Tab welding structure and tab welding method of flexibly packaged lithium ion power battery

A technology of tab welding and power battery, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of unsatisfactory welding strength, small welding area, poor welding strength, etc., to avoid battery short-circuit and micro-short-circuit, The effect of improving the welding strength and avoiding the phenomenon of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

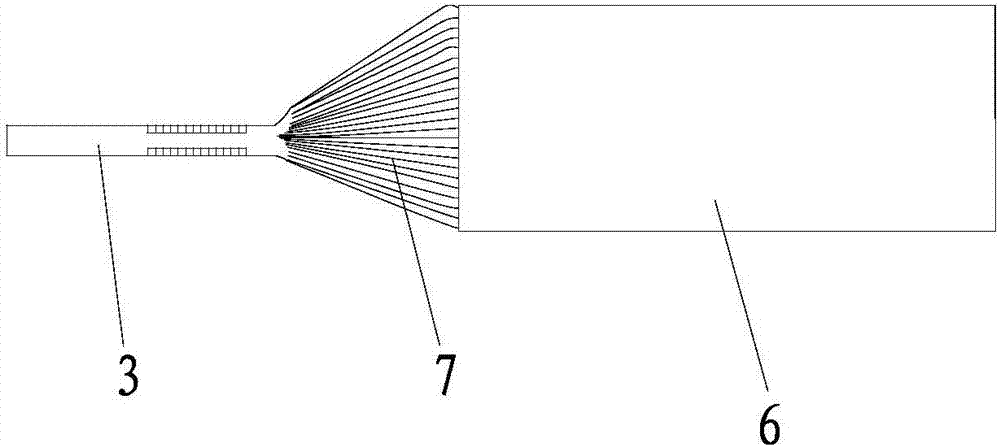

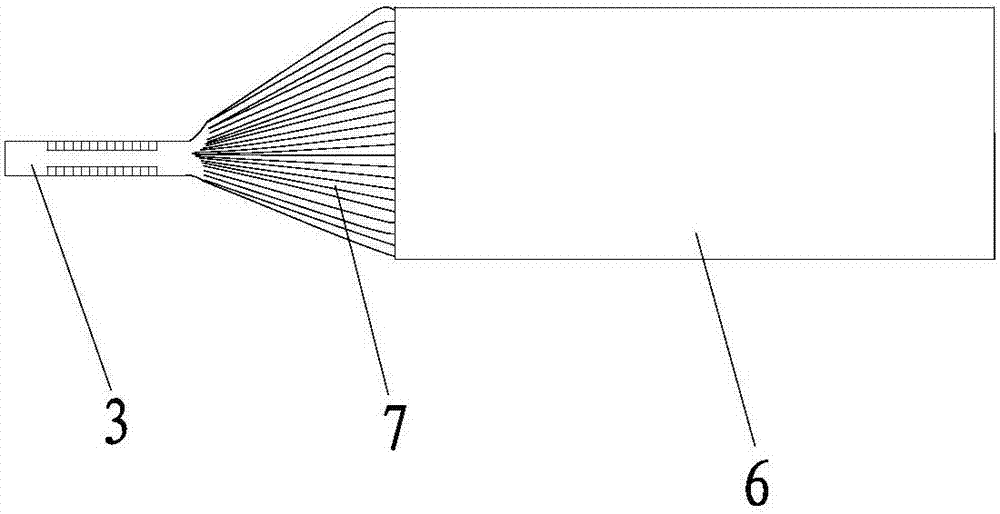

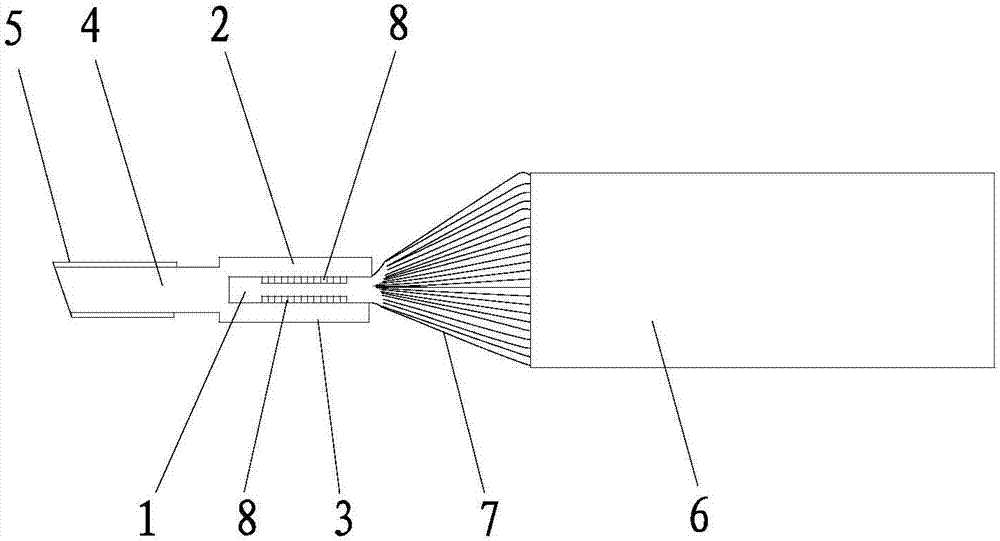

[0026] Such as image 3 As shown, a flexible packaging lithium-ion power battery tab welding structure includes a current collector 1 and a concave tab welding block; the concave tab welding block includes an upper tab welding leg 2, a tab lower welding leg 3, and The main body 4 and the ear piece 5. The upper lug leg and the lower lug leg are fixed at the same end of the lug main body, and the upper lug leg, the lower lug leg and one end of the lug body form a groove, the pole The ear gel blocks are arranged on the upper and lower end surfaces of the main body of the tab; the current collector is welded in the groove.

[0027] Wherein, the main body of the tab has a thickness of 0.35mm, the upper and lower tabs have a thickness of 0.25mm, and the upper and lower tabs are arranged in parallel with a distance of 0.25mm.

[0028] Such as Figure 1-3 As shown, the welding method of the tab welding structure of the flexible packaging lithium-ion power battery includes the follo...

Embodiment 2

