Patents

Literature

234results about How to "Guarantee production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

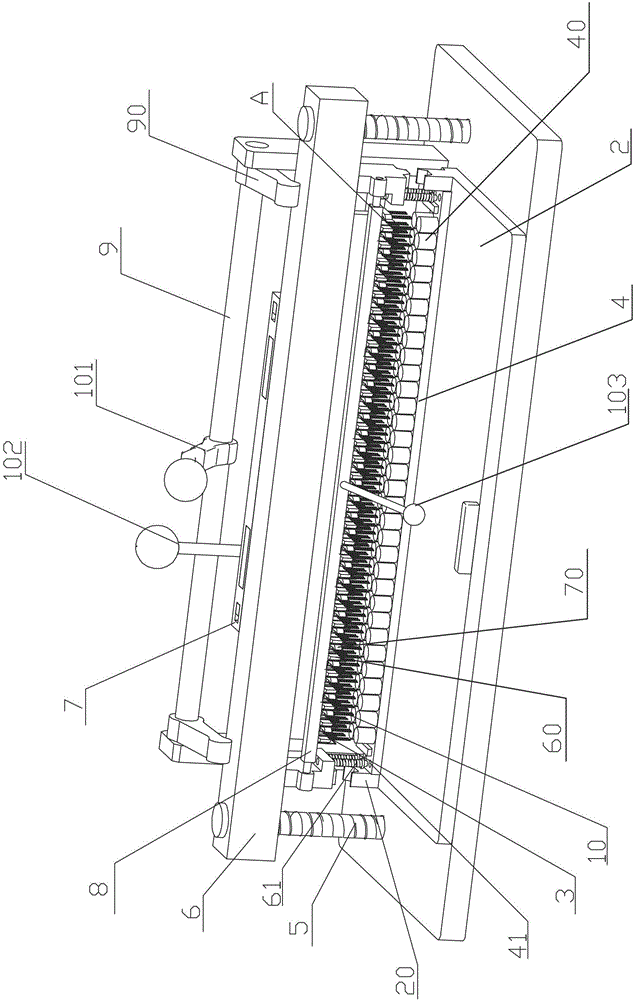

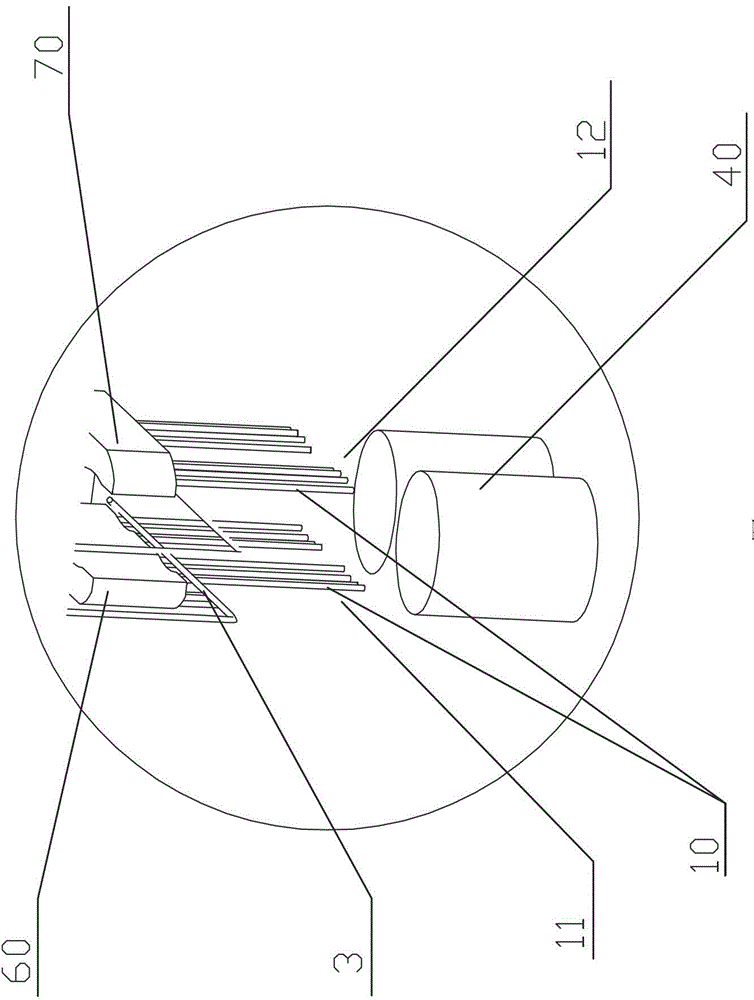

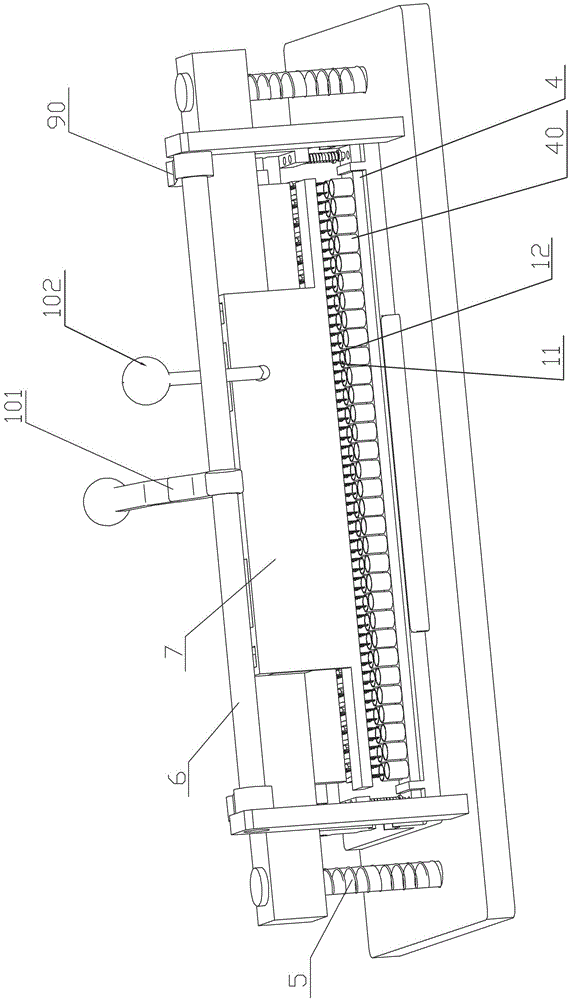

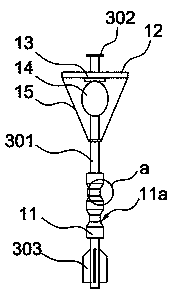

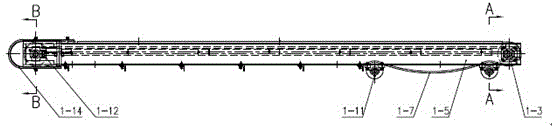

Dart carded felt guillotine

ActiveCN101250806AExtended service lifeReduce usageSevering textilesMetal working apparatusEngineeringMechanical engineering

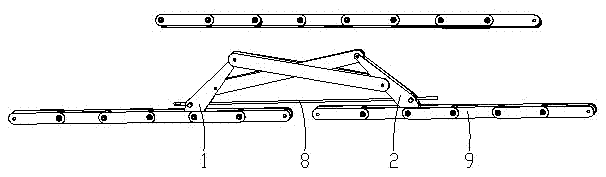

Disclosed is a needled felt cutting machine belonging to the technical field of non-woven machineries, which comprises a cutting table which is provided with a hob cutter groove, a cutting mechanism which comprises a hob cutter motor, a hob cutter motor seat and a hob cutter and a traction mechanism which is fixed on the cutting table, wherein the hob cutter motor is fixed on the hob cutter motor seat which is glidingly matched on the traction mechanism, the hob cutter is fixed on a power take-off shaft of the hob cutter motor and is corresponded with the hob cutter groove, and cutting edges of the hob cutter are made of a plurality of straight flange cutting edges and a plurality of circular cutting edges in alternate spreading with each other. The needled felt cutting machine has the advantages of representing intermittent suspension process when the hob cutter cuts the needled felt, thereby being unable to arose heating and insuring that a cut is not deformed and charred, not only saving numerous operations for exchanging the hob cutter every day and the numbers of usage of the hob cutters, but also guaranteeing productive efficiency, and being capable of increasing operating life of the hob cutter and improving the cut quality of the needled felt.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

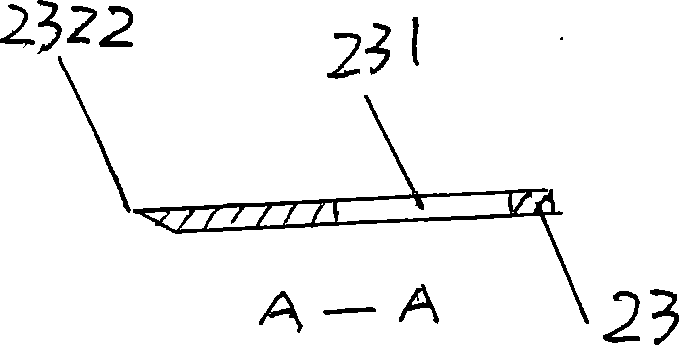

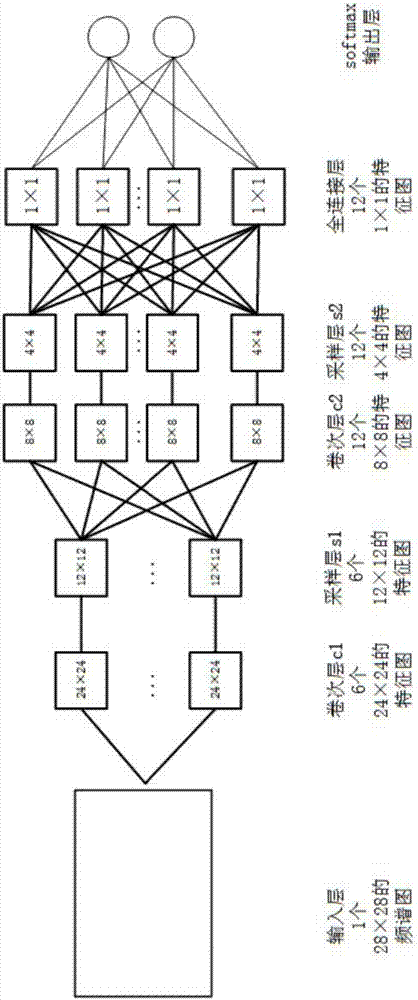

Industrial equipment fault prediction method based on deep learning

ActiveCN107238507AExtend your lifeGuarantee production efficiencyElectrical testingCharacter and pattern recognitionSensing dataFrequency spectrum

The invention relates to an industrial equipment fault prediction method based on deep learning. The method includes the following steps: S1. industrial equipment sensing data are collected through a sensor; S2. a spectrogram is obtained according to timing sequence waves of the sensing data within fixed time; and S3. a deep learning algorithm performs fault prediction on industrial equipment according to the spectrogram. The industrial equipment fault prediction method based on deep learning first collects the industrial equipment sensing data through the sensor, then obtains the spectrogram according to the timing sequence waves of the sensing data within fixed time, and finally adopts the deep learning algorithm based on a convolutional neural network framework to perform fault prediction on the industrial equipment according to the spectrogram, thereby accurately predicting whether the industrial equipment has a fault, greatly prolonging the life of the industrial equipment, preventing a series consequence from being caused by an uncertain fault in industrial production, and maximally guaranteeing production benefits of an enterprise.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

