Formulation of wood-plastic profile as well as preparation method and manufacturing device thereof

A wood-plastic profile and production method, applied in the field of wood-plastic composite materials, can solve the problems of poor heat resistance and ultraviolet resistance, poor hardness and load capacity, difficult installation, etc., and achieve good compatibility and improved impact performance. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

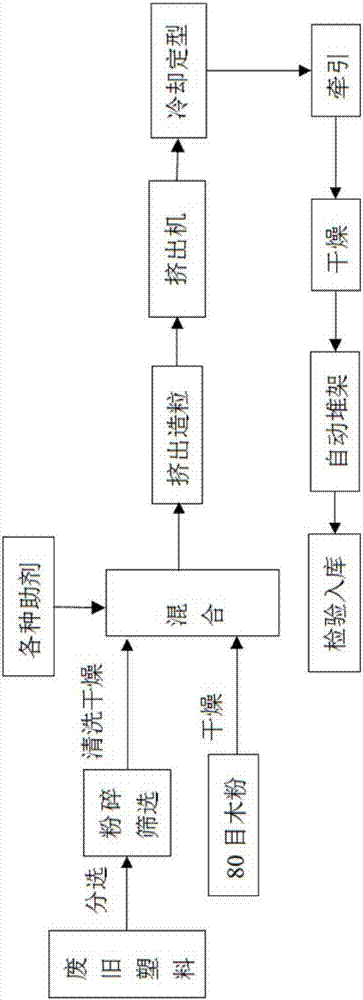

Method used

Image

Examples

Embodiment Construction

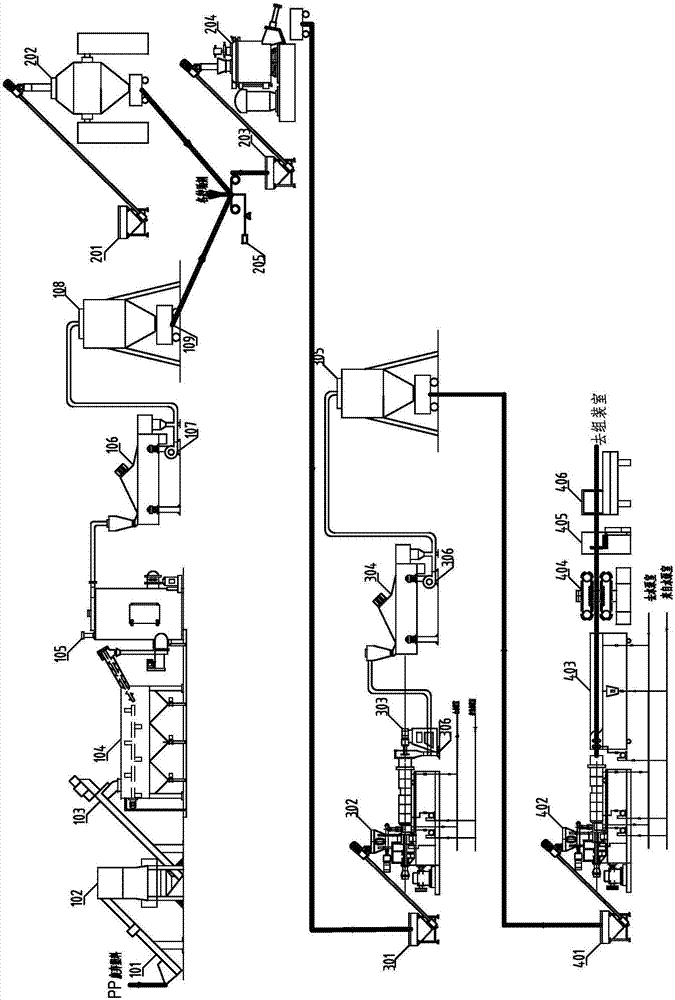

[0038] Such as figure 2As shown: the plastic cleaning device includes a conveyor belt 101, a crusher 102, a first screw feeder 103, a cleaning machine 104, a cyclone dryer 105, a first vibrating screen 106, a first blower 107 and a first silo 108 connected in sequence , the wood powder drying device is the second screw feeder 201 and the double cone rotary dryer 202 connected in sequence, the weighing device is a belt weighing scale 205, and the mixing device is the third screw feeder 204 connected in sequence And high-speed mixer 204, extrusion granulation device is the 4th screw feeder 301, parallel twin-screw extruder 302, pelletizer 303, the second vibrating screen 304 and the second feed bin 305 that are connected successively, described The bottom of the second vibrating screen 304 is provided with two second blowers 306, and the extrusion molding device is the fifth screw feeder 401, conical twin-screw extruder 402, vacuum setting cooling device 403, tractor 404 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com