[0033] Such as image 3 As shown, a flexible packaging lithium-ion power battery tab welding structure includes a current collector 1 and a concave tab welding block; the concave tab welding block includes an upper tab welding leg 2, a tab lower welding leg 3, and The main body 4 and the ear piece 5. The upper lug leg and the lower lug leg are fixed at the same end of the lug main body, and the upper lug leg, the lower lug leg and one end of the lug body form a groove, the pole The ear glue block is arranged on the upper and lower end surfaces of the main body of the ear; the current collector is welded in the groove.

[0034] Wherein, the thickness of the main body of the tab is 0.1 mm, the thickness of the upper and lower solder legs of the tab is 0.1 mm, and the upper solder leg of the tab and the lower solder leg of the tab are arranged in parallel with a distance of 0.1 mm.

[0035] Such as Figure 1-3 As shown, the welding method of the tab welding structure of the fl...

Embodiment 3

[0040] Such as image 3 As shown, a flexible package lithium-ion power battery tab welding structure, including a current collector 1, a concave tab welding block; the concave tab welding block includes a tab upper welding leg 2, a tab lower welding leg 3, a tab The main body 4 and the ear piece 5. The upper lug leg and the lower lug leg are fixed at the same end of the lug main body, and the upper lug leg, the lower lug leg and one end of the lug body form a groove, the pole The ear gel blocks are arranged on the upper and lower end surfaces of the main body of the tab; the current collector is welded in the groove.

[0041] Wherein, the thickness of the main body of the tab is 0.6 mm, the thickness of the upper and lower solder legs of the tab is 0.4 mm, and the upper solder leg of the tab and the lower solder leg of the tab are arranged in parallel with a distance of 0.4 mm.

[0042] Such as Figure 1-3 As shown, the welding method of the tab welding structure of the fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com