Industrial equipment fault prediction method based on deep learning

An industrial equipment and deep learning technology, applied in the field of intelligence, can solve problems such as loss, wear and tear of equipment materials and parts, industrial equipment crash and shutdown, etc., to achieve the effect of improving life expectancy and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiment:

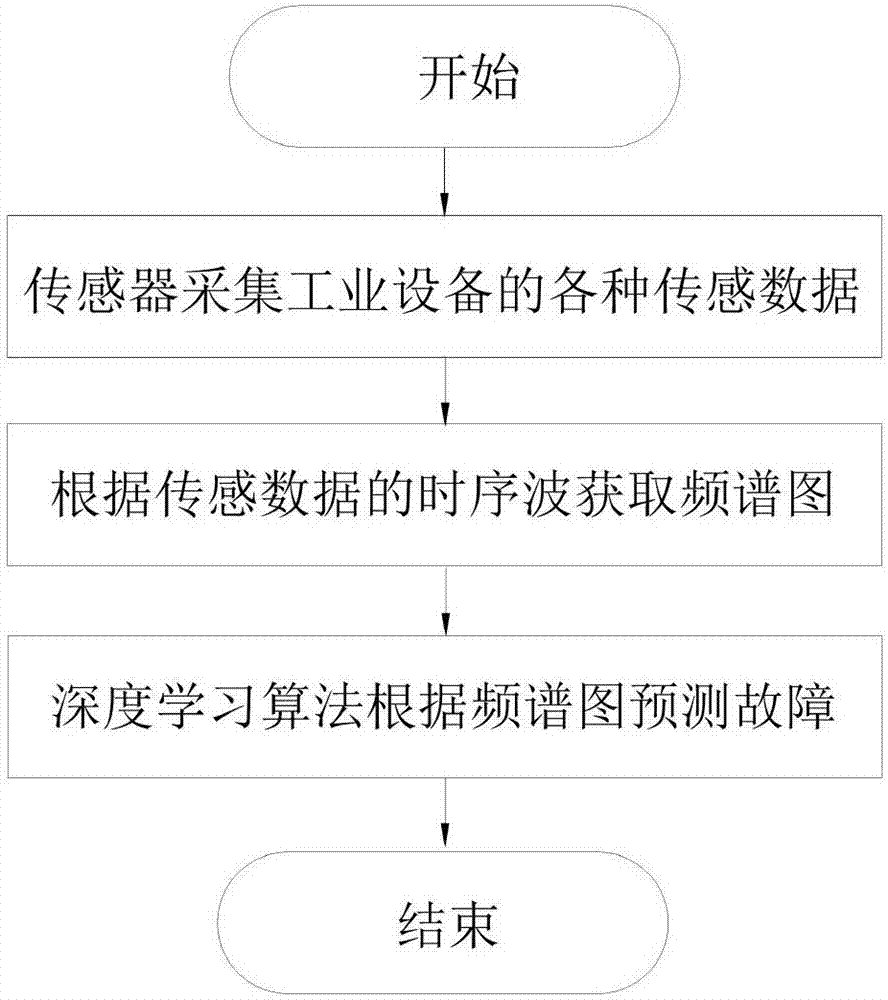

[0030] See attached figure 1 As shown, a deep learning-based industrial equipment failure prediction method described in this embodiment includes the following steps:

[0031] S1. Collect vibration, temperature, current, voltage and other industrial equipment sensing data through sensors;

[0032] S2. Obtain the spectrum diagram according to the timing wave of the sensing data within a fixed time:

[0033] S21. Divide the various sensory data collected into blocks with a fixed duration of t milliseconds;

[0034] S22. Draw the sensing data within t milliseconds as a time series wave;

[0035] S23. Utilize Fourier transform operation to decompose the time-series wave, calculate the energy value of each frequency band, and obtain the time-series wave spectrogram of various sensing data;

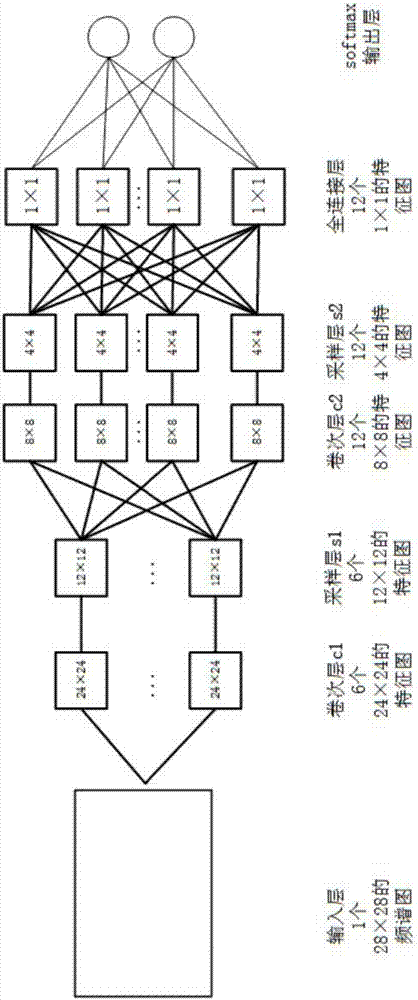

[0036] S3. The deep learning algorithm predicts the fault of industrial equipment acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com