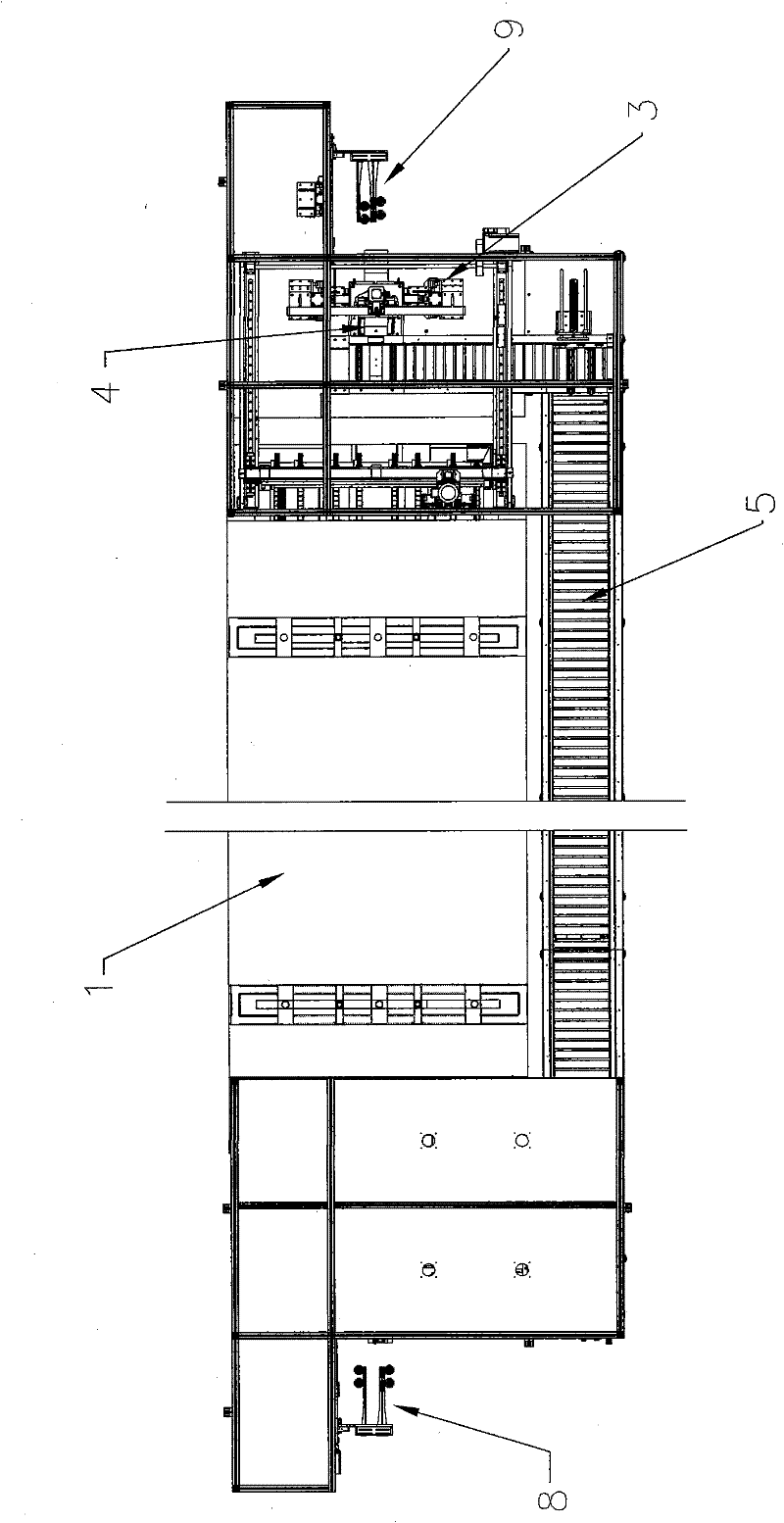

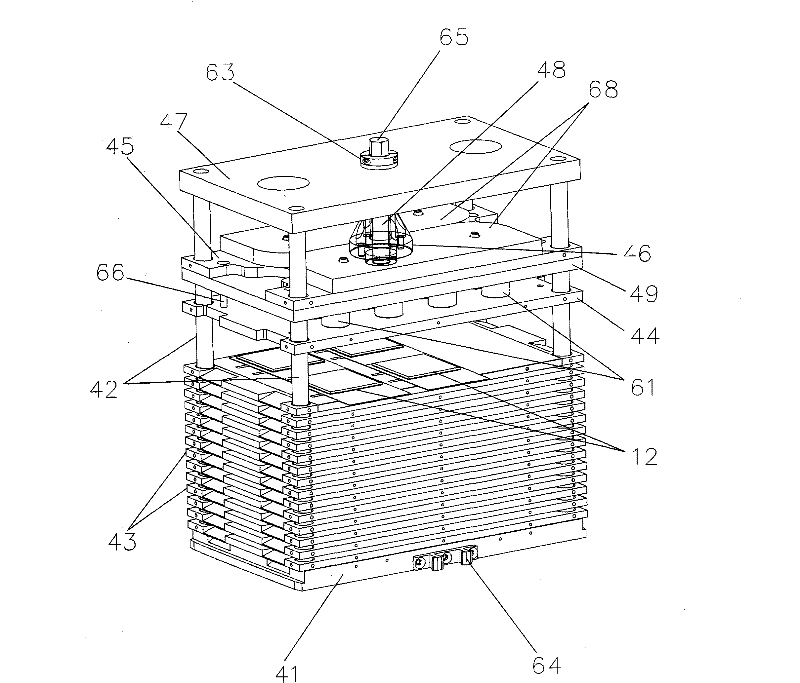

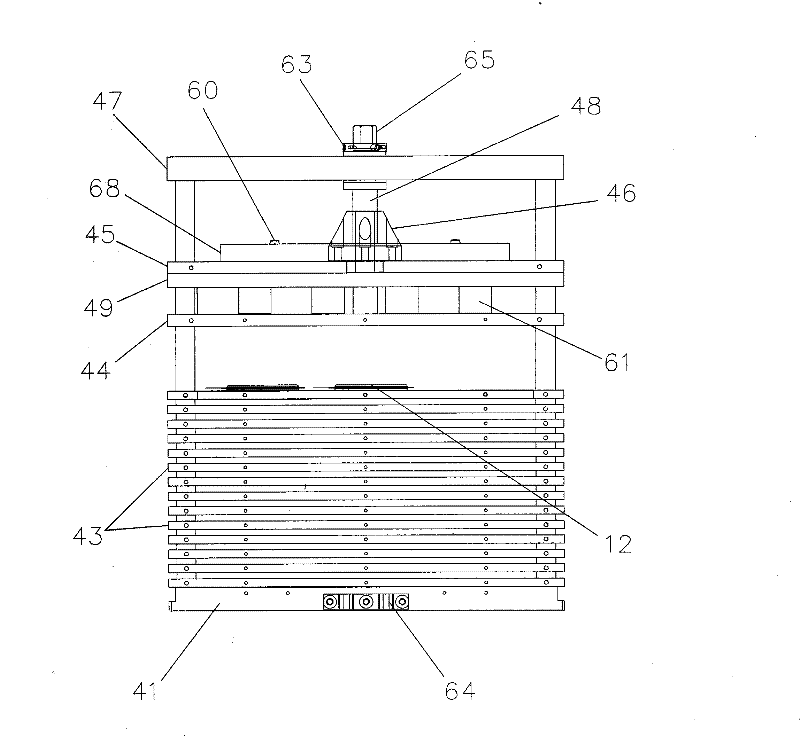

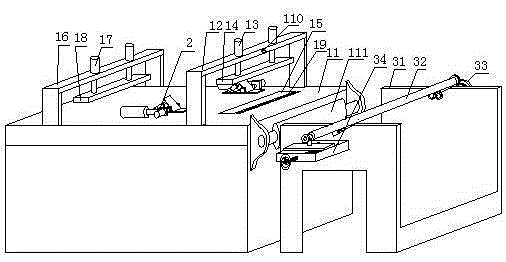

Automatic baking equipment of lithium battery

ActiveCN102340032AQuality assuranceIncrease productivityProgramme-controlled manipulatorFinal product manufactureAutomatic test equipmentEngineering

The invention relates to the technical field of lithium battery production equipment, and in particular relates to automatic baking equipment of a lithium battery. The baking equipment comprises a tunnel furnace and an automatic baking fixture device as well as a carrying mechanical arm, wherein the left and right sides of the tunnel furnace are respectively provided with a material loading mechanical arm and a material unloading mechanical arm; the automatic baking fixture device can move along the tunnel furnace; and the front of the tunnel furnace is provided with a roller recovery line. The automatic baking equipment can improve degree of automation, production efficiency and yield effectively, ensures product quality, and reduces labor intensity and production cost at the same time.

Owner:池州市骏智机电科技有限公司

Method for detecting raw silks of fresh cocoons by using color photometer

InactiveCN103115873AGuarantee production efficiencyAccurate Raw Silk QualityColor/spectral properties measurementsWhiteboardControl system

The invention relates to a method for detecting the whiteness of raw silks, and in particular relates to a method for judging the types of raw silks of fresh cocoons and raw silks of dried cocoons, and identifying the type differences of raw silks. The invention discloses a method for detecting raw silks of fresh cocoons by using a color photometer, which comprises the following specific steps: connecting a spectro-color photometer with a computer, starting a switch of the color photometer, setting a standard light source, opening a color quality control system, carrying out zero correction and whiteboard correction, and establishing data storage files and the like. According to the invention, by using the characteristics of color difference among different raw silks, the exponential value of whiteness is measured by using a spectro-color photometer, and according to a rule that the exponential value of whiteness of raw silks of fresh cocoons is greater than the exponential value of whiteness of raw silks of dried cocoons, the dried and fresh types of raw silks are judged. The method disclosed by the invention has the advantages that the method is rapid, accurate and convenient and the like, facilitates the accurate grasping of quality of raw silks, and ensures the quality of products and the production efficiency of silk articles.

Owner:ZHEJIANG UNIV

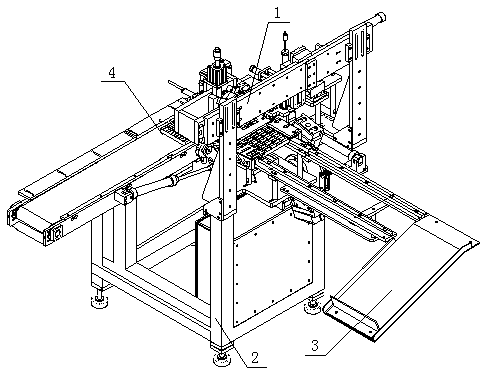

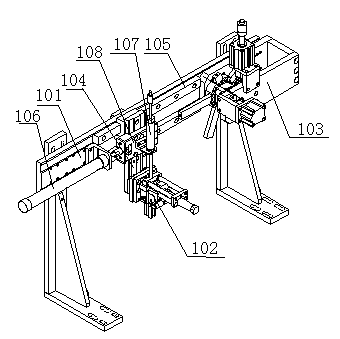

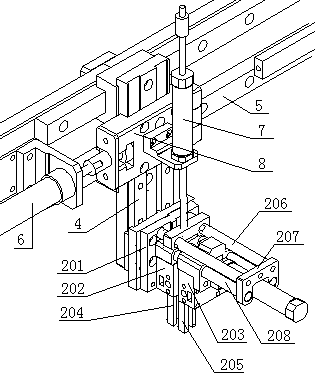

Automatic receiving device of lighter steam boxes

The invention provides an automatic receiving device of lighter steam boxes. The automatic receiving device comprises a machine frame, a discharging device, an inserting plate moving device and a plate receiving hopper, wherein the discharging device is used for moving the lighter steam boxes and enabling the lighter steam boxes to be filled in an inserting plate, the inserting plate moving device is used for conveying the inserting plate and locating the inserting plate, and the plate receiving hopper is used for collecting the inserting plate. The discharging device and the inserting plate moving device are both fixed on the machine frame, the discharging device is arranged above the inserting plate moving device, and the plate receiving hopper is arranged on the end portion of the inserting plate moving device. The automatic receiving device can achieve successive conveying of the inserting plate through the arranged inserting plate moving device, the lighter steam boxes can be automatically and accurately inserted into the inserting plate in sequence through movement of an infrared sensor, movement of the inserting plate, and the discharging device, the lighter steam boxes can be successively filled in the inserting plate, and the inserting plate is then pushed to a position of the inserting plate which collects the lighter steam boxes and is filled with the lighter steam boxes. The whole production process is full automatic, and free of people operation, facilitates production and use, and effectively improves production efficiency.

Owner:LANGXI DONGHAI PHOTOELECTRIC TECH

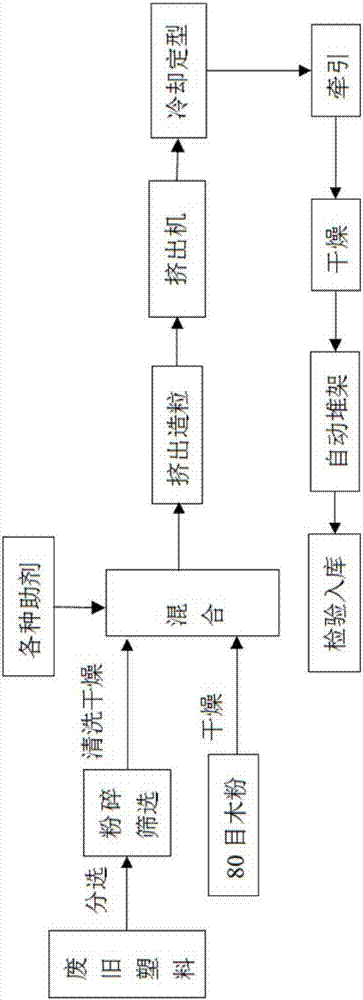

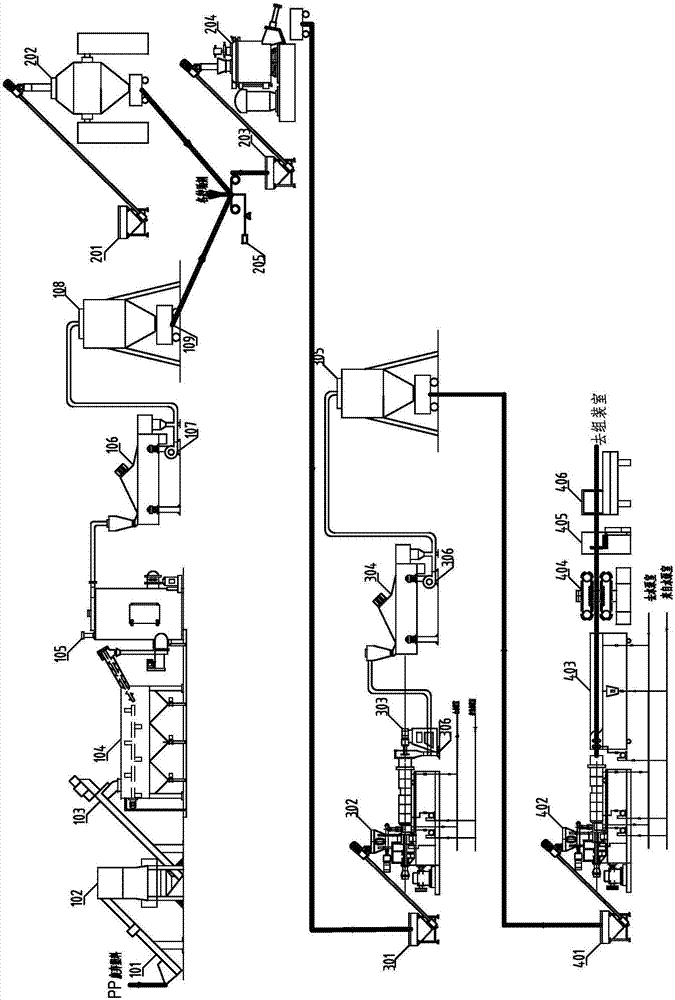

Formulation of wood-plastic profile as well as preparation method and manufacturing device thereof

InactiveCN107189216AImprove impact performance at room temperatureHigh low temperature impact resistanceHeat resistanceAntioxidant

The invention particularly relates to a formulation of wood-plastic profile as well as a preparation method and a manufacturing device thereof. The formula is characterized by being prepared from the following raw materials in parts: 100 parts of PP waste plastic with good mobility, 20 to 75 parts of wood powder, 5 to 15 parts of flexibilizer; 2 to 10 parts of compatibilizer; 1 to 10 parts of lubricant; 0.1 to 1 part of main antioxidant; 0.1 to 0.5 part of auxiliary antioxidant; 0.02 to 0.5 part of light stabilizer and 0.1 to 4 parts of antibacterial agents; the preparation method is characterized by comprising the following steps:(1) recycling the PP waste plastic with good mobility; (2) cleaning, crushing and drying; 3) drying the wood powder; 4) extruding and granulating; and 5) extruding and molding; and the manufacturing device is characterized by comprising a plastic cleaning device, a wood powder drying device, a weighing device, a mixing device, an extrusion granulation device and an extrusion molding device. The invention has the advantages of low cost, durability, long life, good heat resistance, good resistance to ultraviolet rays, high hardness and high load capacity.

Owner:YANTAI UNIV

Industrialized production method for glutinous rice dumplings

ActiveCN103416679AKeep the flavorSolve the complicated processFood preparationBiotechnologyCastanopsis sclerophylla

The invention discloses an industrialized production method for glutinous rice dumplings. The method comprises the following steps: using raw materials including pork belly, bone and tenderloin flesh, washing and slabbing the pork belly, washing and boiling the bone in boiling water, and mincing the tenderloin flesh; using vegetables including champignon, dried shrimps (dried oyster or egg yolk), and Chinese chestnut (peanut, lotus seed, red bean, henry steudnera tuber, bamboo shoot or the like), and washing and soaking; washing and soaking glutinous rice, and draining for use; soaking, cleaning, and boiling zongzi leaves for further using after cooling; stewing the bone to obtain bone soup; taking out the pork belly, vegetables and bone soup for stewing to obtain stewed meat and stewed soup; frying the tenderloin flesh to fry out lard oil, adding shallots for stir-frying again, fishing up the shallots and the oil residue in a boiler, and adding glutinous rice and the stewed soup for frying; packing the glutinous rice, the stewed meat and glutinous rice in the zongzi leaves, cooking and taking out for cooling; and performing vacuum packing, and high-pressure sterilization. Due to the adoption of the method, the industrialized production for the glutinous rice dumplings is realized.

