Online fault detection and protection method and system for bag type dust remover

A bag dust collector and fault detection technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of limited temperature resistance characteristics, heavy labor of filter bags, poor working conditions, etc., to ensure production benefit, reduce the probability of downtime, improve the effect and the effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

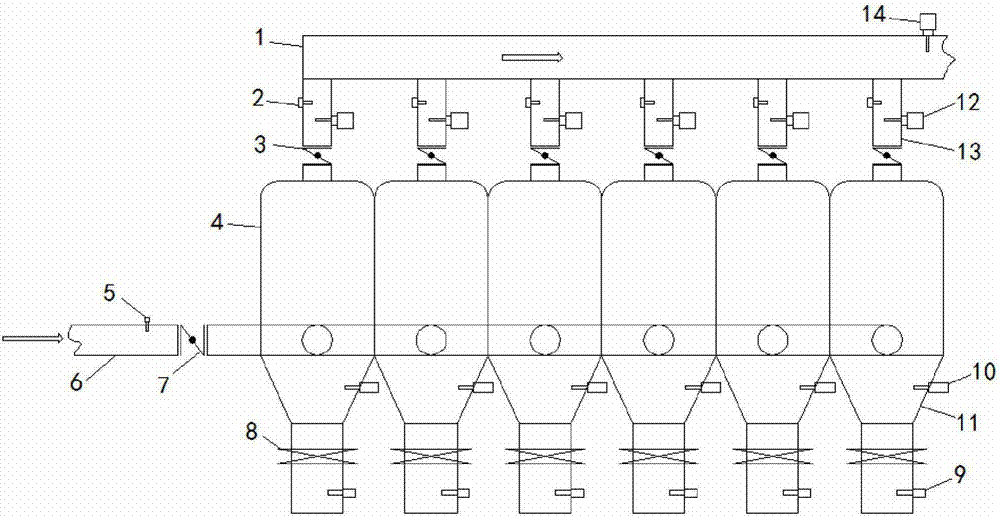

[0025] Embodiment 1: as figure 1 As shown in the figure, an online fault detection and protection system for a bag filter, the intake main pipe 6 is connected to the temperature instrument 5 and the intake valve 7; the chamber exhaust pipe 13 is connected to the anemometer 2, the leak detector 12, the chamber switching Valve 3; exhaust main pipe 1 is connected to dust concentration meter 14 and chamber exhaust pipe 13; ash hopper 11 is connected to material level switch 10 and chamber ash discharge valve 8; the lower part of ash discharge valve 8 is connected to solid flow switch 9; The upper part of the bucket 11 is connected to the dust removal chamber 4;

[0026] The temperature meter 5 is located at the front of the intake valve 7, the dust concentration meter 14 is located on the exhaust main pipe 1, and is located at the rear of each dust removal chamber 4 of the bag and the exhaust pipe 13;

[0027] There are more than 2 dust removal chambers 4, and the outlet of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com