Dry quenching furnace bracket repairing method

A CDQ coke oven and repair method technology, applied in the repair field, can solve problems such as insufficient stability of corbel bricks, short service life of corbels, large gaps in corbel bricks, etc., to prolong service life, reduce repair times, and stabilize the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] The CDQ coke oven corbel restoration method comprises the following steps:

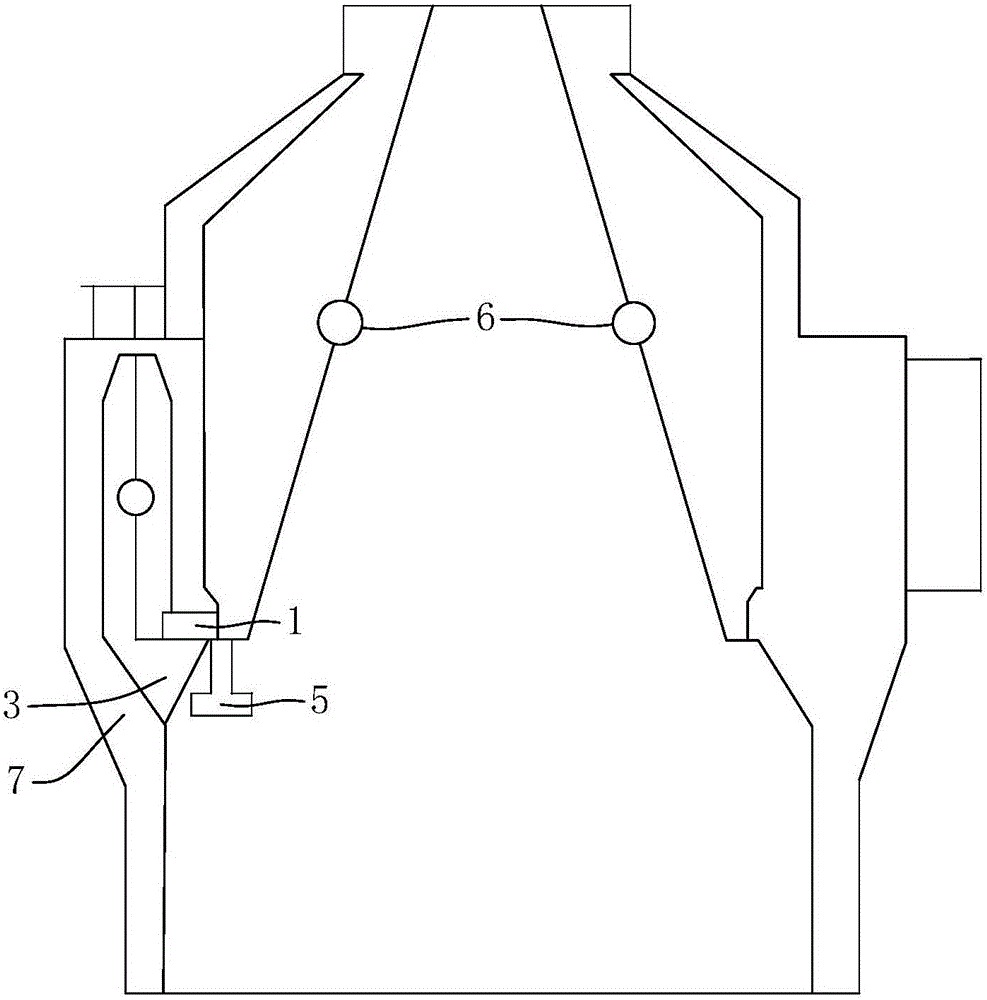

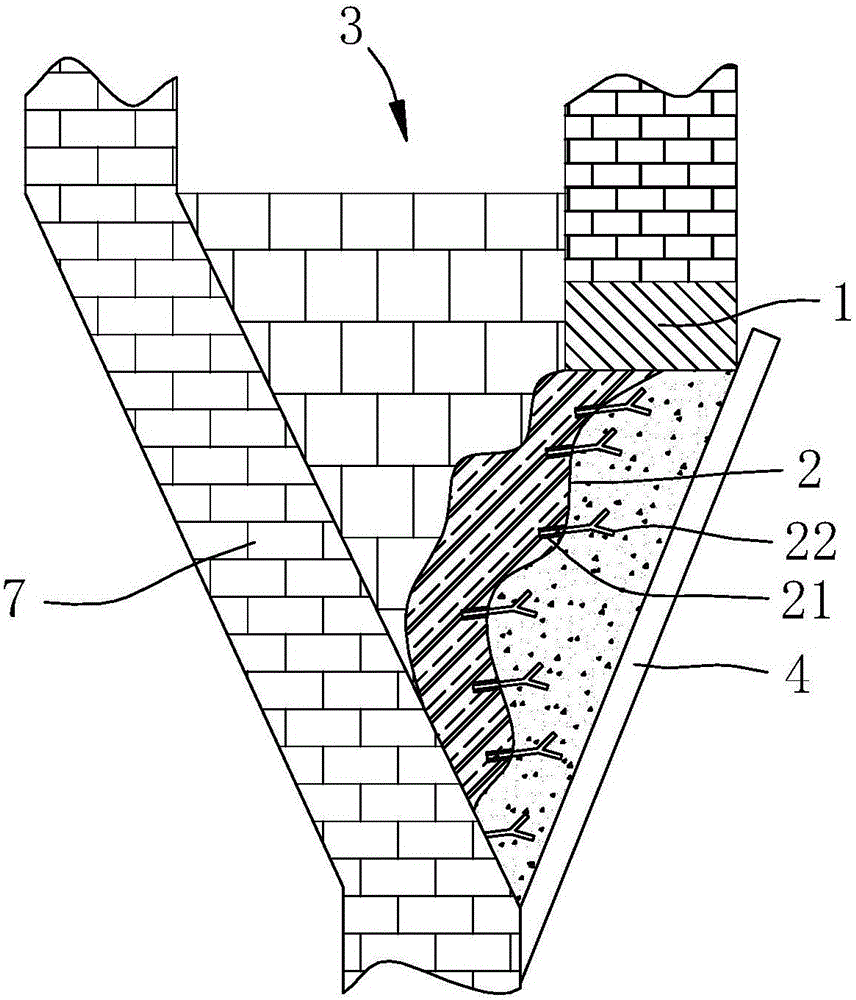

[0024] a. After supporting the inner ring brick ring beam 1 of the CDQ coke oven, remove the damaged corbel brick in the corbel 3 to be repaired; in this step, the inner ring brick ring beam 1 is usually supported by the steel column 5 and pulled by hand The gourd 6 lifts and fixes the steel column 5, so as to avoid the collapse of the inner ring brick after removing the damaged corbel brick, such as figure 1 As shown; the way of setting steel columns 5 is to set a plurality of steel columns 5 at the bottom of the inner ring brick ring beam 1 of the CDQ coke oven according to the predetermined interval along the circumferential direction of the CDQ coke oven, and the top of each steel column 5 is connected with the corbel 3 The top of each steel column 5 is flush with each other, and each s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com