Owner:XIAMEN YINXIANG GROUP

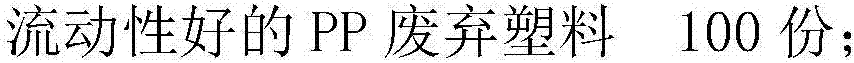

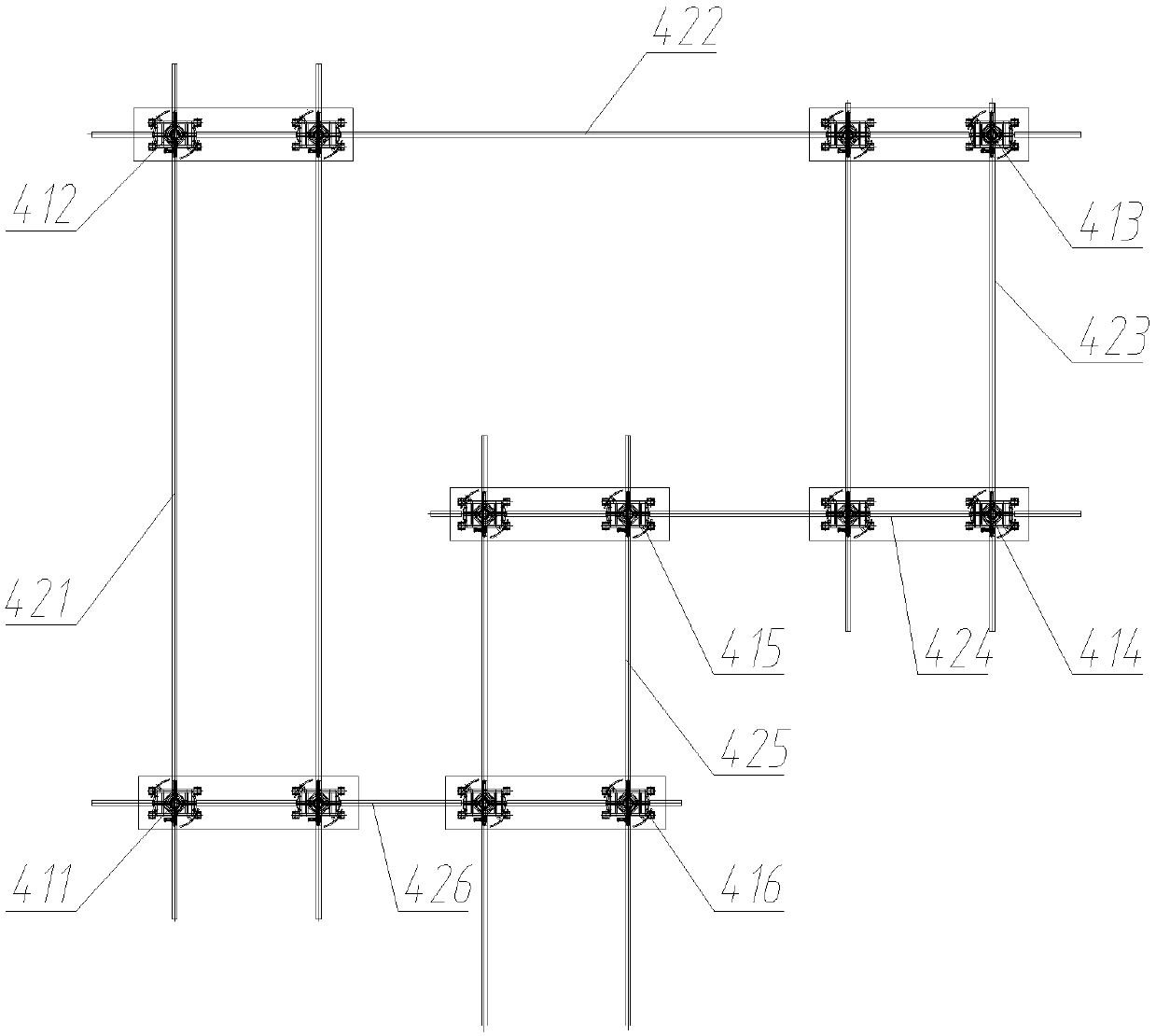

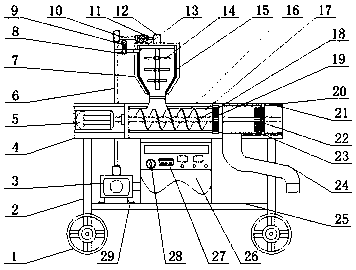

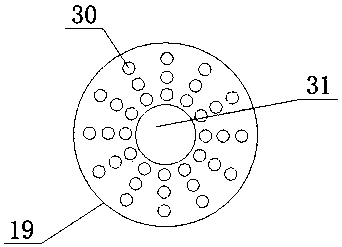

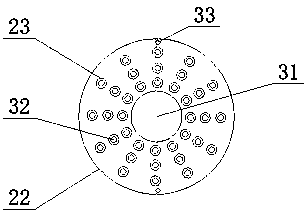

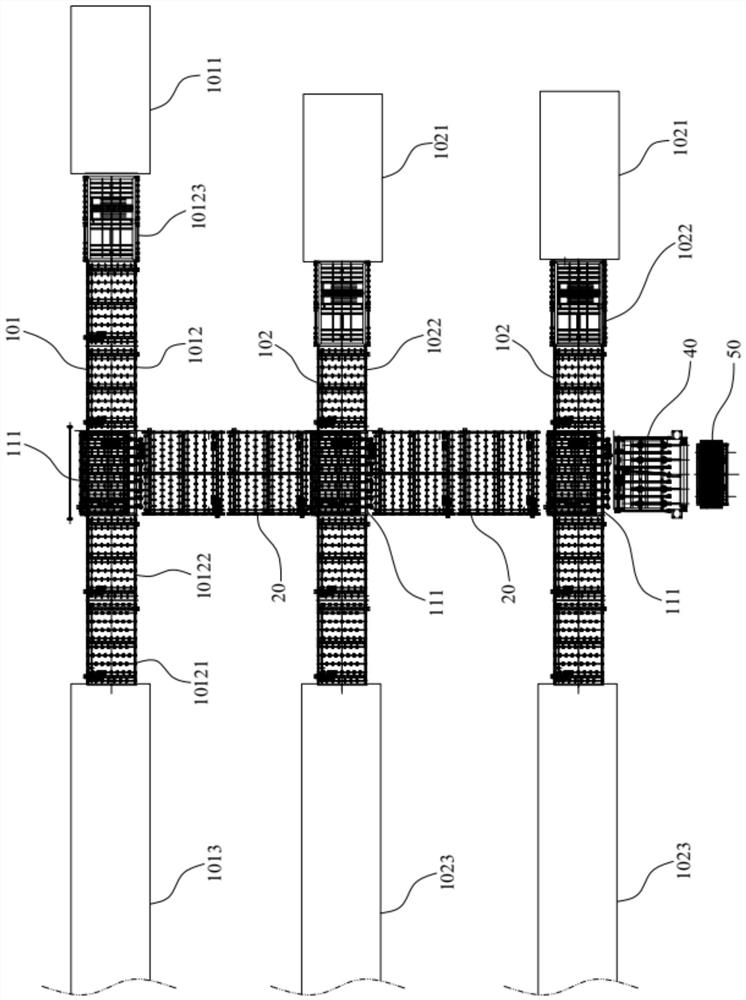

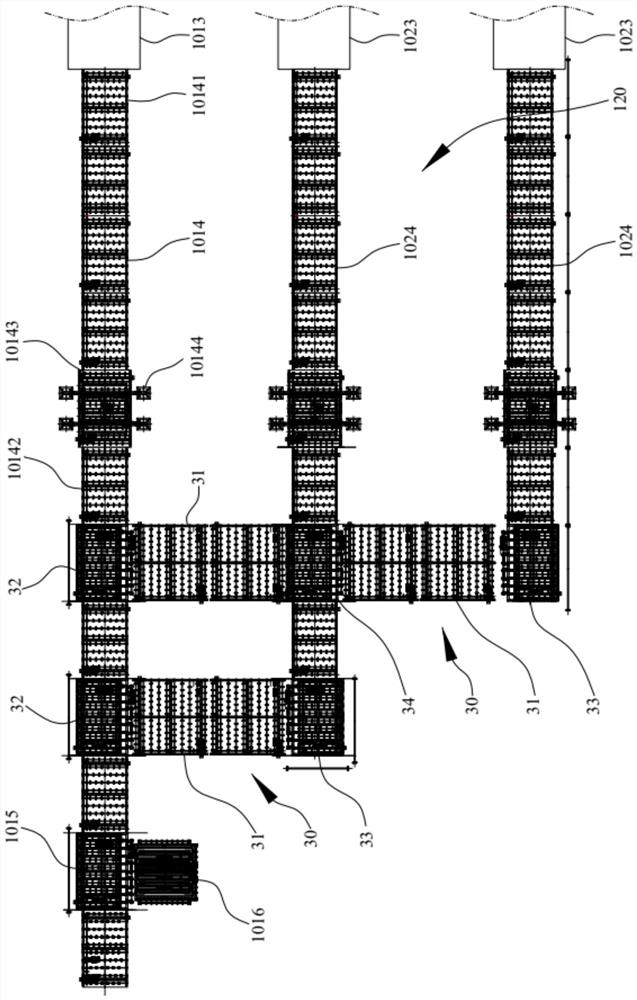

Closed-loop hot galvanizing production line and control method

ActiveCN107557708ARealize secondary cleaningReduce surface quality defectsHot-dipping/immersion processesDirt cleaningProduction lineProcess engineering

The invention discloses a closed-loop hot galvanizing production line and a control method. The closed-loop hot galvanizing production line comprises a preplating device (1), a galvanizing device (2),a postplating device (3), a travelling rail unit and an electronic control unit. The device (1) used before galvanizing comprises a degreasing pool (12), a water washing pool I (13), a zinc removal pool (14), an acid cleaning pool (15), a reduction pool (16), a water washing pool II (17), a spraying pool (18), an addition agent pool (19) and a drying chamber (110), wherein the degreasing pool (12), the water washing pool I (13), the zinc removal pool (14), the acid cleaning pool (15), the reduction pool (16), the water washing pool II (17), the spraying pool (18), the addition agent pool (19)and the drying chamber (110) are connected with the interior of a chamber (11) used before galvanizing in sequence. The postplating device (3) and the galvanizing device (2) are perpendicularly arranged. The travelling rail unit comprises a travelling rail device (4) and a travelling rail electronic control circuit, wherein the travelling rail device (4) is located above the preplating device (1), the galvanizing device (2) and the postplating device (3). By the adoption of the closed-loop hot galvanizing production line and the control method, the content of iron entering the hot galvanizingworking procedure can be effectively reduced, the waste of liquid zinc is reduced, the frequency of treatment of dangerous waste iron mud is reduced, the purpose that the surface quality of a galvanized part is better is achieved, and the production efficiency is improved.

Owner:徐州瑞马智能技术有限公司

Cryoprotectant applied to facility vegetables and preparation method thereof

InactiveCN101589713ALoss Prevention and MitigationEasy to makeBiocidePlant growth regulatorsPolyethylene glycolDistilled water

The invention discloses a cryoprotectant applied to facility vegetables and a preparation method thereof. The cryoprotectant consists of the following components in portion by weight: 1 to 2.5 portions of glucose, 0.03 to 2 portions of polyethylene glycol, and 95.5 to 98.97 portions of distilled water. The preparation method comprises the following steps: taking proper quantities of glucose powder, the polyethylene glycol and the distilled water in proportion; dissolving the glucose and the polyethylene glycol into 10 portions of the distilled water respectively for dilution first; after mixing together, adding the rest distilled water; and mixing the mixture evenly, and standing the product at a temperature of 25 DEG C for 1 hour for use. The vegetable cryoprotectant has the advantages of simple preparation, convenient use, labor and time conservation, low cost and obvious effect; and the raw material components not only are the cryoprotectant but also are nutrient substances for the vegetables, have no toxic hazard to the vegetables and no safety threat to human bodies, and are wide applicable to the production of the facility vegetables in north China. The cryoprotectant can prevent and slow down the loss of the vegetables caused by the low temperature and guarantee the production benefit and the stable income for vegetable growers.

Owner:VEGETABELE INST AGRI SCI ACAD SHANXI PROV

Feed particle-producing machine used for agricultural machinery

InactiveCN107625185AIncrease production capacityUniform moisture contentFeeding-stuffAgricultural engineeringHigh pressure water

The invention discloses a feed particle-producing machine used for agricultural machinery. The machine includes a housing body, a screw-shaft motor, a first extrusion hole and a second extrusion hole.A hopper is arranged on the upper side of the housing body. A support column is arranged under the left end of the housing body. A wheel is arranged under the support column. A high-pressure water pump is arranged on the right side of the support column. A water tank is arranged on the right side of the high-pressure water pump. A power switch is arranged on the upper left end of the water tank.A plurality of improvements are made in the prior feed particle-producing machines. Through the arrangement of the water tank, the water pump, a flow meter and a heater, feed particles of different sizes can be produced by the machine. Feeding water into a feed inlet and performing heating can endow feed with uniform water content and a moderate aging degree and can kill other pathogens like parasites in the feed so as to avoid the feed with excessively high or excessively low water content causing the produced feed particles with excessively more powder which cause extrusion hole blockage andinconvenient transportation and storage.

Owner:白皓

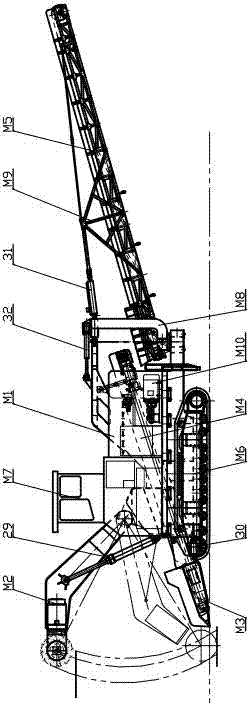

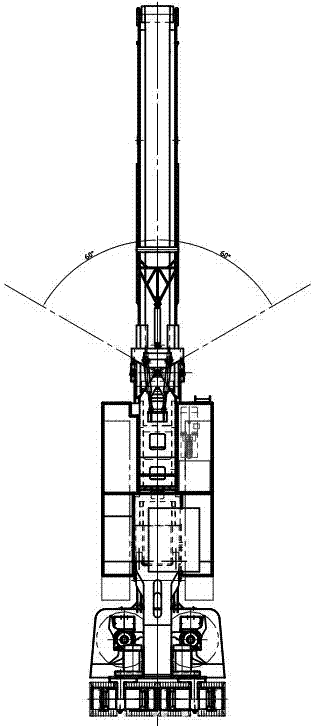

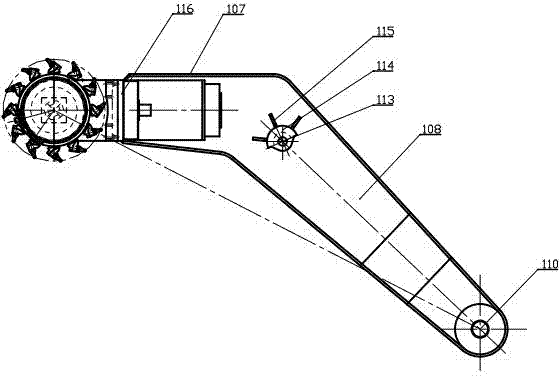

Roll-cutting type continuous mining machine

InactiveCN103775087AReasonable designImprove work efficiencyOpen-pit miningHydraulic motorVehicle frame

A roll-cutting type continuous mining machine comprises a car frame body, a cutting mechanism, a star wheel type loading mechanism, a scraper conveyor, a belt conveyer, an operating arm lifting oil cylinder, a belt conveyer rotary oil cylinder, a belt conveyer lifting oil cylinder, a hydraulic control system, a power supply system and a PLC (Program Logic Controller) control system, wherein the car frame body is equipped with a travel pedrail assembly and a cab, and the travel pedrail assembly comprises a left travel motor and a right travel motor; the scraper conveyor is obliquely mounted, the rear end of the scraper conveyor is hinged onto the car frame body, and a drive roller of the scraper conveyor is driven by a scraper hydraulic motor; the star wheel type loading mechanism is mounted at the front end of the scraper conveyor; a shoveling plate lifting oil cylinder is arranged between the star wheel type loading mechanism and the car frame body; a star wheel of the star wheel type loading mechanism is driven by the star wheel hydraulic motor. The mining machine not only can achieve continuous operation of cutting and loading, and has the advantages of large mining area, high mining working efficiency, low fault rate, less dust in the mining process, long service life and the like.

