Automatic receiving device of lighter steam boxes

A technology of automatic material collection and lighter, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effects of easy production and use, full automation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

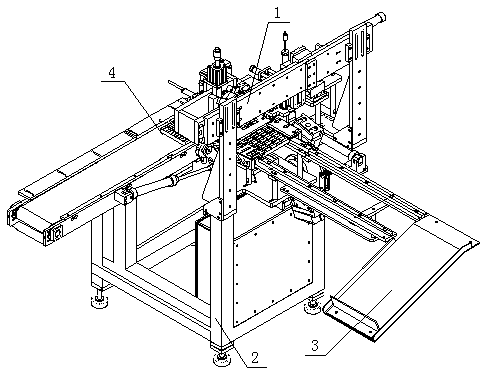

[0029] like figure 1 As shown, the present embodiment provides an automatic receiving device for lighter gas tanks, including a frame 2, a blanking device 1 for moving the lighter gas tanks and filling the lighter gas tanks into the insert tray, and a feeding device 1 for transporting the insert trays. And the inserting tray transfer device 4 that is positioned for the inserting tray and the closing hopper 3 for collecting the inserting tray, the blanking device 1 and the inserting tray transfer device 4 are all fixed on the frame 2, and the blanking device 1 is arranged above the disk transfer device 4, and the closing bucket 3 is arranged at the end of the disk transfer device 4.

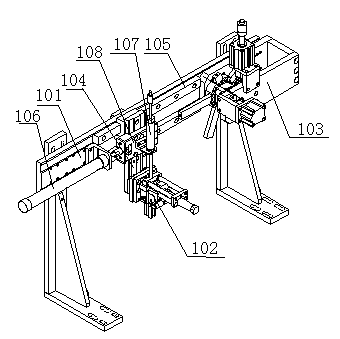

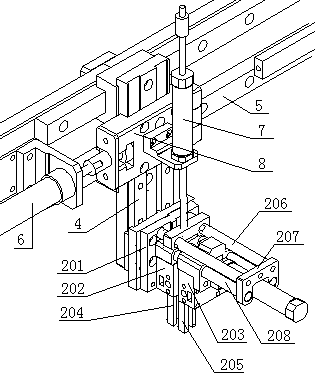

[0030] like figure 2 As shown, the blanking device 1 includes a support frame 101, a blanking clamp 102 for clamping the lighter gas tank, a vertical track 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com