Welding method and device of frame support rings of bag type dust collector

A bag filter and welding method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of many specifications, damage to the filter bag of the filter, system loss, etc., to achieve long service life, bright welding spot Complete, easy to put circle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

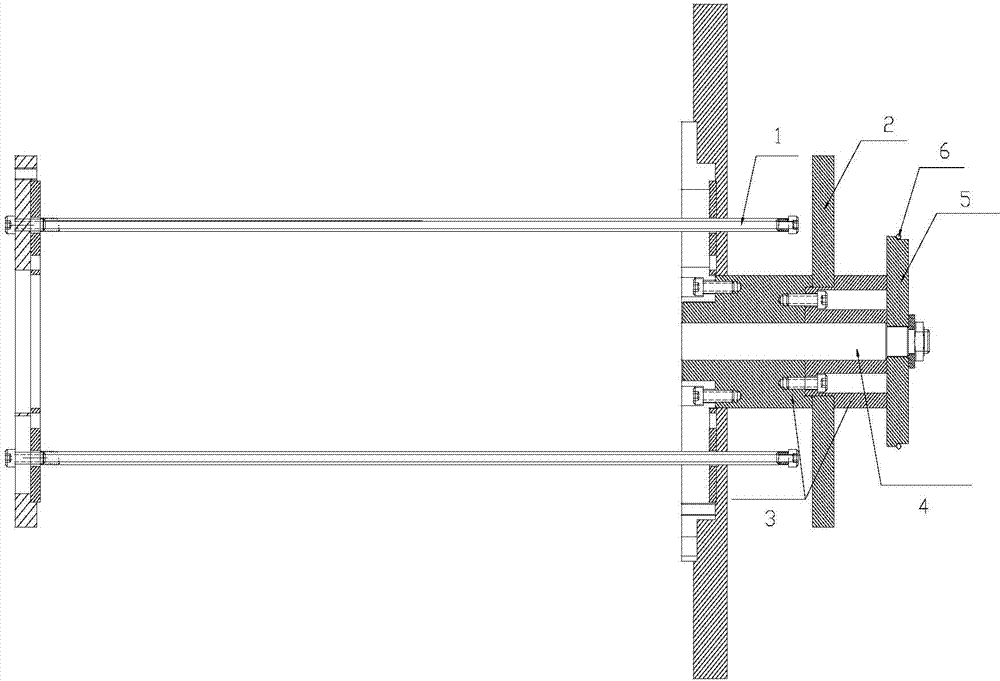

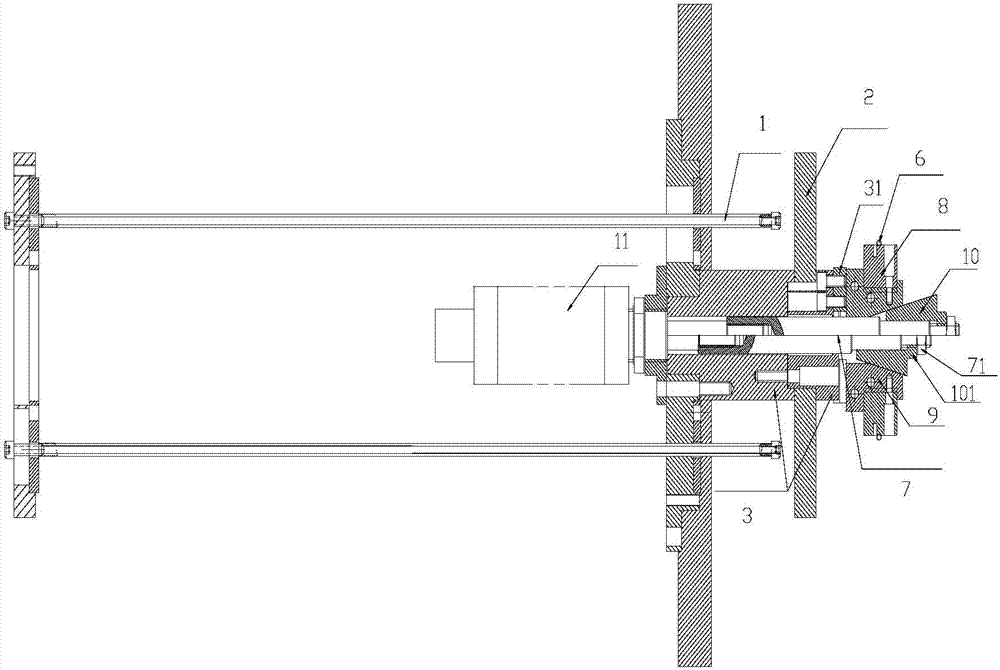

[0022] Such as figure 2 As shown, an expandable central electrode device includes a longitudinal wire guide tube 1, a longitudinal wire guide plate 2, a longitudinal wire guide plate fixing seat 3, an expandable central electrode pull rod 7, a central electrode block 8, and a tensioning slider 9. Tension block 10, tie rod cylinder 11, the longitudinal wire guide tube 1 is arranged in front of the longitudinal wire guide plate 2, the longitudinal wire guide plate 2 is fixed on the longitudinal wire guide plate fixing seat 3, the The tensioning block 10 is set on the expansion-opening central electrode pull rod 7, and is matched with the tensioning slider 9. The central electrode block 8 is fixed on the tensioning slider 9, and the tensioning rod cylinder 11 is connected to the tensioning slider 9. Type center electrode pull rod 7, and drive the expansion-open type center electrode pull rod 7 to drive the tension block 40 to tighten or loosen the tension slider 9, thereby drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com