Owner:FUJIAN TIANJUN IND

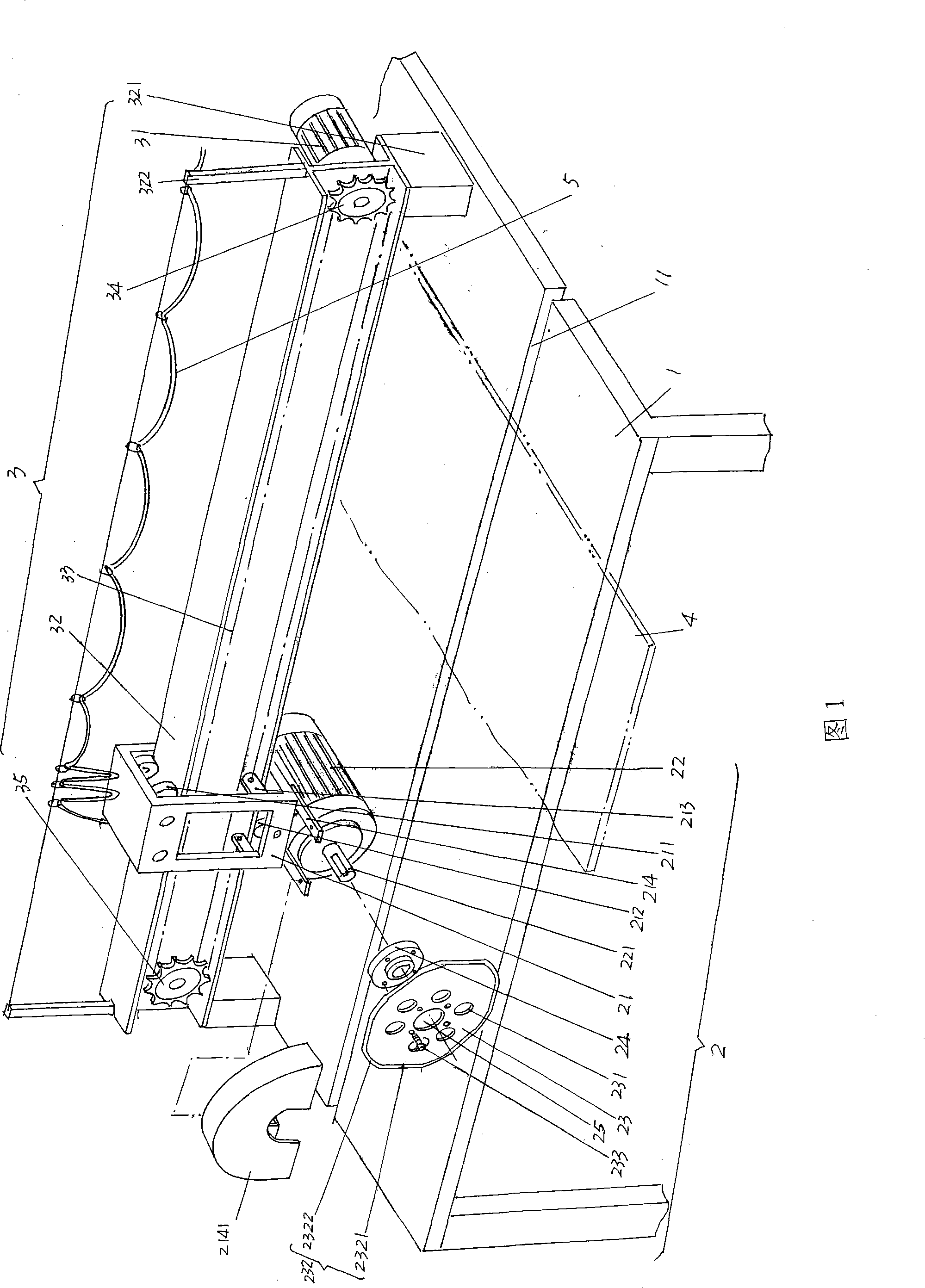

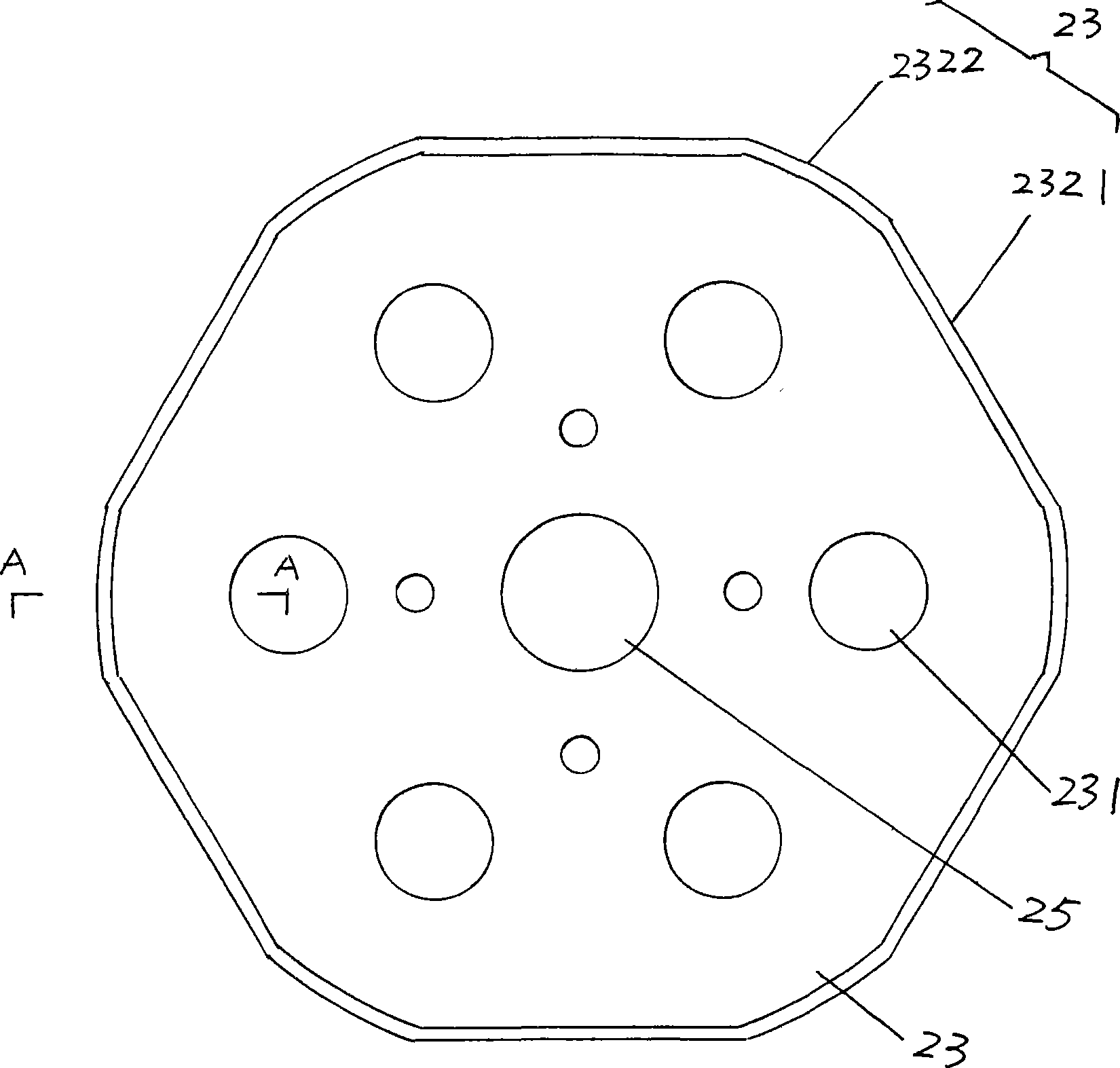

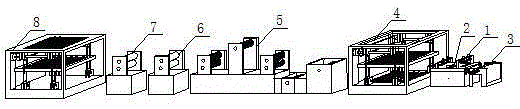

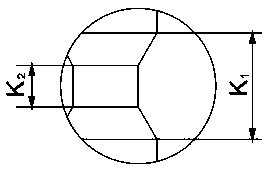

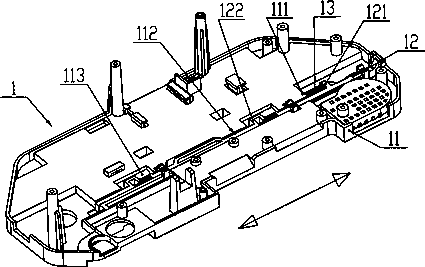

Dart carded felt guillotine

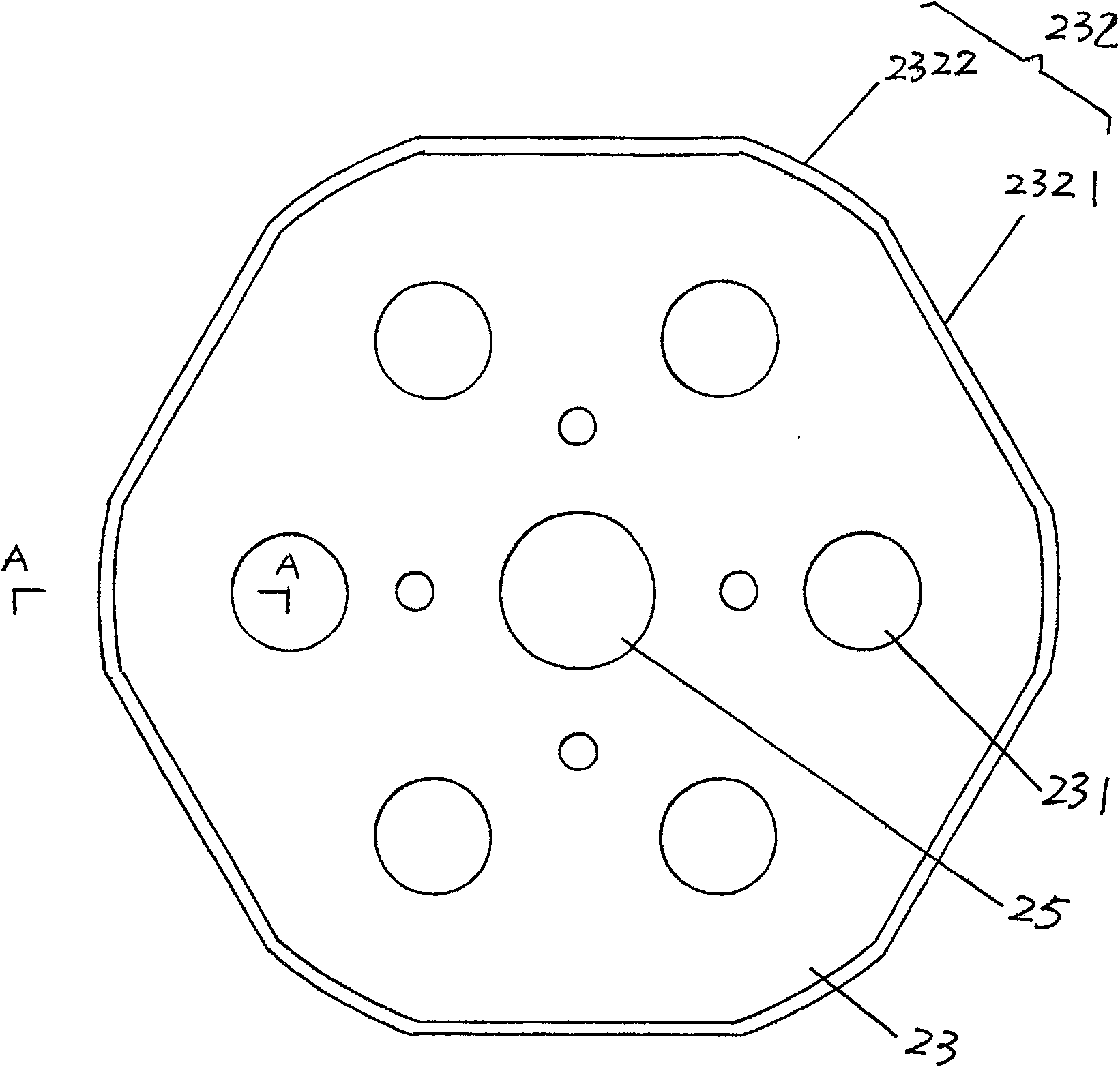

ActiveCN100587152CExtended service lifeReduce usageSevering textilesMetal working apparatusOperating lifeFlange

Disclosed is a needled felt cutting machine belonging to the technical field of non-woven machineries, which comprises a cutting table which is provided with a hob cutter groove, a cutting mechanism which comprises a hob cutter motor, a hob cutter motor seat and a hob cutter and a traction mechanism which is fixed on the cutting table, wherein the hob cutter motor is fixed on the hob cutter motorseat which is glidingly matched on the traction mechanism, the hob cutter is fixed on a power take-off shaft of the hob cutter motor and is corresponded with the hob cutter groove, and cutting edges of the hob cutter are made of a plurality of straight flange cutting edges and a plurality of circular cutting edges in alternate spreading with each other. The needled felt cutting machine has the advantages of representing intermittent suspension process when the hob cutter cuts the needled felt, thereby being unable to arose heating and insuring that a cut is not deformed and charred, not only saving numerous operations for exchanging the hob cutter every day and the numbers of usage of the hob cutters, but also guaranteeing productive efficiency, and being capable of increasing operating life of the hob cutter and improving the cut quality of the needled felt.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

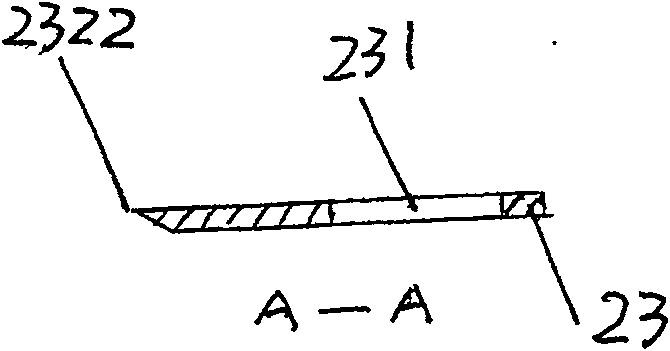

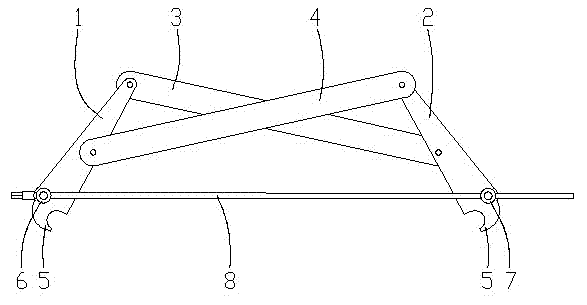

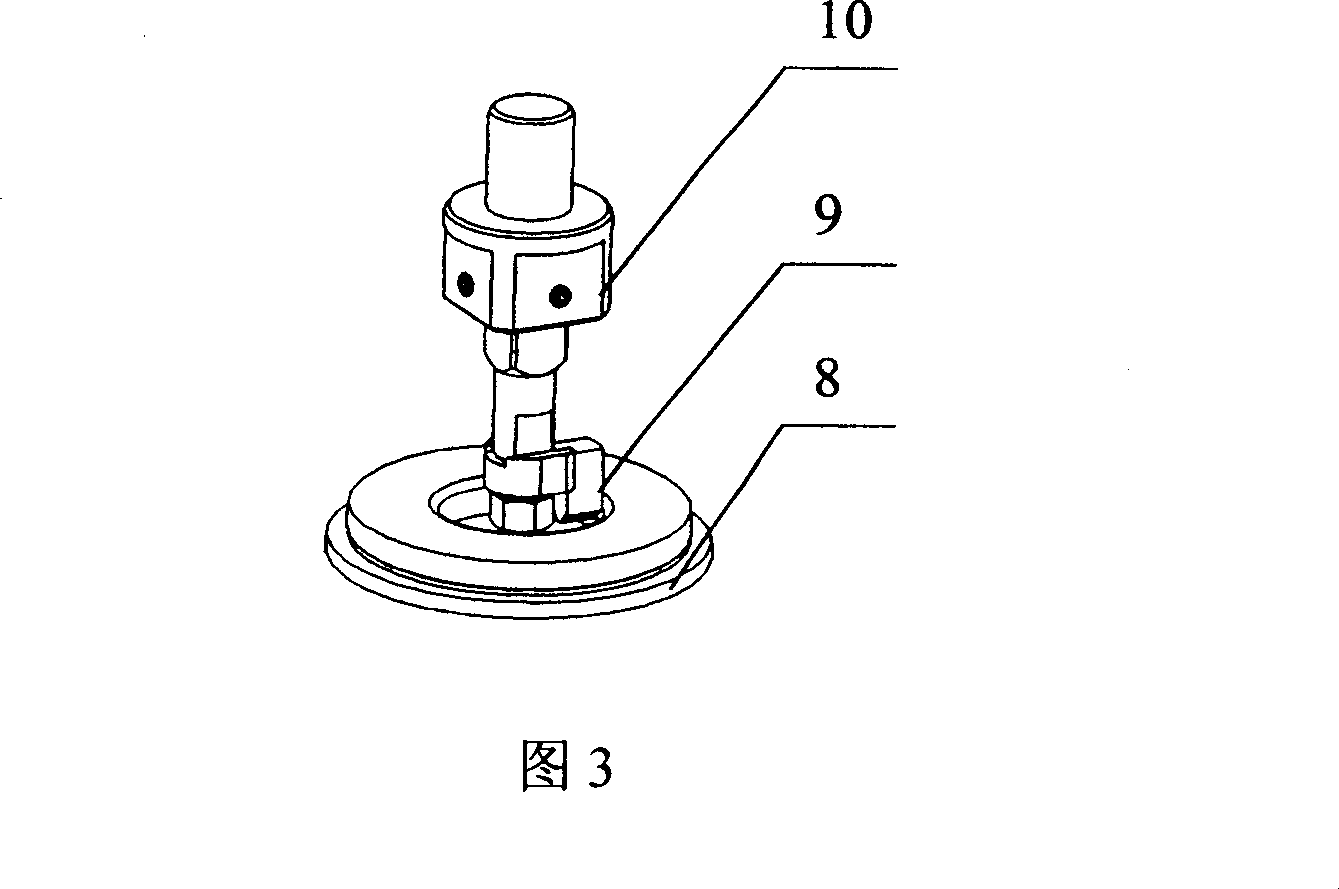

Chain Repair Device

The invention discloses a chain maintenance device. A first grapple (1) and a second grapple (2) are symmetrically arranged on the left and right, and crossed between the first grapple (1) and the second grapple (2). The first balance arm (3) and the second balance arm (4), the bottom ends of the first grapple (1) and the second grapple (2) are provided with a hook head (5), and one of the grapples The lower part of the hook is fixed with a bracket (6), and the lower part of the other grapple is fixed with a nut sleeve (7). The bracket (6) is rotatably connected to the tightening screw (8), and the tightening screw (8) can (6) Rotate on the spot, and the nut sleeve (7) is threadedly matched with the tightening screw rod (8). The invention has the advantages of simple structure, convenient operation and labor saving, which can facilitate the repair and maintenance of the drive chain of the plate chain production line, save the time for emergency repair of the chain, and provide guarantee for the normal progress of automobile production.

