Liquid crystal display device

A liquid crystal display device and liquid crystal panel technology, which is applied to static indicators, light guides, optics, etc., can solve problems such as reducing the display screen of liquid crystal panels, and achieve the effects of improving assembly work efficiency, preventing wrinkles, and increasing the display screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. However, the embodiments described below are examples of liquid crystal display devices that embody the technical idea of the present invention, and are not intended to limit the present invention to such liquid crystal display devices, and are similarly applicable to other embodiments included in the claims. way of liquid crystal display devices.

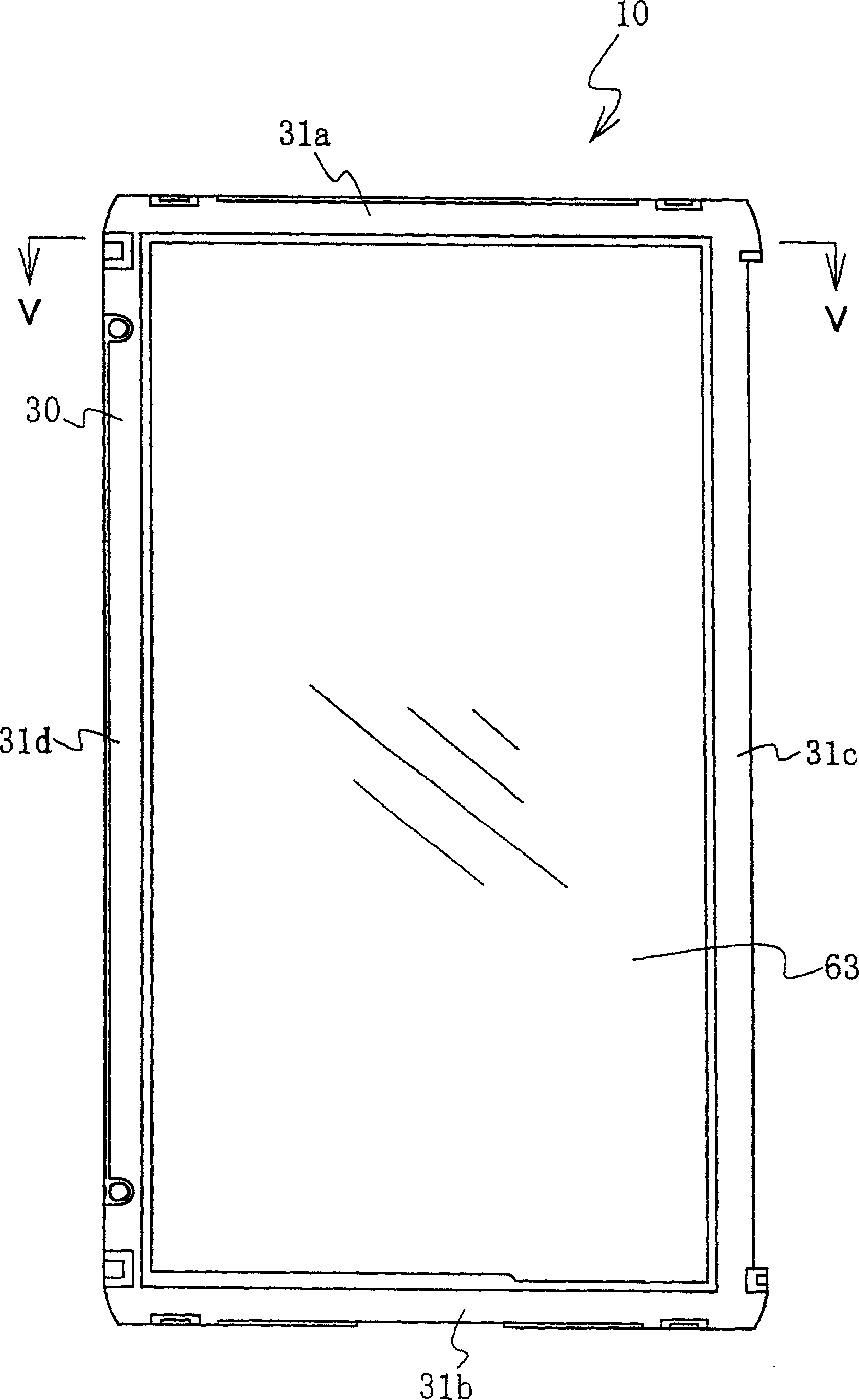

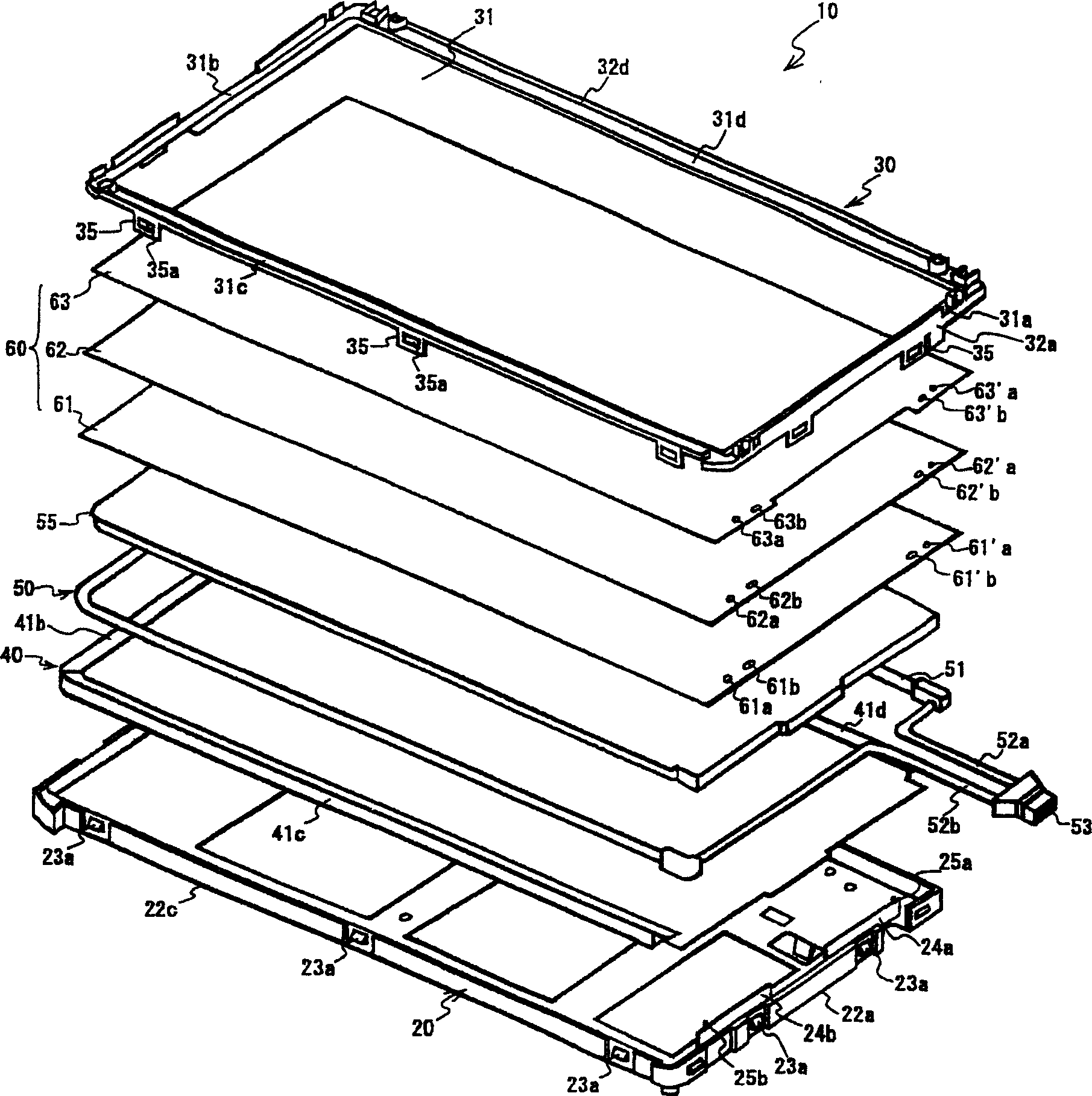

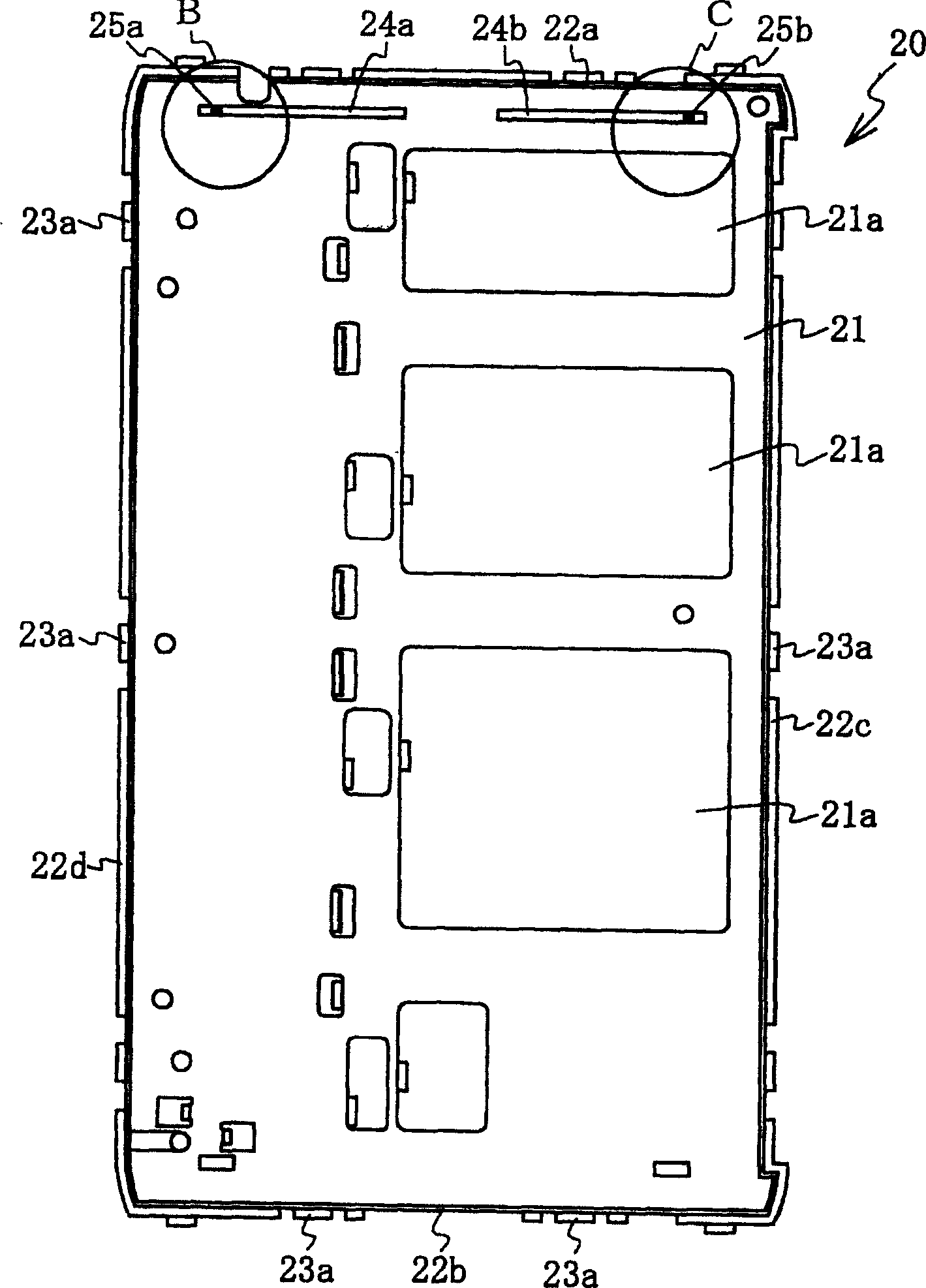

[0041] Liquid crystal display device 10, such as figure 2 As shown, it includes: a light source 50; a flat light guide plate 55 that transmits light from the light source 50; a reflective sheet 40 configured along the back of the light guide plate 55; an optical sheet 60 placed on the light guide plate 55. The laminate composed of these components is inserted between the main frame 20 and the sub-frame 30, and the sub-frame 30 is installed on the main frame 20, thereby positioning and fixing the aforementio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com