Automatic baking equipment of lithium battery

A baking equipment, lithium battery technology, applied in the direction of lighting and heating equipment, non-aqueous electrolyte battery, electrolyte battery manufacturing, etc., can solve the problems of reducing production efficiency, affecting product quality, increasing production costs, etc., to improve the degree of automation and Production efficiency, reduce labor intensity and production cost, improve production efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

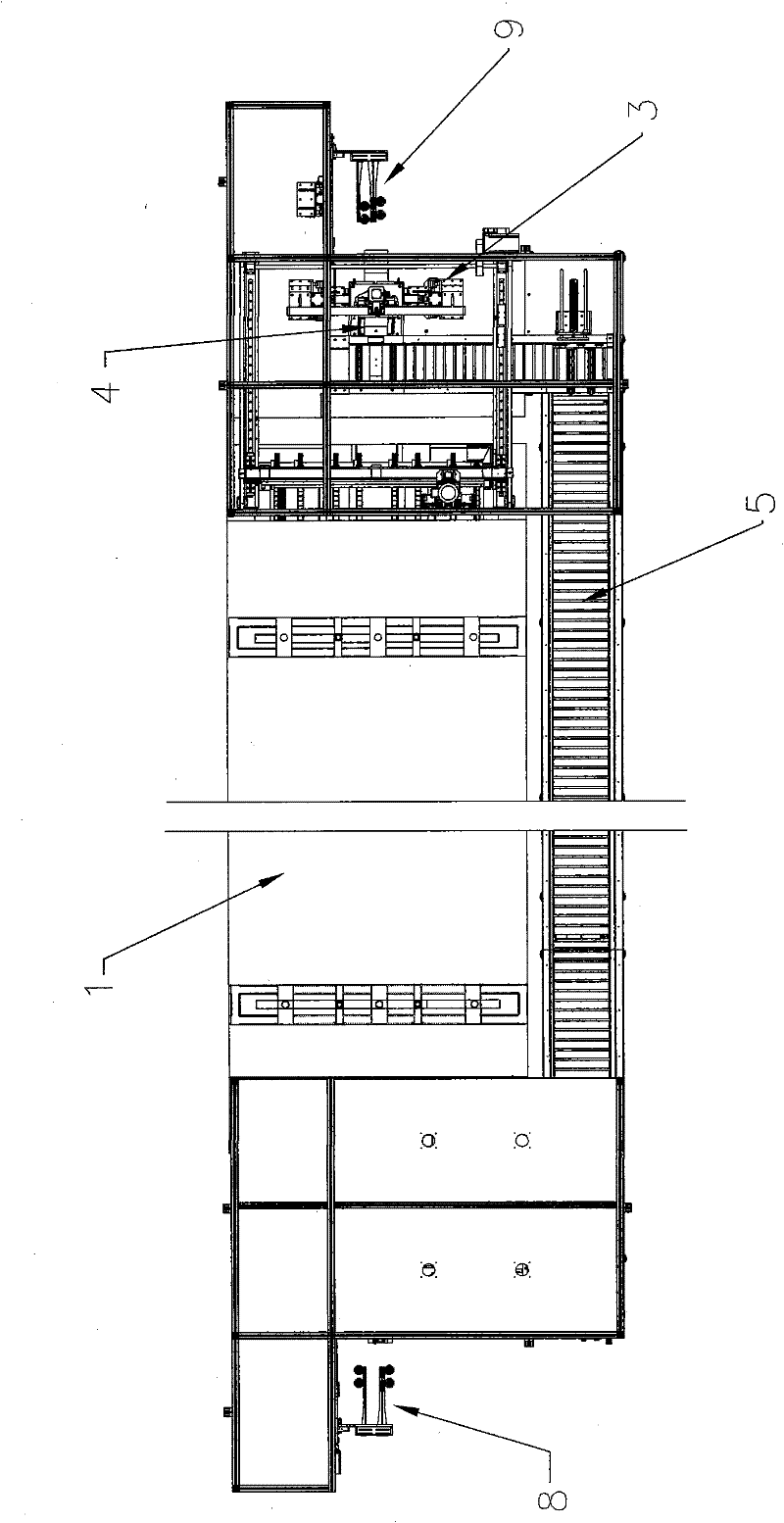

[0027] Such as Figure 1 to Figure 6 As shown, the lithium battery automatic baking equipment of the present invention includes a tunnel furnace 1, and the left and right sides of the tunnel furnace 1 are respectively provided with a feeding manipulator 8 and a feeding manipulator 9. Automatic baking jig device 4 and baking jig handling manipulator 3; the front side of the tunnel furnace 1 is provided with a drum recovery line 5;

