Hydrolysis-resistant and low-temperature-resistant PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composite and preparation method thereof

A composite material and low-temperature-resistant technology, which is applied in the field of polymers, can solve the problems of easy brittleness and large drop in impact strength of finished products, and achieve the effects of improving stability, high low-temperature impact resistance, and improving low-temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

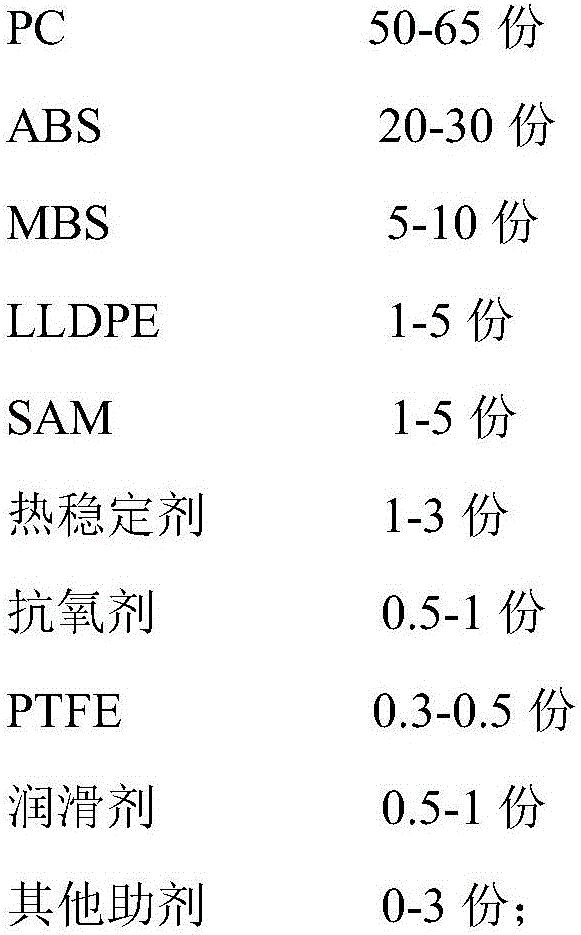

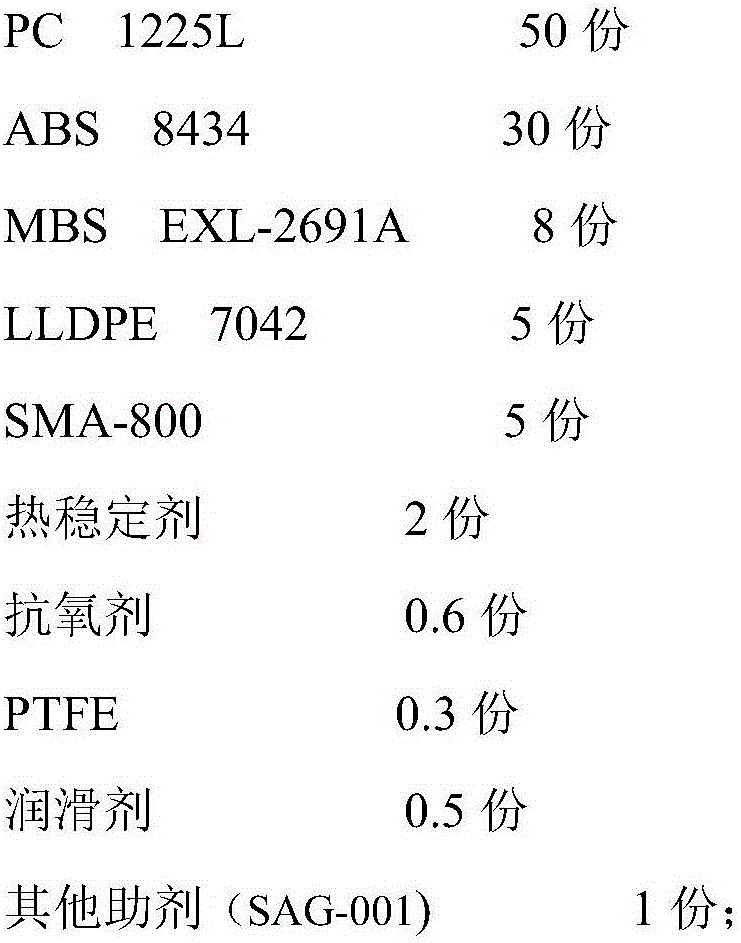

[0037] The hydrolysis-resistant and low-temperature-resistant PC / ABS composite material in this embodiment is made up of the following raw materials by weight:

[0038]

[0039] Concrete preparation method comprises the following steps:

[0040] (1) According to the proportion, weigh 50 parts of raw materials PC, 30 parts of ABS, 8 parts of MBS, 5 parts of LLDPE, 5 parts of SAM, 2 parts of heat stabilizer, 0.6 parts of antioxidant, 0.3 parts of PTFE, 0.5 parts of lubricant, 1 part of other additives was weighed and added to the high-speed mixer (set speed 500rpm / min), mixed for 4 minutes until uniform, and discharged to obtain the mixture;

[0041] (2) The mixture is put into the hopper of the twin-screw extruder, and a screw combination with strong shear is selected;

[0042] (3) Set the screw speed of the twin-screw extruder at 400-550r / min, the main feed at 15-25HZ, the vacuum at -0.04--0.08MPa, and the temperature at 235-270°C. The rotational speed of the granulator i...

