Fused magnesia smelting process multilevel demand control method

A technology of fused magnesia and a control method, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problems of not considering the operation type of fused magnesia furnace, reducing power consumption efficiency, overshoot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

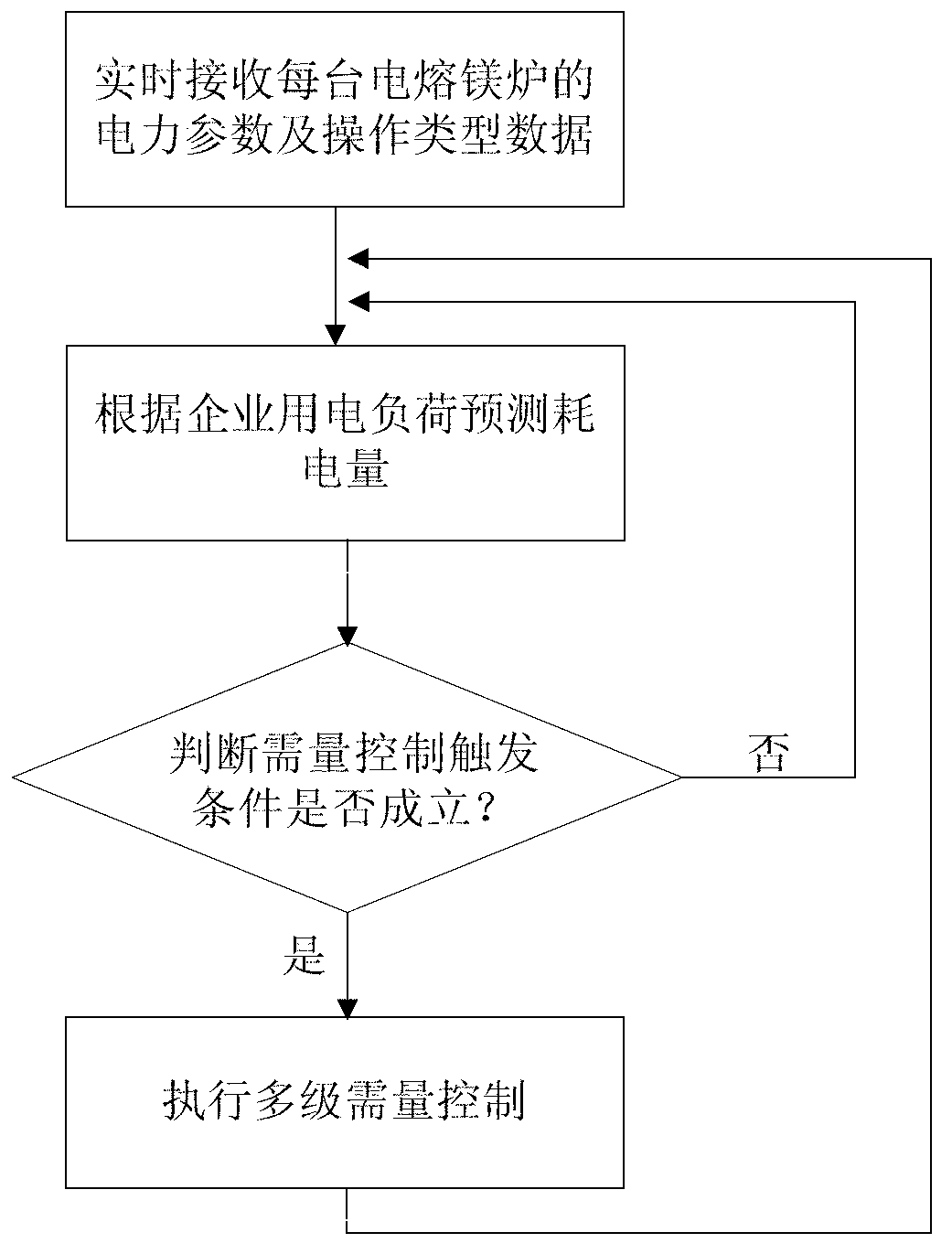

[0074] A multi-stage demand control method for fused magnesia smelting process, the process is as follows figure 1 shown, including the following steps:

[0075] Step 1: Obtain the power parameters and operation types of the current smelting process of each electric fused magnesium furnace. The power parameters include: electrode current, secondary side voltage of the transformer in front of the furnace, and power factor; the operation types include feeding and exhaust and main melt;

[0076] In the embodiment of the present invention, the communication connection between the electrode lifting control system of the fused magnesium furnace and the demand control system is established. Every 1 second, the demand control system receives data such as power parameters and operation types of each fused magnesium furnace sent by the electrode lifting contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com