Lithium ion battery point bottom connecting piece and preparation method of lithium ion battery

A lithium-ion battery and connecting piece technology, which is applied to battery pack components, circuits, electrical components, etc., to reduce internal resistance, improve welding strength, and reduce false welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

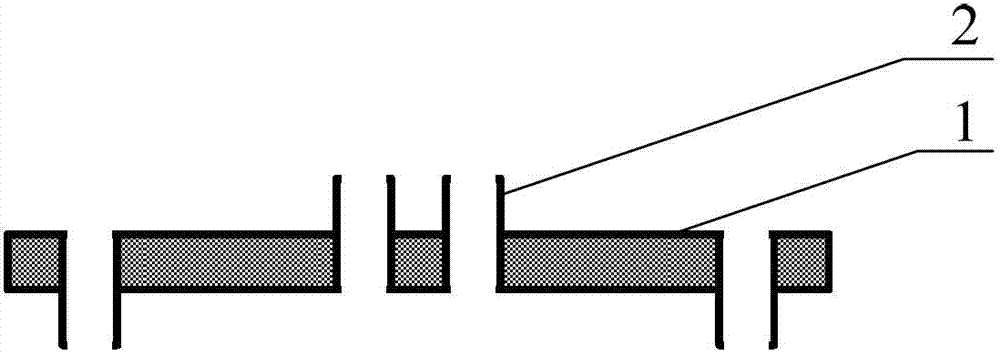

[0032] like Figure 5 Shown, a kind of preparation method of lithium ion battery comprises the following steps:

[0033] 1) Process the two surfaces of the nickel-plated steel strip with burrs 2 by mechanical stamping method, and press according to the size of the lithium-ion battery shell 3 to obtain the bottom connection piece of the lithium-ion battery, which is degreased and dried for later use;

[0034] 2) First weld the lithium-ion battery shell 3 to the bottom connection piece of the lithium-ion battery, and then weld the bottom connection piece of the lithium-ion battery to the tab 5 on the battery cell. The welding head 4 will be larger during the welding process. The current is discharged through the burr 2, which can effectively melt the burr 2 in an instant, and firmly weld the bottom connecting piece of the lithium-ion battery to the bottom of the lithium-ion battery case 3 and the tab 5 and the bottom connecting piece of the lithium-ion battery, and then Subsequ...

Embodiment 1

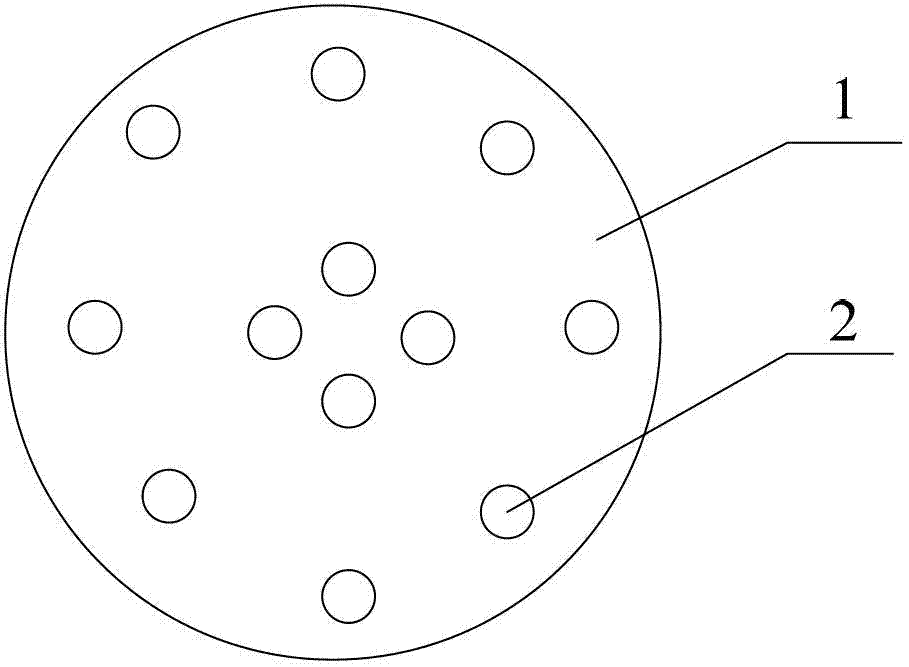

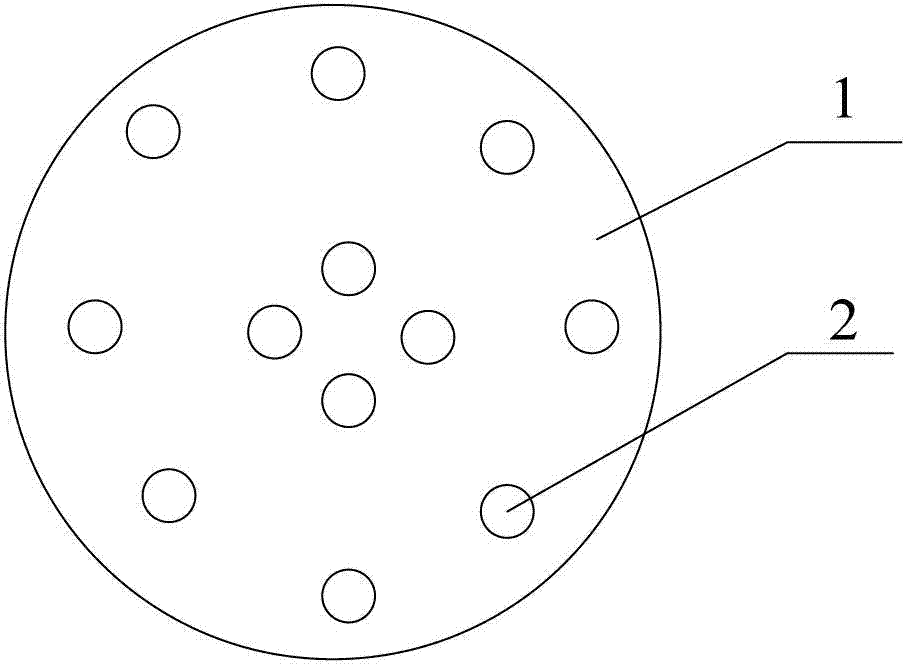

[0037] like figure 1 and figure 2 As shown, the lithium-ion battery dot-bottom connecting piece of the present invention (specifically, the dot-bottom connecting piece for 18650 lithium-ion power battery) includes a connecting substrate 1 and burrs 2 arranged on both sides of the connecting substrate 1, and the burr 2 is a hollow structure glitches. The connecting substrate 1 is disc-shaped, and the burrs 2 on one side of the disc-shaped connecting substrate 1 (that is, the burrs 2 on the upper surface of the disc-shaped connecting substrate 1) are located in the middle of the disc-shaped connecting substrate 1, and the other The burrs 2 on one side (that is, the burrs 2 on the lower surface of the disc-shaped connecting substrate 1 ) are located on the outer periphery of the disc-shaped connecting substrate 1 . There are four burrs 2 arranged in the middle of the disc-shaped connection substrate 1, the four burrs 2 are distributed in a square, and the four burrs 2 are dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com