Embodiment 2

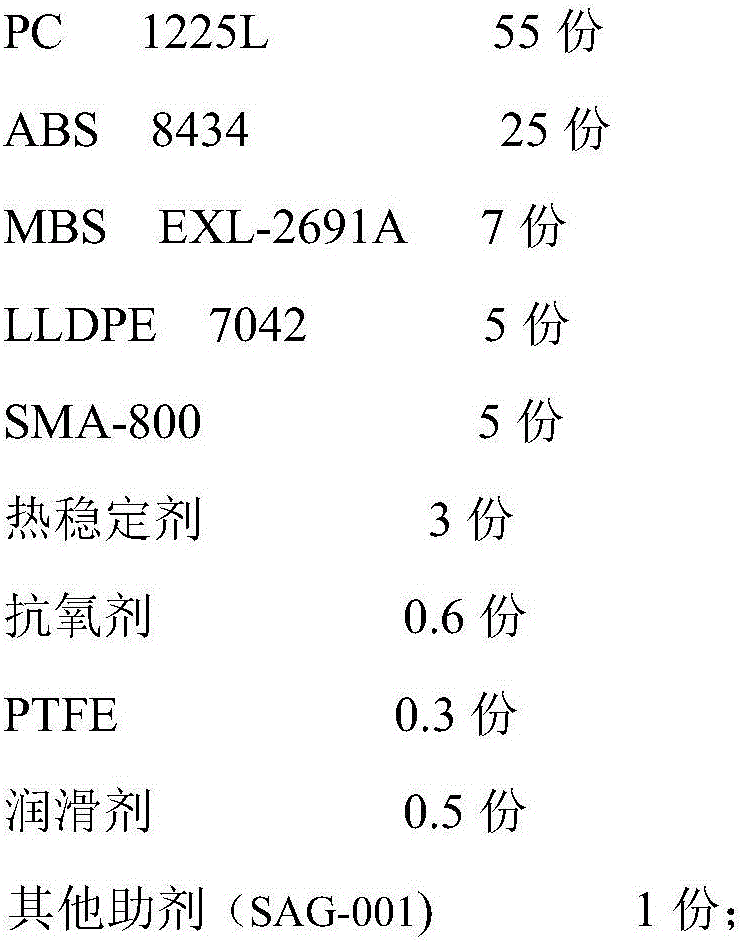

[0044] The hydrolysis-resistant and low-temperature-resistant PC / ABS composite material in this embodiment is made up of the following raw materials by weight:

[0045]

[0046] Concrete preparation method comprises the following steps:

[0047] (1) According to the proportion, weigh 55 parts of raw materials PC, 25 parts of ABS, 7 parts of MBS, 5 parts of LLDPE, 5 parts of SAM, 3 parts of heat stabilizer, 0.6 parts of antioxidant, 0.3 parts of PTFE, 0.5 parts of lubricant, 1 part of other additives was weighed and added to the high-speed mixer (set speed 500rpm / min), mixed for 4 minutes until uniform, and discharged to obtain the mixture;

[0048] (2) The mixture is put into the hopper of the twin-screw extruder, and a screw combination with strong shear is selected;

[0049] (3) Set the screw speed of the twin-screw extruder at 400-550r / min, the main feed at 15-25HZ, the vacuum at -0.04--0.08MPa, and the temperature at 235-270°C. The rotational speed of the granulator i...

Embodiment 3

[0051] The hydrolysis-resistant and low-temperature-resistant PC / ABS composite material in this embodiment is made up of the following raw materials by weight:

[0052]

[0053] Concrete preparation method comprises the following steps:

[0054](1) According to the ratio, weigh 58 parts of raw materials PC, 23 parts of ABS, 7 parts of MBS, 5 parts of LLDPE, 5 parts of SAM, 2 parts of heat stabilizer, 0.6 parts of antioxidant, 0.3 parts of PTFE, 0.5 parts of lubricant, 1 part of other additives was weighed and added to the high-speed mixer (set speed 500rpm / min), mixed for 4 minutes until uniform, and discharged to obtain the mixture;

[0055] (2) The mixture is put into the hopper of the twin-screw extruder, and a screw combination with strong shear is selected;

[0056] (3) Set the screw speed of the twin-screw extruder at 400-550r / min, the main feed at 15-25HZ, the vacuum at -0.04--0.08MPa, and the temperature at 235-270°C. The rotational speed of the granulator is 700-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com