Owner:力帆科技(集团)股份有限公司

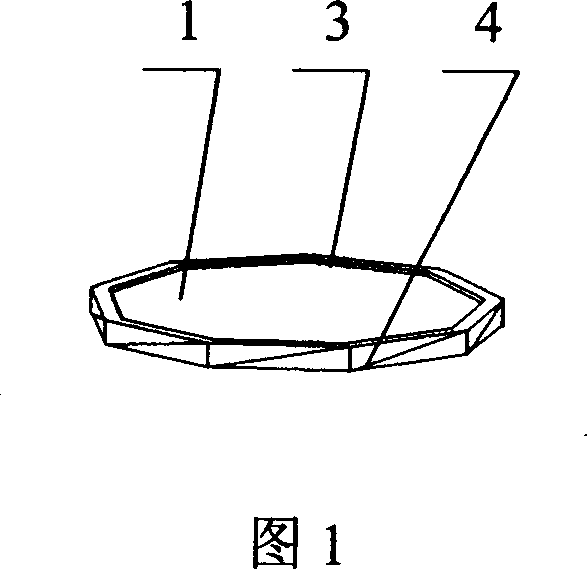

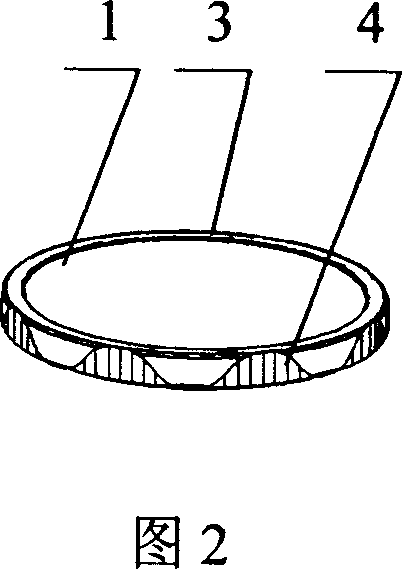

Coin with geometric pattern at edge and its preparing method

InactiveCN1943466AChange the status quoIncrease manufacturing difficultyCoinsEngineeringGeometric figure

The invention discloses a hard coin with edge part having geometric figure, characterized by side part of coin podium without said geometric figure, said figure height is same with coin thickness or thinner then thereto thickness; said coin is in the shape of circular, polygon or any there of; said geometric figure comprising shape of arc, ladder-shaped, triangular, hackle-shaped or mixture of them.

Owner:CHINA BANKNOTE PRINTING & MINTING

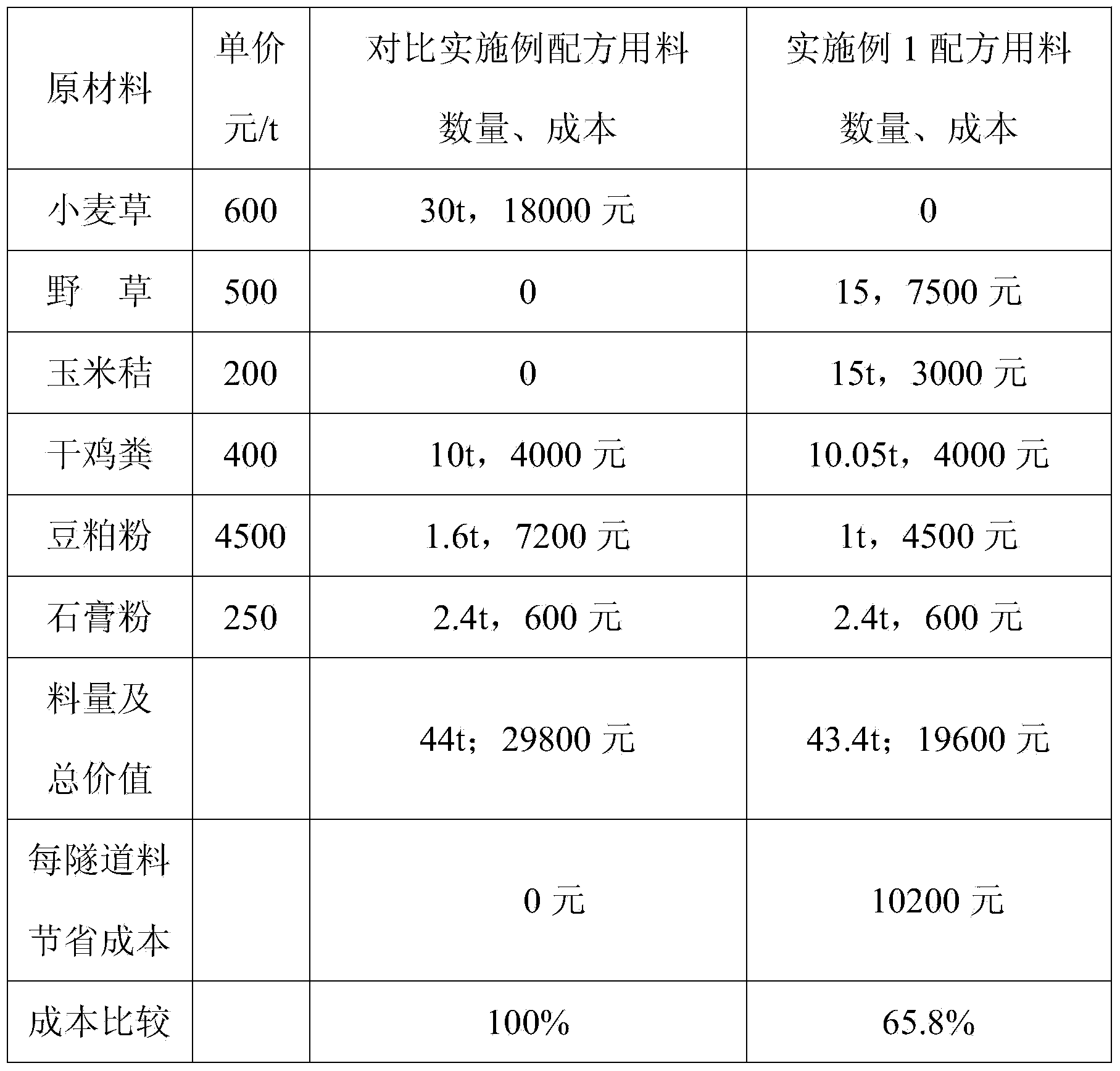

Agaricus bisporus culture medium material and preparation technology thereof

InactiveCN104250125AQuality improvementImprove production efficiencyBio-organic fraction processingOrganic fertiliser preparationDry weightPoultry manure

The invention discloses an agaricus bisporus culture medium material and a preparation technology thereof. The agaricus bisporus culture medium material is mainly composed of weed, corn stalks, livestock and poultry manure and gypsum according to the dry weight ratio of 0.5-1.5:0.5-1.5:0.3-1:0.1-0.2. Compared with the prior art, the main raw materials needed by the agaricus bisporus culture medium material are corn stalks and weed which are easy to obtain and low in cost, the compost quality is improved, the production benefit is substantially improved, and the agaricus bisporus culture medium material also guarantees the yield of agaricus bisporus.

Owner:承德润隆食品有限公司

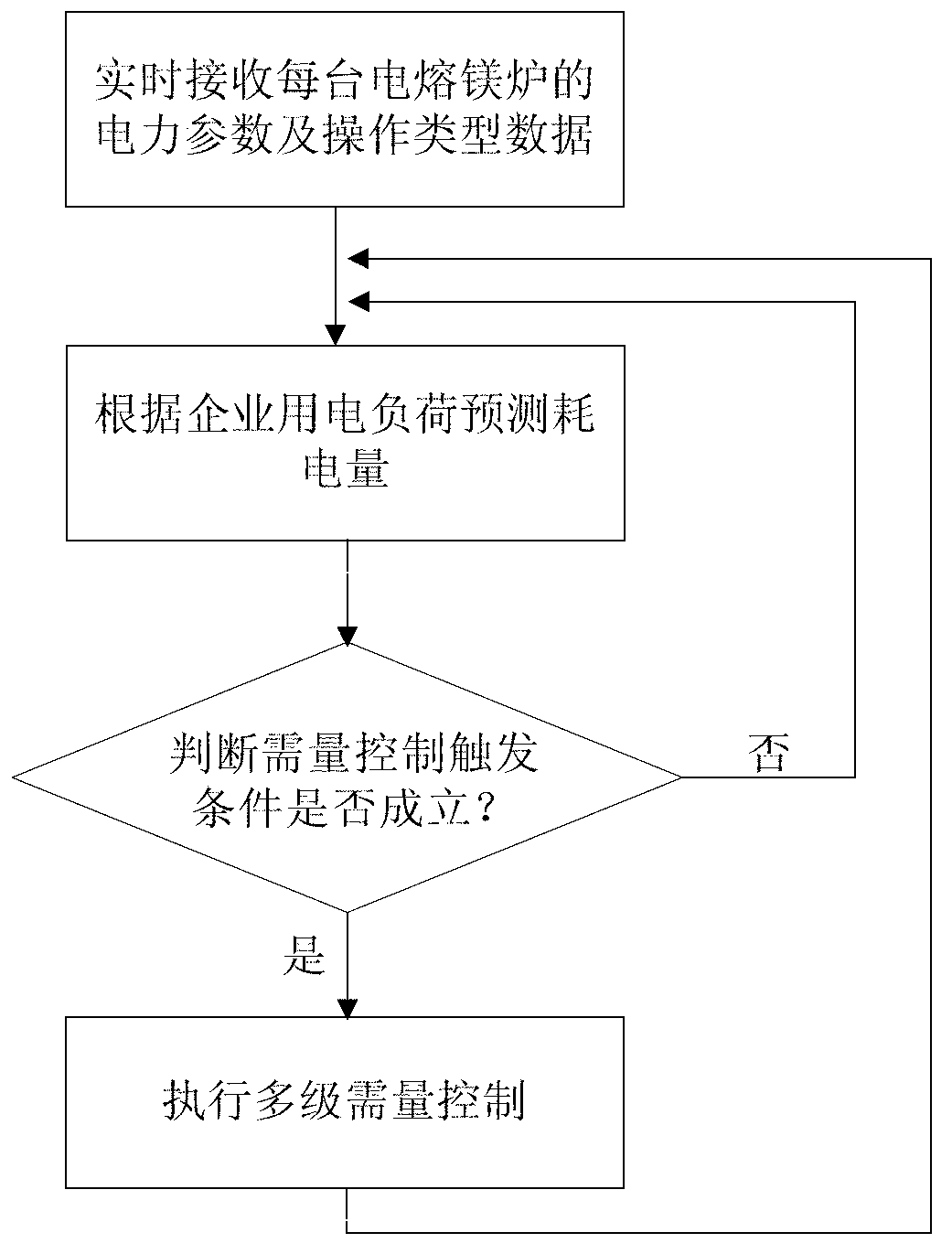

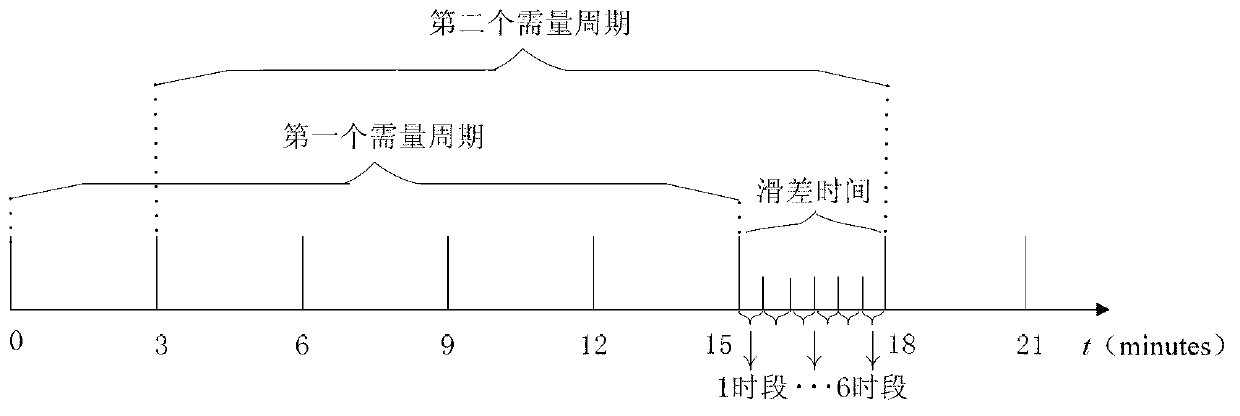

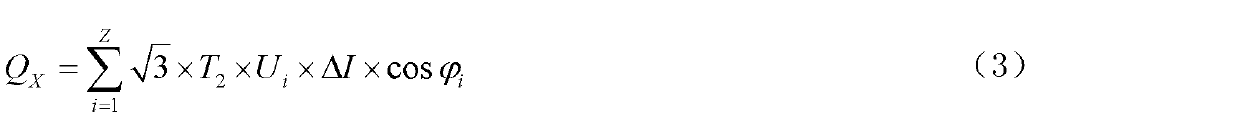

Fused magnesia smelting process multilevel demand control method

ActiveCN103135466AReduced demand control measuresEnsure safetyProgramme control in sequence/logic controllersElectricityProduction effect

The invention discloses a fused magnesia smelting process multilevel demand control method and belongs to the field of electricity utilization demand control. Electric parameters and operation types of all fused magnesia furnaces in a current smelting process are obtained, and power consumption is predicted according to current general electric loads of all the fused magnesia furnaces. Whether demand control trigger conditions are established or not is judged, and multilevel demand control is executed. When electric demand of the whole factory is predicted to exceed maximum demand limit, demand control measures are not taken immediately, and whether demand control can be achieved or not when the measures are taken again when delay goes on to a next time interval is judged, and therefore when prediction is not accurate, unnecessary control measures can be reduced. In addition, when demand control is performed, the measure affecting the fused magnesia smelting process to the lowest degree is chosen so as to ensure safety and production effect of the smelting process.

Owner:NORTHEASTERN UNIV LIAONING

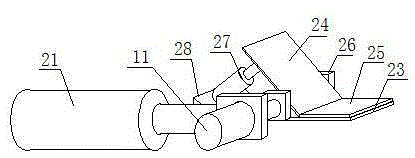

Anti-wrinkling laminating device for waterproof roll

InactiveCN105398172ASuitable temperatureRealize continuous feedingLamination ancillary operationsLaminationActivated carbonAsphalt

The invention provides an anti-wrinkling laminating device for a waterproof roll. The anti-wrinkling laminating device comprises a laminating assembly, an adhesive extruding assembly, a drying assembly and a waste gas recycling treatment assembly, wherein the adhesive extruding assembly is arranged at the discharging end of the laminating assembly, and the drying assembly is arranged at the discharging end of the adhesive extruding assembly; the laminating assembly comprises a laminating rack, an adhesive dipping tank, an adhesive dipping roller, a lower film guide roller, a lower film laminating assembly, an upper film guide roller and an upper film laminating assembly; the drying assembly comprises a drying rack, an electric heating upper drying roller and an electric heating lower drying roller; the waste gas recycling treatment assembly comprises a recycling pipeline, a cyclone separator, a condenser, a heat exchanger, a plasma processor, an activated carbon sponge filter and a discharge pipeline. The device is used for treating waste gas produced in production and then recycling the gas for cooling liquid asphalt in the production, so that the asphalt is at a more appropriate temperature and is more suitable for laminating operation, the wrinkling phenomenon after laminating is effectively avoided, and the processing quality can be guaranteed.

