Asphalt mixture workability index tester

A technology of asphalt mixture and tester, which is applied in the directions of instruments, flow characteristics, measuring devices, etc., can solve the problems of different workability and unreasonable asphalt mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

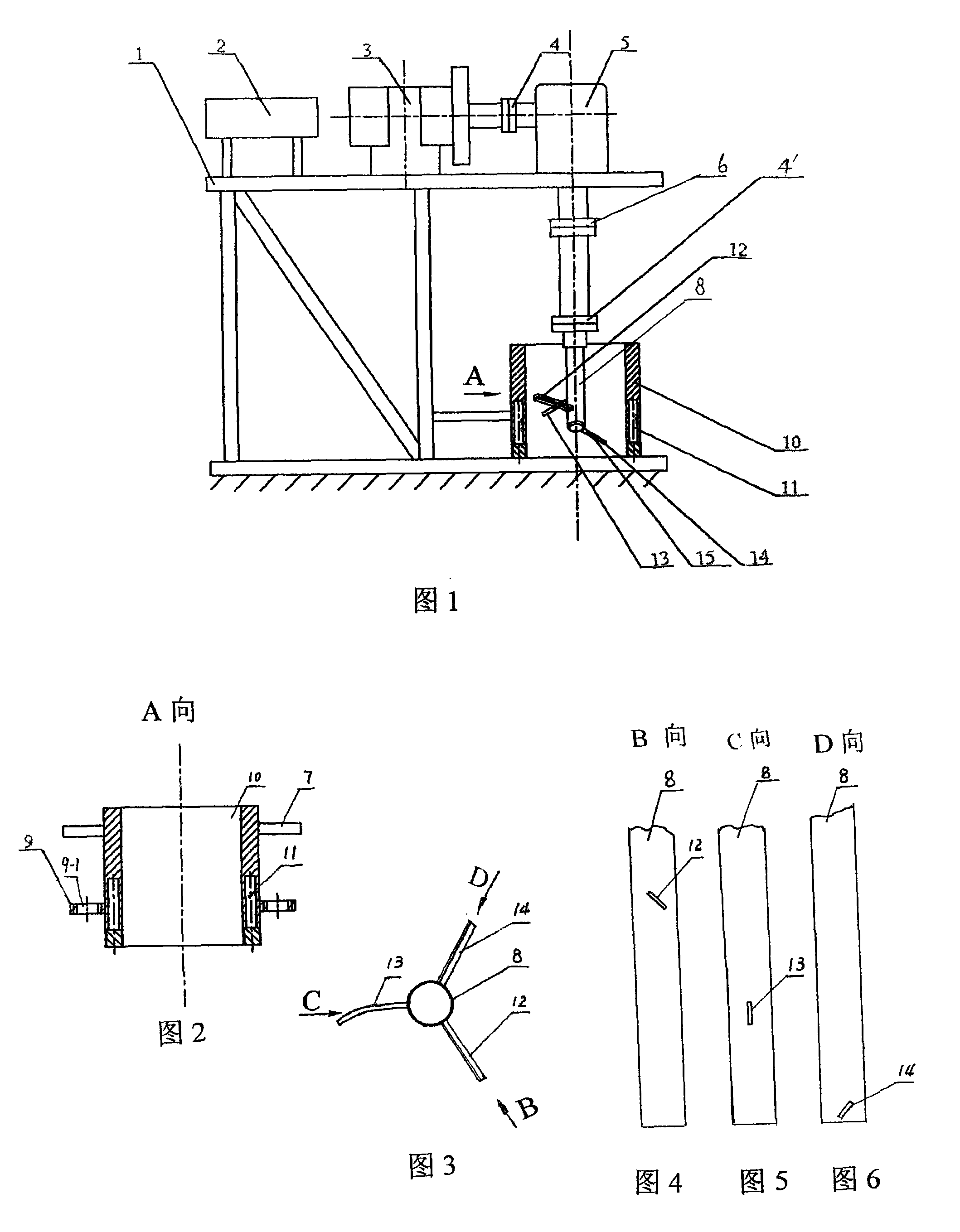

Method used

Image

Examples

Embodiment 1

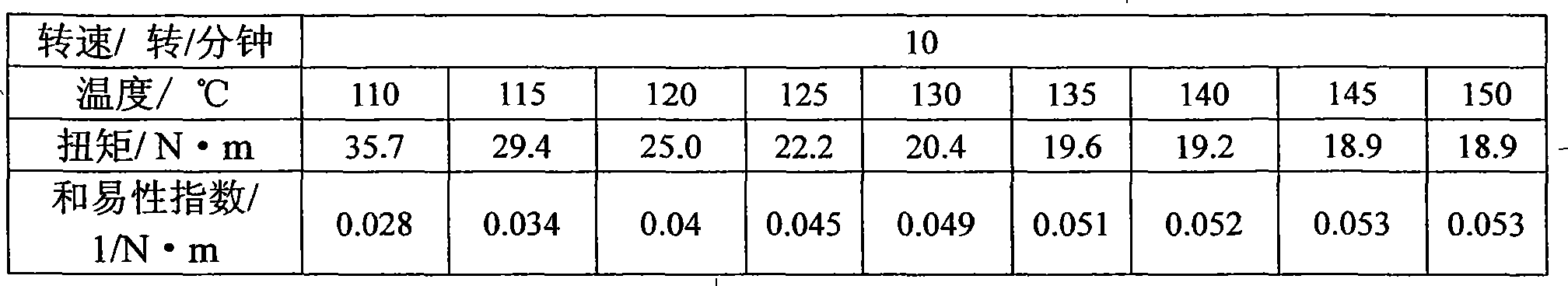

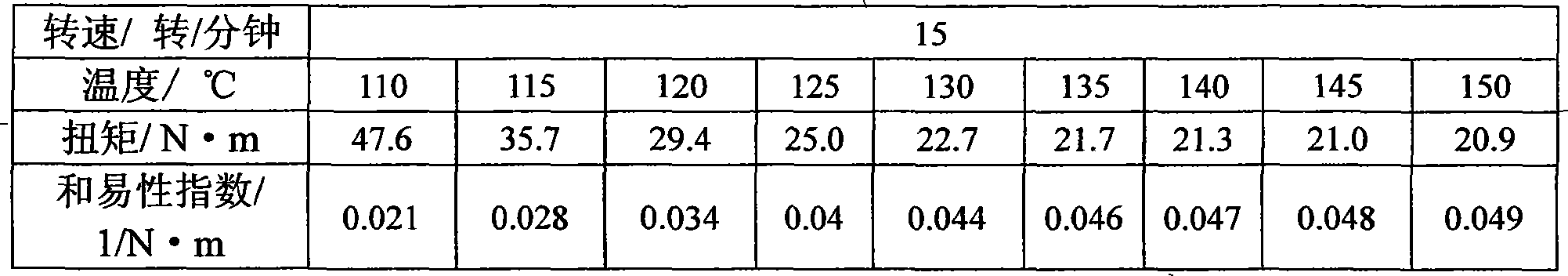

[0029] Workability index test of AC13 asphalt mixture under different speed and temperature conditions

[0030] The relationship between different temperatures and workability index of AC13 asphalt mixture is shown in Table 1(1) and Table 1(2) under the conditions of tester speed of 10 rpm and 15 rpm respectively.

[0031] Table 1(1)

[0032]

[0033] Table 1(2)

[0034]

[0035] The test results in Table 1(1) and Table 1(2) show that the workability index of the asphalt mixture increases with the increase of temperature under the two speeds of 10 rpm and 15 rpm of the agitator, and the asphalt mixture Enhanced workability. When the temperature exceeds 135°C, if the asphalt mixture temperature continues to increase, the workability index of the asphalt mixture will increase slightly and remain almost unchanged. Therefore, it can be determined that the optimum compaction temperature of the asphalt mixture is 135°C, and The workability index corresponding to 135°C is us...

Embodiment 2

[0037] Both AC13 and AC20 asphalt mixtures were mixed at a stirring speed of 15 rpm, and their workability indices at different temperatures were tested respectively.

[0038] The test results of AC13 asphalt mixture are shown in Table 2 (1), and the test results of AC20 asphalt mixture are shown in Table 2 (2).

[0039] Table 2(1)

[0040]

[0041]

[0042] The test results in Table 2(1) and Table 2(2) show that at the same temperature, the coarser the aggregate, the smaller the workability index of the mixture and the worse the compactability. For AC13 asphalt mixture, when the temperature is higher than 135℃, the workability index changes little, so 135℃ can be regarded as the optimal compaction temperature of AC13 asphalt mixture. For AC20 asphalt mixture, when the temperature is higher than 140℃, the workability index changes little, so 140℃ can be regarded as the optimum compaction temperature of AC20 asphalt mixture. Therefore, in the construction process, in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com