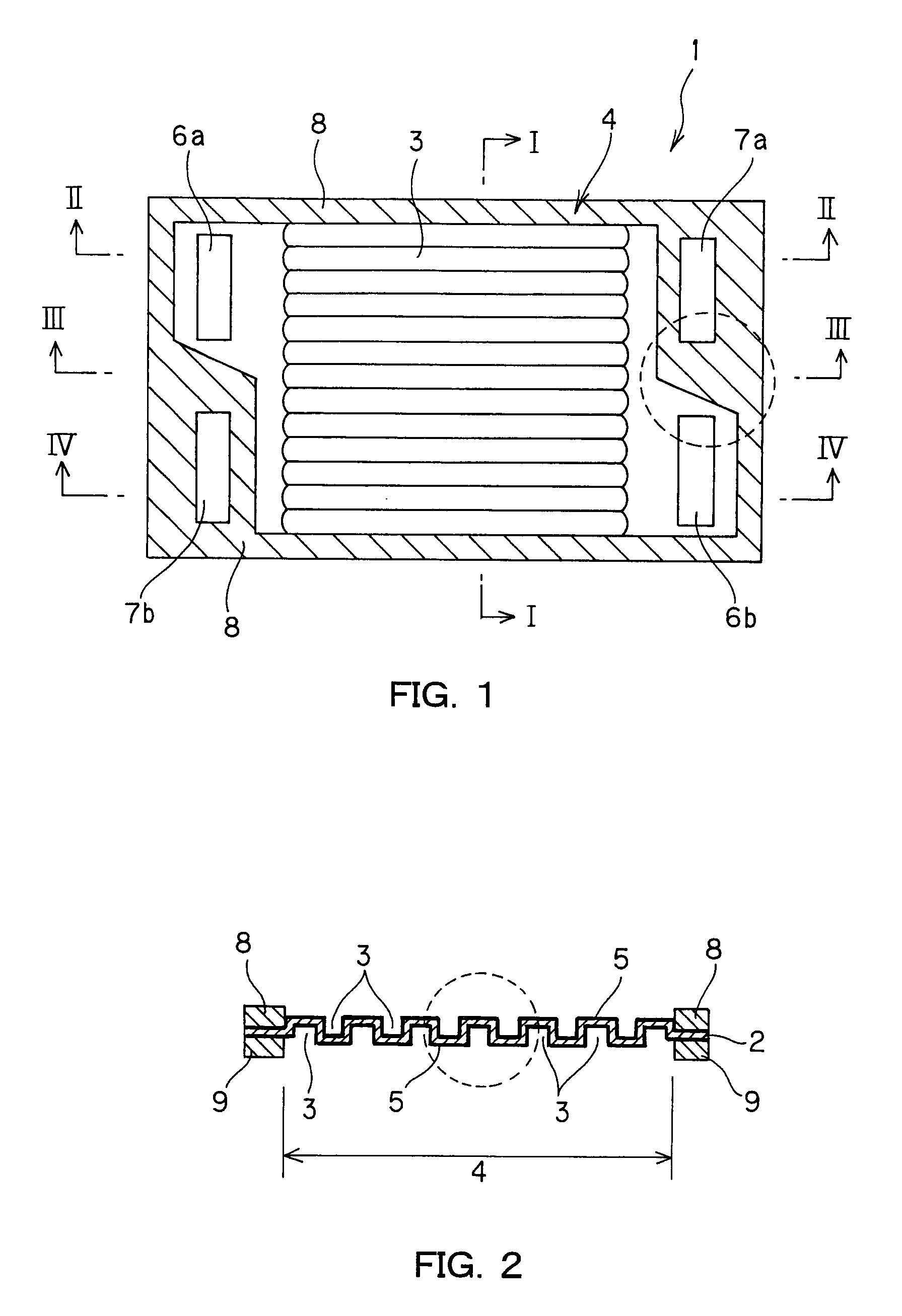

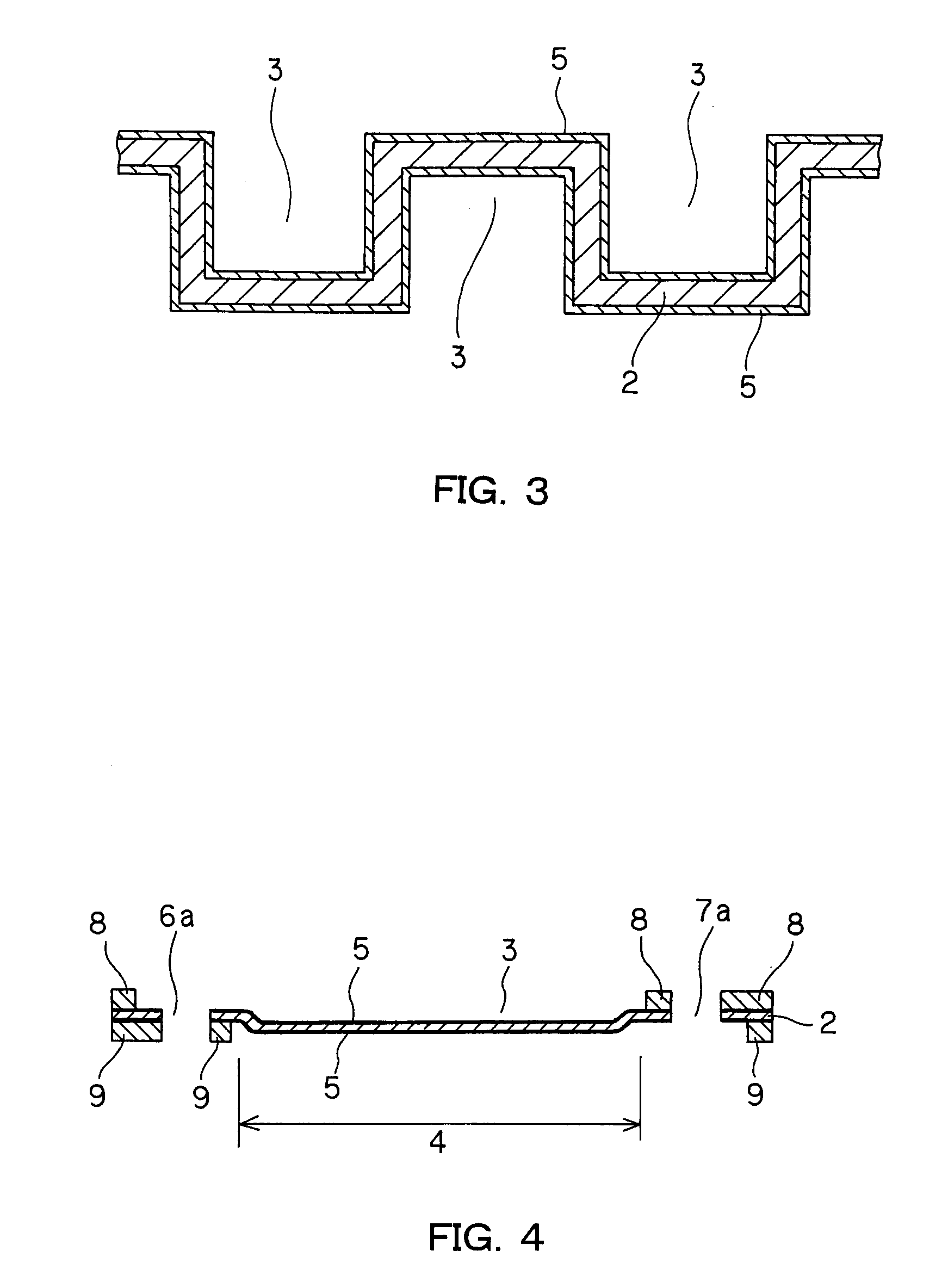

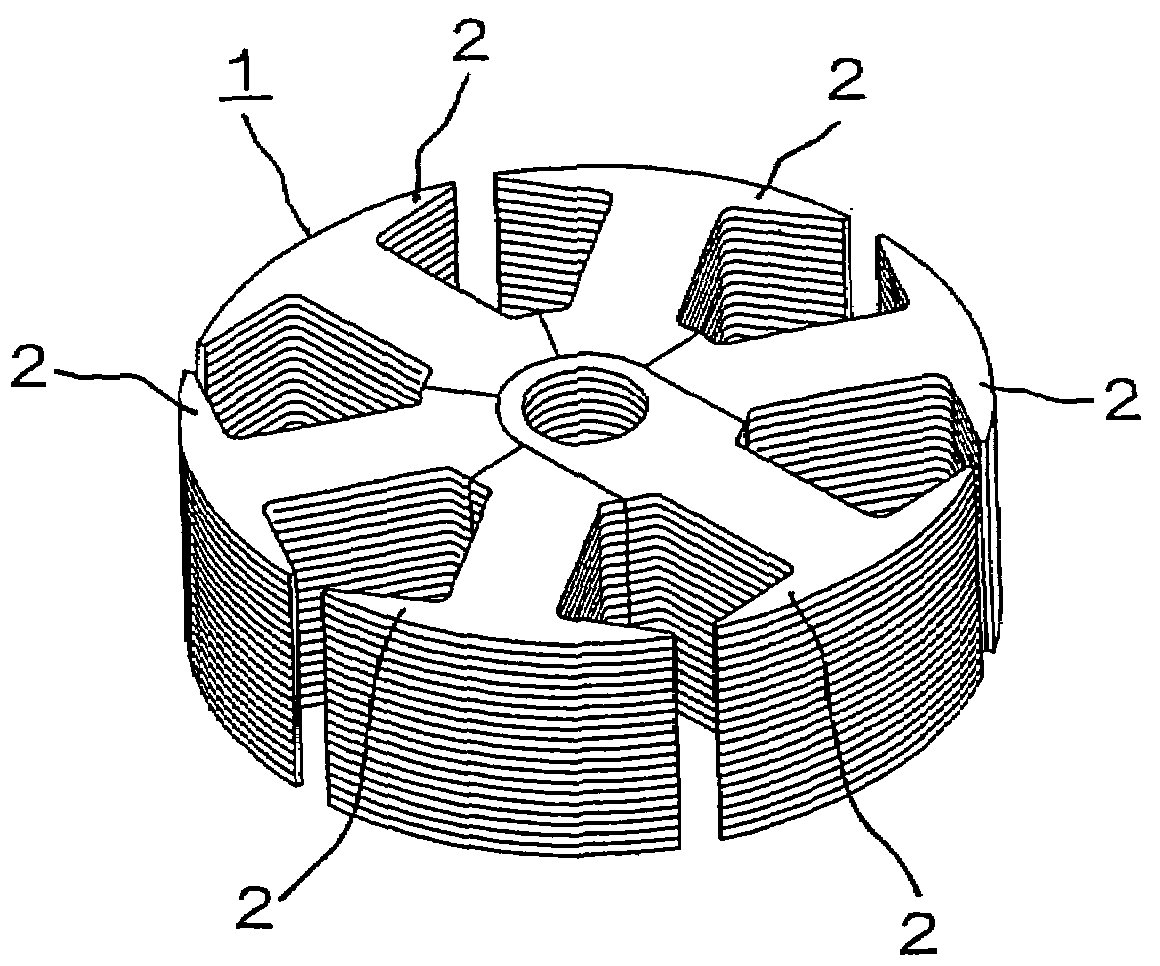

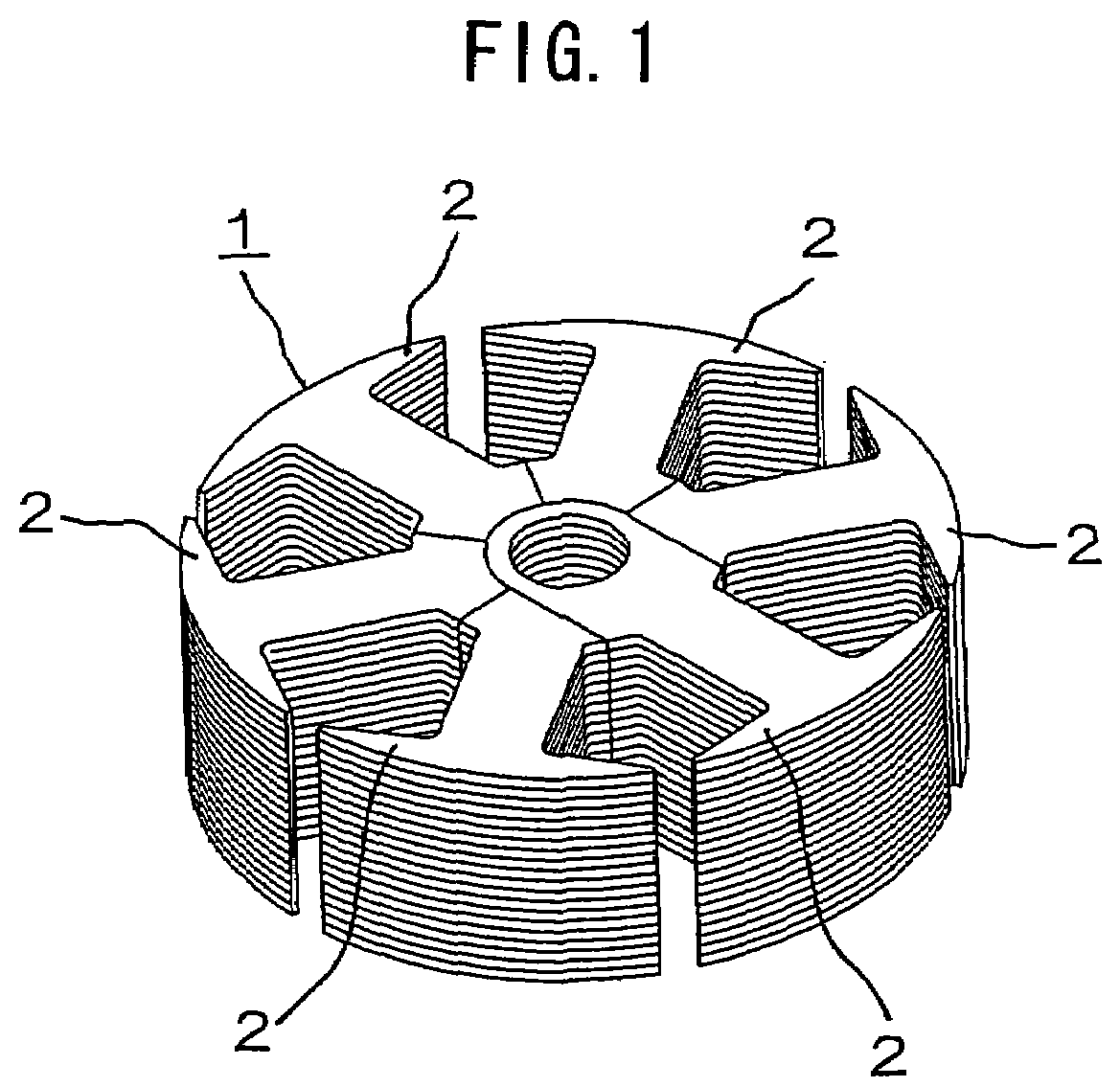

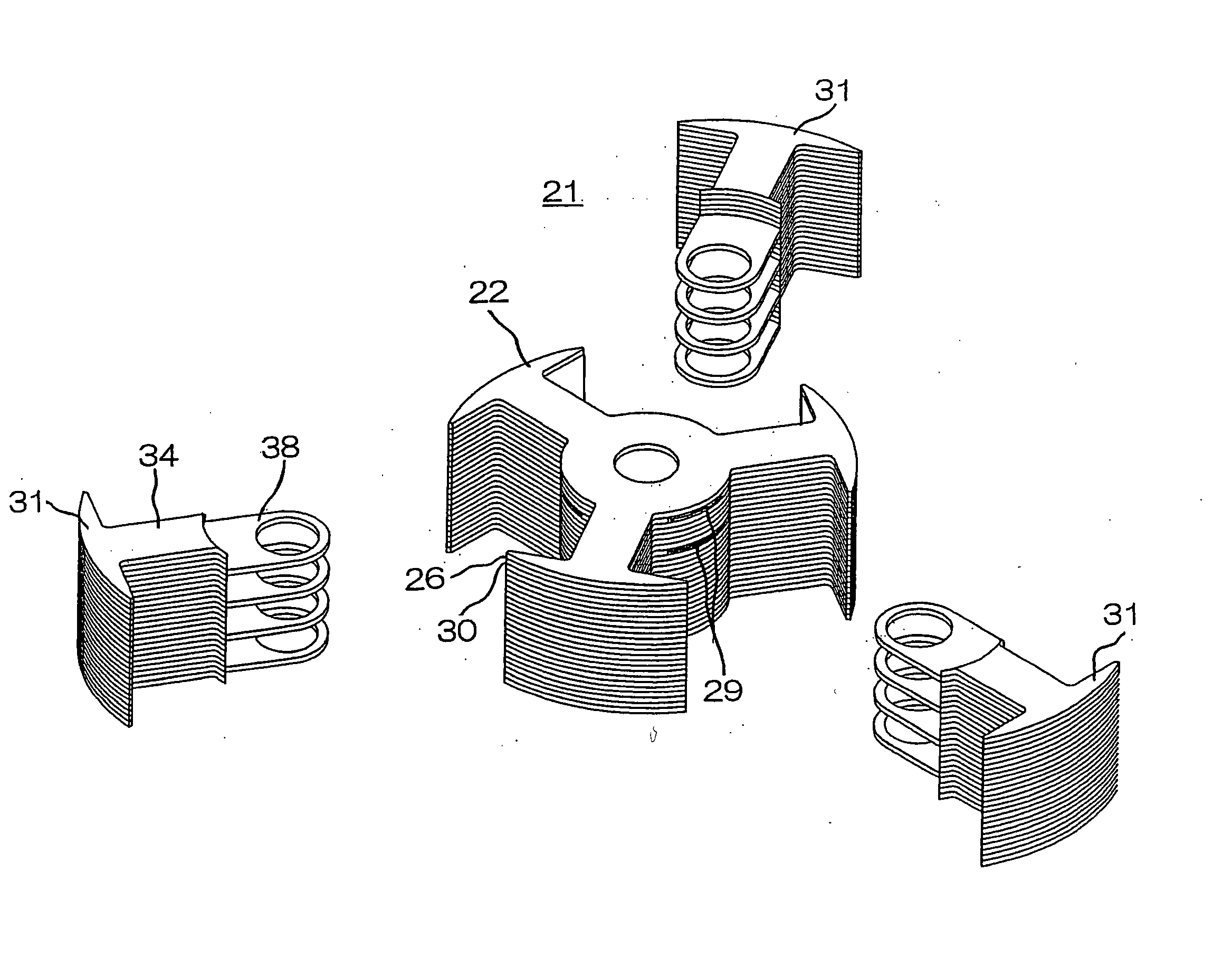

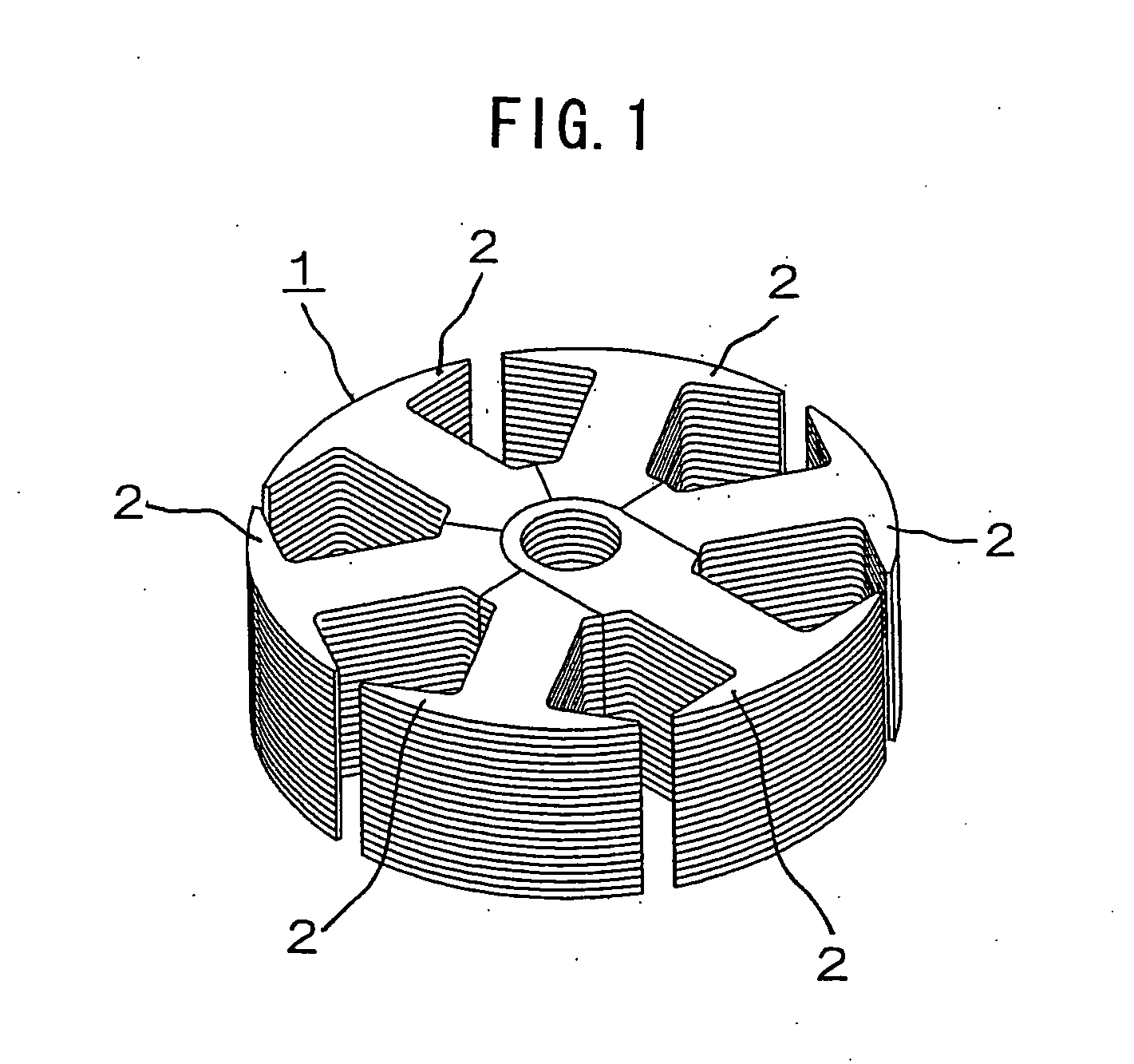

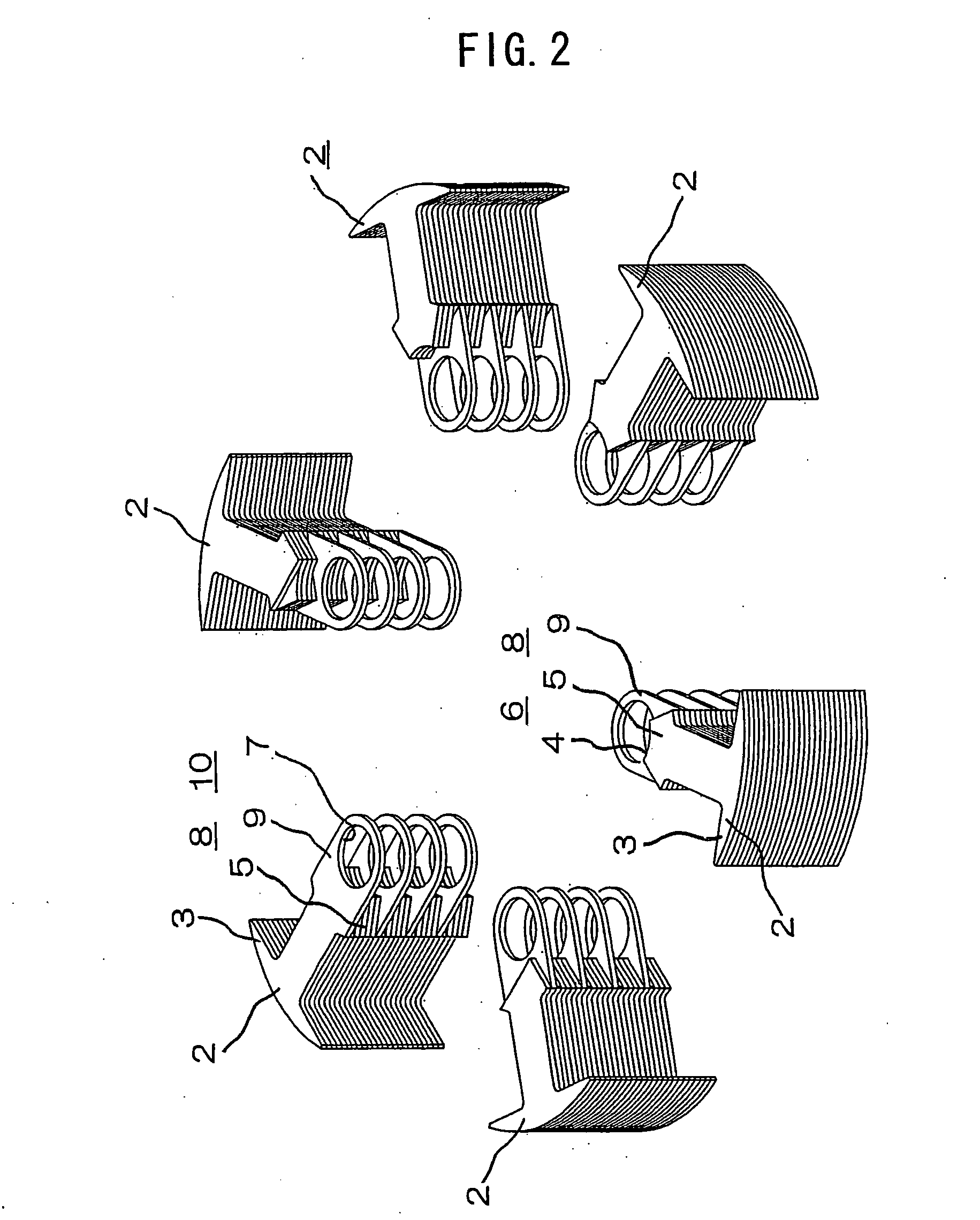

Armature core of rotating electric machine

ActiveUS7285891B2Improve assembly work efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

A rotating electric machine armature core (1) is configured by combining such a number of magnetic tooth sections (2) that corresponds to the number of magnetic poles, each of the magnetic tooth sections (2) including a plurality of first sheet members (6) each of which includes a magnetic tooth portion (3) formed at one end and a root portion (5) formed at the other end with an end face of the root portion (5) having a prescribed external shape, and at least one second sheet member (10) inserted between the individual first sheet members (6) in a laminating direction thereof at a location different from the locations of the other sheet members, the second sheet member (10) including the magnetic tooth portion (3) formed at one end and an overlapping portion (9) formed at the other end, the overlapping portion (9) forming a back yoke portion (8) together with the root portion (5) with a through hole (7) formed at a specified position in the overlapping portion (9), the overlapping portion (9) jutting out from the root portion (5) in such a manner that the overlapping portion (9) can fit on the end face of the root portion (5) of the first sheet member (6), wherein the magnetic tooth sections (2) are combined in a radial form with the through holes (7) in the individual overlapping portions (9) aligned at the same location.

