Duplex spot welding electrode

A double-spot welding and electrode technology, applied in the field of electrodes, can solve problems such as affecting production efficiency, and achieve the effects of improving welding efficiency, reducing use costs, and avoiding virtual welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

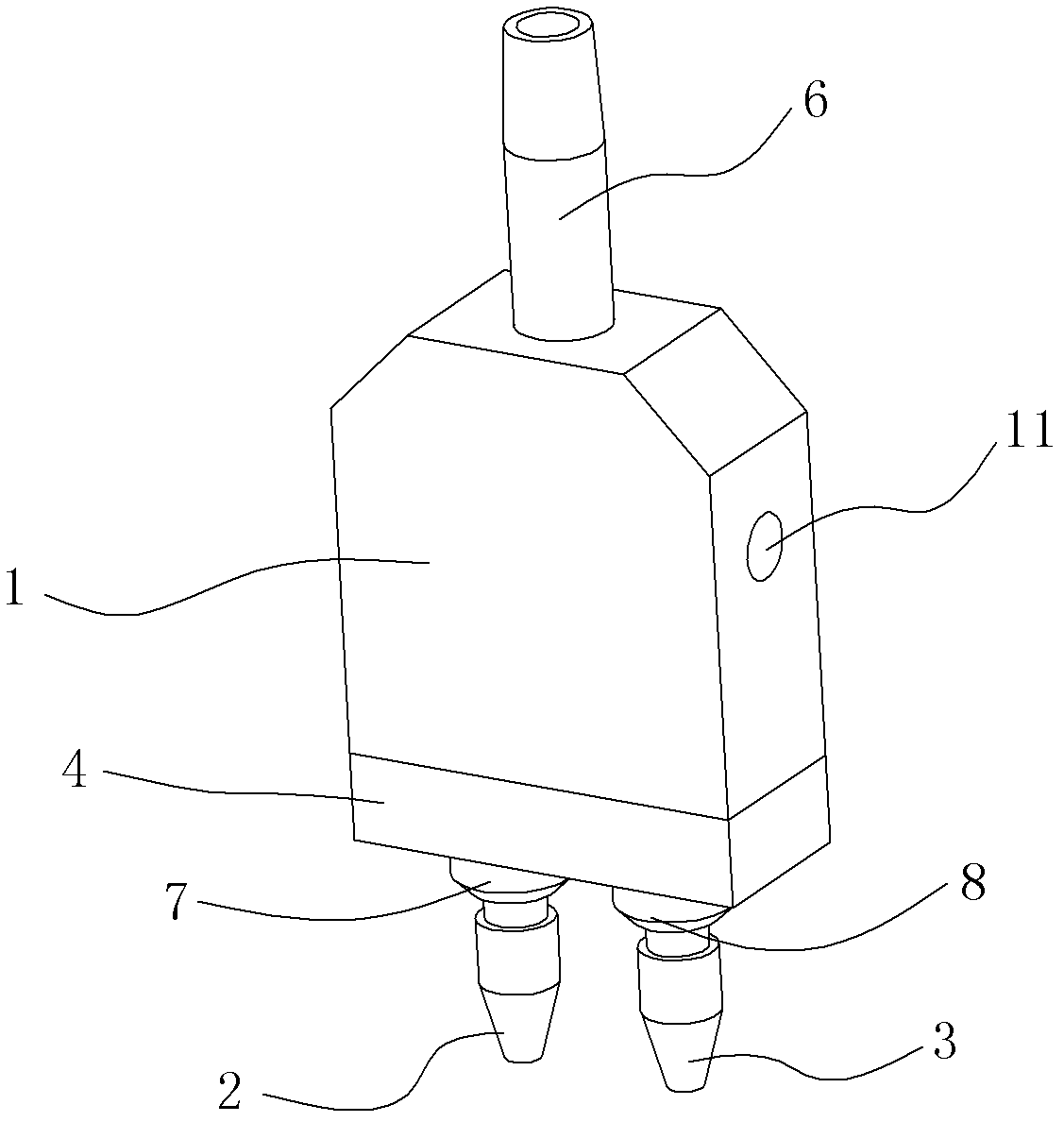

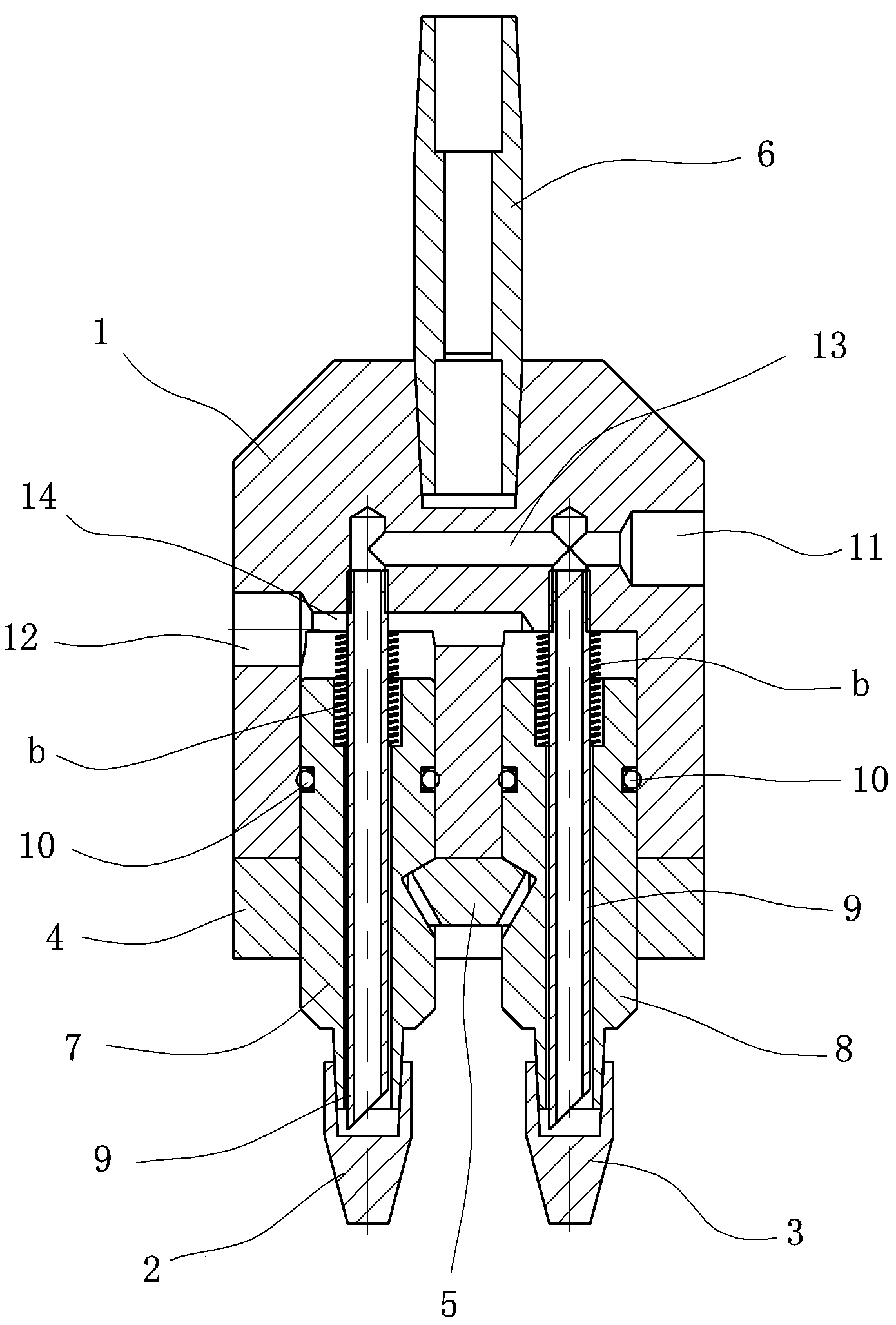

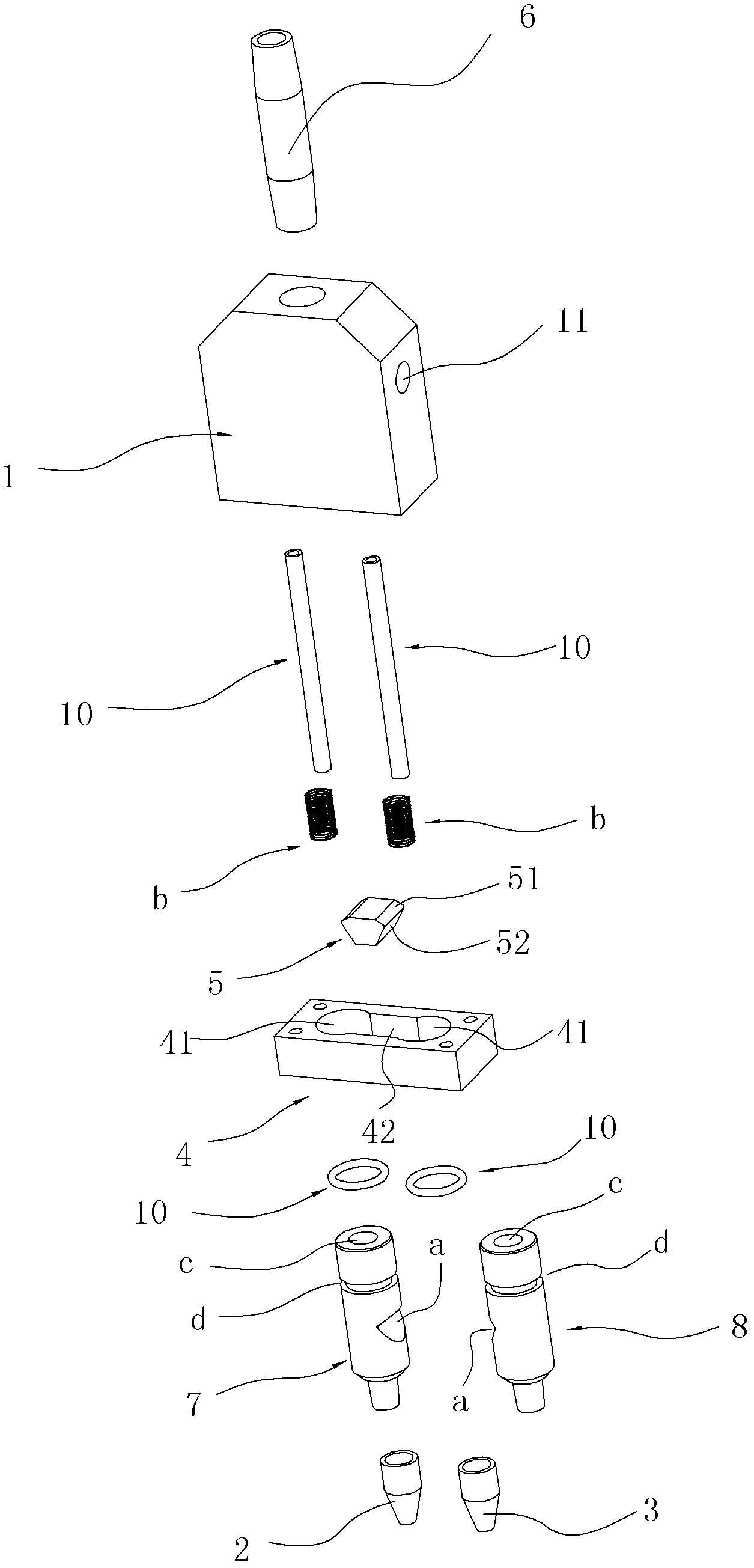

[0020] Such as Figure 1 to Figure 3 As shown, the double spot welding electrode includes an electrode base 1, a first electrode 2 and a second electrode 3, an auxiliary block 4 and a slider 5, wherein the upper part of the electrode base 1 is fixed with a connecting rod 6, and the lower part is provided with spaced vertically distributed Two installation holes, the first guide post 7 and the second guide post 8 are respectively inserted in the two installation holes, the above-mentioned first electrode 2 is fixed on the lower end of the first guide post 7, and the second electrode 3 is fixed on the second guide post 8 the lower end.

[0021] The above-mentioned auxiliary block 4 is fixed on the bottom of the electrode holder 1, and two through-holes 41 corresponding to the two installation holes are opened on the auxiliary block 4 for the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com