Owner:安徽五星凯虹防水建材科技有限公司

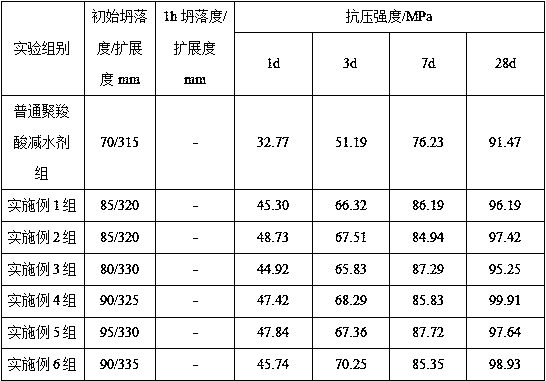

Early strength type polycarboxylic acid water reducing agent for C80 pipe pile concrete

The invention provides an early strength type polycarboxylic acid water reducing agent for C80 pipe pile concrete, wherein 1000 parts of the polycarboxylic acid water reducing agent are prepared fromthe following components by weight: 331-344 parts of a polyether macromonomer with a molecular weight of 3500-3800, 27-34 parts of acrylic acid, 4-10 parts of an amide-based small monomer, 4-10 partsof a rigid small monomer, 2-6 parts of 27.5% industrial-grade hydrogen peroxide, 2-5 parts of unsaturated sulfonate, 0.4-1.5 parts of a reducing agent, 1.8-2.4 parts of a chain transfer agent, 6-12 parts of a neutralizing agent, and the balance of water, wherein the prepared finished product has a mass fraction of 40%, and an acid-to-ether ratio is controlled at 4.3-4.8. According to the present invention, the water reducing agent molecule having the long main chain and the long branched chain is obtained by matching the amine ether macromonomer and the polyether macromonomer according to a mass ratio of 7:2, and the rigidity of the main chain can be strengthened by introducing the rigid small monomer, such that the main chain shape change caused by the too large steric hindrance of the side chain can be avoided, and the good anchoring effect of the water reducing agent molecule on the surface of the cement particles can be ensured.

Owner:HUBEI UNIV OF TECH

Larva clamping machine for mechanized production of royal jelly

The invention provides a larva clamping machine for the mechanized production of royal jelly. The larva clamping machine for the mechanized production of the royal jelly comprises larva clamping mechanisms, wherein the larva clamping mechanisms consist of left larva clamping components and right larva clamping components; the left larva clamping components and the right larva clamping components consist of multiple vertical steel wires respectively; the left larva clamping components or the right larva clamping components are movable larva clamping components which can move relative to the other party; and the larva clamping machine is also provided with movable larva poking components. According to the larva clamping machine for the mechanized production of the royal jelly, the steel wires are initially used as the larva clamping components; the larva clamping components clamp larvae like chopsticks with easiness in control and precision; the larva clamping components of the larva clamping machine have the advantages of flexibility and little royal jelly adhesion; when being clamped, the larvae are not hurt under the condition of certain flexibility, so that the quality of the royal jelly is guaranteed; when the steel wires are used as the larva clamping components, not only is little royal jelly adhered, but also the effect of a screen is realized; during the process of clamping the larvae, the adhered royal jelly leaks out from the larva clamping components; the royal jelly rarely exists between the larvae and the larva clamping components, so that the production benefits are guaranteed; the larva clamping machine is integrated with a larva clamping operation and a larva poking operation; and therefore, the larva clamping components adhere no larva, and the favorable continuous implementation of the mechanized production is guaranteed.

Owner:王俞兴 +2

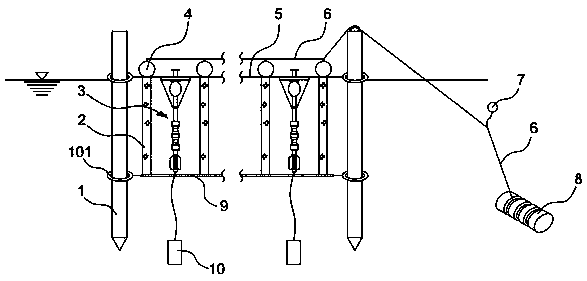

Steel pile type laver culture device in shallow water area

ActiveCN109042285APromote recoveryImprove stabilityCultivating equipmentsSeaweed cultivationEngineeringSeabed

The invention provides a steel pile type laver culture device in a shallow water area and belongs to the field of laver culture devices. The device includes steel piles uniformly distributed on a seabed, and each steel pile is sleeved with at least two floating rings; a culture net which is horizontally distributed is connected to the floating rings at the topmost ends of the steel piles, and suspension rods which are horizontally distributed are connected to the floating rings at the bottommost ends of the steel piles; net pieces and drying assemblies both of which are perpendicular to the culture net are uniformly distributed between the culture net and the suspension rods. By means of the device, the effect of thoroughly drying the laver is great, the stability of the device is high, the seedling drop rate is low, the growth rate of the laver during culture is calculated, and the manual work intensity can also be effectively reduced.

Owner:吴常文

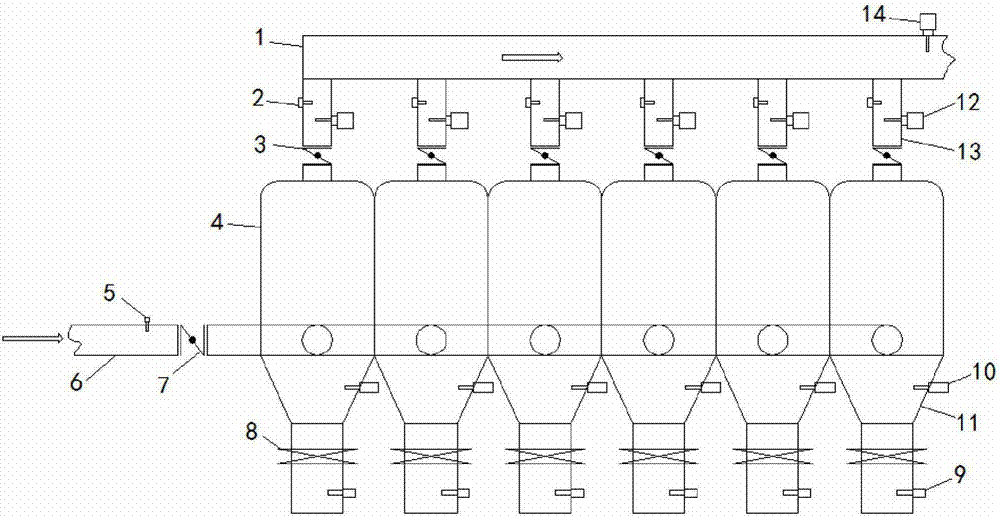

Online fault detection and protection method and system for bag type dust remover

The invention relates to an online fault detection and protection method and system for a bag type dust remover and belongs to the technical field of bag type dust removers. A main air inlet pipe is connected with a temperature instrument and an air inlet valve; a bin chamber exhaust pipe is connected with an anemometer, a leak detector and a bin chamber switching valve; a main air exhaust pipe is connected with a dust concentration meter and the bin chamber exhaust pipe; an ash hopper is connected with a material level switch and a bin chamber ash discharging valve; the lower part of the ash discharging valve is connected with a solid flow switch; and the upper part of the ash hopper is connected with a dust removal bin chamber. The method and system provided by the invention have the advantages that the operation state of a cloth bag is detected in real time, safe and efficient operation of the bag type dust remover can be effectively protected, daily operation maintenance effect and maintenance efficiency of the bag type dust remover are improved, the probability of halt caused by tiny faults of the bag type dust remover is reduced, and a positive effect is produced in the practical project application.

Owner:BMEI

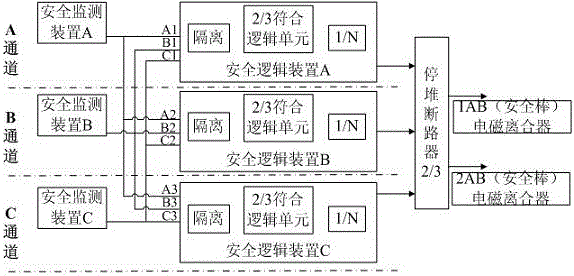

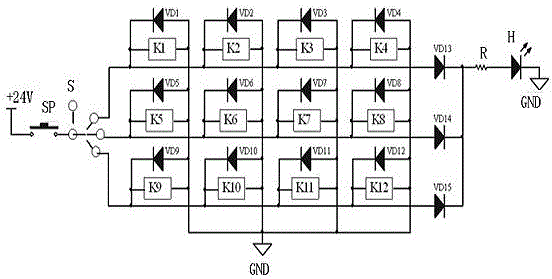

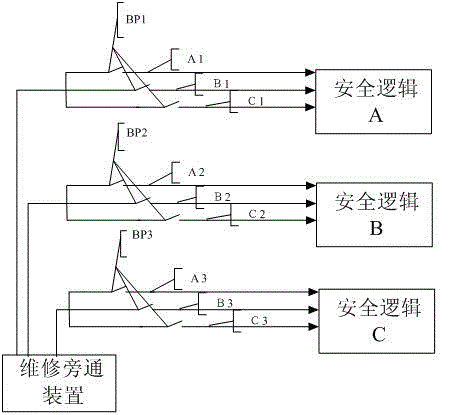

Reactor protection system two-out-of-three conforming maintenance bypass system

ActiveCN105788687AGuaranteed uptimeRealize online maintenancePower plant safety arrangementNuclear energy generationRotary switchControl engineering

The invention discloses a reactor protection system two-out-of-three conforming maintenance bypass system, comprising a reactor protection system and a 2 / 3 conforming logic bypass unit, wherein the 2 / 3 conforming logic bypass unit comprises a rotary switch S which is provided with four gear contactors and also comprises twelve relays which are all normally open relays. Every four relays of the twelve relays are seen as one group; input ends of input circuits of the four relays of the first group are all connected to first gear contactors, input ends of input circuits of the four relays of the second group are all connected to second gear contactors, and input ends of input circuits of the four relays of the third group are all connected to third gear contactors. According to the system, a bypass device is arranged between a safety monitoring device and a safety logic device so that the protection system maintenance bypass function is added. Device on-line maintenance and test can be achieved; non-planned reactor shutdown probability due to device fault is reduced; the performability of reactors is increased; and production efficiency is guaranteed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

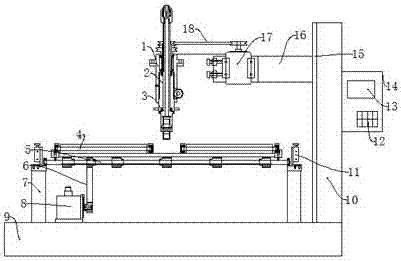

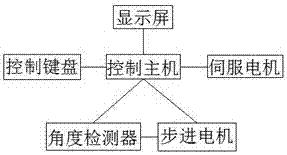

Multi-angle drilling device for motor production

InactiveCN107150134AGuarantee production efficiencyDrilling Operation GuaranteeAutomatic control devicesManufacturing dynamo-electric machinesAutomatic controlEngineering

The invention discloses a multi-angle drilling device for motor production, which includes a base, a fixing frame, a reinforcing plate and a control box, the fixing frame is arranged on the base, and an angle detector is arranged on the fixing frame , a stepper motor is arranged on the side of the fixed frame, a transmission gear pair is arranged at the end of the stepper motor, a rotating shaft is arranged at the end of the transmission gear pair, a clamp is arranged on the rotating shaft, and a clamp is arranged on the base The end is provided with the reinforcing plate. The beneficial effect is that the drilling device is provided with a feedback control loop composed of an angle detector, a control host and a stepping motor, which can automatically control the rotation angle of the fixture to a preset value, and then the drilling operation is performed by the cutter, which ensures that the device can be multi-functional. The drilling operation of the workpiece at an angle replaces the traditional production method of manually disassembling the workpiece to adjust the angle, which reduces the production steps and ensures the production efficiency of the motor.