Owner:MITSUBISHI ELECTRIC CORP

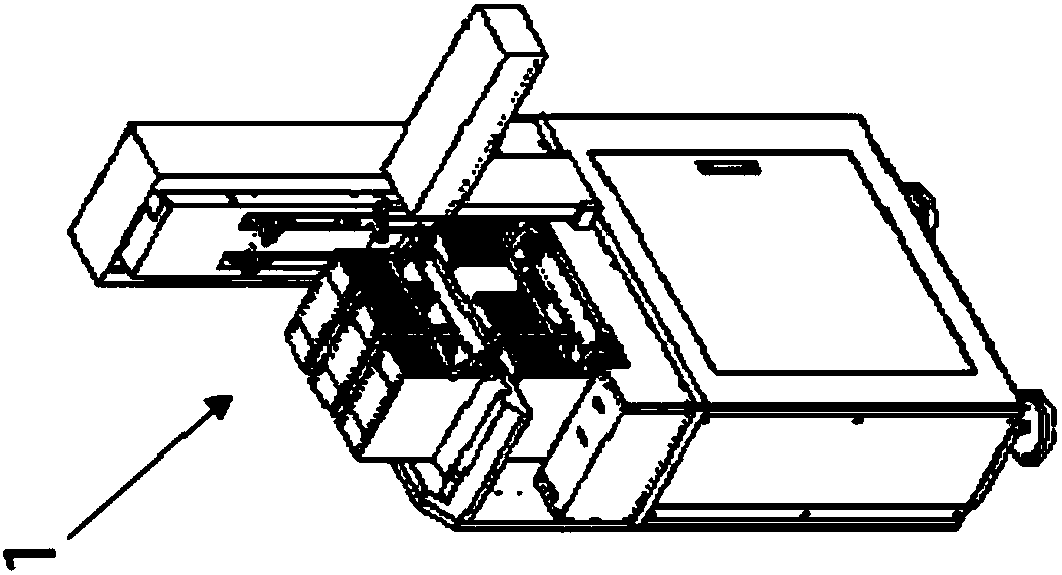

Automatic magnet assembly machine

InactiveCN109230495AImprove assembly work efficiencyImprove production yieldMetal working apparatusConveyor partsEngineeringManipulator

The invention discloses an automatic magnet assembly machine. The automatic magnet assembly machine comprises a machine body, a feeding platform and an assembly platform, and the feeding platform andthe assembly platform are arranged on the machine body; the feeding platform is provided with a supplying mechanism, a pulling mechanism and a manipulator, and the assembly platform is provided with agluing mechanism and a loading and positioning mechanism; the feeding mechanism provides a magnet, and the manipulator clamps the magnet pulled out of the supplying mechanism by the pulling mechanism; the loading and positioning mechanism loads and positions on an iron ring to be assembled, the gluing mechanism glues the position, to which the magnet is about to be assembled, of the iron ring, and the manipulator assembles the clamped magnet onto the iron ring. By means of the automatic magnet assembly machine, a mechanical mode replaces a manual mode for loading assembly, the efficiency of magnet assembly work is improved, the production yield of a product is increased, and the manufacturing cost is reduced.

Owner:苏州市朗电机器人有限公司

Armature core of rotating electric machine

ActiveUS20070035199A1Improve assembly work efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

A rotating electric machine armature core (1) is configured by combining such a number of magnetic tooth sections (2) that corresponds to the number of magnetic poles, each of the magnetic tooth sections (2) including a plurality of first sheet members (6) each of which includes a magnetic tooth portion (3) formed at one end and a root portion (5) formed at the other end with an end face of the root portion (5) having a prescribed external shape, and at least one second sheet member (10) inserted between the individual first sheet members (6) in a laminating direction thereof at a location different from the locations of the other sheet members, the second sheet member (10) including the magnetic tooth portion (3) formed at one end and an overlapping portion (9) formed at the other end, the overlapping portion (9) forming a back yoke portion (8) together with the root portion (5) with a through hole (7) formed at a specified position in the overlapping portion (9), the overlapping portion (9) jutting out from the root portion (5) in such a manner that the overlapping portion (9) can fit on the end face of the root portion (5) of the first sheet member (6), wherein the magnetic tooth sections (2) are combined in a radial form with the through holes (7) in the individual overlapping portions (9) aligned at the same location.

