Low odor acrylate adhesive for level bonding and preparation method of low odor acrylate adhesive

An acrylate, low-odor technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor plastic bonding strength, unfriendly environment, low temperature resistance and impact resistance, etc. Good low temperature impact, good peel strength and shear strength, low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and

[0048] Embodiment 1 and comparative example:

Embodiment 1

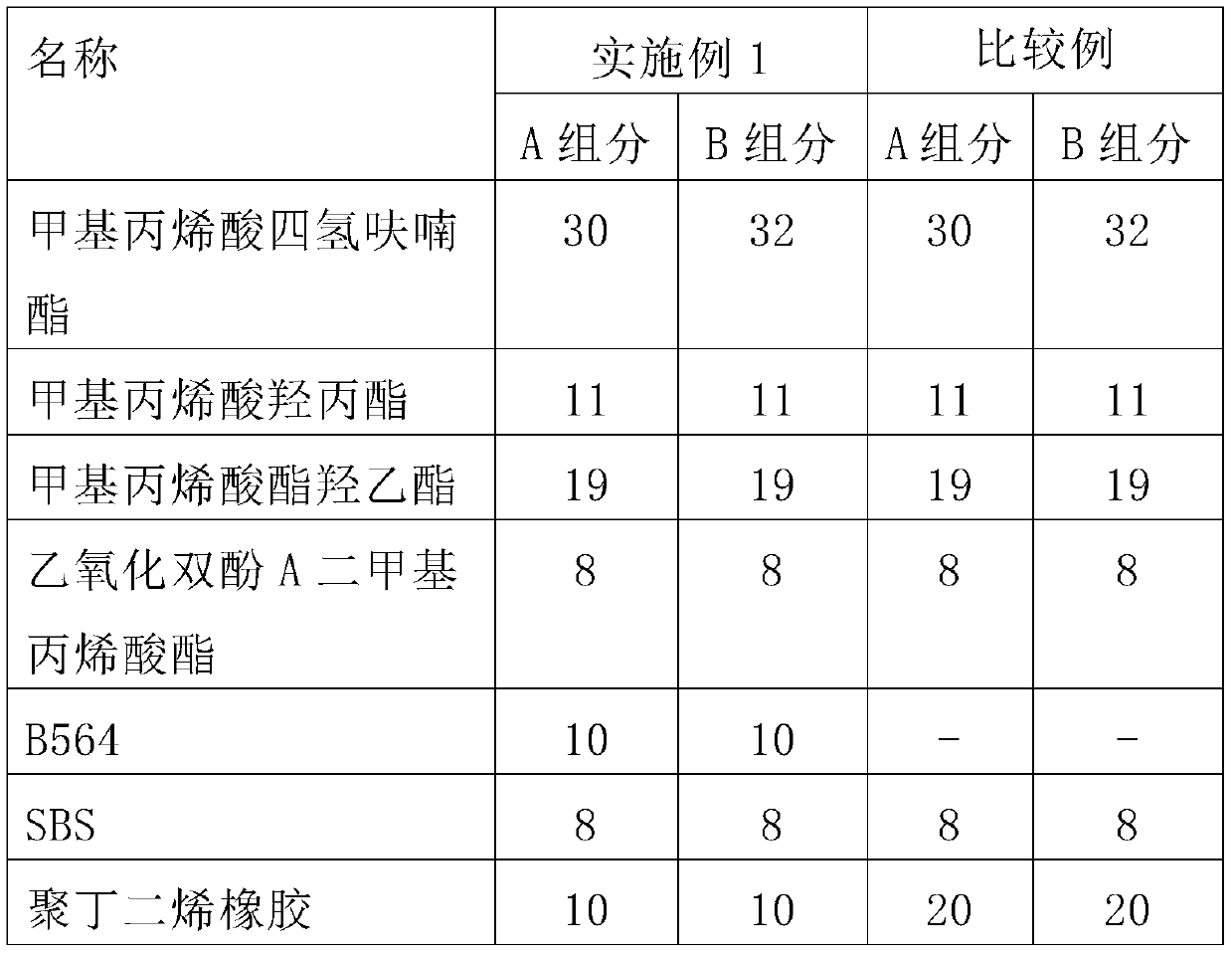

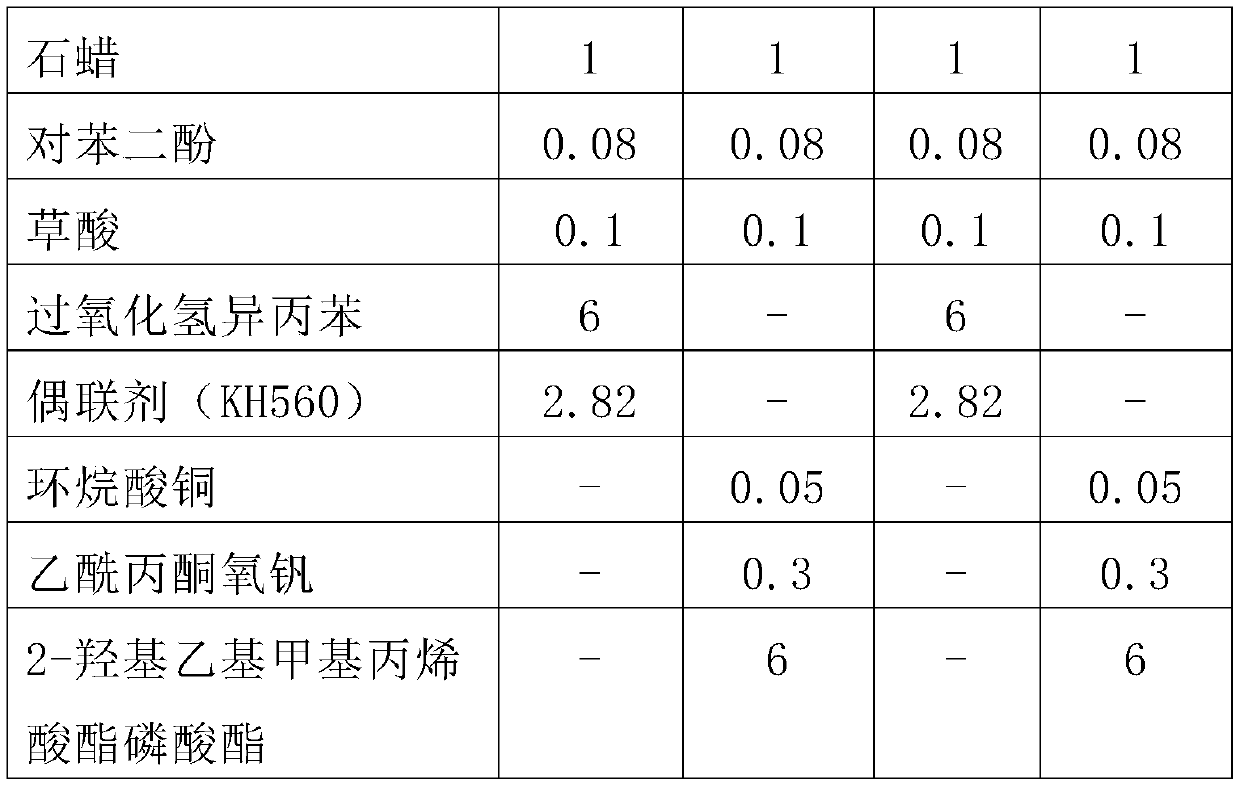

[0049] Embodiment 1 and comparative example are specifically shown in Table 1:

[0050] Table 1

[0051]

[0052]

[0053] Preparation Process:

[0054] Preparation of component A: tetrahydrofuryl methacrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, ethoxylated bisphenol A dimethacrylate, B564, SBS, polybutadiene