Crawler chassis and engineering machine with same

A construction machinery and crawler-type technology, which is applied to crawler vehicles, cranes, motor vehicles, etc., can solve the problems of poor working stability of the whole machine, poor local structural rigidity, and poor working stability, so as to improve assembly work efficiency and force bearing , Improve the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

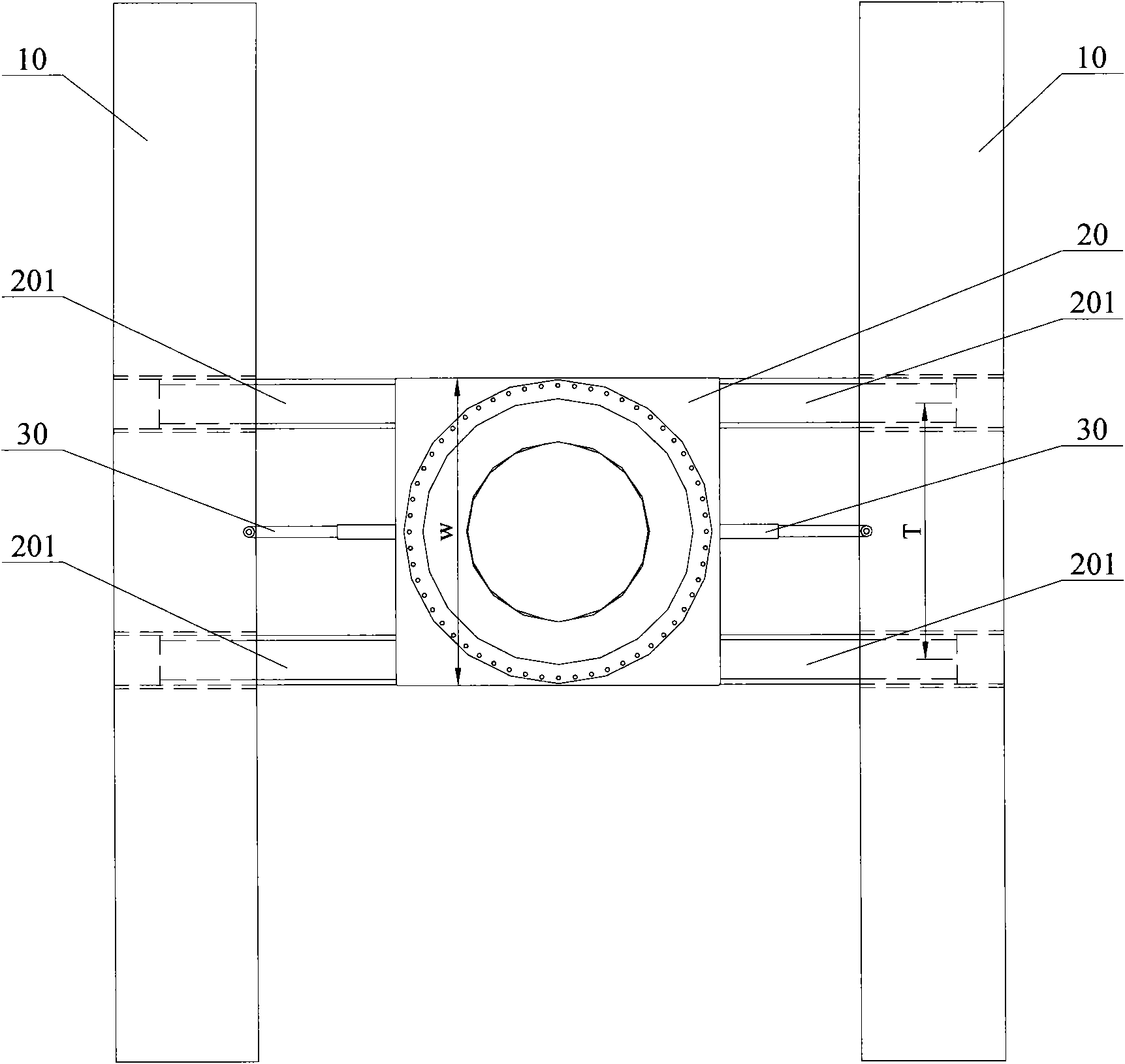

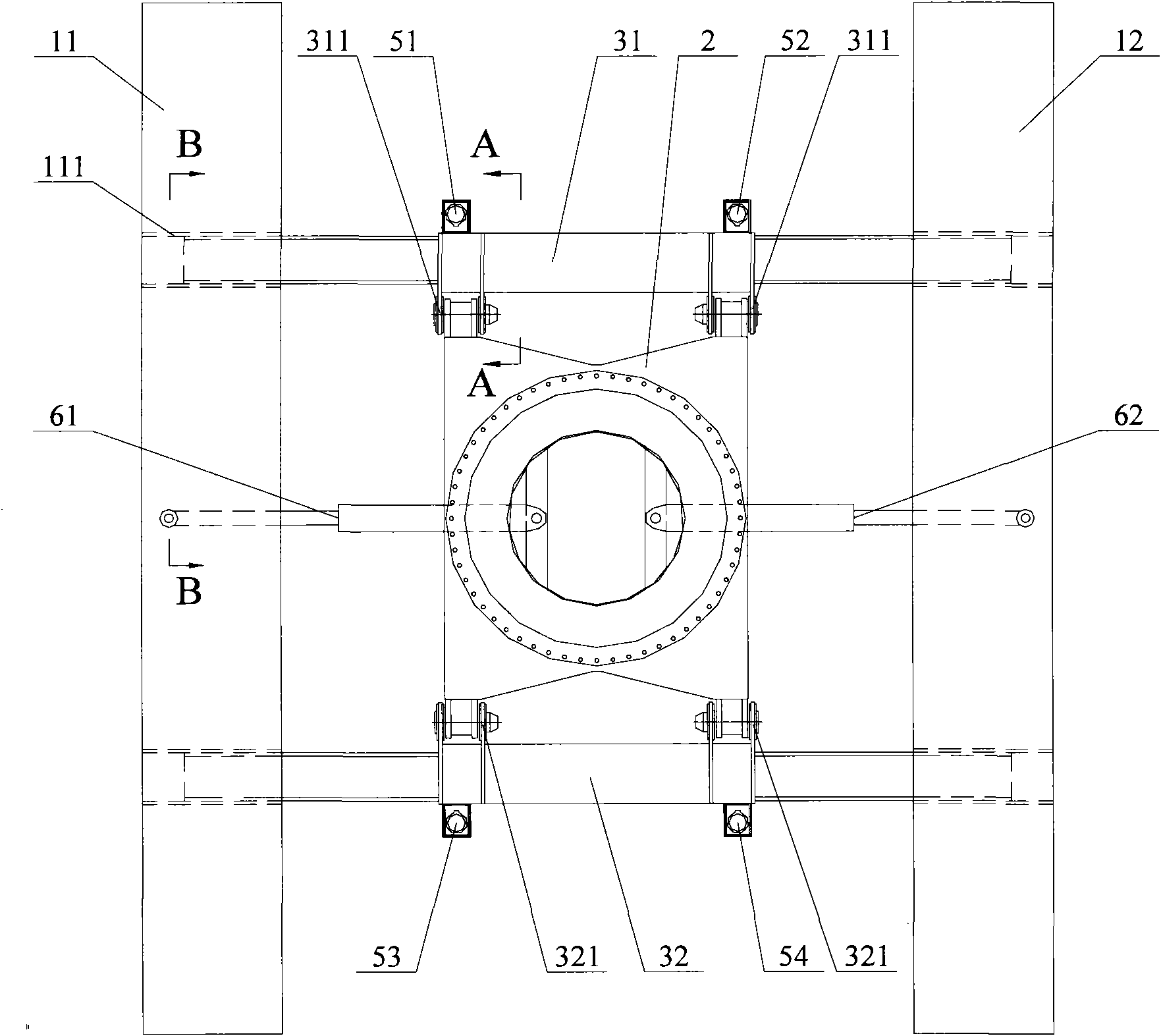

