Static balance method applied to floater of liquid floated gyroscope

A liquid floating gyroscope and static balance technology, applied in the field of liquid floating gyroscopes, can solve the problems of increasing working time, reducing work efficiency, complex process, etc., and achieve the effects of saving assembly costs, improving efficiency, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0021] A method for static balancing of a float applied to a liquid floating gyroscope, comprising the following steps:

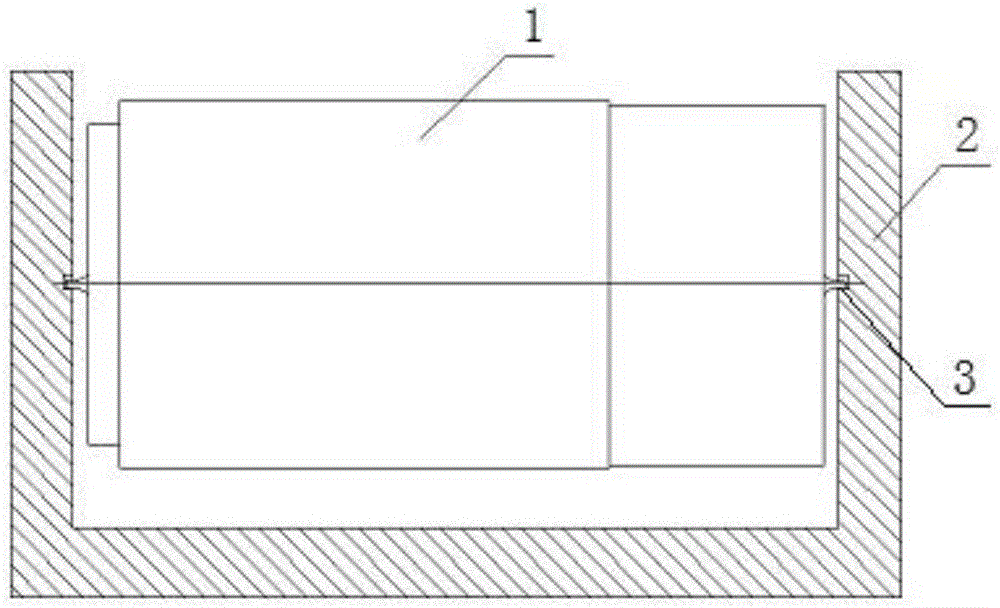

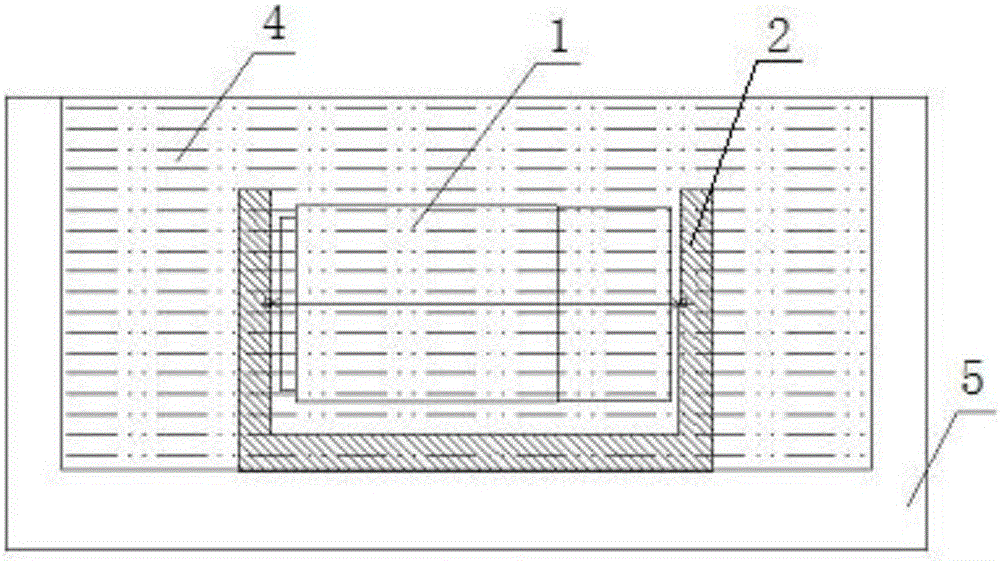

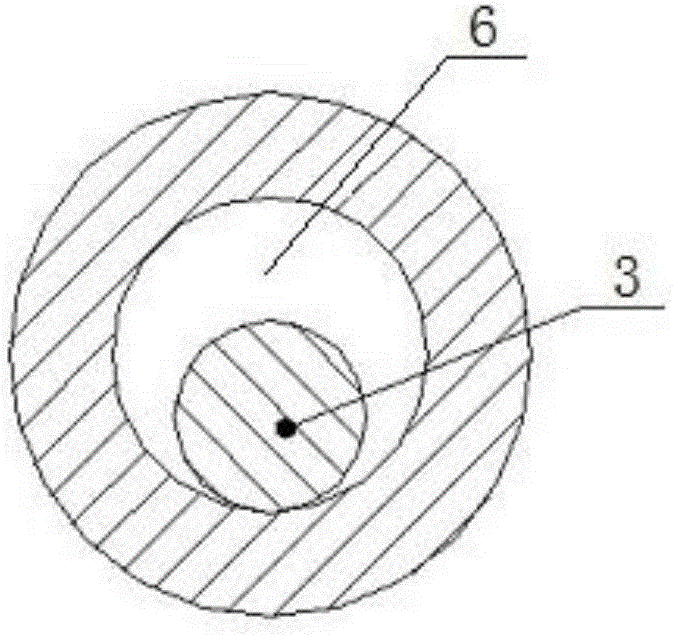

[0022] ⑴. Install the float 1 on the balance bracket 2, place the small ball shaft 3 at both ends of the float in the bearing hole 6 of the balance bracket, and then put the float and the balance bracket together into the oil tank 5, which is filled with balance oil 4;

[0023] ⑵. Put the oil tank on the vibrating table 7, and adjust the vibration parameters to keep the balance bracket still, but the balance oil starts to vibrate, and the vibration of the oil liquid drives the float to vibrate, and the small ball shafts at both ends of the float break away from the bearing hole. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com