Owner:MITSUBISHI ELECTRIC CORP

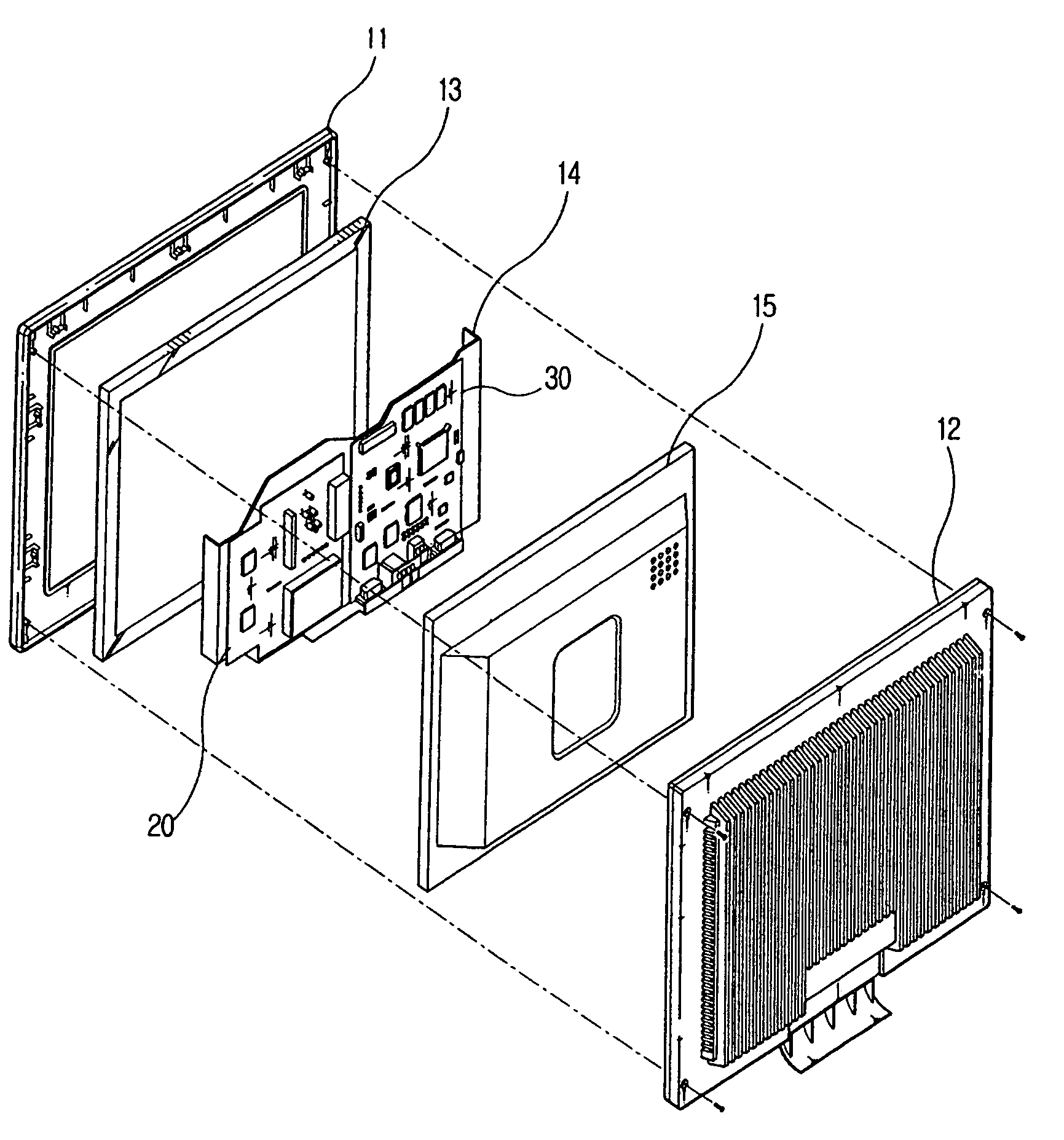

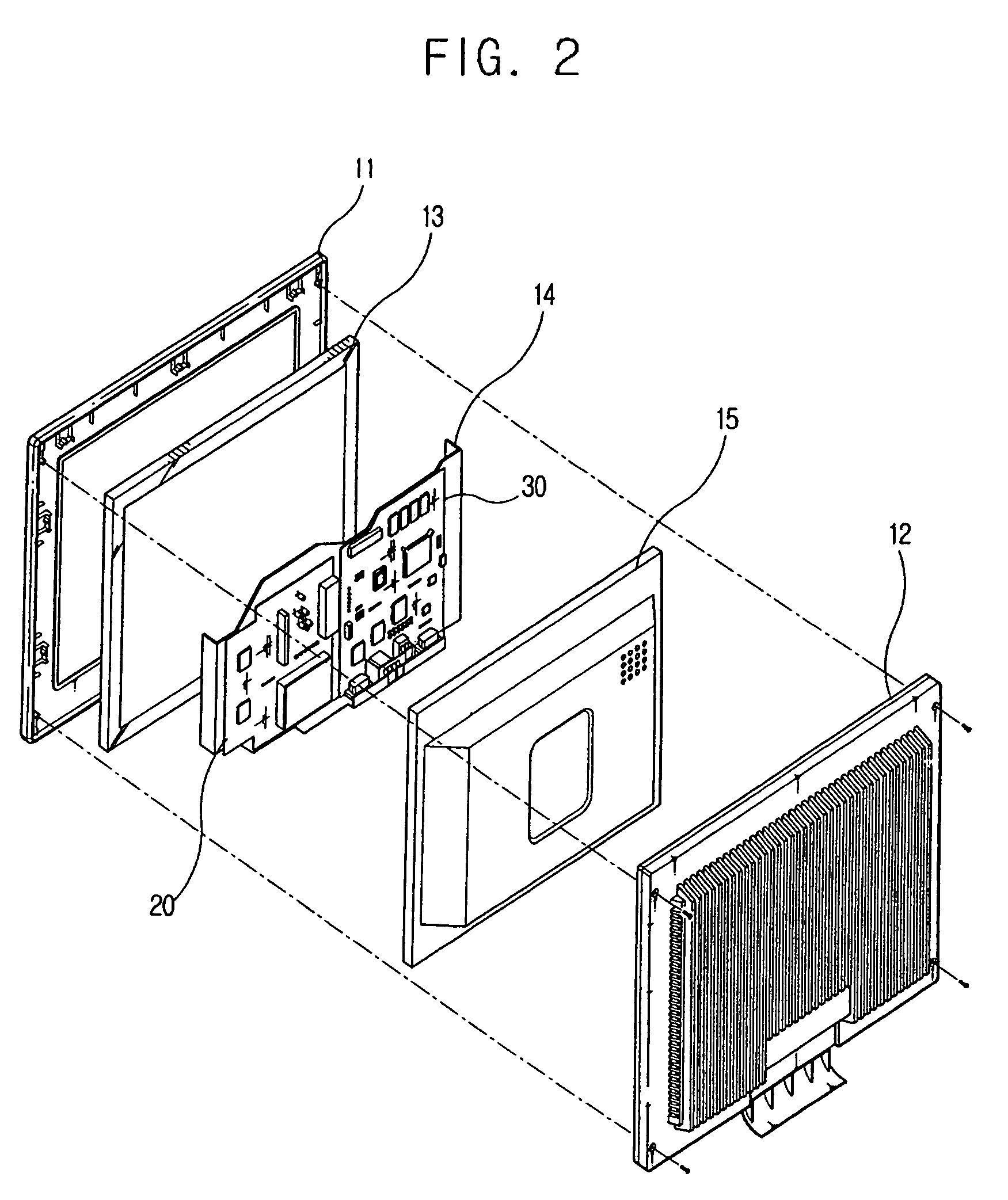

Display apparatus having a display module that supports various functions

InactiveUS7411796B2Easily groundedEasy to assembleTelevision system detailsMagnetic/electric field screeningEngineeringPrinted circuit board

A display apparatus having a display module to display images includes a first printed circuit board arranged on a rear side of the display module, a shielding cover to shield a rear side of the first printed circuit board to accommodate the first printed circuit board therein, a first connection port mounted on the first printed circuit board at an edge portion thereof and projected from a surface of the first printed circuit board, at least one second connection port mounted on the first printed circuit board adjacent to the first connection port and projected from the surface of the first printed circuit board by a second height different from the first height of the first connection port, a grounding bracket combined with the first printed circuit board and disposed over the first and second connection ports to be in contact with the first connection port, a second grounding plate arranged between the grounding bracket and the second connection port to be in contact with the grounding bracket and the second connection port, and a first grounding plate disposed between the shielding cover and the grounding bracket to be in contact with the shielding cover and the grounding bracket so that the grounding bracket is grounded to the shielding cover.

Owner:SAMSUNG ELECTRONICS CO LTD

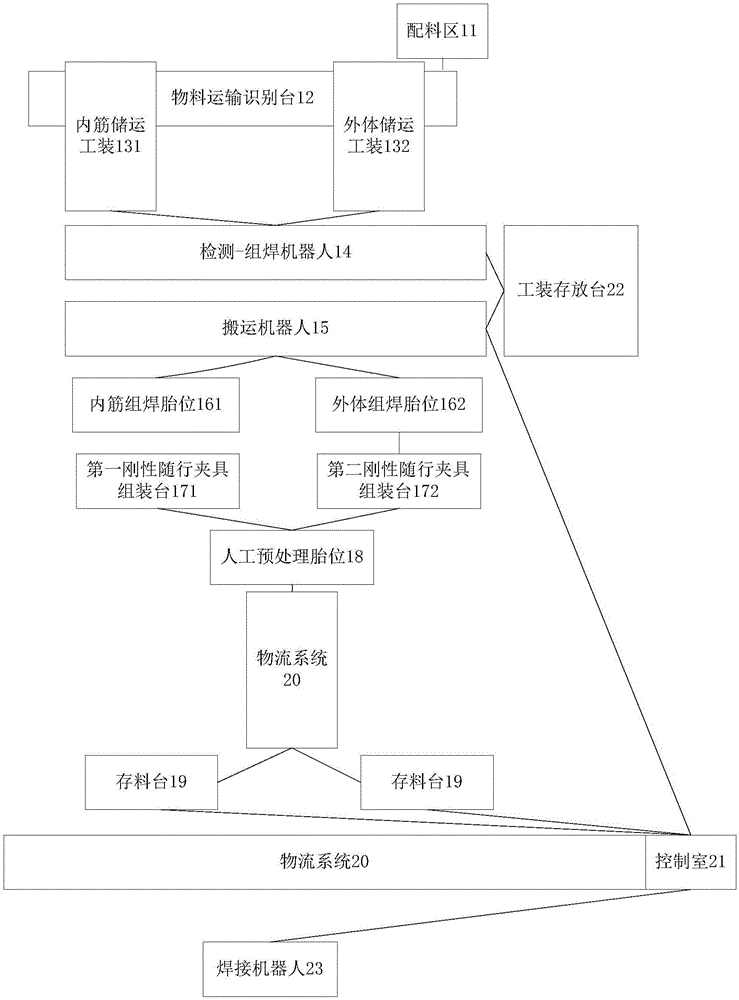

Automatic assembling system for bogie side beam

ActiveCN106112330AAutomate operationsImprove assembly work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesBogieEngineering