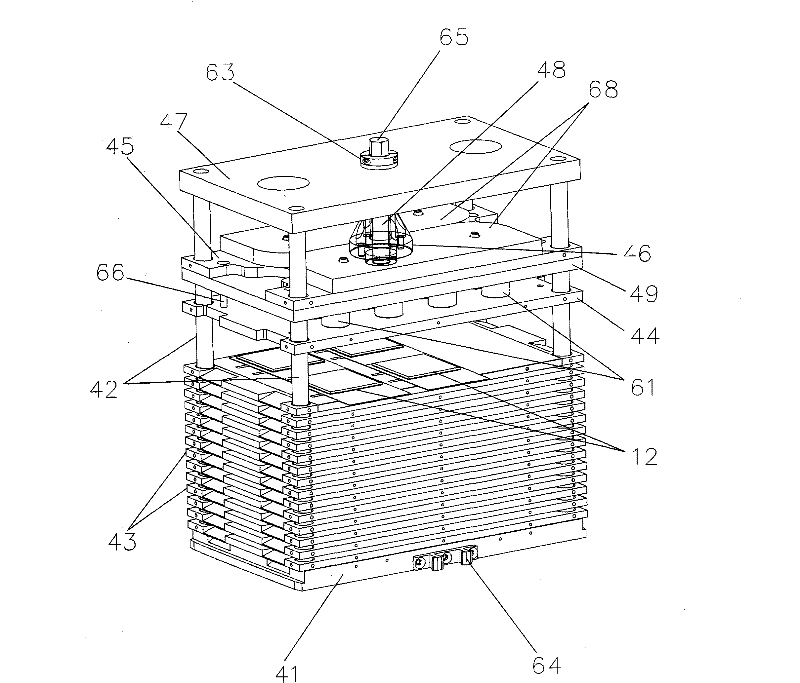

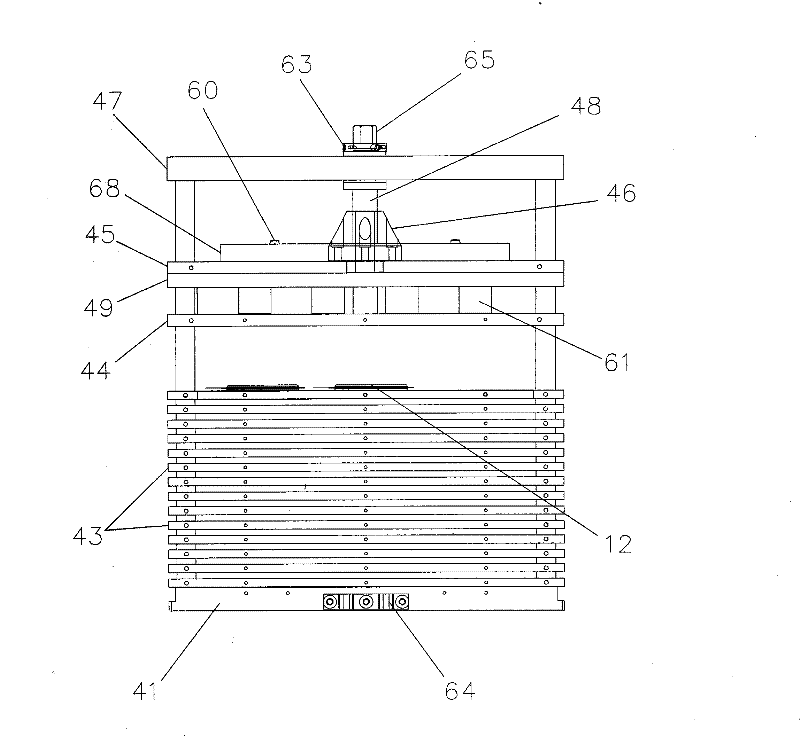

[0028] The automatic baking fixture device 4 includes a baking fixture, and the baking fixture includes a top plate 47, a bottom plate 41, a guide post 42, a pressing plate 44, a spring pressing plate 49, a floating plate 45, a compression spring 61, a screw rod 48, and a screw sleeve 46 And some dividing plates 43; The top plate 47 and the bottom plate 41 are respectively arranged on the upper and lower ends of the guide column 42, and the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com