Non-excavation inspection wheel comprehensive repairing method

A repair method and an all-round technology, applied in the field of municipal engineering, can solve the problems affecting the normal passage of vehicles in the municipal pipe network, the problems of inspection wells cannot be discovered in time, increase the repair and use costs of inspection wells, and achieve the improvement of repair quality and interval The effect of increasing and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

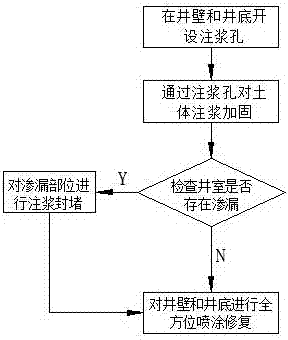

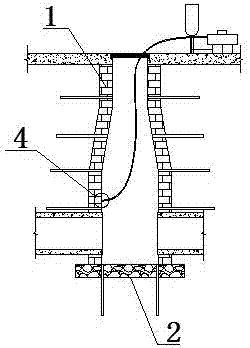

[0028] Such as figure 1 As shown, a non-excavation inspection well all-round repair method, at least includes the following steps:

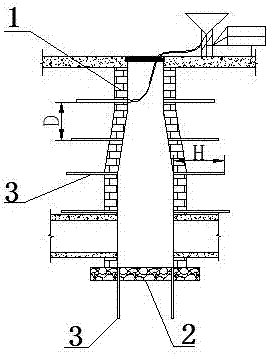

[0029] The steps are as figure 2 As shown, a number of grouting holes 3 protruding into the surrounding soil of the inspection well are opened on the wall 1 and bottom 2 of the inspection well; the depth H of the grouting holes 3 is 0.5~1m.

[0030] Step two as figure 2 As shown, Portland cement is used as the grouting material, injected from the grouting hole 3, and the soil around the well wall 1 and the well bottom 2 is grouted and reinforced. It not only fills the hole area that may exist in the soil around the well chamber; moreover, the interaction of grouting materials between different grouting holes can play the role of the soil around the lock column. On the premise of strengthening the foundation, it can also Prevent soil movement, improve the overall performance of the inspection shaft and the ability to resist damage.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com