The invention discloses an automatic assembling system for a bogie side beam. The automatic assembling system comprises a material conveying and identifying platform and a detection robot, wherein the material conveying and identifying platform is used for identifying parts for consisting the side beam and conveying the parts to storage and transportation fixtures; the detection robot is used for identifying 2-dimensional bar code information of the parts in the storage and transportation fixtures and transmitting the 2-dimensional bar code information to a control chamber; the control chamber is used for transmitting side beam model information to a conveying robot according to the received 2-dimensional bar code information, and transmitting an installing and welding command matched with the model of the side beam to a detecting, installing and welding robot; a conveying robot is used for conveying the parts in the storage and transportation fixtures to installing and welding stations, and setting up the parts according to the side beam model information; the installing and welding robot is used for installing and welding the set up parts according to the installing and welding command; and a manual pretreatment station is used for manually detecting workpieces which are installed and welded at the installing and welding stations. By adopting the system, automatic operation for installing and welding of each part during assembly of the side beam can be realized, so that working efficiency for assembly is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

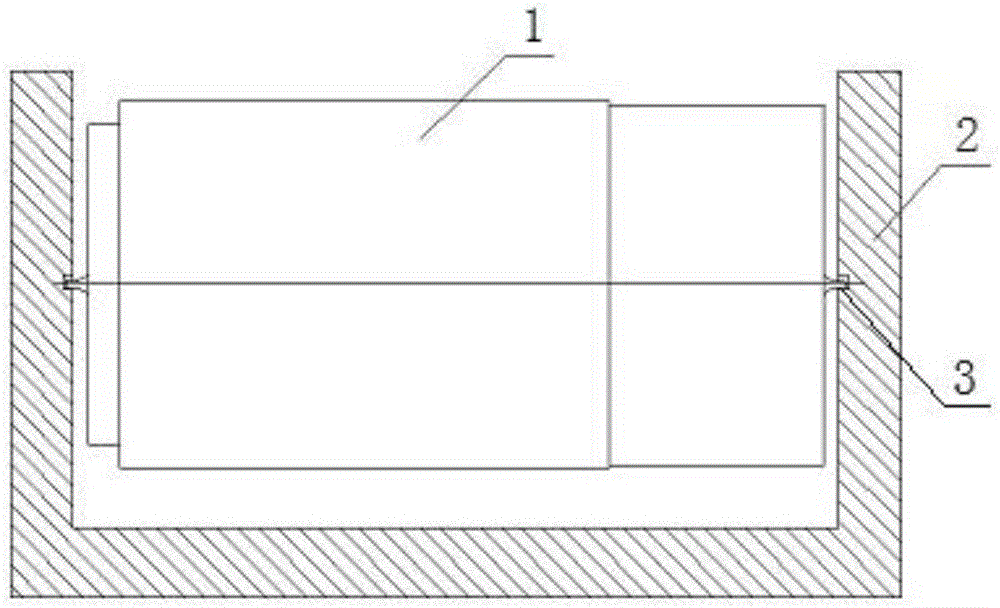

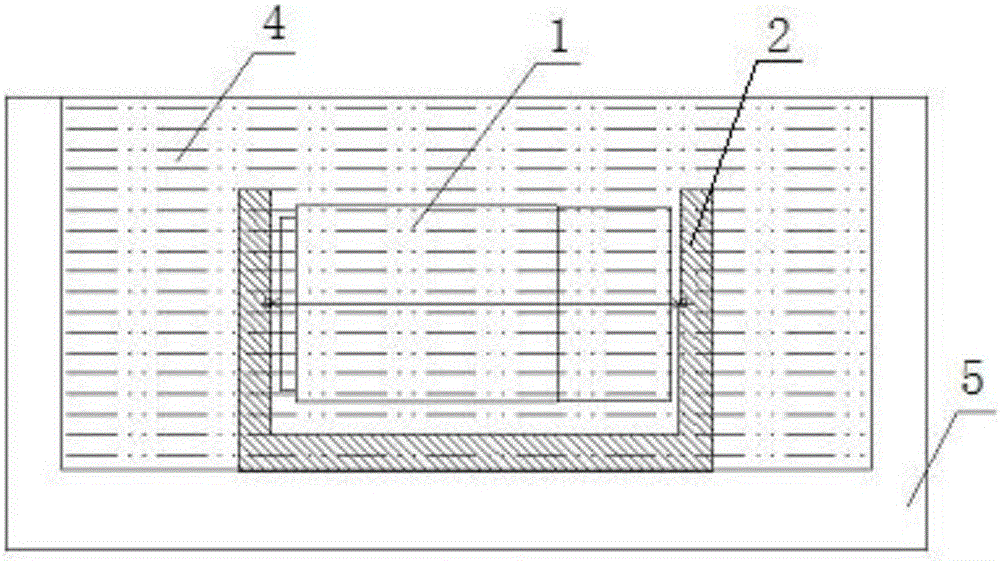

Static balance method applied to floater of liquid floated gyroscope

InactiveCN106885562AStatic balanceEliminates fine balancing stepRotary gyroscopesGyroscopeStatic friction

The invention relates to a static balance method applied to a floater of a liquid floated gyroscope. The method comprises the steps of installing the floater on a balance support, enabling ball small shafts on two ends of the floater to be located in bearing holes of the balance support, and then putting the floater and the balance support into an oil groove, wherein the oil groove is full of balance oil; putting the oil groove on a vibration table, and enabling the balance support to keep static through adjusting vibration parameters; when the balance oil starts to vibrate, driving the floater to vibrate through the vibration of the oil liquid, and enabling the ball small shafts on the two ends of the floater to separate from the bearing holes, so that static friction disappears, and the floater meets the static balance requirement. The invention relates to the static balance method applied to the floater of the liquid floated gyroscope, through a step of improving the coarse balance of the floater, the balance accuracy of the balance oil is utilized, and the static balance requirement of the gyroscope is met through one step, so that the structure of the gyroscope is simplified, the assembly difficulty is reduced, and the assembly work efficiency is improved.

