Bilateral locking device

A locking device and locking lever technology, applied in the field of locks, can solve the problems of affecting the normal use of the locking device, insufficient to effectively overcome the spring force, low assembly work efficiency, etc., so as to avoid the unqualified operating force and the incomplete handle. The effect of resetting and improving the efficiency of assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

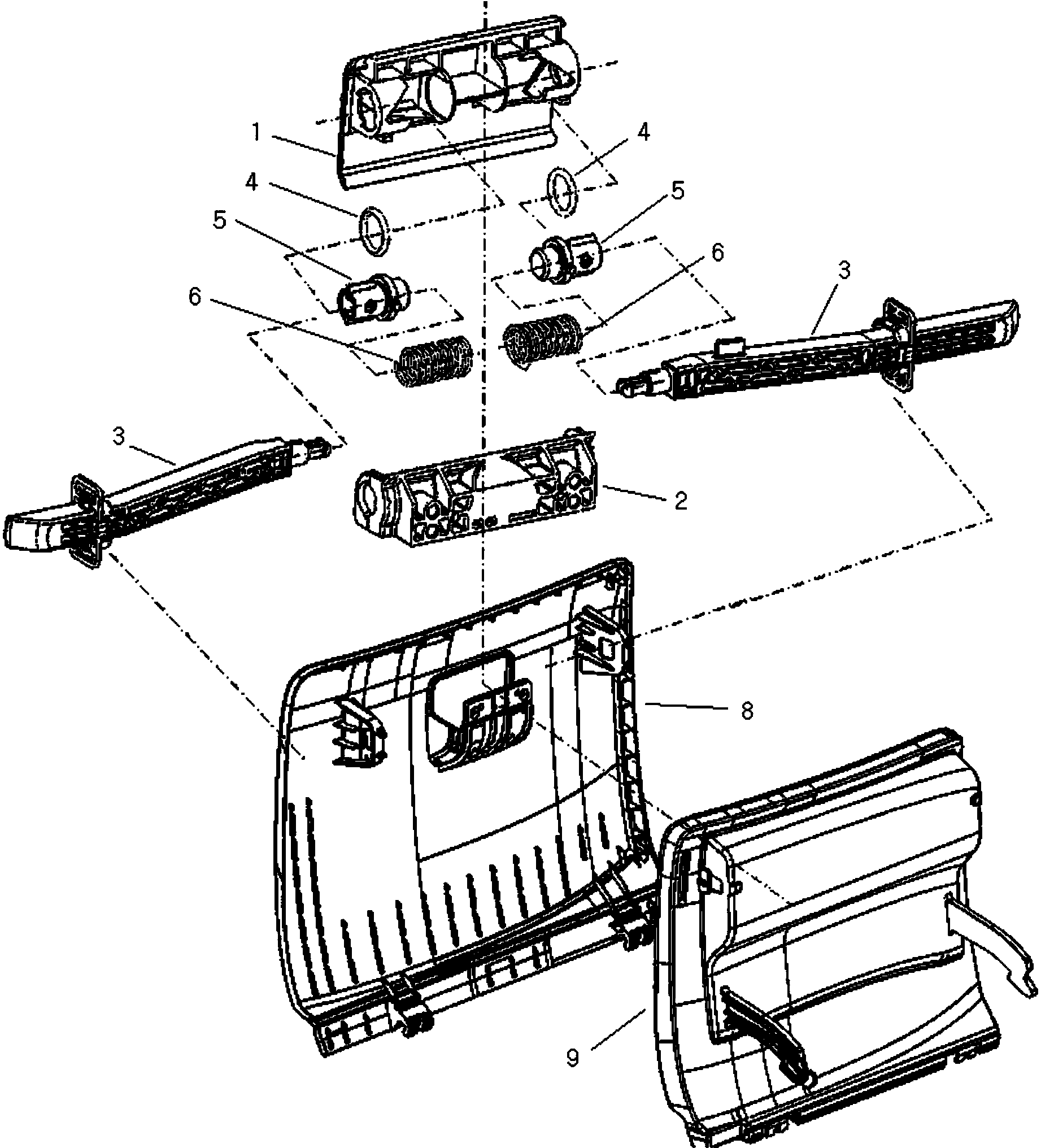

[0056] Such as Figure 1-21 As shown, a double-sided locking device provided by the embodiment of the present invention includes an outer cover plate 8, a main body part 2, and a handle 1;

