A technology for bon a dual-row QFN integrated circuit

An integrated circuit and welding process technology, which is applied in the field of double-row QFN integrated circuit welding process, can solve problems such as increasing risks, and achieve the effects of increasing tin climbing height, reducing volume, and solving virtual soldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A double-row QFN integrated circuit welding process is characterized in that it comprises the following process steps:

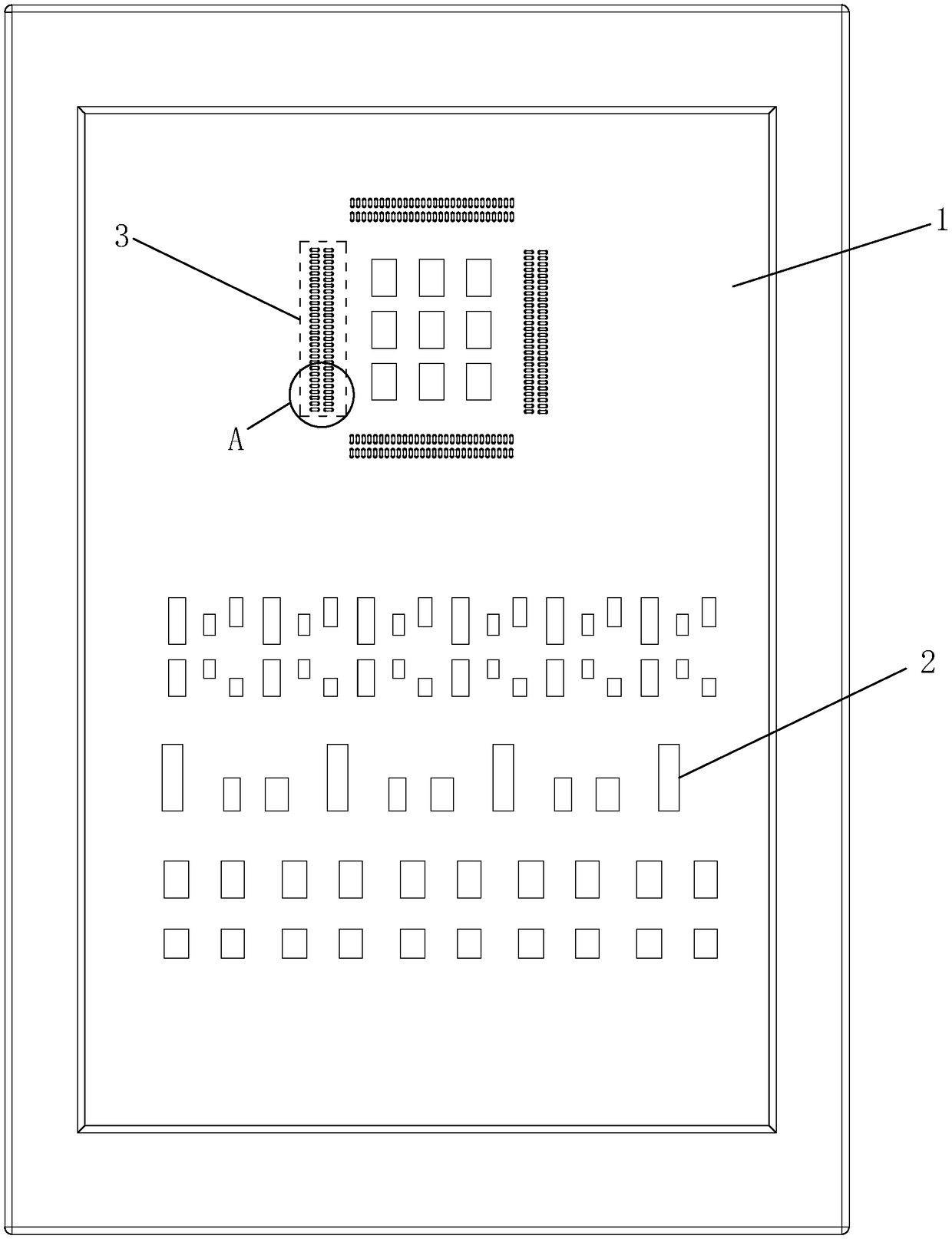

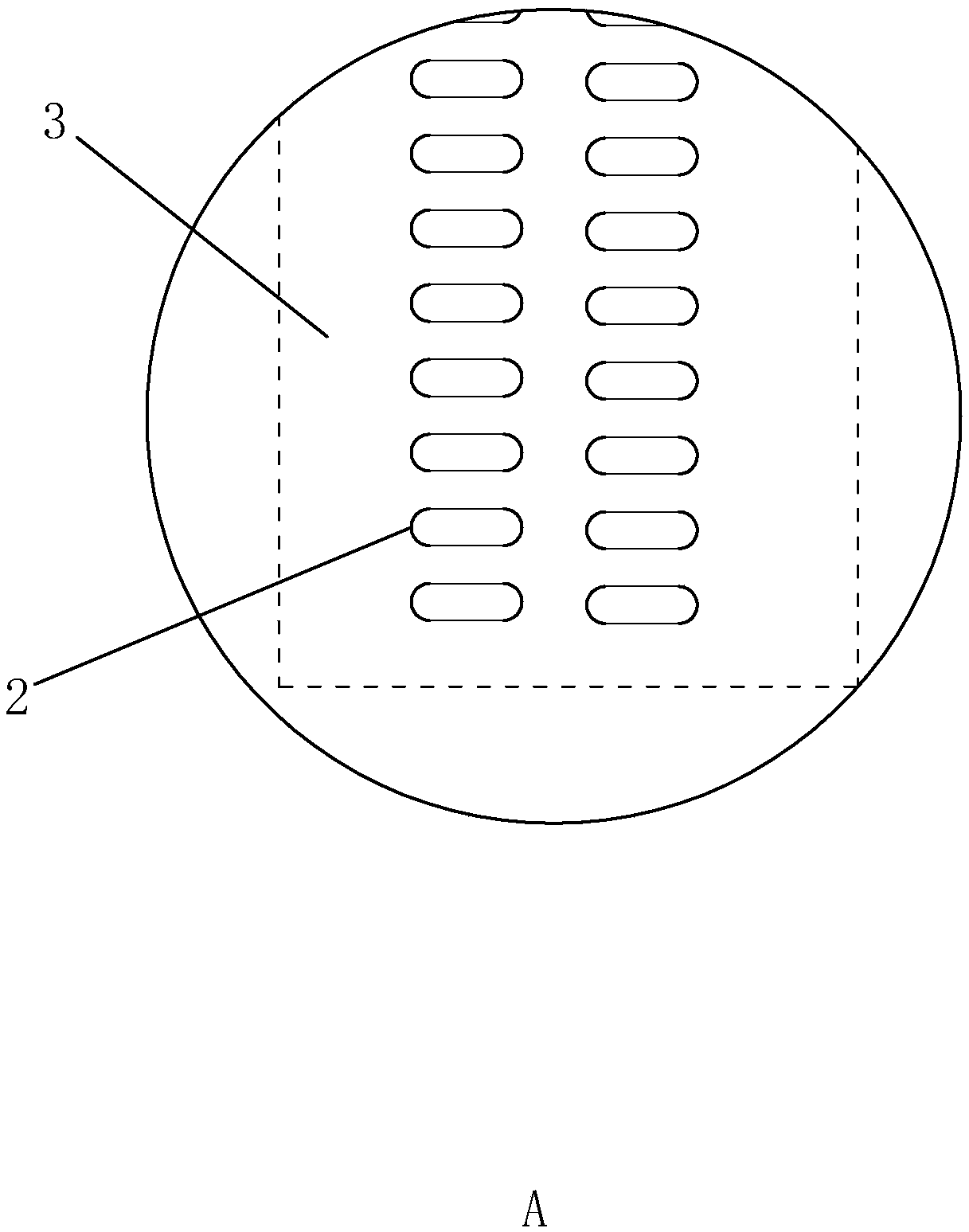

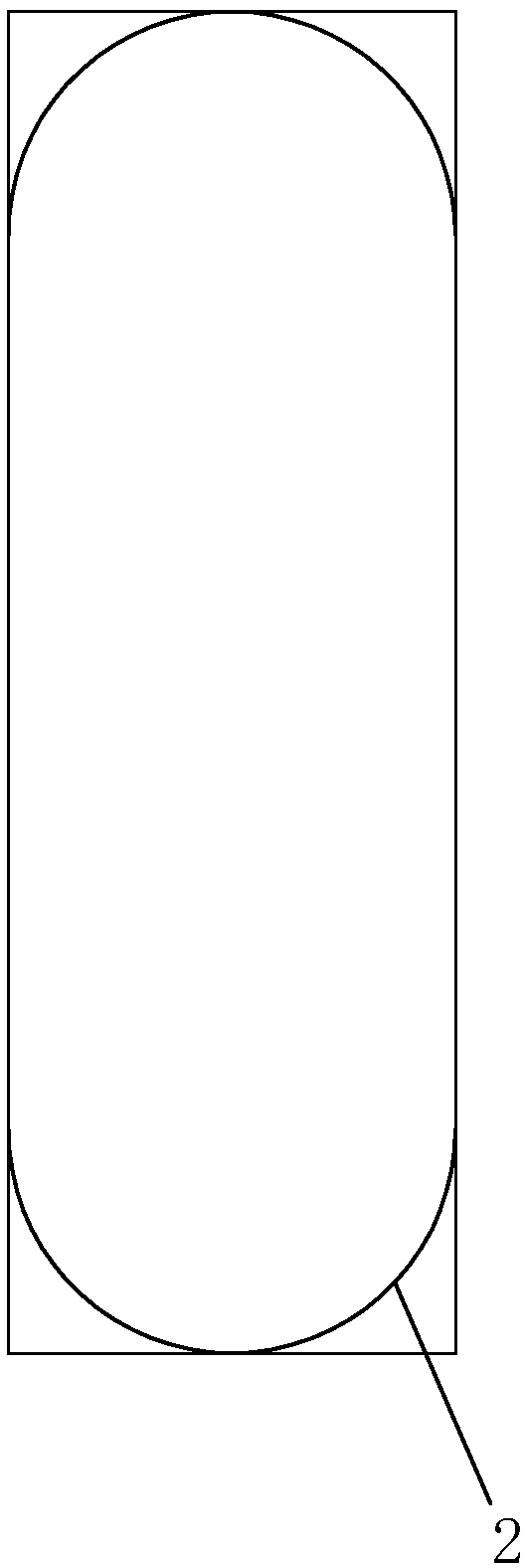

[0028] S1) Screen printing: Use a screen printing machine to brush solder paste on the pads of the circuit board, wherein the area where the distance between the openings 2 on the steel plate 1 is less than or equal to 0.2mm is set as the fine-pitch area 3, and the fine-pitch area The ratio of the area of the opening 2 in 3 to the area of the circuit board pad is 0.85, the opening 2 in the fine-pitch area 3 is waist-shaped, and the two long sides of the opening 2 in the fine-pitch area 3 are straight lines parallel to each other And the two