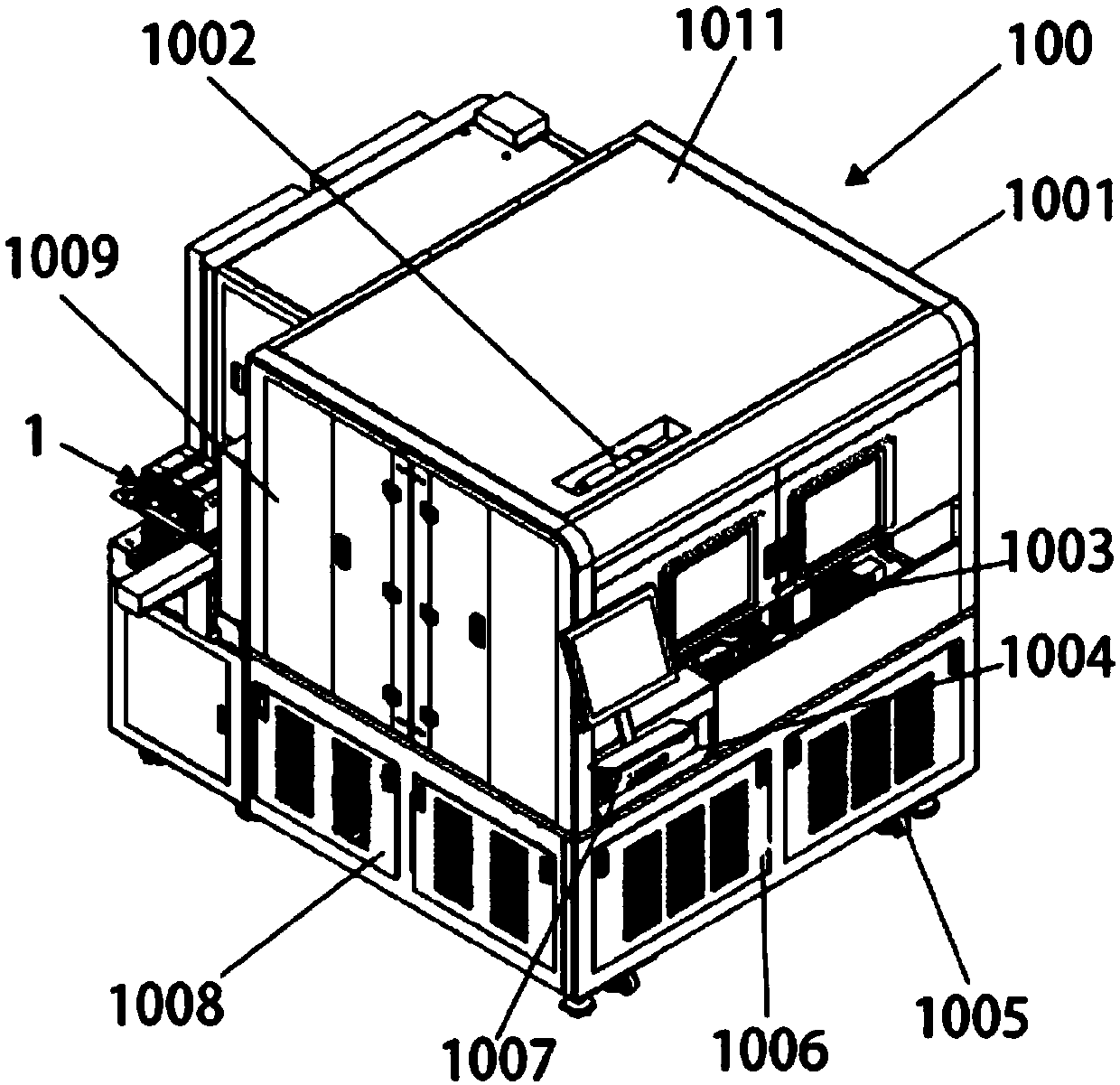

Dual-camera module assembling device

A technology for assembling equipment and camera modules, applied in mechanical equipment, installation, instruments, etc., can solve problems such as no improvement, and achieve the effects of less transfer, simple equipment, and high alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

