Anti-wrinkling laminating device for waterproof roll

A technology of waterproof roll material and lamination device, which is applied in lamination device, lamination auxiliary operation, lamination and other directions, can solve the problems of personal injury, inability to accurately monitor the need for continuation of the tire base, personnel negligence, etc., to ensure the processing quality, to avoid wrinkling, to ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

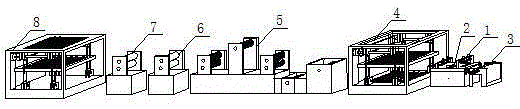

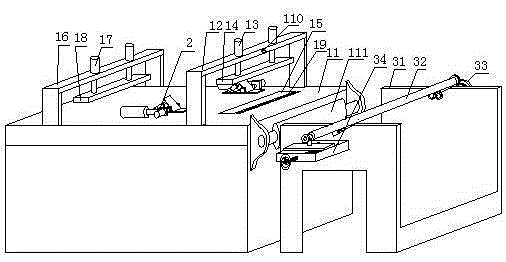

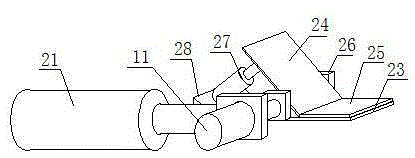

[0038] An anti-eccentric production equipment for waterproof rolls, such as figure 1 , including a continuous connection frame 11, a material guide adjustment component 3, a positioning component, a clamping and feeding component 2, a thermal connection component 1, a winding temporary storage mechanism 4, a film coating component 5, a glue extrusion component 6, a drying component 7 and The exhaust gas reuse processing assembly, the positioning assembly, the clamping and feeding assembly 2 and the thermal bonding assembly 1 are sequentially arranged on the connecting frame 11, such as figure 2 , the thermal connection assembly 1 includes a thermal connection frame 12, a thermal connection cylinder 13, a heating upper plate 14, and a heating lower plate 15. Above, the heating upper plate 14 is arranged on the piston rod of the thermal bonding cylinder 13 , and the base of the thermal bonding cylinder 13 is disposed on the thermal bonding frame 12 .

[0039] By overlapping th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com