Owner:荣成市志诚电机厂

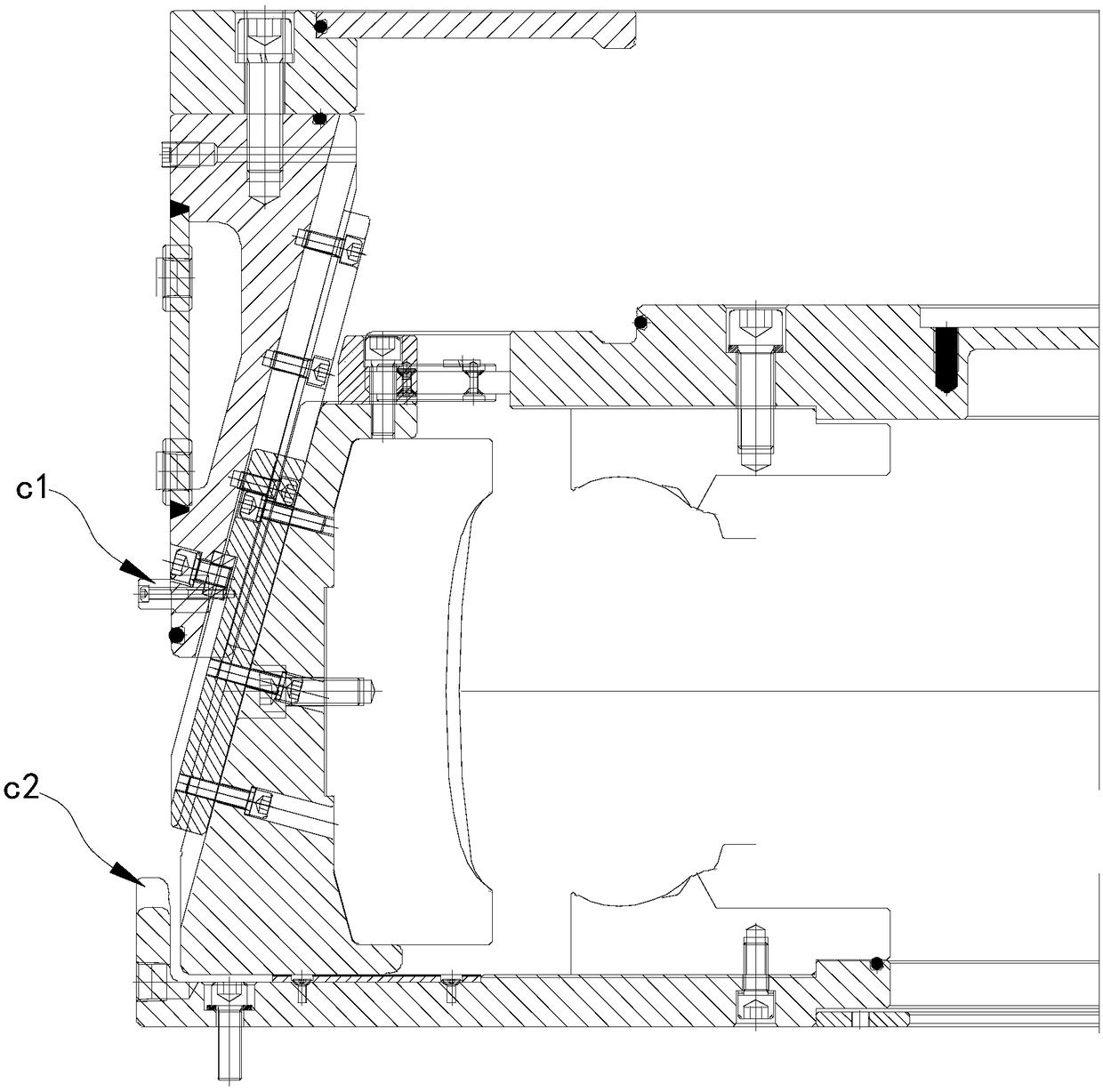

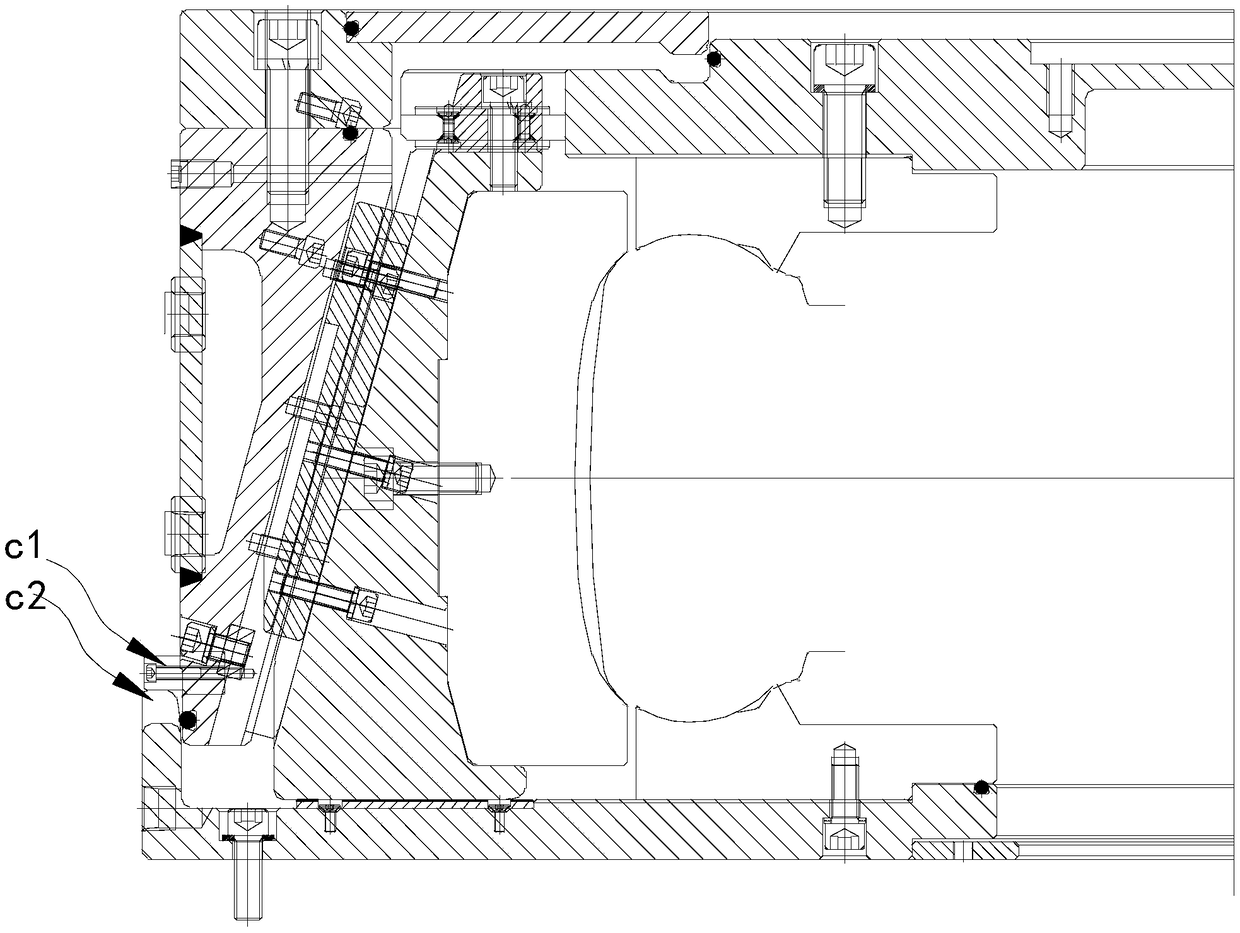

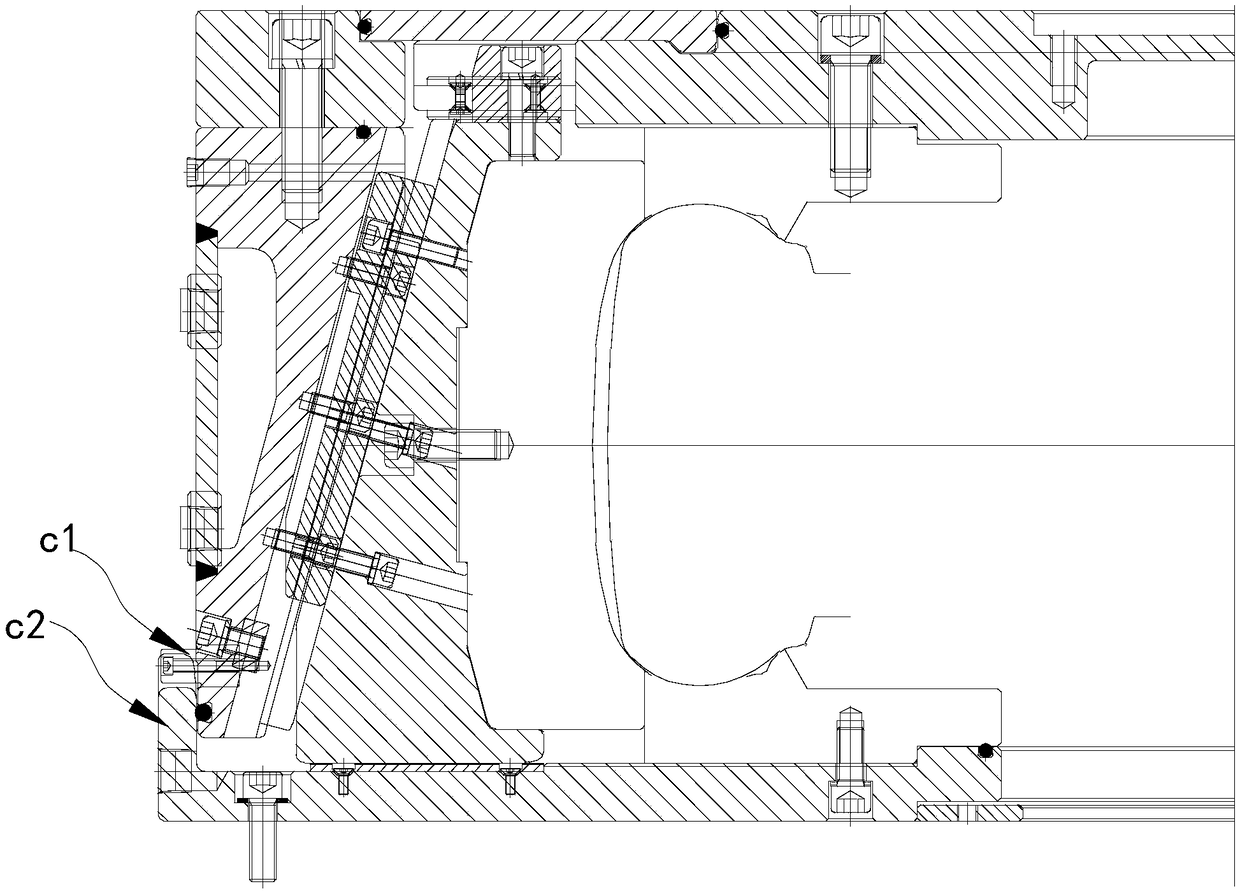

Sealing device and vacuum tire mould

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

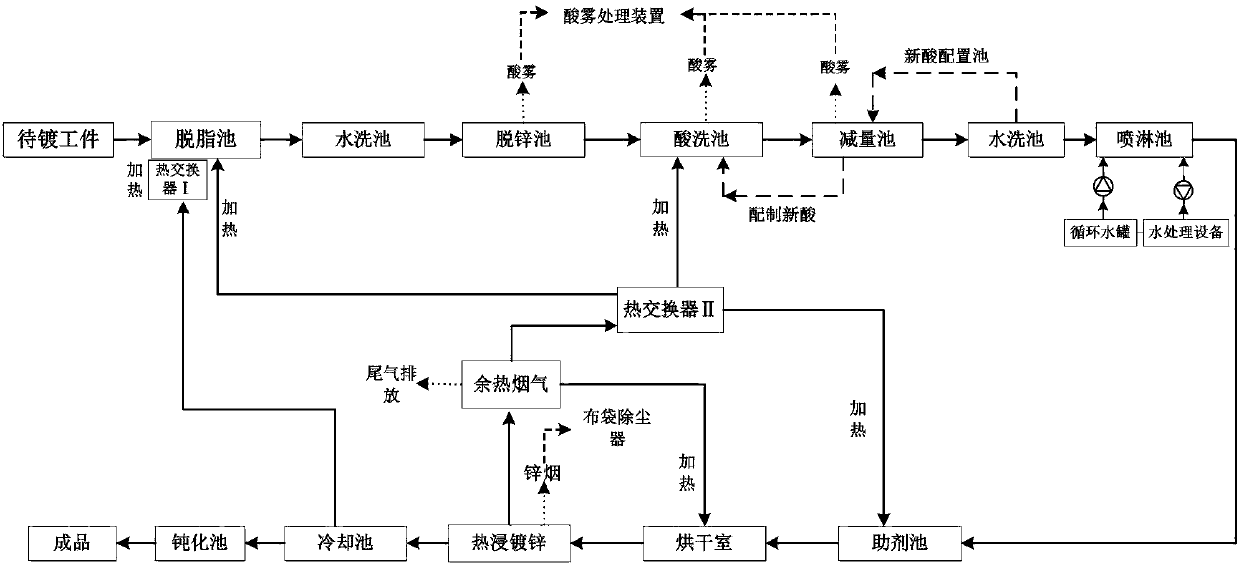

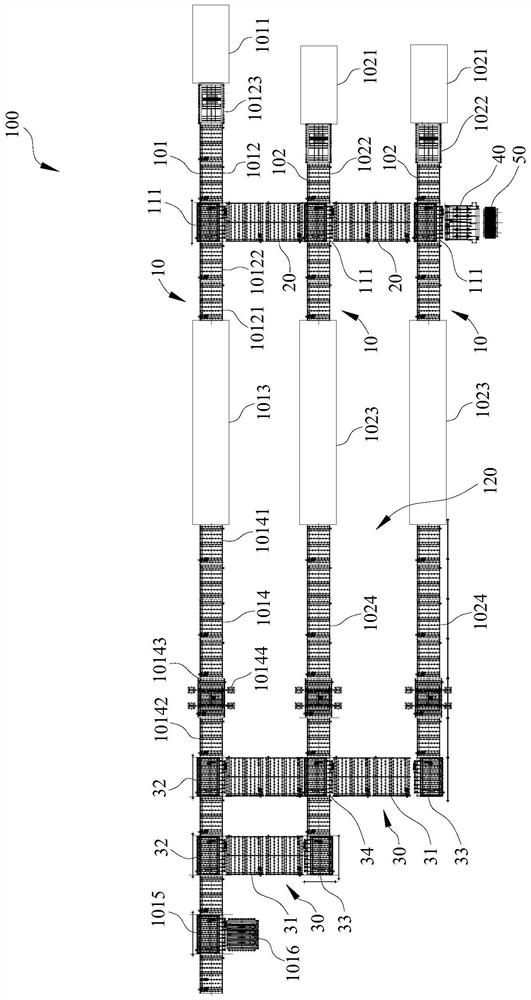

Glass machining transfer line, glass production line and glass machining transfer method

PendingCN112374155AGuaranteed processing efficiencyGuarantee production efficiencyCharge manipulationConveyor partsProduction lineTransfer mechanism

The invention relates to the technical field of glass machining, and provides a glass machining transfer line, a glass production line and a glass machining transfer method. The glass machining transfer line comprises at least two machining lines and a transition transfer mechanism, both machining lines are used for machining glass and transferring the glass to a toughening process, each machiningline is provided with at least two machining sections used for machining glass and a conveying section used for connecting the two adjacent machining sections and conveying the glass between the twomachining sections, the transition transfer mechanism is connected to the transfer sections of the at least two machining lines, so that the glass on the transfer section of one machining line can betransferred to the other transfer section of the other machining line through the transition transfer mechanism. By adoption of the technical scheme, interconnection and intercommunication between themachining sections of the machining lines are achieved, even if the machining section of a certain machining line breaks down or is overhauled, only local shutdown is needed, other machining sectionscan still work normally, and therefore the machining efficiency of glass is guaranteed, full-load operation of follow-up toughening procedure is facilitated, and the production efficiency of a toughening furnace is guaranteed.

Owner:刘伟

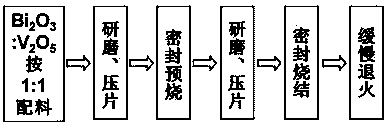

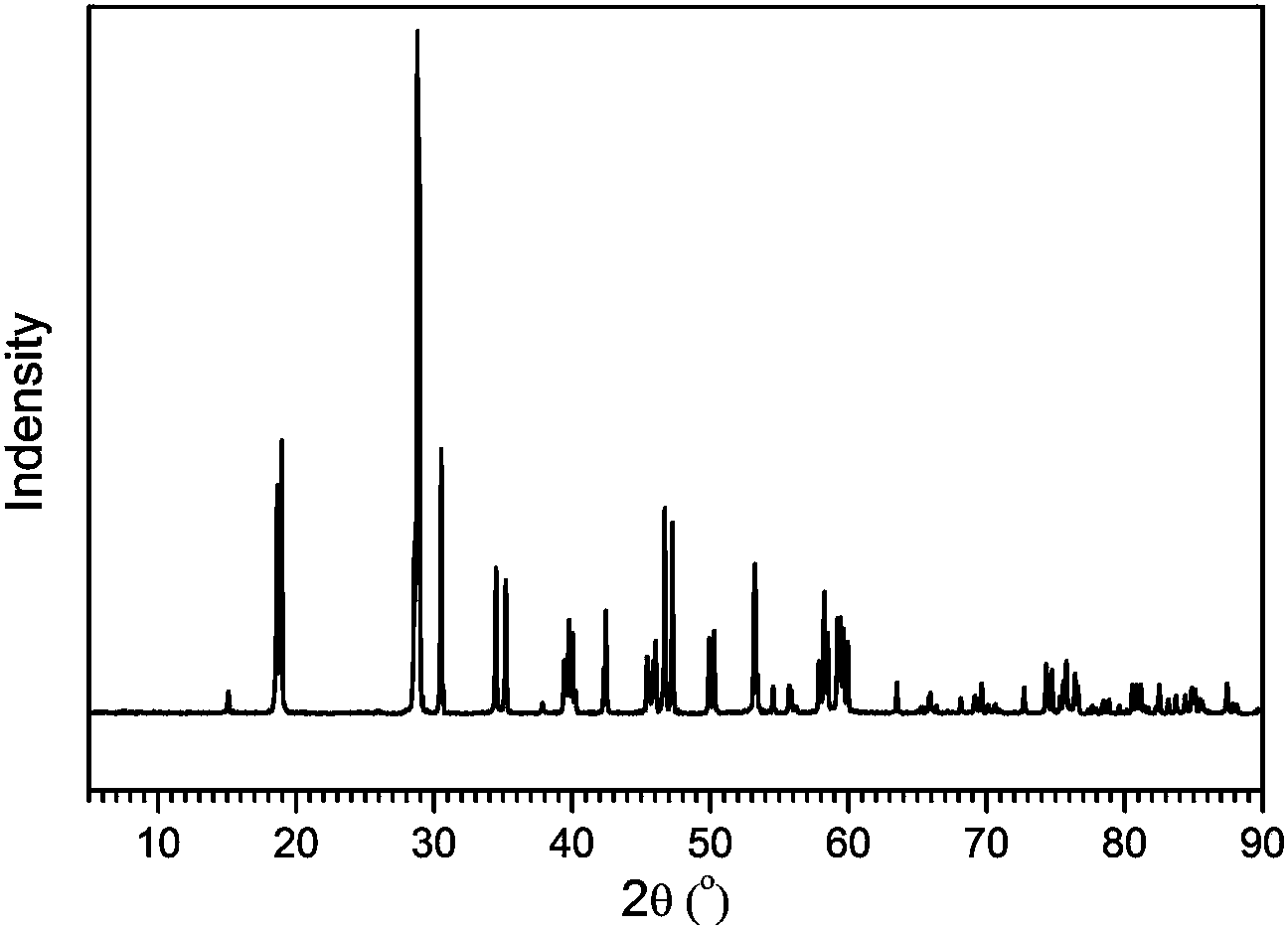

Preparation method of high-density bismuth vanadate ceramic

The invention discloses a preparation method of high-density bismuth vanadate ceramic. The prepared bismuth vanadate ceramic has the density of more than 97%. The preparation method comprises the steps of with Bi2O3 powder and V2O5 powder as raw materials, mixing and tabletting, then, presintering at the temperature of 890 DEG C in a sealed quartz die, and then, grinding into powder; tabletting again, and calcining in the sealed quartz die; after the calcining is ended, cooling from 890 DEG C to 800 DEG C at the speed of 1.5 DEG C / min, cooling to 700 DEG C at the speed of 1.7 DEG C / min, then, cooling to 550 DEG C at the speed of 2.5 DEG C / min, and next, cooling to 350 DEG C at the speed of 3.3 DEG C / min; finally, naturally cooling to room temperature, and then, polishing to obtain the orange yellow bismuth vanadate ceramic.