rubber, paraffin wax , Hydroquinone, and oxalic acid are put into the reaction kettle, and stirred until B564 and SBS are completely dissolved; then, cumene hydroperoxide and KH560 are put into the reaction kettle and stirred for 1-2 hours until the mixture is uniform, and the bubbles are removed in a vacuum to obtain component A ;

[0055] Preparation of component B: tetrahydrofuryl methacrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, ethoxylated bisphenol A dimethacrylate, B564, SBS, polybutadiene rubber, paraffin wax , hydroquinone, and oxalic acid were put into the reactor, and stirred until B564 and SBS were completely dis...

Embodiment 2

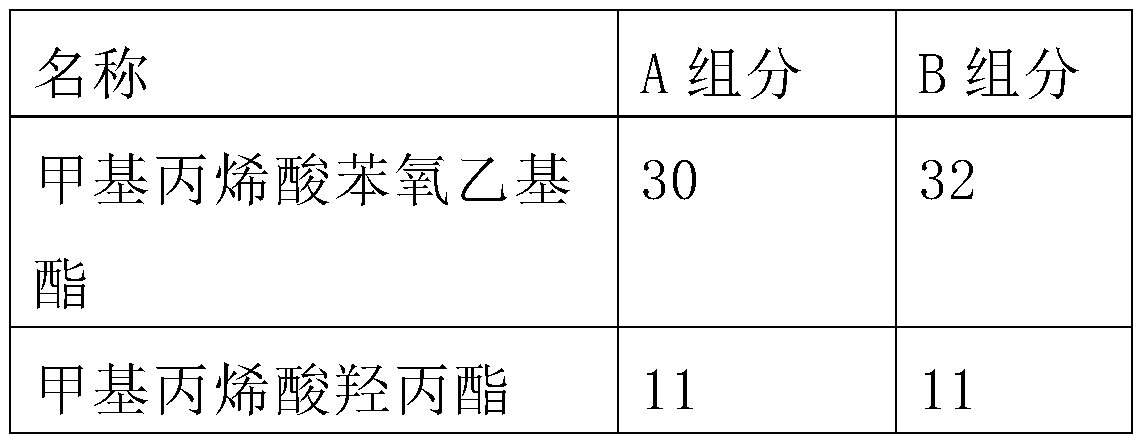

[0058] Embodiment 2 is specifically shown in Table 2:

[0059] Table 2

[0060]

[0061]

[0062] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com