Owner:TIANJIN NAVIGATION INSTR RES INST

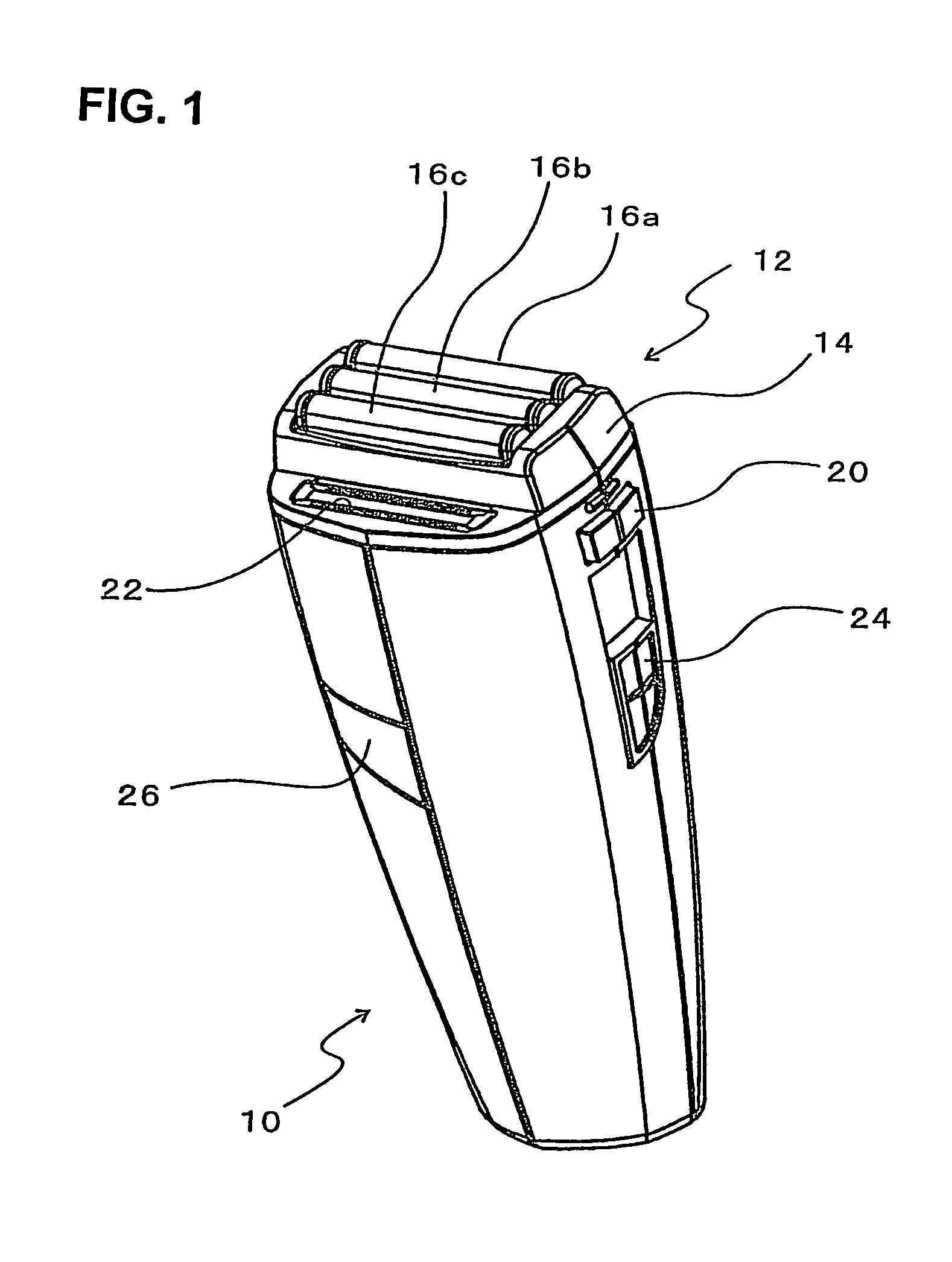

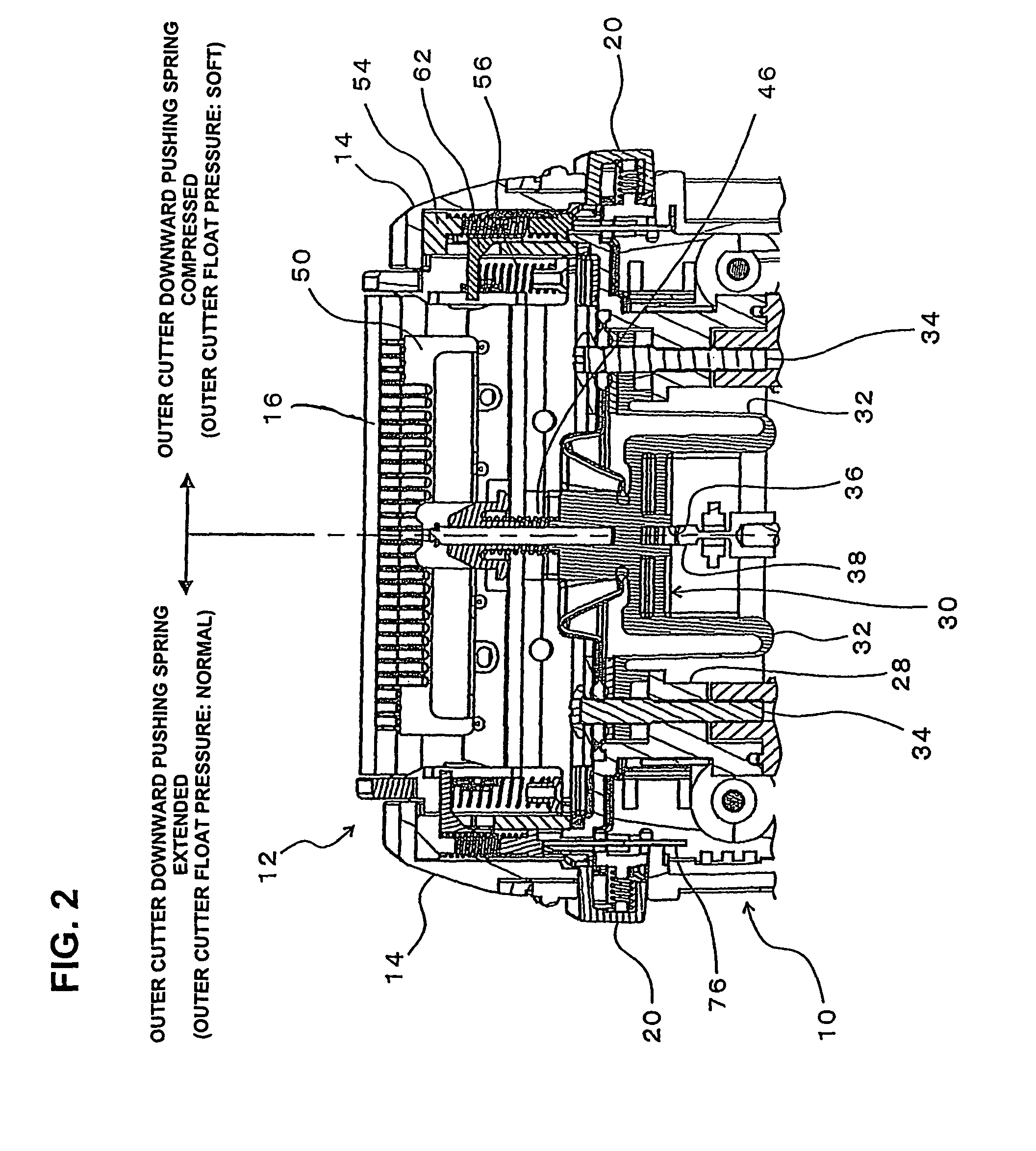

Locking device

InactiveUS8136249B2Improve assembly work efficiencyIncreased Design FreedomSlide fastenersMetal working apparatusPush-buttonEngineering

A locking device for securing an attachment member to a main body including first engagement pawls provided in the attachment member so that the first engagement pawls extend in the direction of attachment-detachment of the attachment member and along the inner surface of the main body and a push button assembly secured to the inner surface of the main body. The push button assembly includes a back panel for being secured to an inner surface of the main body, a push button for protruding through an opening in the main body, second engagement pawls formed on the push button and a compression spring provided between the push button and the back panel.

Owner:IZUMI PROD CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com