Polyphenylether material and preparation method thereof

A technology of polyphenylene ether and polyphenylene ether resin, which is applied in the field of polyphenylene ether materials and its preparation, and can solve the problems of reduced flame retardancy and high melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

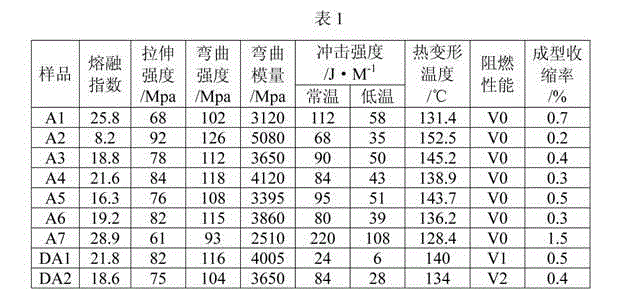

Examples

Embodiment 1

[0033] This example is used to illustrate the polyphenylene ether material disclosed in the present invention and its preparation method.

[0034] 69.5 parts by weight of poly(2,6-diethyl-1,4-phenylene) ether (viscosity at 25°C is 0.4 Pa·S), 5 parts by weight of SiC fiber, 5 parts by weight of silicone-acrylate- Styrene copolymer, 20 parts by weight of polyresorcinol-bis(diphenyl phosphate), 0.25 parts by weight of N445 and 0.25 parts by weight of N412S are added to the high mixer, stirred at 1000rpm / min for 3 minutes to obtain the mixed material Put the mixed material into the twin-screw extruder and melt and extrude it at 220-260°C. The feeding rate is 5rpm / min, and the host speed is 200rpm / min; the extruded polyphenylene ether material is passed through Water-cooled, air-dried, and finally pelletized by a pelletizer at 100 rpm / min to obtain polyphenylene ether material pellets S1.

Embodiment 2

[0036] This example is used to illustrate the polyphenylene ether material disclosed in the present invention and its preparation method.

[0037] 45 parts by weight of poly(2-ethyl-6-methyl-1,4-phenylene) ether (viscosity at 25°C is 0.4 Pa·S), 25 parts by weight of carbon fiber, 25 parts by weight of silicone-acrylate- Styrene copolymer, 4 parts by weight of triphenyl phosphate, 0.5 parts by weight of N445 and 0.5 parts by weight of N412S are added to the high mixer, and stirred at 200rpm / min for 10 minutes to obtain a mixed material; the mixed material is put into the double The screw extruder is melted and extruded at 240-280°C, the feeding rate is 40rpm / min, and the host speed is 400rpm / min; the extruded polyphenylene ether material is water-cooled, air-dried, and finally passed through a pelletizer Cut into pellets at 1200 rpm / min to obtain polyphenylene ether material pellets S2.

Embodiment 3

[0039] This example is used to illustrate the polyphenylene ether material disclosed in the present invention and its preparation method.

[0040] 65.4 parts by weight of poly(2,6-dimethyl-1,4-phenylene) ether (viscosity at 25°C is 0.4 Pa·S), 12 parts by weight of chopped glass fiber, 12 parts by weight of silicone-acrylate - Styrene copolymer, 10 parts by weight of bisphenol A bis(diphenyl) phosphate, 0.3 parts by weight of N445 and 0.3 parts by weight of N412S are added to the high mixer, and stirred at 800rpm / min for 5 minutes to obtain the mixed material; Put the mixed material into the twin-screw extruder and melt and extrude it at 240-270°C. The feeding rate is 27rpm / min, and the host speed is 335rpm / min; the extruded polyphenylene ether material is water-cooled , air-dried, and finally pelletized by a pelletizer at 800 rpm / min to obtain polyphenylene ether material pellets S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com