Shaft ringshield mounting device

A technology of installation device and shaft retaining ring, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low measurement accuracy of manual feeler gauge, low qualified rate of finished products, time-consuming and other problems, and achieve low noise and rotation accuracy. High, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

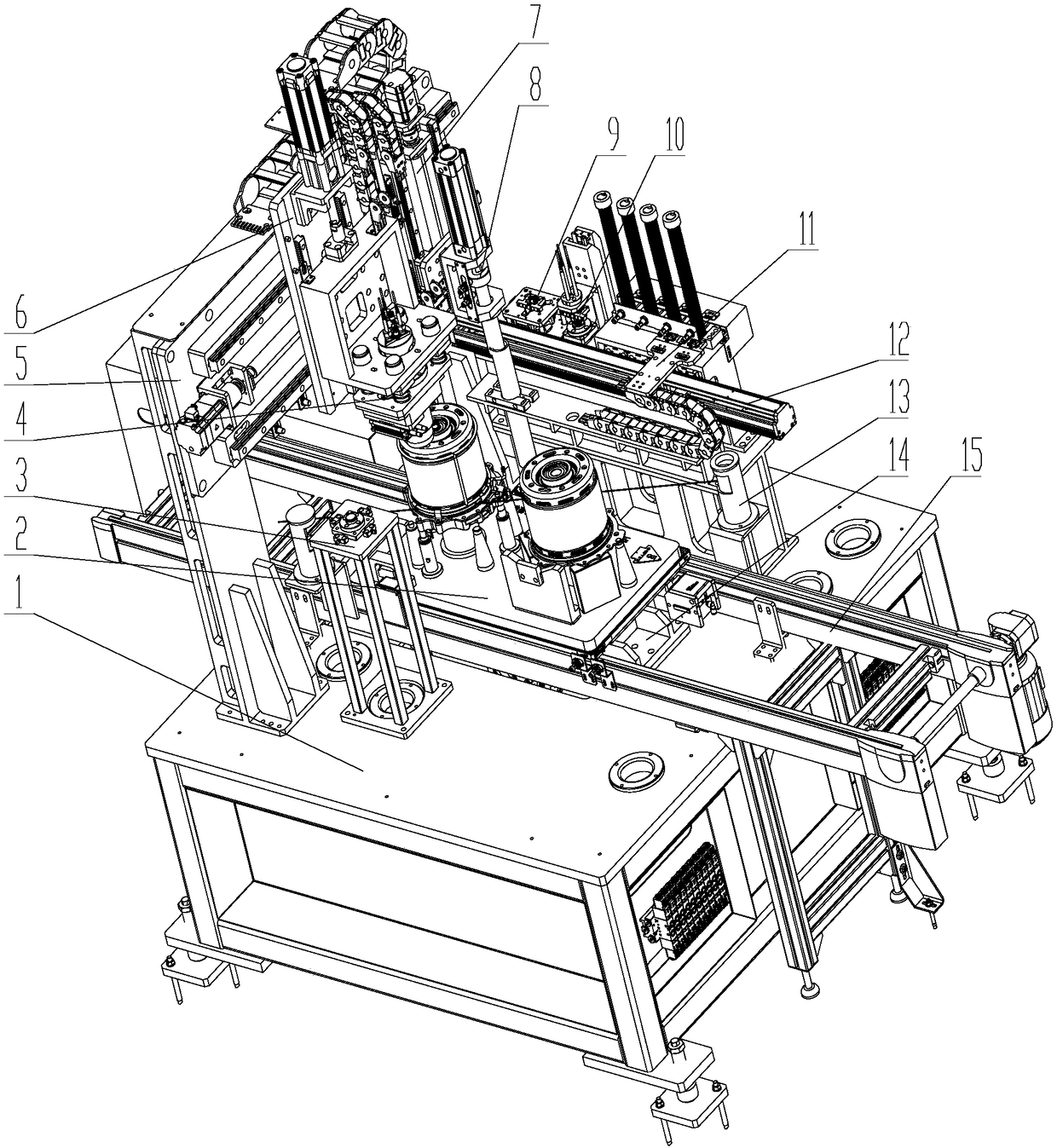

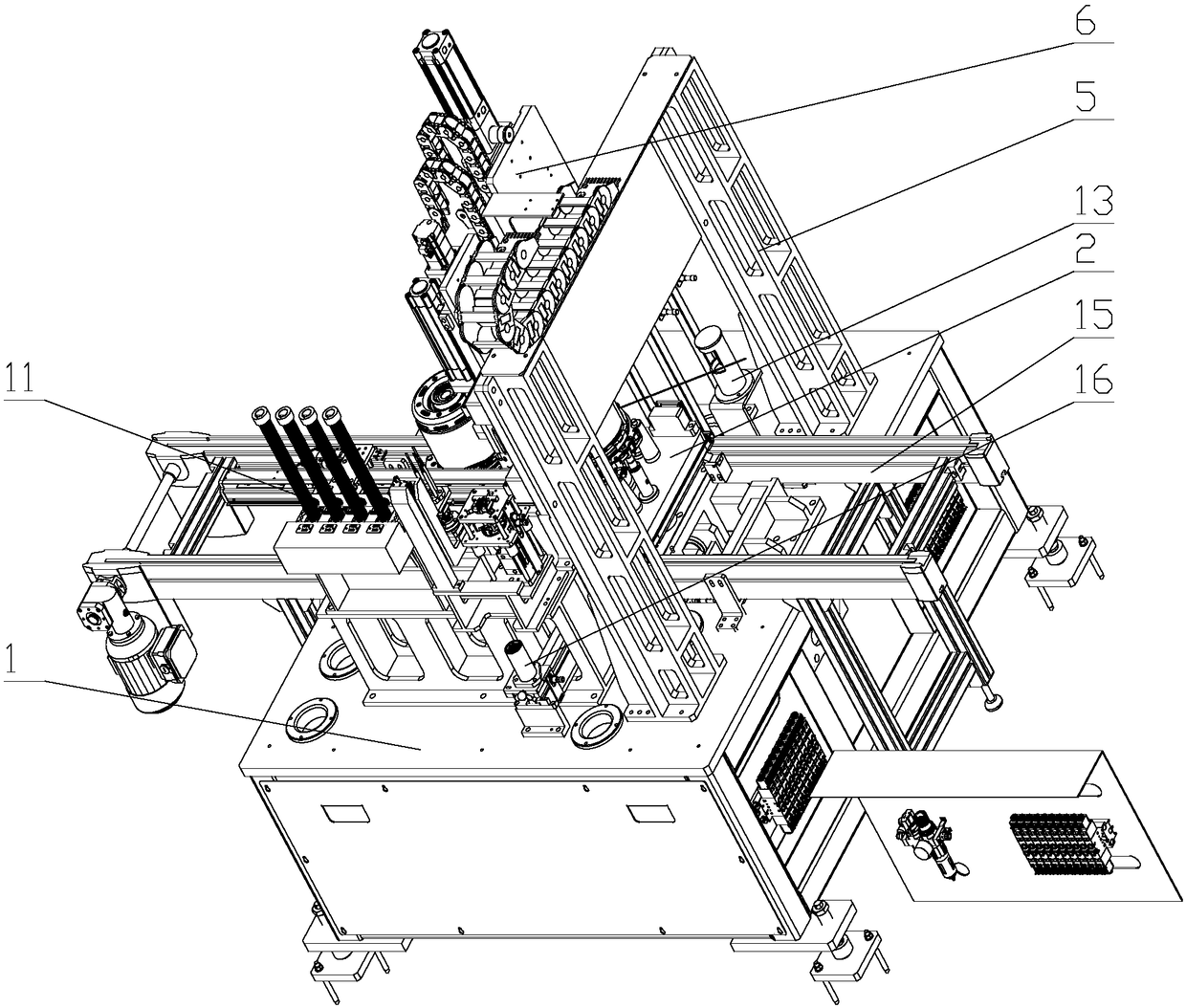

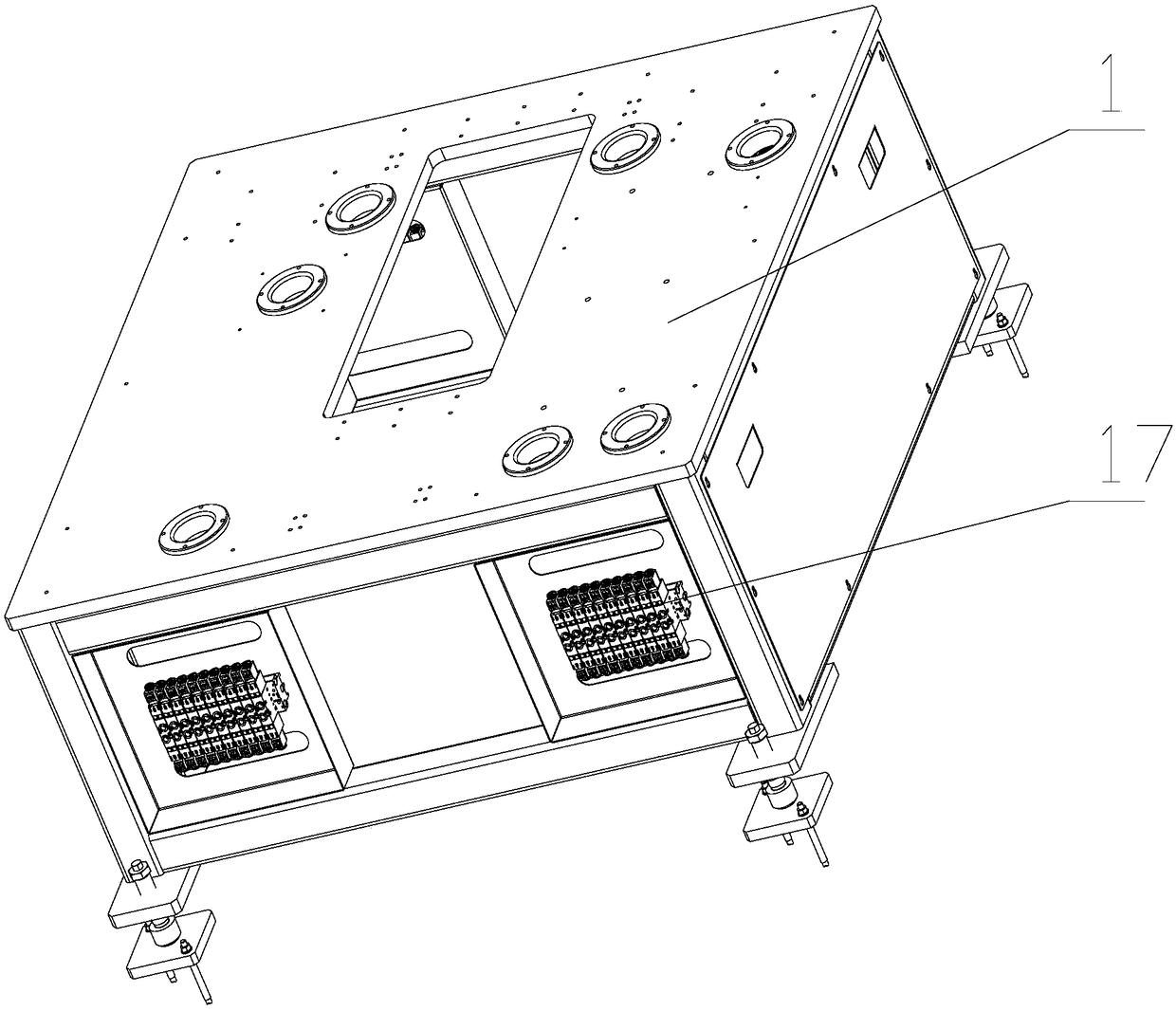

[0063] The specific embodiment of the present invention is shown in the accompanying drawings. The installation device for the retaining ring for the shaft includes: a base 1, a workpiece tray 2, a snap ring measurement and calibration device 3, a snap ring measurement device 4, a servo traverse device 5, and a snap ring measurement and lifting device. 6. Pressure head servo lifting device 7, snap ring pressure head device 8, snap ring expansion device 9, snap ring re-inspection device 10, snap ring feeding device 11, snap ring transfer device 12, secondary positioning jacking device 14 and the delivery track 15; the delivery track 15 spans the top of the base 1; the workpiece tray 2 is transported along the delivery track 15, and the workpiece to be assembled is placed on the workpiece tray 2; Calibration device 3; the other side of the conveying track 15 is equipped with a snap ring expansion device 9, a snap ring re-inspection device 10, a snap ring feeding device 11, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com