Electric compressor

A technology of electric compressors and electric motors, which is applied in the direction of electric components, machines/engines, liquid fuel engines, etc. It can solve the problems of reduced efficiency of compressor assembly operations, waiting time for insulating resin curing, and unusable sealed terminals, etc., to achieve The effect of high assembly work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

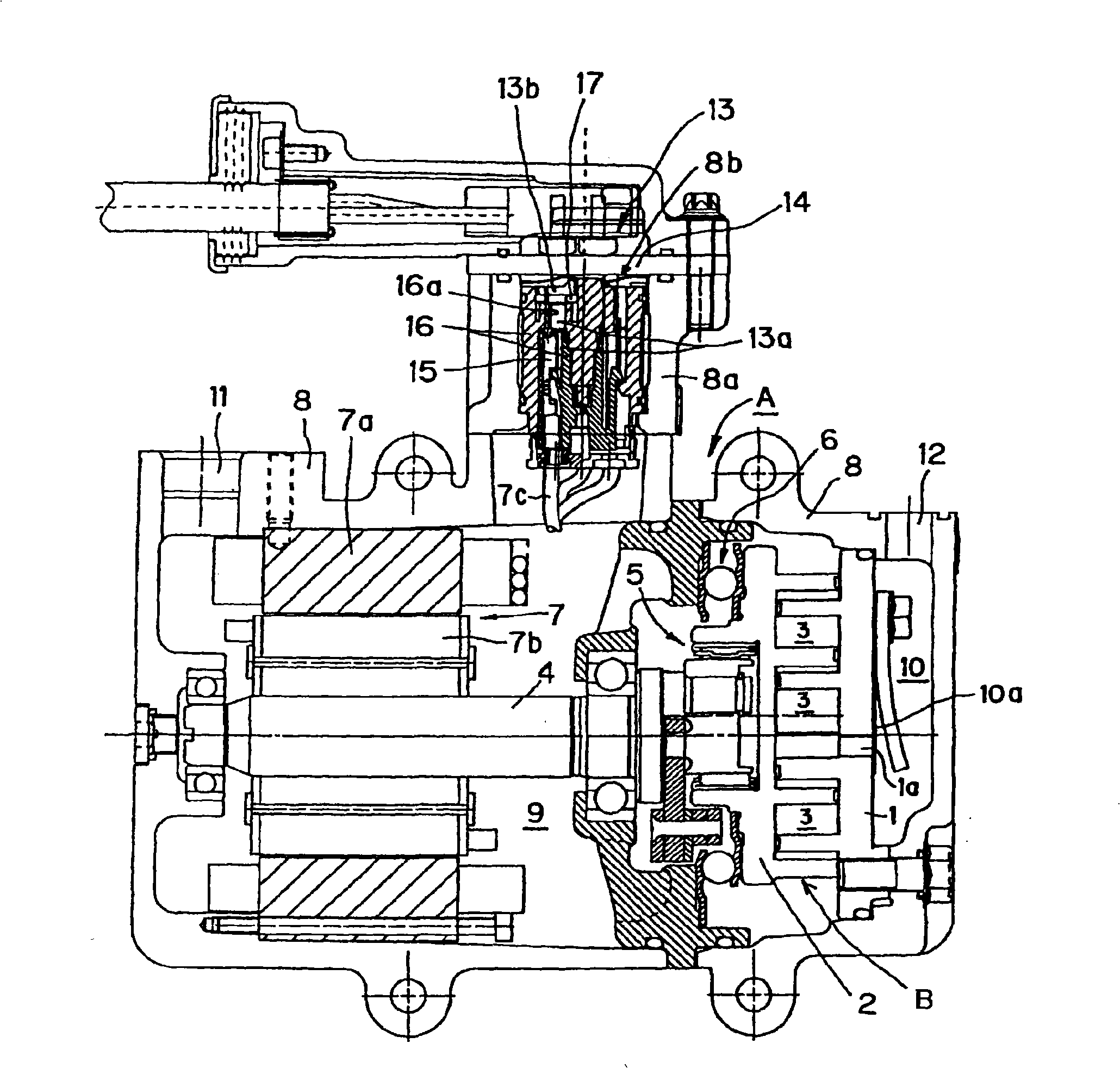

[0042] figure 1 Shown is an electric compressor according to one embodiment of the present invention, and a scroll electric compressor A is configured in this embodiment. The scroll compressor A includes: a fixed scroll 1 having a discharge hole 1a formed in the center thereof and having an end plate and a scroll body; and a movable scroll 2 having an end plate and a scroll body. The scroll body of the fixed scroll 1 and the scroll body of the movable scroll 2 are engaged with each other to form multiple pairs of working spaces 3 . Arranged are a main shaft 4 , a motion conversion mechanism 5 that converts the rotational motion of the main shaft 4 into a swivel motion and transmits it to the movable scroll 2 , and an anti-rotation mechanism 6 that prevents the movable scroll 2 from rotating. These fixed scroll 1 , movable scroll 2 , main shaft 4 , moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com