Steel pile type laver culture device in shallow water area

A shallow water area and steel column technology, which is applied in the field of steel column pile-type seaweed cultivation devices in shallow water areas, can solve problems such as easy rollover or tilt, manual operation, and high labor intensity, so as to improve wind and wave resistance, reduce management costs, Guarantee the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

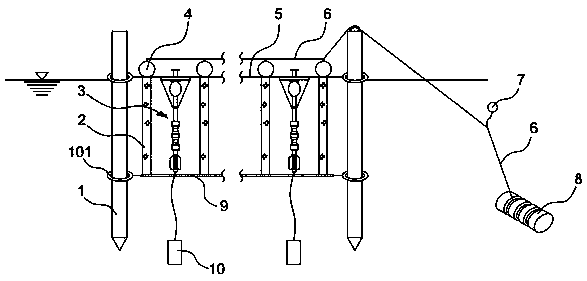

[0028] Such as figure 1 , 4 , shown in 5, a kind of shallow-water area steel pile type laver cultivation device, comprises the steel pile 1 that is evenly distributed on the seabed, and the steel pile 1 is sleeved with at least two floating rings 101; Floating ring 101 connects the culture net 5 that lays horizontally, and the suspension bar 9 that steel column stake 1 lowermost floating ring 101 connects horizontal arrangement; Dry dew component3. The present invention utilizes the dry dew component 3 and the natural force of the tidal range to make the breeding net 5 dry out of the water automatically when the tide is high, and the drying effect is good, and no personnel are needed for management and operation, just regular inspection or inspection, which effectively reduces management costs. The column pile 1 effectively ensures the stability of the column pile on the seabed while preventing the column pile from being corroded by seawater. The floating ring 101 can make t...

Embodiment 2

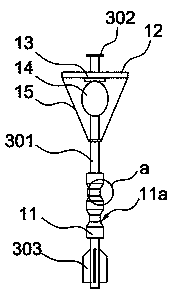

[0035] refer to figure 2 , 3 , this embodiment is further optimized on the basis of Embodiment 1 as follows: the dry dew assembly 3 includes a support rod 301 vertically arranged with the aquaculture net 5, the upper end of the support rod 301 is located above the aquaculture net 5 and is provided with a limit bar 302, the support rod The lower end of 301 is provided with empennage 303 . When the breeding net 5 floats up and down with the tide water, it can float up and down on the support rod 301, and prevent the breeding net 5 from breaking away from the support rod 301 by the limit bar 302, further improving the stability of the breeding net 5 in the demarcated breeding area. The tail fin 303 is provided at the lower end to improve the stability of the support rod 301, preventing waves from affecting the support rod 301 and causing the support rod 301 to swing violently, which affects the drying effect of laver.

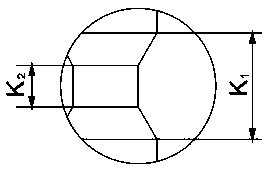

[0036] The support rod 301 below the limit bar 302 is con...

Embodiment 3

[0043] When the device of the present invention is actually used: select a suitable shallow sea culture area, put the device of the present invention into the shallow sea area and plan the culture area, avoid dense crowding in the same sea area, and choose to stock at the end of September or early October, Do a good job in seedling picking preparations, and pay attention to strengthening management after the net sheets are used for picking seedlings. The buoyancy increases obviously, and the floating block 14 floats upwards relative to the support bar 301. Because the structure of the floating block 14 can separate the pick bar 12 and the culture net 5 from the seawater surface, the laver can be dried out. During the floating process of the floating block 14, the floating Block 14 generates extrusion force to dynamometer 13, and dynamometer 13 can transmit the force measurement data collected to land computer through wireless transmission technology, and calculate the growth ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com