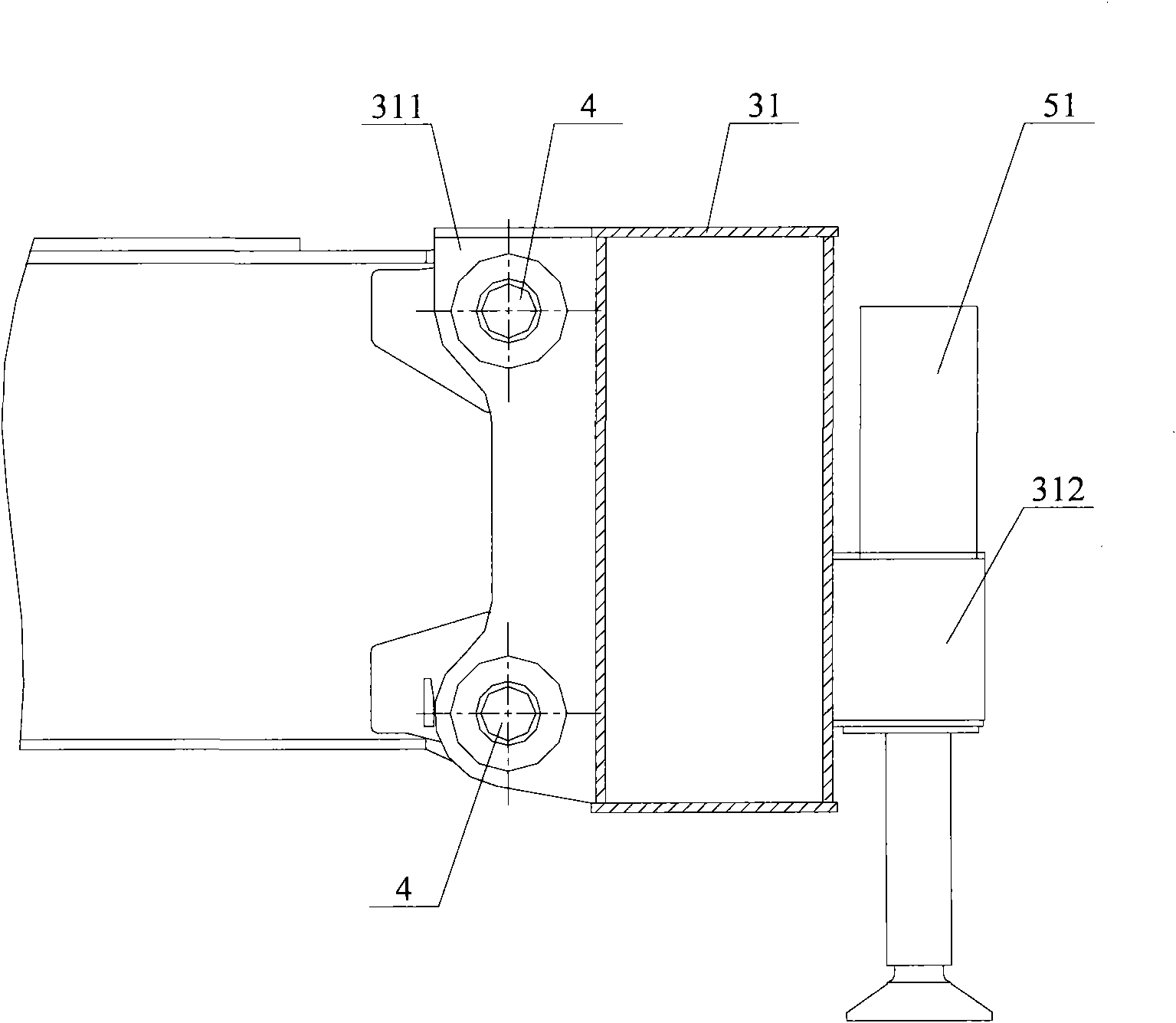

[0031] The present invention improves the design based on the existing crawler chassis. The core of the scheme is that the chassis adopts a split structure between the connecting beams on the front and rear sides, and the connecting beams respectively have attachments extending toward the chassis. seat to reliably connect the fixed connection relationship between the crossbeam and the underframe; the length of the attached seat is designed according to the task requirements, thereby ensuring that the distance between the front and rear beams on each side of the underframe and the track frame meets the working stability requirements Require.

[0032] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0033] The orientation words such as front, rear, left, and right involved in this article are defined based on the traveling direction of the crawler chassis. It should be understood that the use of the orientation words shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com