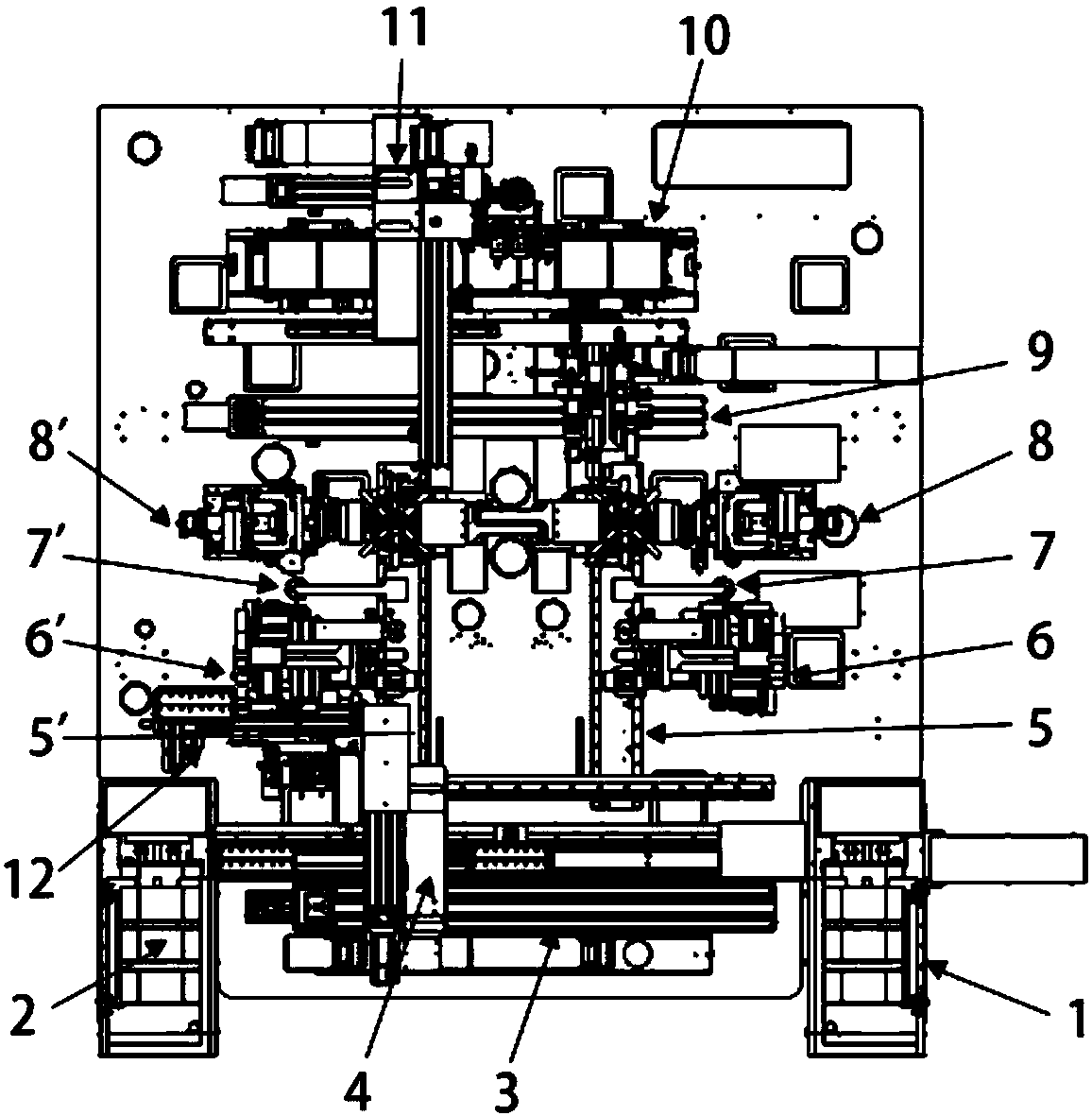

Method used

Image

Examples

Embodiment approach

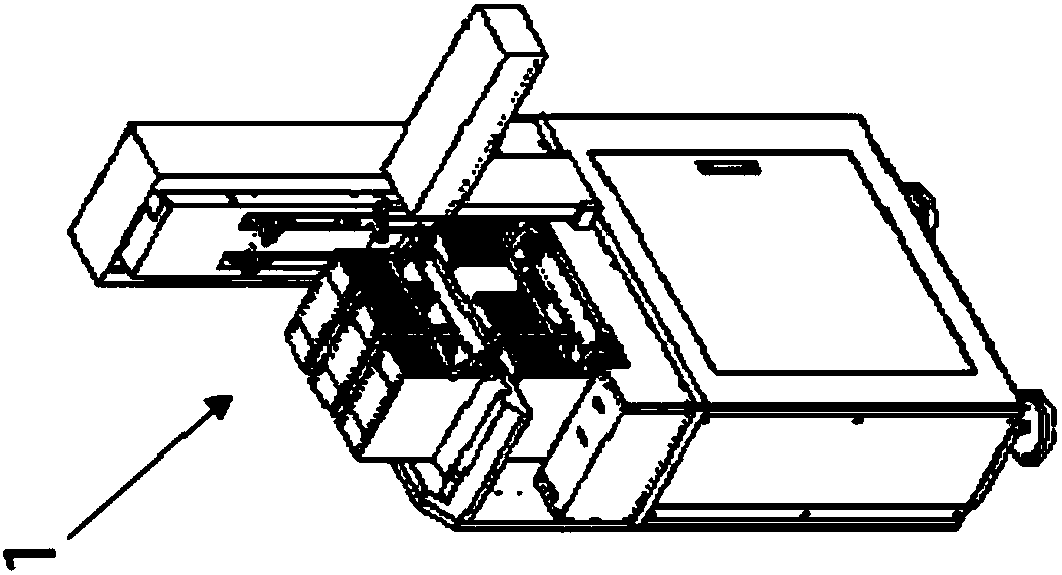

[0104] According to an embodiment of the present invention, the chipset picking unit 4 further includes a circuit board material holding mechanism 403 , a circuit board unloading holding mechanism 404 , and a camera mechanism 405 . After the circuit board material holding mechanism 403 sucks the circuit board from the circuit board carrier, the camera mechanism 405 takes a picture of it to obtain the relevant parameter information such as the position of the circuit board. The purpose of taking pictures of the circuit board is to obtain the accurate position of the circuit board, so that the glue can be accurately applied to the correct position to be bonded during subsequent gluing. Therefore, in actual operation, what is photographed determines the relative position of the circuit board relative to the clamping mechanism that clamps the circuit board or the clamping workpiece. Subsequently, the circuit board material holding mechanism 403 transfers the circuit board to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com