[0057] The back side of the outer cover plate 8 is fixed with an annular lock bar buckle 81 on the left and right (see Figure 16 );

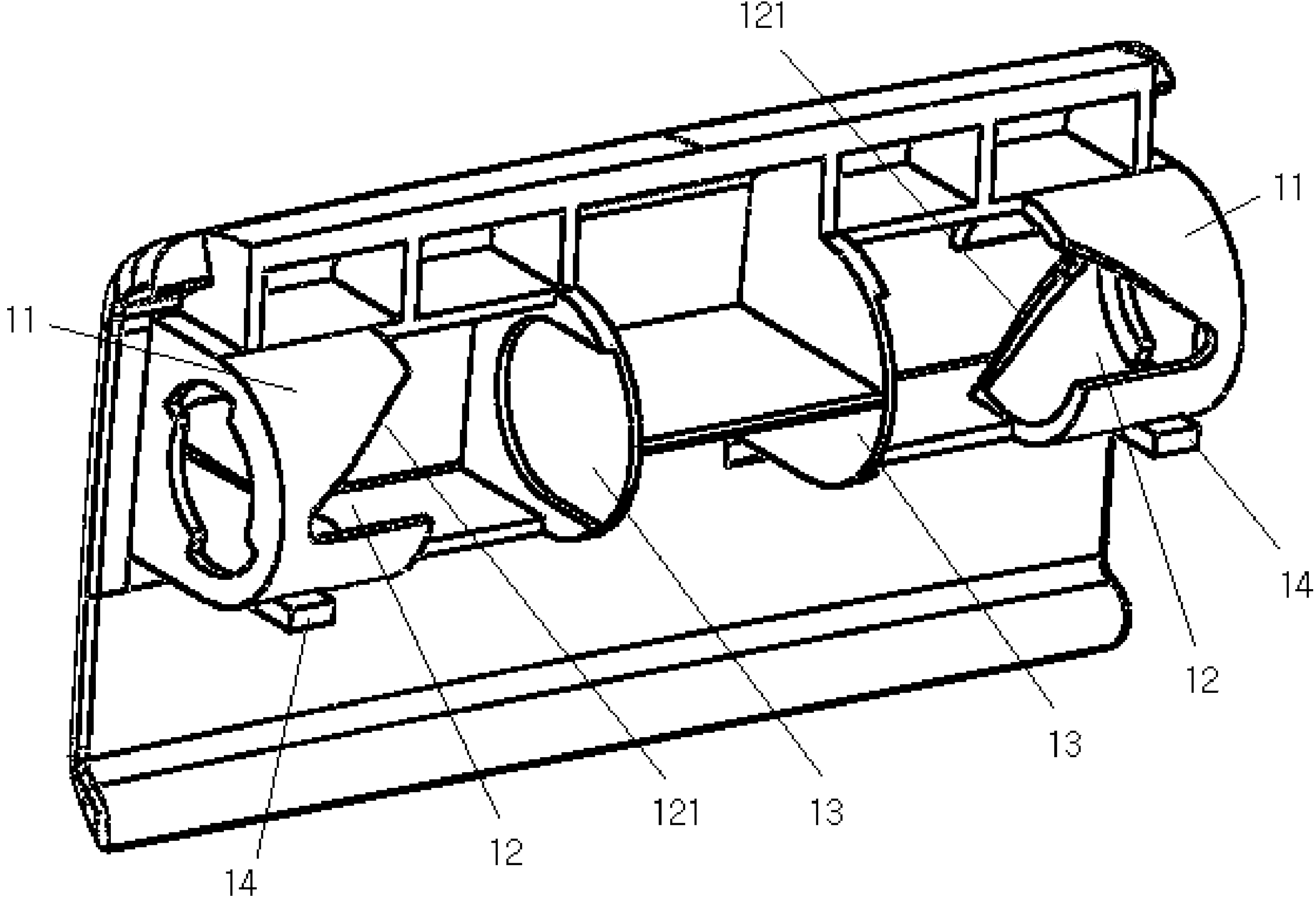

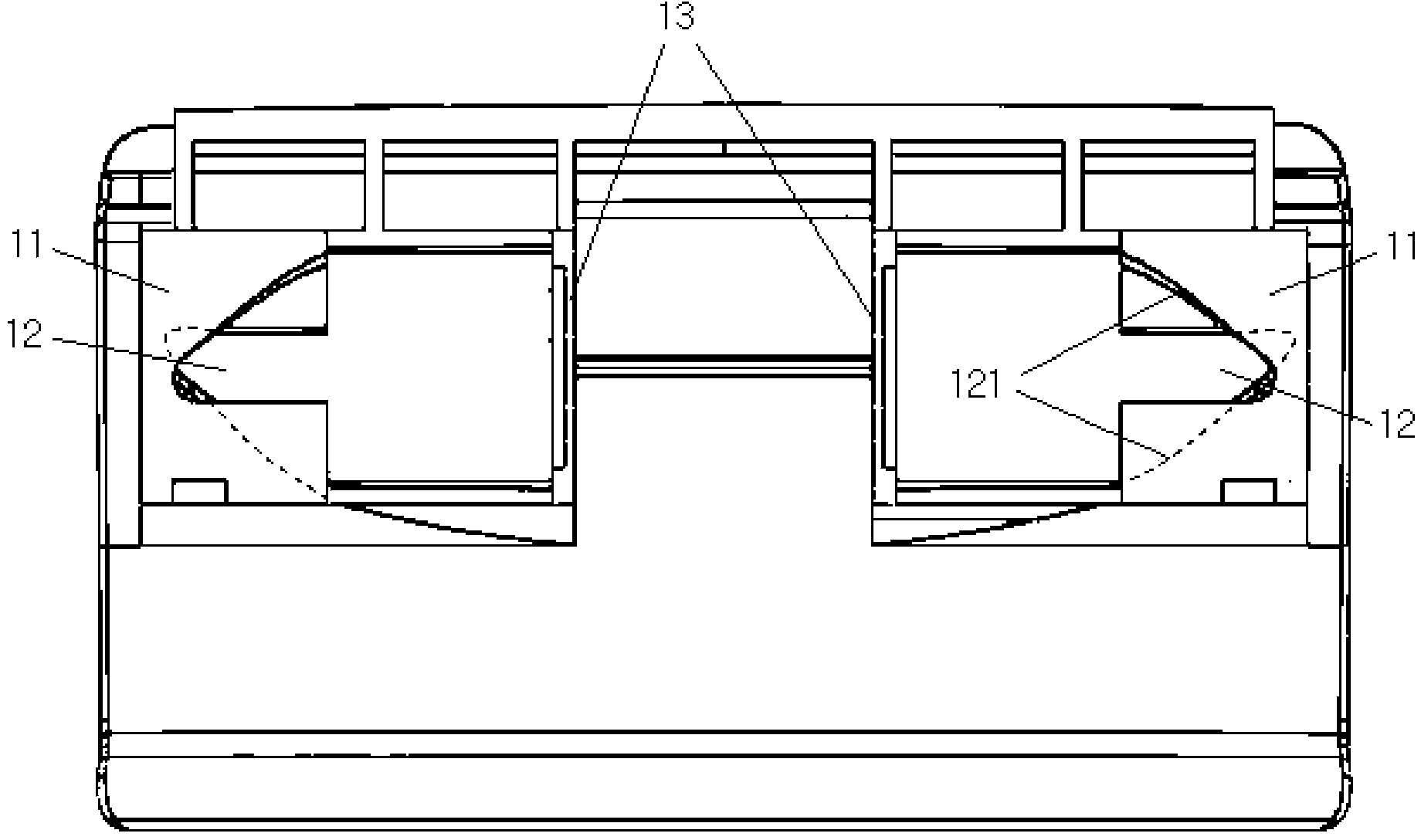

[0058] The main body part 2 is fixed on the outer cover plate 8 and is located between two lock bar buckles, and the main body part is provided with a main body end hole 21 on the left and right (see Figure 9 , Figure 10 ), each body end hole 21 has two axisymmetrically distributed end hole bayonet soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com