Tin soldering device for I-shaped inductor processing

An I-shaped inductor and soldering technology, applied in auxiliary devices, metal processing, metal processing equipment, etc., can solve the problems of weak welding position, reduced inductance quality, poor solder joint forming quality, etc., to improve processing quality and production. Efficiency, improve stability and reliability, and improve the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

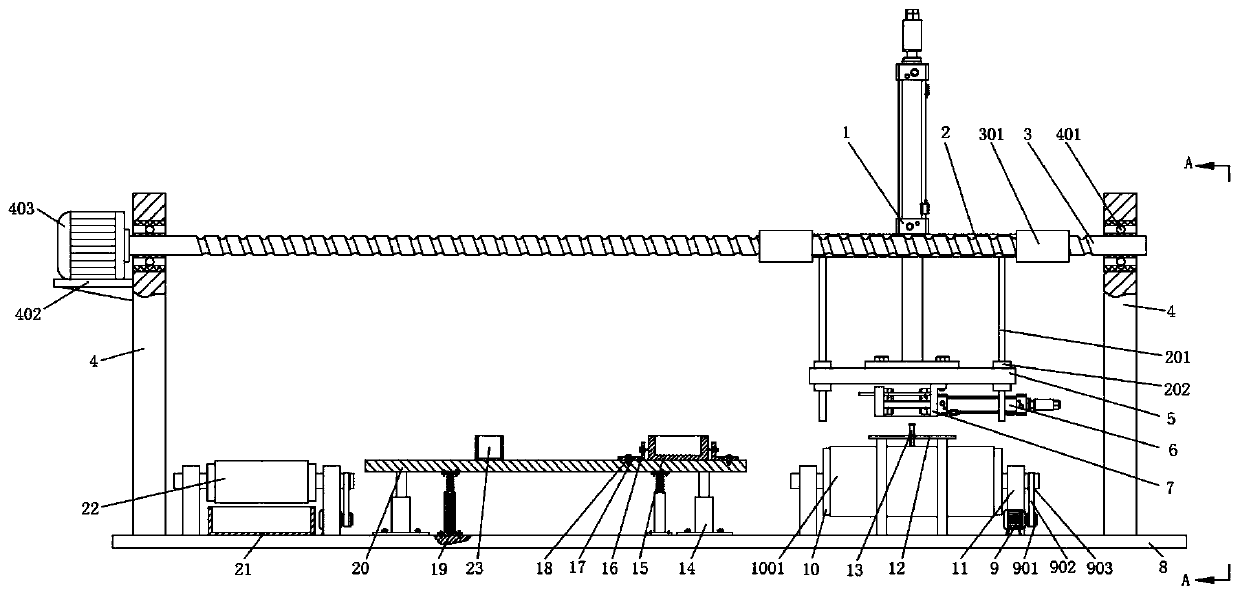

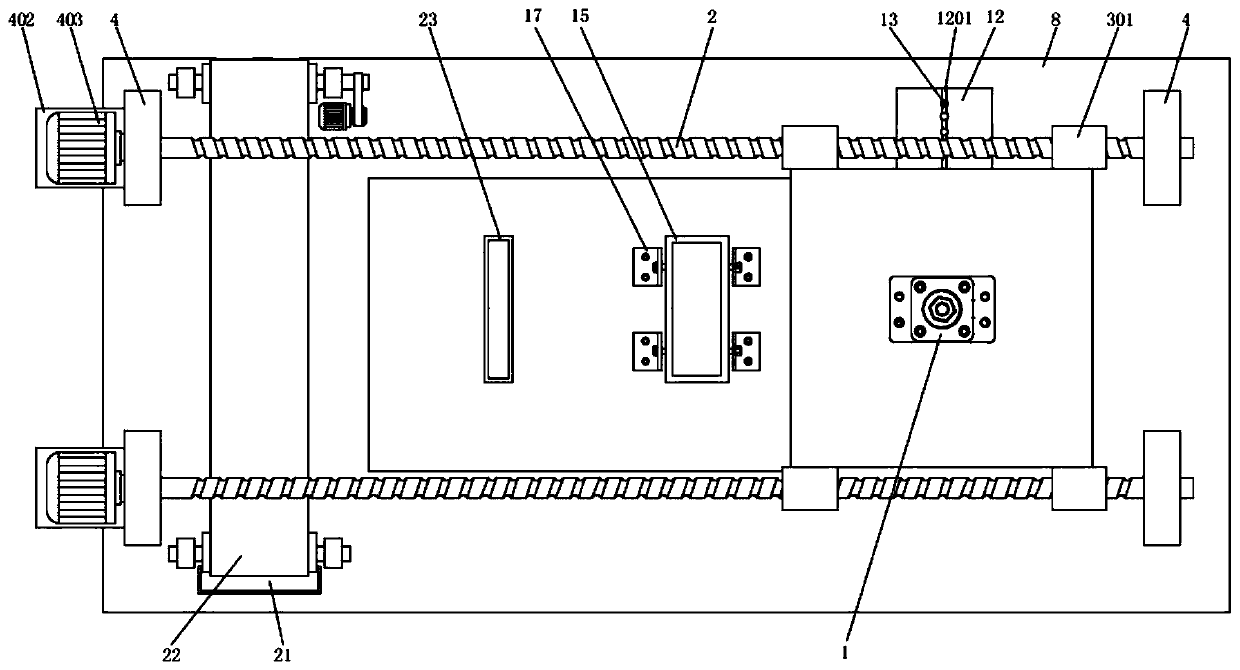

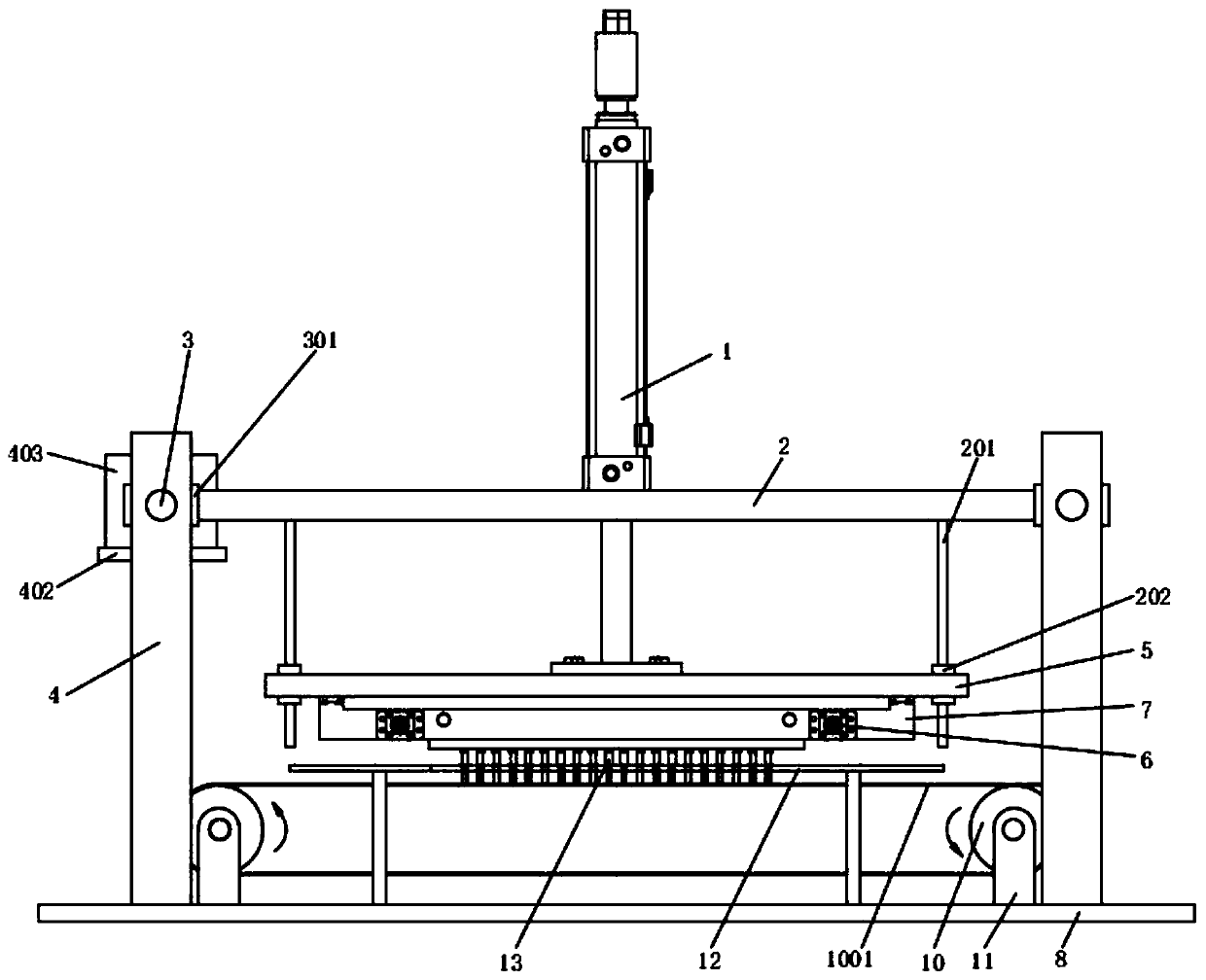

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0026] Such as Figure 1-Figure 6 Shown, the specific structure of the present invention is: it comprises base plate 8, and base plate 8 tops are provided with four brackets 4 at fixed intervals, and screw mandrel 3 is set horizontally and laterally in brackets 4, and screw mandrel nut 301 is arranged at spacing on screw mandrel 3, and screw mandrel 3 The side end of the rod nut 301 is fixedly provided with a supporting platform 2, and the middle part of the upper surface of the supporting platform 2 is provided with a lifting cylinder 1. The material mechanism 7, below the material clamping mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com