Owner:CHEM & CHEM ENG GUANGDONG LAB

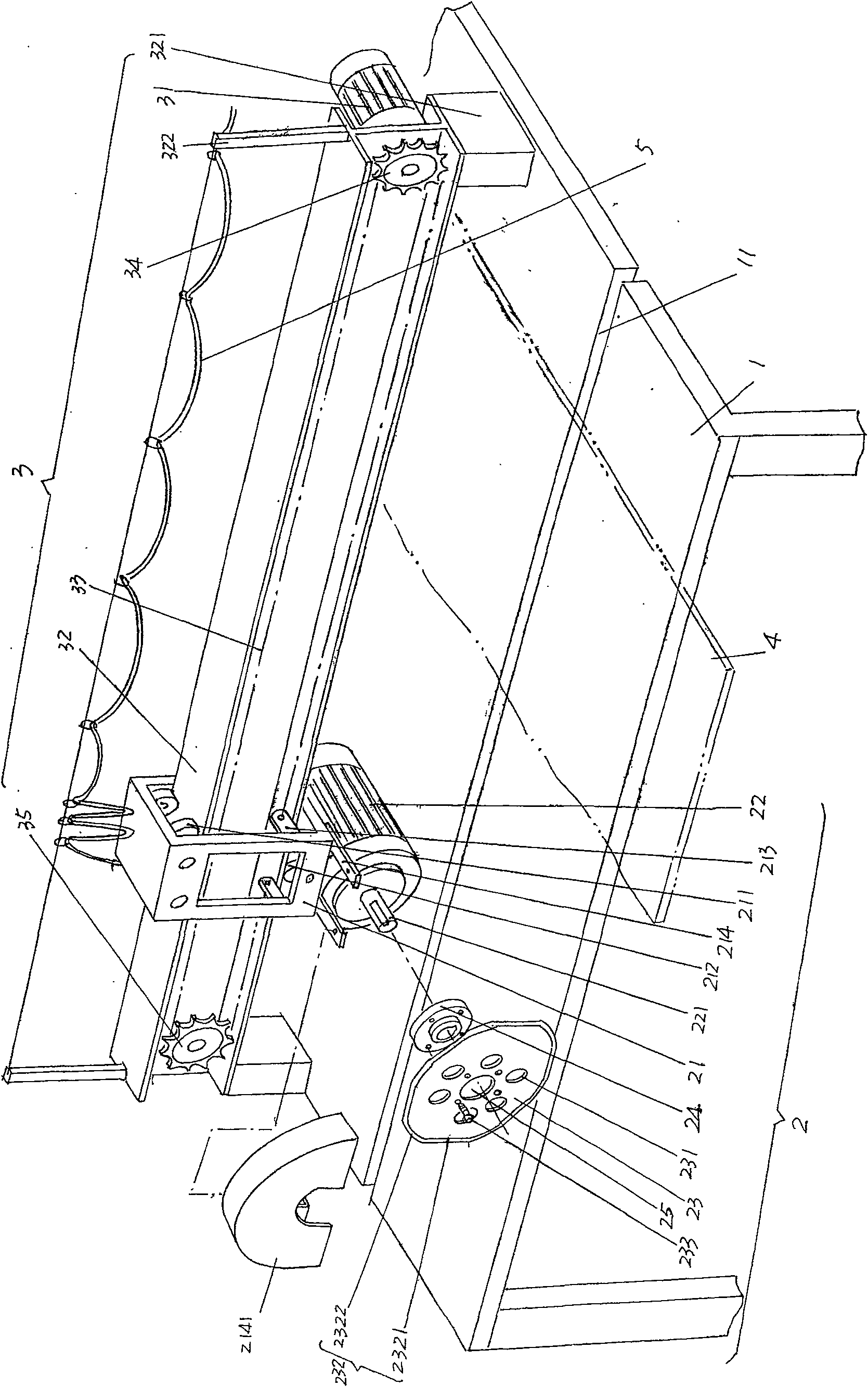

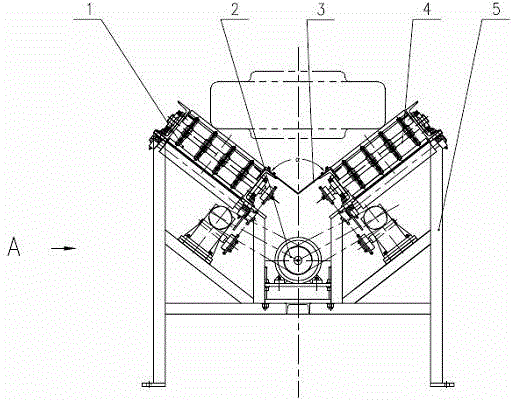

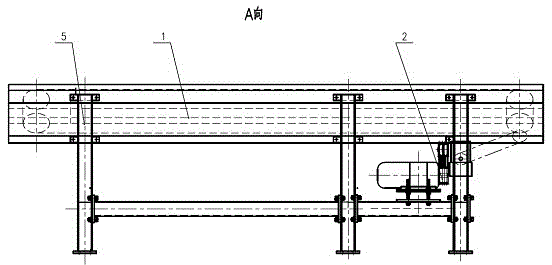

Green tire conveyor for radial tires

InactiveCN105752584AReduce empty or stacked tiresGuarantee production efficiencyConveyorsSprocketRadial tire

The invention discloses a green tire conveyor for radial tires. The green tire conveyor comprises a conveying device I (1) and a conveying device II (4) which are symmetric in structure, arranged in a mirror manner to form a V-shape and mounted on a rack (5) comprising a group of M-shaped brackets, wherein the two conveying devices are connected by a V-shaped connecting plate (3), chain wheels on driving shafts of the two conveying devices are connected with a chain wheel (2-3) on a speed reducer I (2-1) and a chain wheel (2-6) on a speed reducer II (2-7) through chains, a V-belt pulley (2-2) on the speed reducer I (2-1) and a V-belt pulley (2-8) on the speed reducer II (2-7) are connected with a V-belt pulley (2-4) on a variable-frequency motor (2-5) through V-belts, the variable-frequency motor (2-5) drives the speed reducer I (2-1) and the speed reducer II (2-7) to rotate simultaneously when started, and then power is transmitted to the conveying device I (1) and the conveying device II (4) through the chain wheels and the chains, so that conveying belts on the two conveying devices move simultaneously in the same direction at the same speed. The green tire conveyor is simple in structure, adjustable in speed, capable of effectively preventing green tires from deforming during conveyance and protecting formed shapes of the green tires and applicable to conveyance of the green tires of tires with multiple specifications.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Phosphorus trichloride tail gas treatment process

InactiveCN105413402AIncrease profitEmission reductionGas treatmentGroup 5/15 element organic compoundsPhosphorous acidDimethylaniline N-oxide

The invention discloses a phosphorus trichloride tail gas treatment process. Phosphorus trichloride tail gas is introduced into two sets of process routes to be treated. According to the first process route, the phosphorus trichloride tail gas is introduced into a water absorption tower, and unabsorbed tail gas is introduced into an alkali absorption tower; according to the second process route, the phosphorus trichloride tail gas is introduced into a reaction kettle, a mixture of absolute ethyl alcohol, ortho-dichlorobenzene and N,N-dimethylaniline is added into the reaction kettle, and unabsorbed tail gas is introduced into the alkali absorption tower. According to the phosphorus trichloride tail gas treatment process, a traditional process is optimized, the phosphorus trichloride tail gas is treated, byproducts of phosphorous acid and triethyl phosphite are obtained, the utilization rate of phosphorus trichloride of the phosphorus trichloride tail gas is increased, and the probability of discharging the phosphorus trichloride into the atmosphere is extremely decreased. By means of the phosphorus trichloride tail gas treatment process, the production benefit is guaranteed, and the natural environment is protected.

Owner:NINGGUO LONG DAY CHEM CO LTD

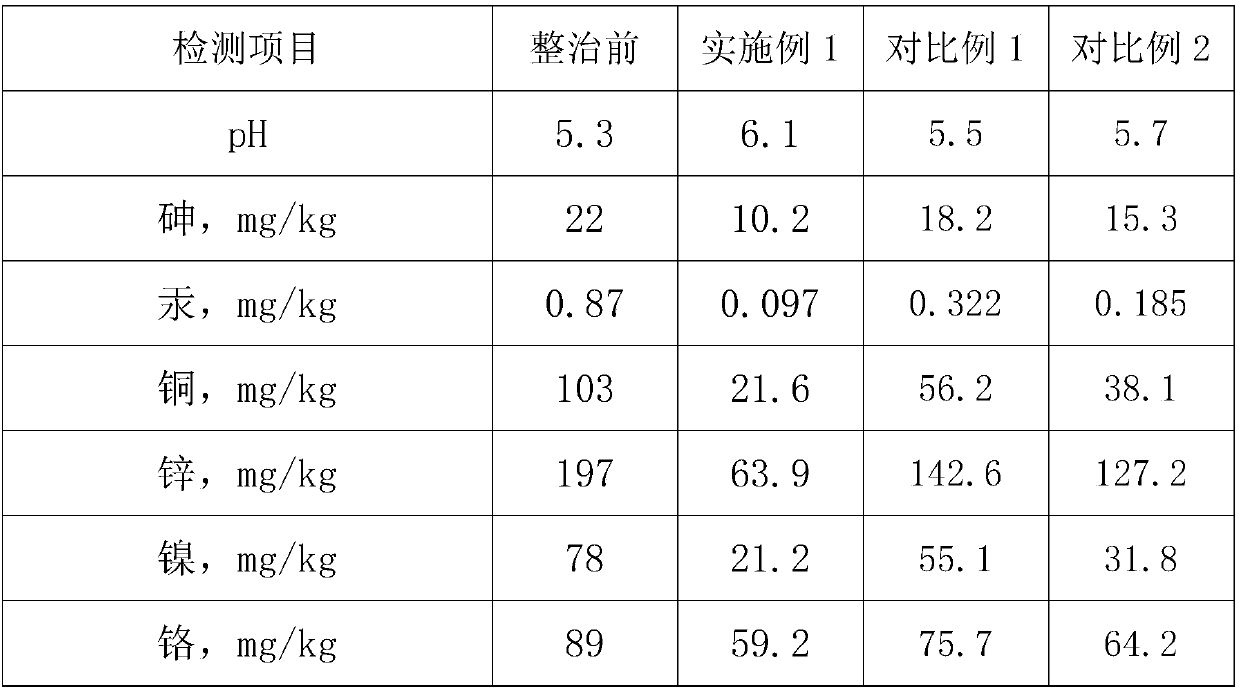

Soil remediation liquid and using method thereof

ActiveCN109609132AImprove the transformation effectGuarantee production efficiencyContaminated soil reclamationOrganic fertilisersEcological environmentOrganic farming

The invention discloses a soil remediation liquid, which comprises the following components: polyhydroxyalkanoates (PHA), polybutylene succinate (PHS), Pseudomonas strain, Acetobacter aceti, aldehydeoxidizing microorganism strain and water. The soil remediation liquid is produced by reverse neutralization reaction and membrane separation technology, harmful ingredients in soil are naturally degraded, at the same time, the traditional agricultural land rearing mode is combined, means of plant migration are used, soil restoration can be realized in a short period and the effect of soil renovation can be greatly enhanced, which can fundamentally solve and transform the organic ecological environment of the land and restore the natural organic agriculture, the soil remediation liquid is green, environmental protection and effective, and the agricultural production benefits are ensured.

Owner:汪朝震

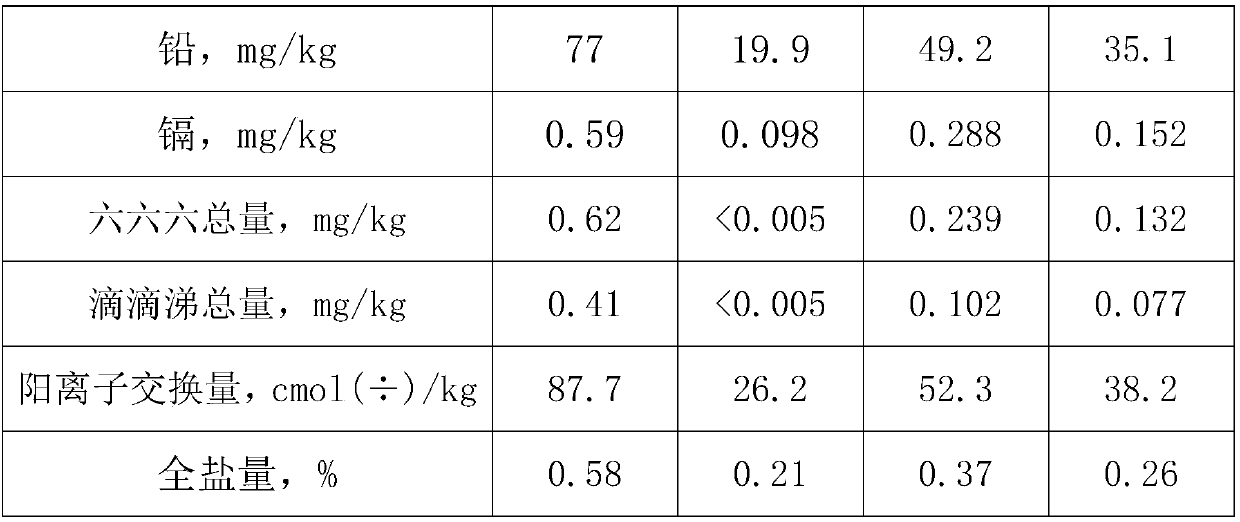

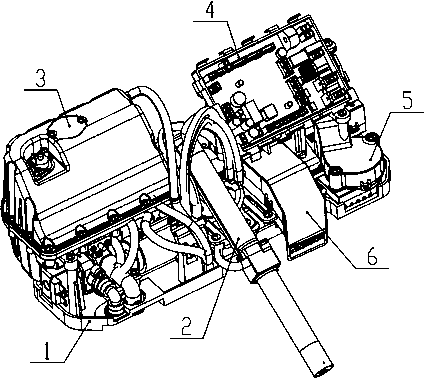

Integrated machine core of intelligent toilet bowel

InactiveCN103266655ASimplify the production processIncrease productivityLavatory sanitoryLarge capacityElectromagnetic valve

The invention relates to an integrated machine core of an intelligent toilet bowel. The integrated machine core of the intelligent toilet bowel comprises a base module, wherein a water-heating module, a cleaning module, a drying module and a deodorizing module are sequentially fixed on the base module from left to right. A control module is fixed above the drying module and the deodorizing module. A water-heating box, a water inlet electromagnetic valve and a water outlet pressure pump are integrated on the water-heating module. A water passage distributing device and a cleaning spraying pipe are integrated on the cleaning module. A drying fan, a drying air channel and a drying heater are integrated on the drying module. A deodorizing fan, a deodorizing air channel and a deodorizing catalytic agent are integrated on the deodorizing module. A main controller and an electric control power supply are integrated on the control module. Because a core control part of the intelligent toilet bowel is integrated on the integrated machine core, and modularized, standardized and high-capacity designs are adopted, production processes can be simplified, production efficiency is improved, and production and after-sale maintenance cost is reduced. Each functional component can be independently upgraded and updated by itself. Therefore, the competitiveness of the integrated machine core of the intelligent toilet bowel is improved.

Owner:无锡欧枫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com