A welding method for dual-interface smart card

A dual-interface smart card and welding method technology, which is applied in the field of smart cards, can solve problems such as long time required for soldering, impact on the appearance of smart cards, PVC deformation, etc., and achieve the effects of short time, improved welding reliability and yield, and smooth solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

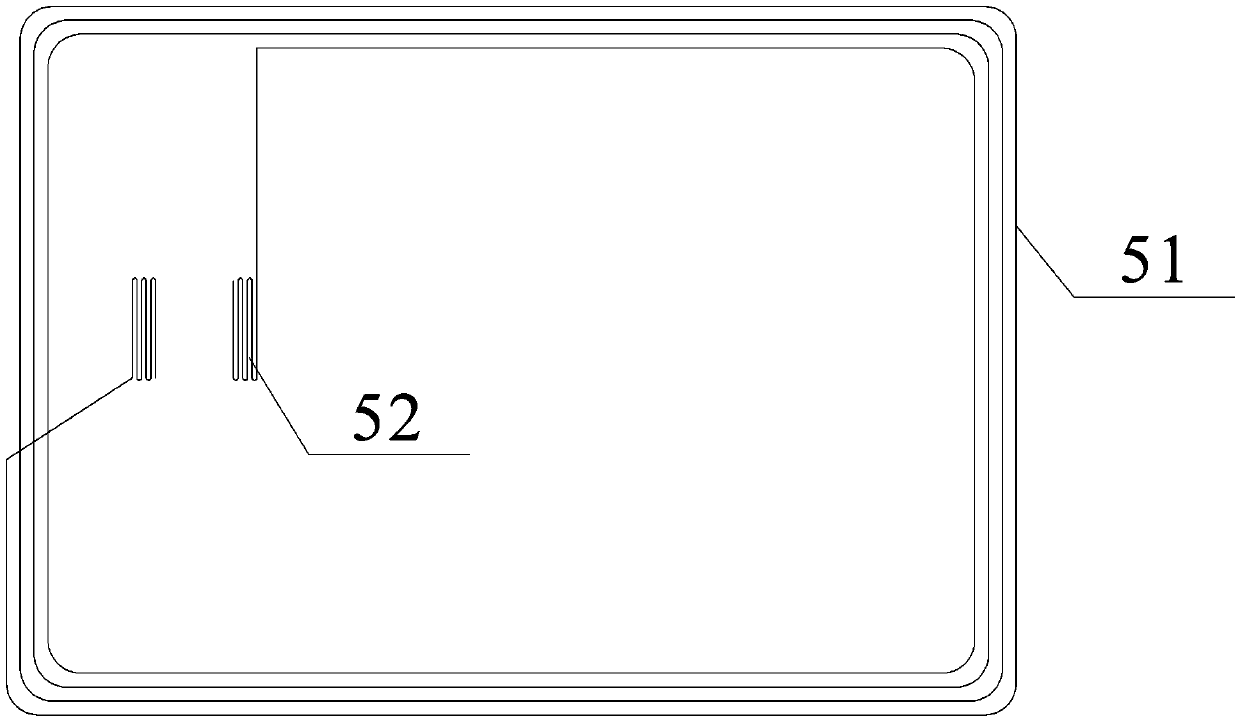

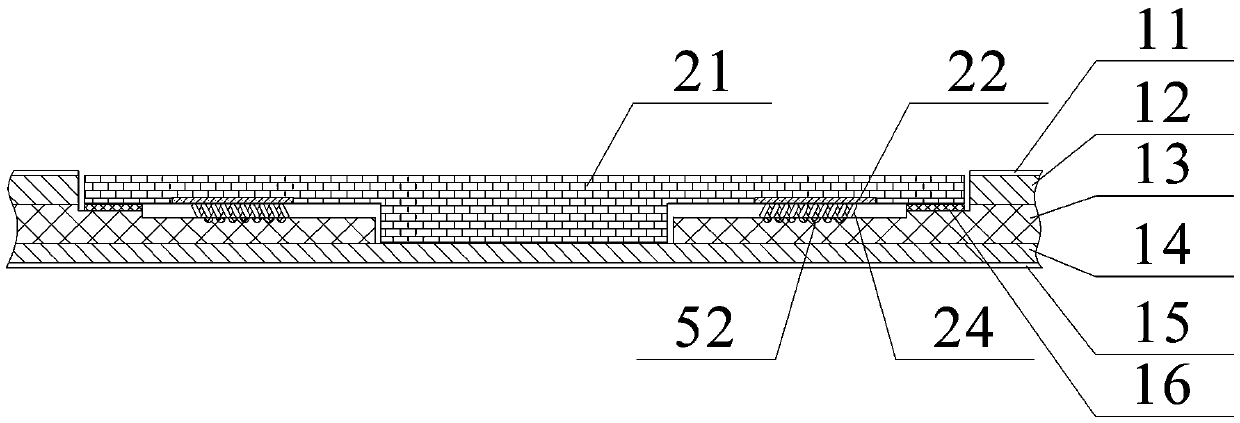

[0026] The dual-interface smart card in this embodiment adopts the middle layer 13 of the card body with copper enameled wire as the antenna, and the copper enameled wire antenna has two antenna pads 52 .

