Low-noise and bearing-assembled ball feeder

A technology of bearing assembly and ball adding machine, which is applied in the field of mechanical processing, can solve problems such as surface damage of rolling elements, influence on appearance quality, and damage to bearing rings, so as to improve bearing noise, improve assembly quality, and prevent injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

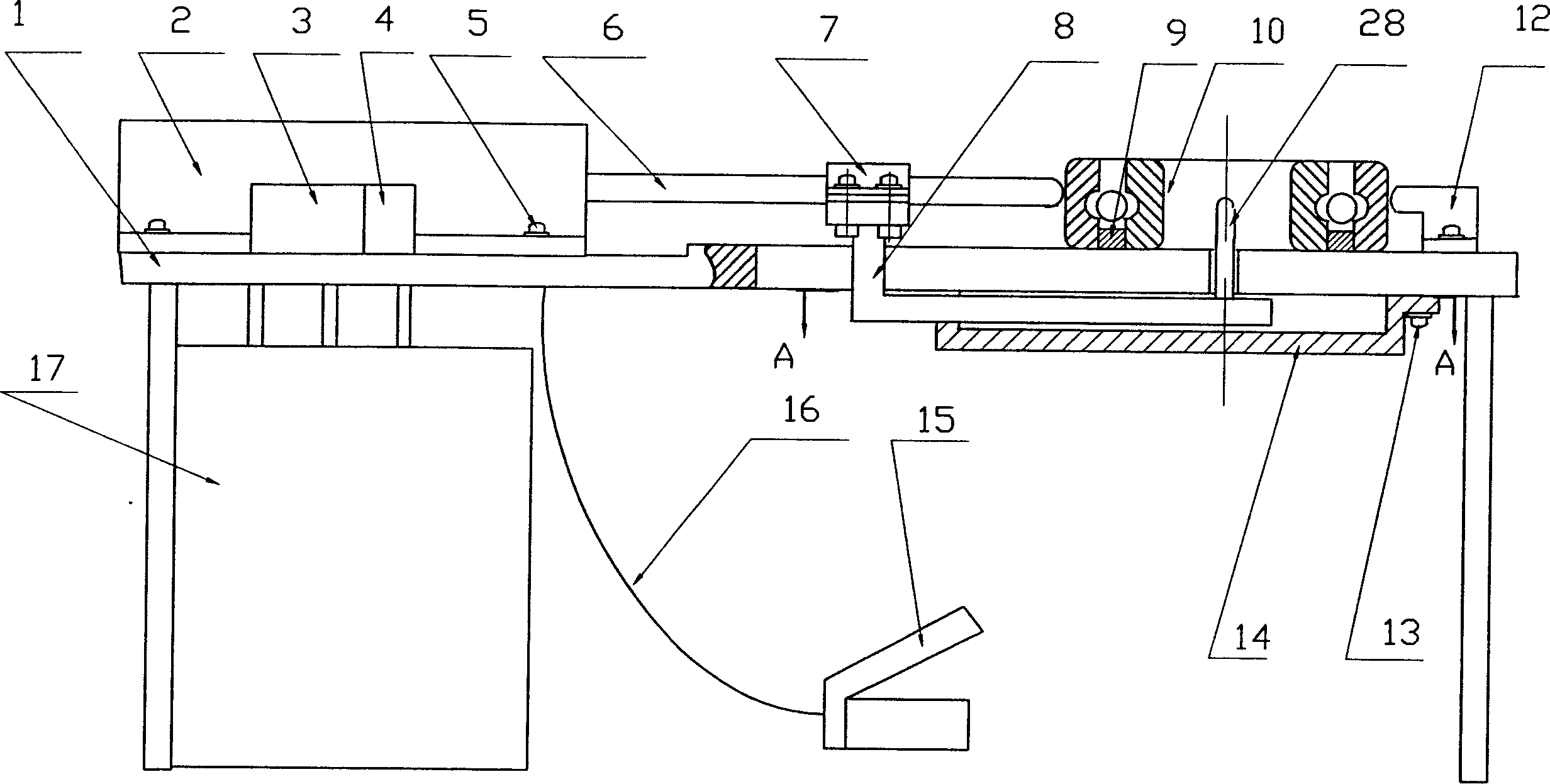

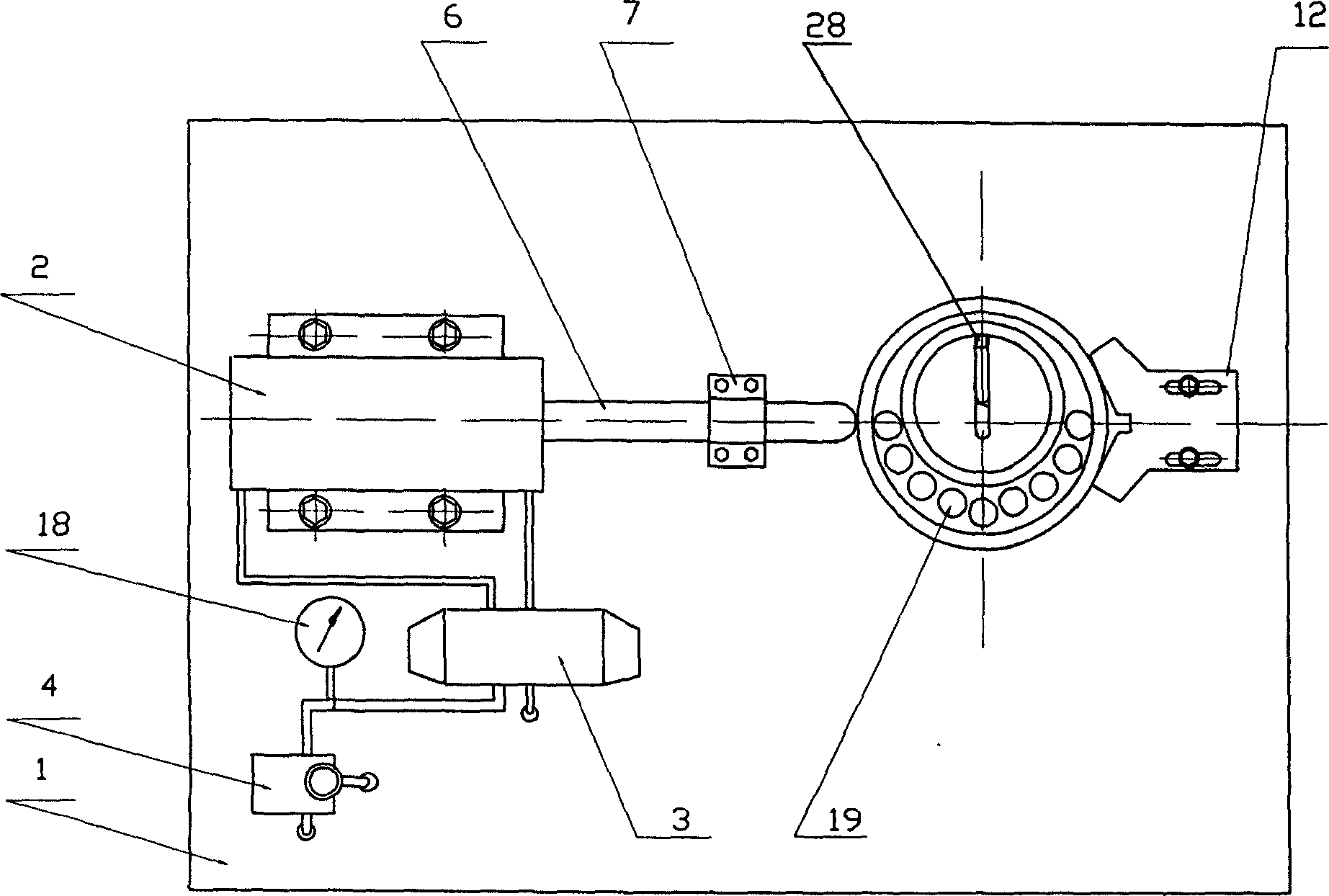

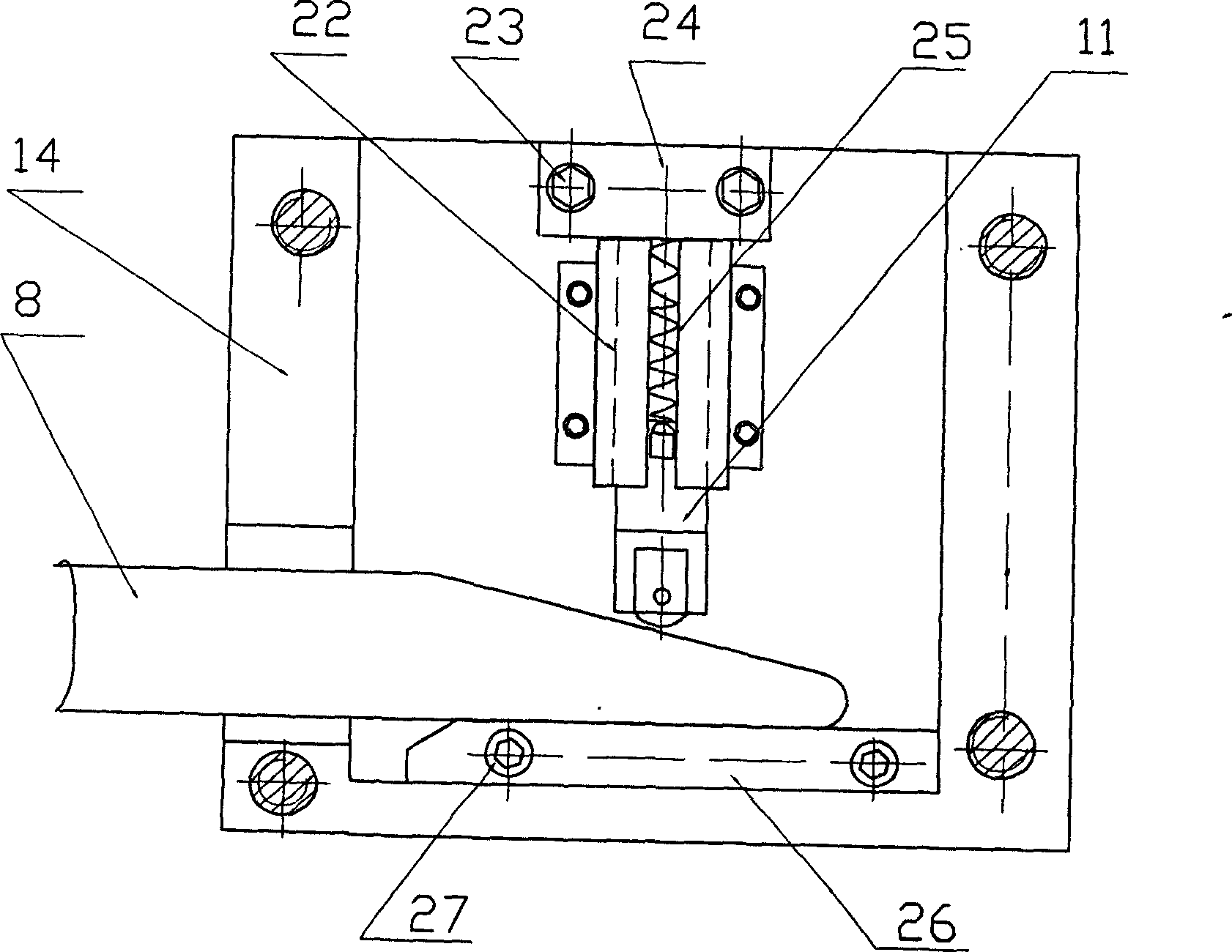

[0018] Example: Combine figure 1 , figure 2 ,image 3, Figure 4 , Figure 5 As shown, the present invention includes a workbench, a pressure device arranged on the workbench 1 to apply force to the bearing 10 and a support device 12 to support the bearing, and the pressure device to apply force to the bearing acts on the outer ring of the bearing and the bearing outer ring through the piston rod 6, respectively. On the inner ring of the bearing, make it produce elastic deformation and add balls. The pressure device that exerts force on the bearing 10 includes an oil pump, an oil cylinder 2 driven by the oil pump, a two-position four-way electromagnetic reversing valve 3 that controls the operation of the oil cylinder 2, a relief valve 4 and a pressure gauge 18 installed on the oil circuit, and the direct action of left and right movement. The oil cylinder piston rod 6 on the bearing outer ring and the device that moves left and right together with the oil cylinder piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com