Floating conveying assembling vehicle

A technology for assembling vehicles and universal balls, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of high labor intensity, heavy assembly weight, and low work efficiency, and achieve low labor intensity and labor-saving assembly operations , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

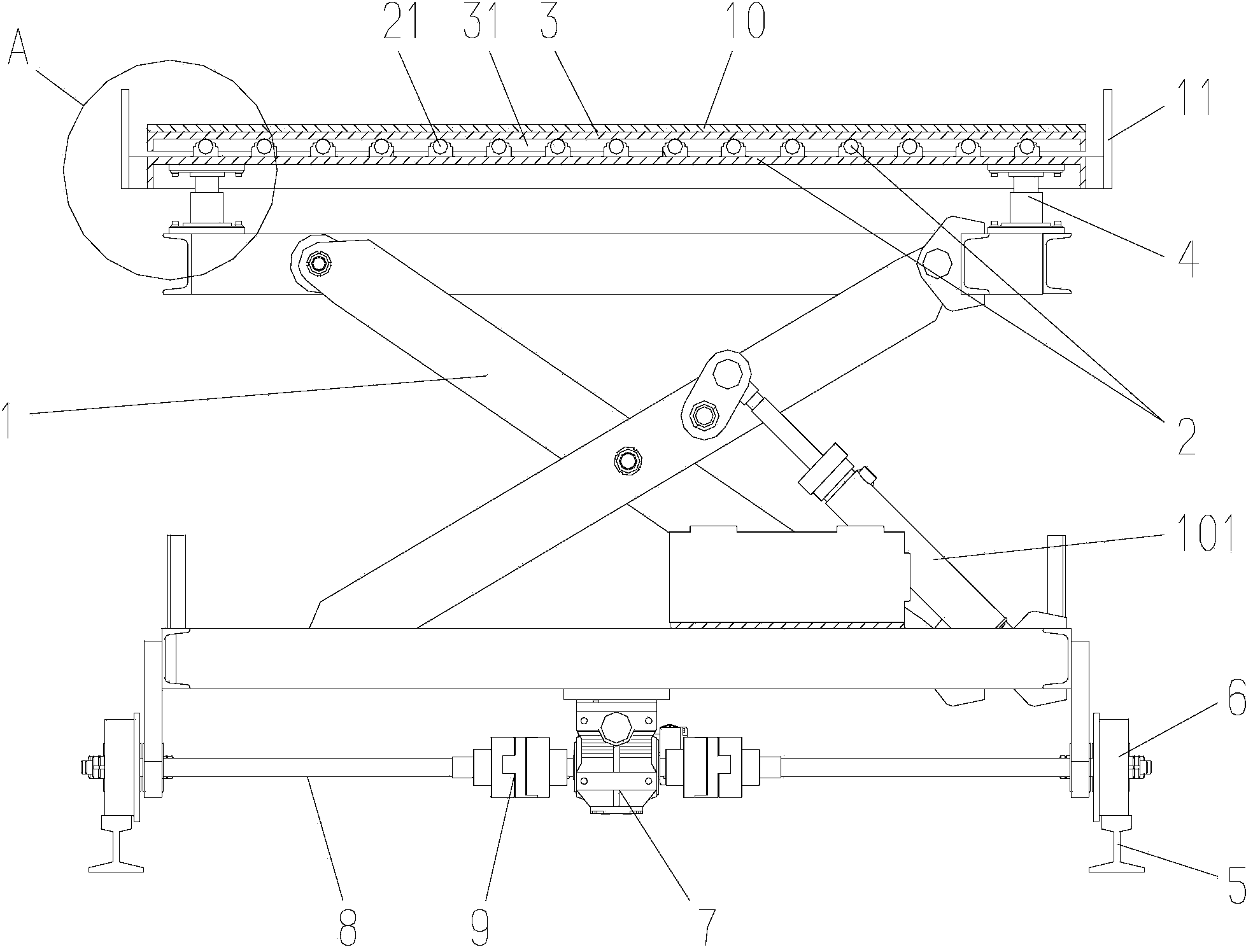

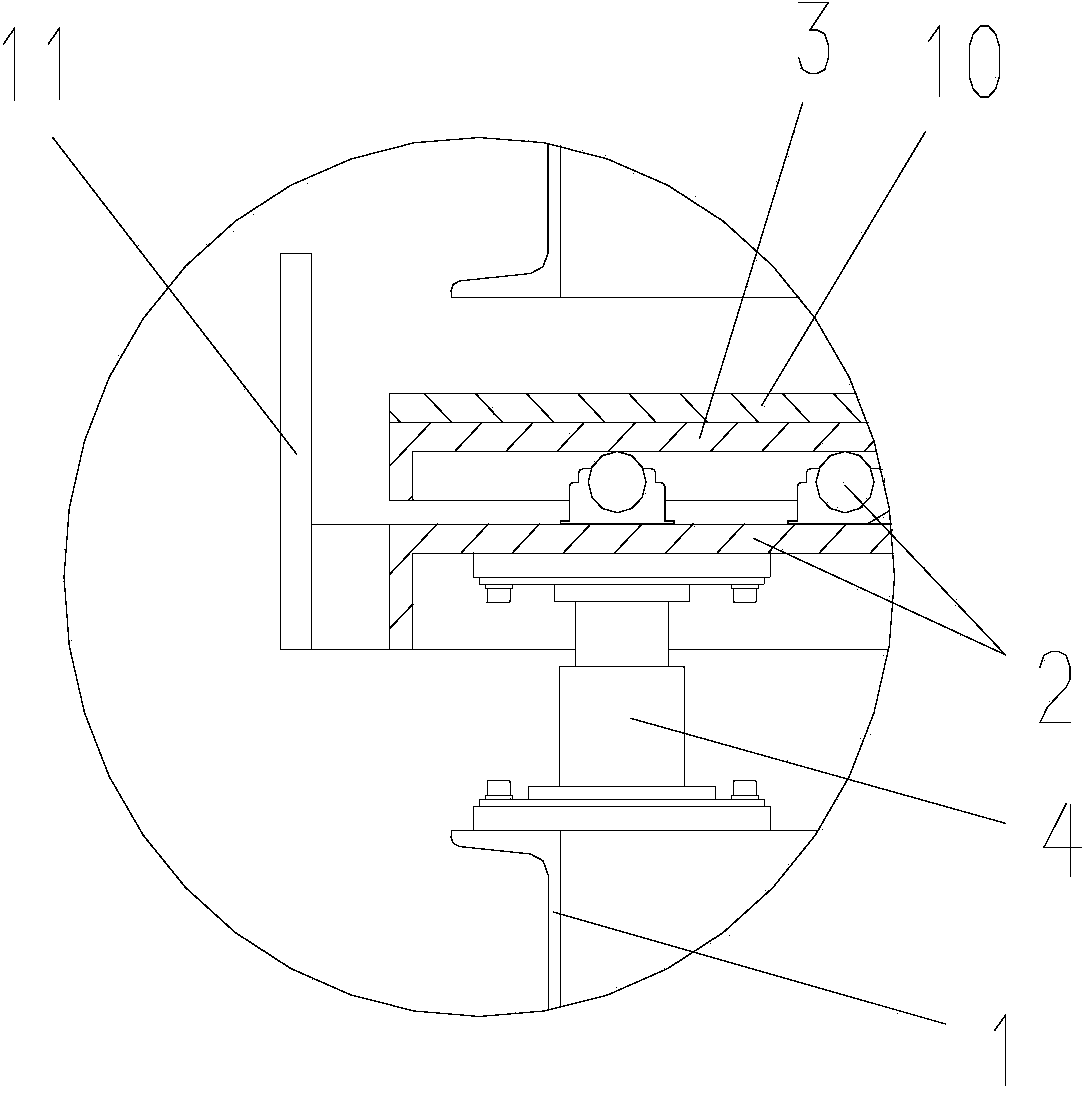

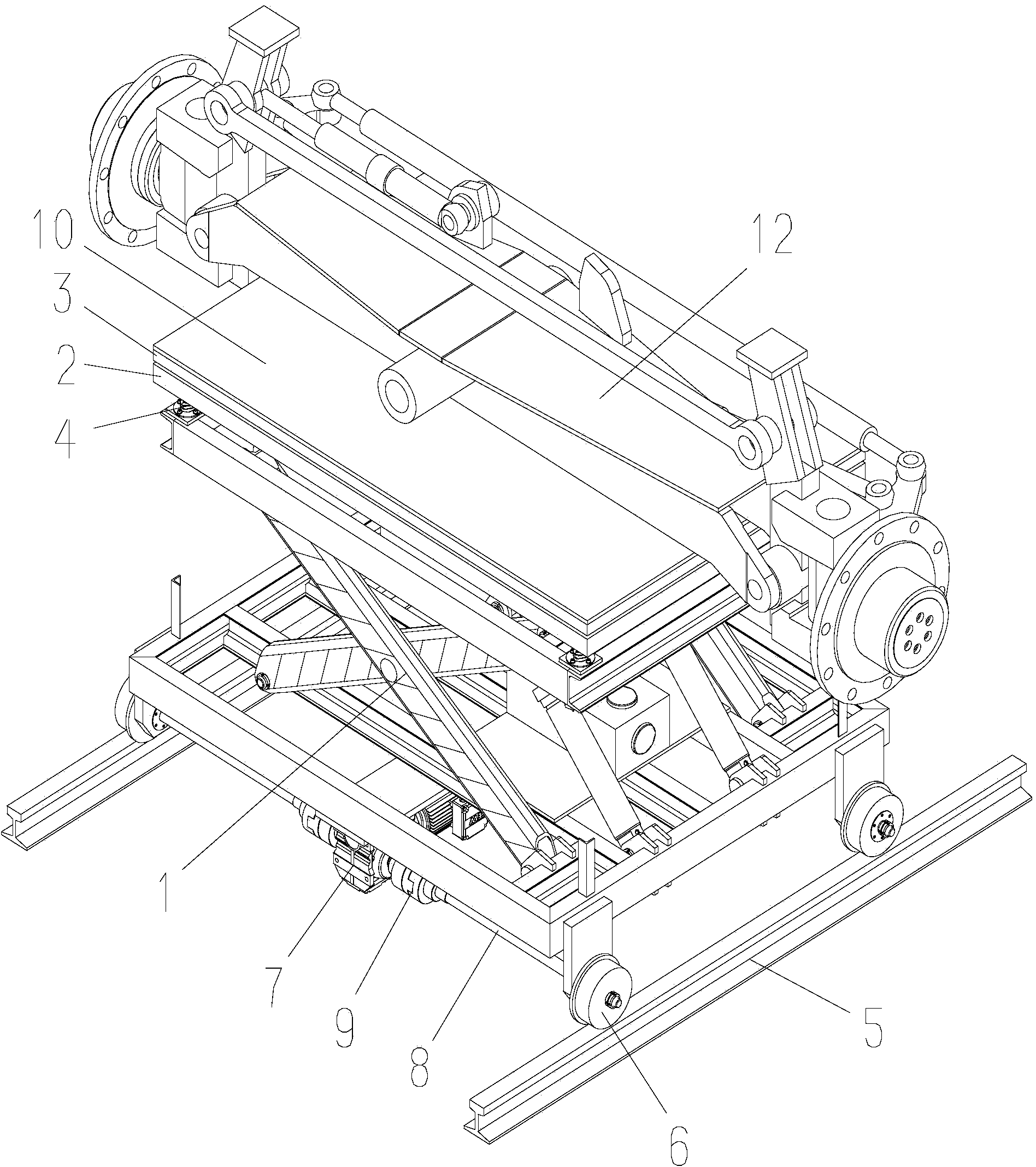

[0026] As shown in the figure, the floating conveying assembly vehicle of this embodiment includes an elevator 1, a universal ball platform 2 and a workbench 3 placed on the universal ball platform 2, and the universal ball platform 2 is arranged on the elevator through a spring support 4 The upper part of 1.

[0027] The operation process of assembling the front axle of the motor grader through the floating conveyor assembly vehicle is as follows:

[0028] 1) Place the front axle 12 on the workbench 3, and transport the front axle to the bottom of the front frame through the elevator 1;

[0029] 2) Raise the front axle to the U-shaped opening at the lower part of the front frame through the elevator 1, and make the pin holes on the front axle basically align with the through holes on the front frame by jogging;

[0030] 3) Manually push the front axl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com