[0027] The card base 61 of the dual-interface smart card is made by binding and layering the card body intermediate layer 13 with the metal antenna 51, the first transparent film 11, the first printed layer 12, the second printed layer 14 and the second transparent film 15. obtained after pressing.

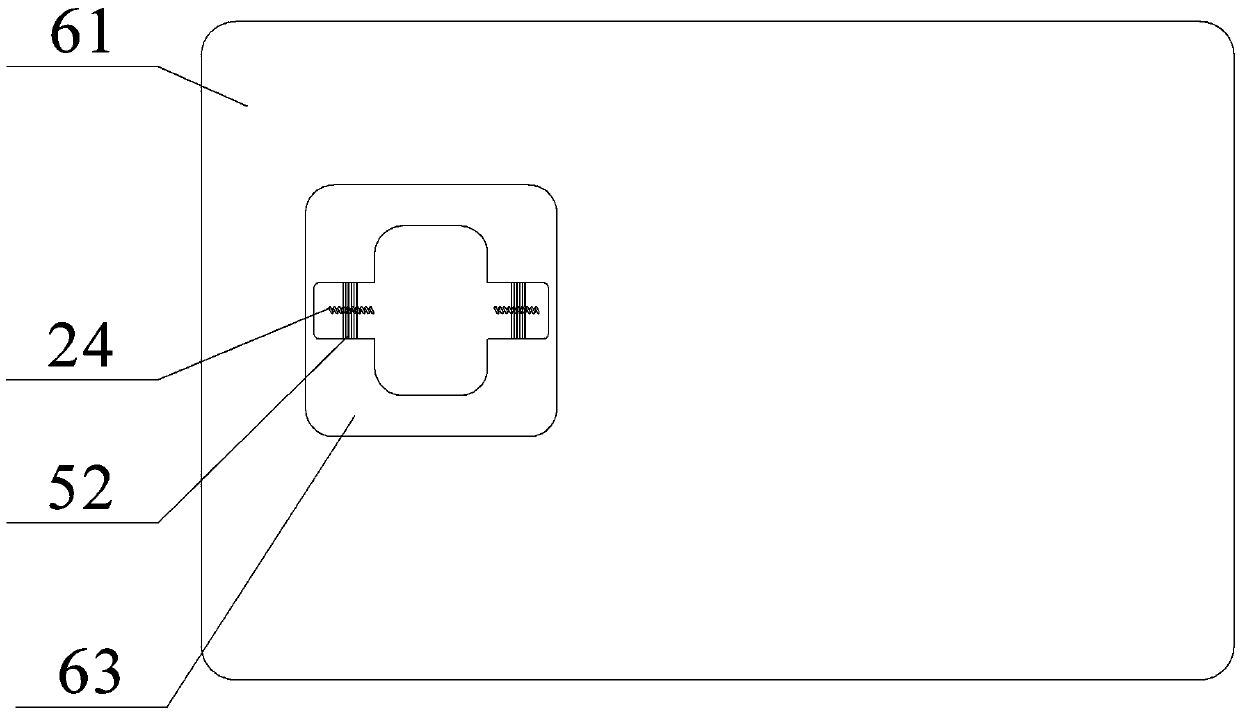

[0028] The module slot 63 is provided on the surface of the card base 61 of the dual-interface smart card, and a module slot 63 for placing the dual-interface module 21 is milled out by using a milling cutter.

[0029] By performing secondary milling on the area of the antenna pad 52, two antenna pads 52 are exposed, and the dual-interface module 21 is placed in the module groove 63 milled by the card base 61 of the dual-interface smart card, and the two antennas The pads 52...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com