ends of the length direction of the opening 2 are symmetrical circular arcs, the thickness of the steel plate 1 is 0.09mm, the thickness ratio of the thickness of the fine-pitch area 3 to the thickness of the steel plate 1 is 0.85; the printing speed of the screen printing machine is 30mm / s, The front and rear ...

Embodiment 2

[0035] A double-row QFN integrated circuit welding process is characterized in that it comprises the following process steps:

[0036] S1) Screen printing: Use a screen printing machine to brush solder paste on the pads of the circuit board, wherein the area where the distance between the openings 2 on the steel plate 1 is less than or equal to 0.2mm is set as the fine-pitch area 3, and the fine-pitch area The ratio of the area of the opening 2 in 3 to the area of the circuit board pad is 0.9, the opening 2 in the fine-pitch area 3 is waist-shaped, and the two long sides of the opening 2 in the fine-pitch area 3 are straight lines parallel to each other And the two ends of the length direction of the opening 2 are symmetrical circular arcs, the thickness of the steel plate 1 is 0.1mm, and the thickness ratio of the thickness of the fine-pitch area 3 to the thickness of the steel plate 1 is 0.9; the printing speed of the screen printing machine is 36mm / s, The front and rear...

Embodiment 3

[0043] A double-row QFN integrated circuit welding process is characterized in that it comprises the following process steps:

[0044] S1) Screen printing: Use a screen printing machine to brush solder paste on the pads of the circuit board, wherein the area where the distance between the openings 2 on the steel plate 1 is less than or equal to 0.2mm is set as the fine-pitch area 3, and the fine-pitch area The ratio of the area of the opening 2 in 3 to the area of the circuit board pad is 0.95, the opening 2 in the fine-pitch area 3 is waist-shaped, and the two long sides of the opening 2 in the fine-pitch area 3 are straight lines parallel to each other And the two ends of the length direction of the opening 2 are symmetrical circular arcs, the thickness of the steel plate 1 is 0.11mm, the thickness ratio of the thickness of the fine-pitch area 3 to the thickness of the steel plate 1 is 0.95; the printing speed of the screen printing machine is 40mm / s, The front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com