Patents

Literature

421results about "Dynamoelectric machine connectors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

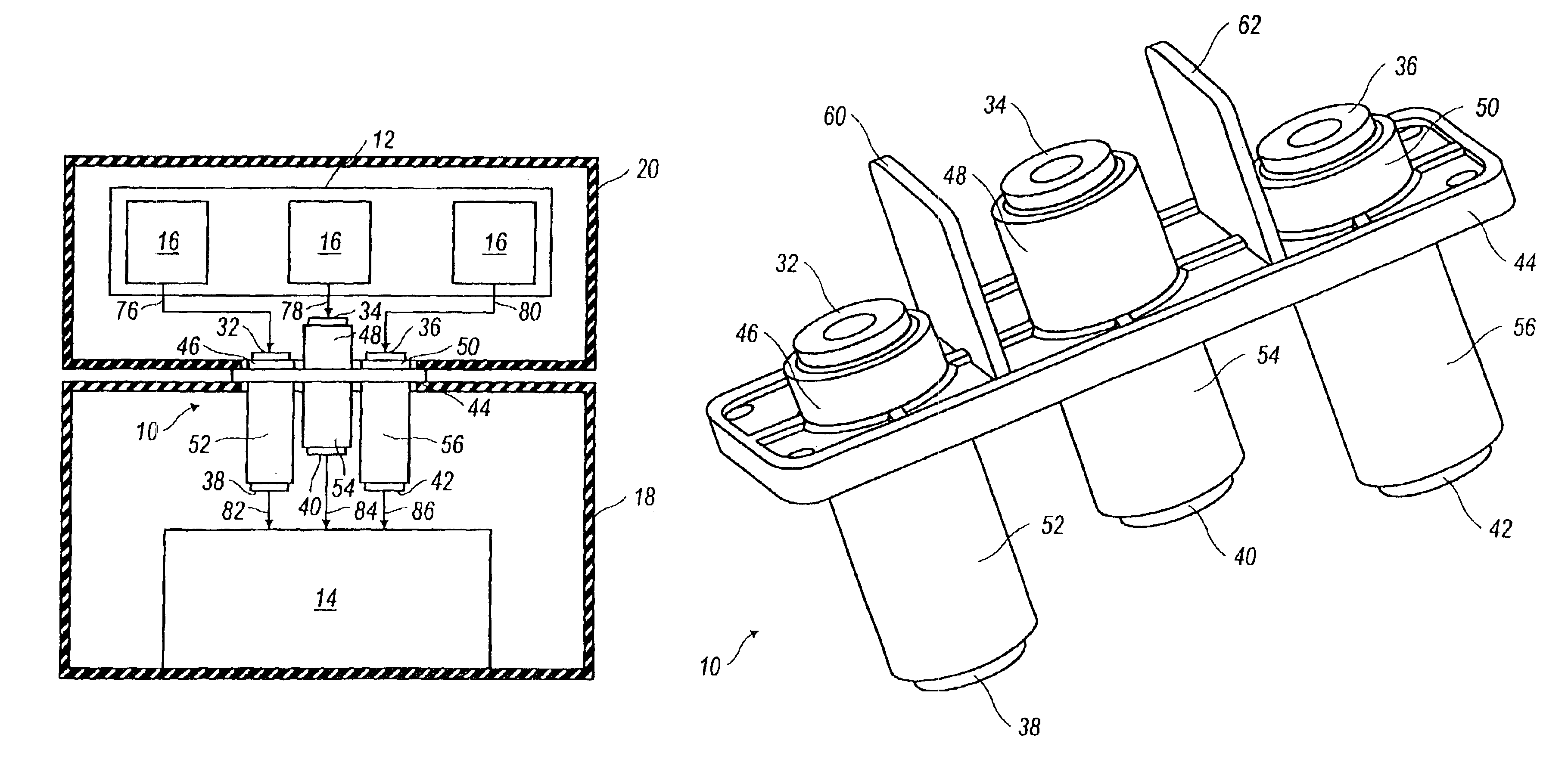

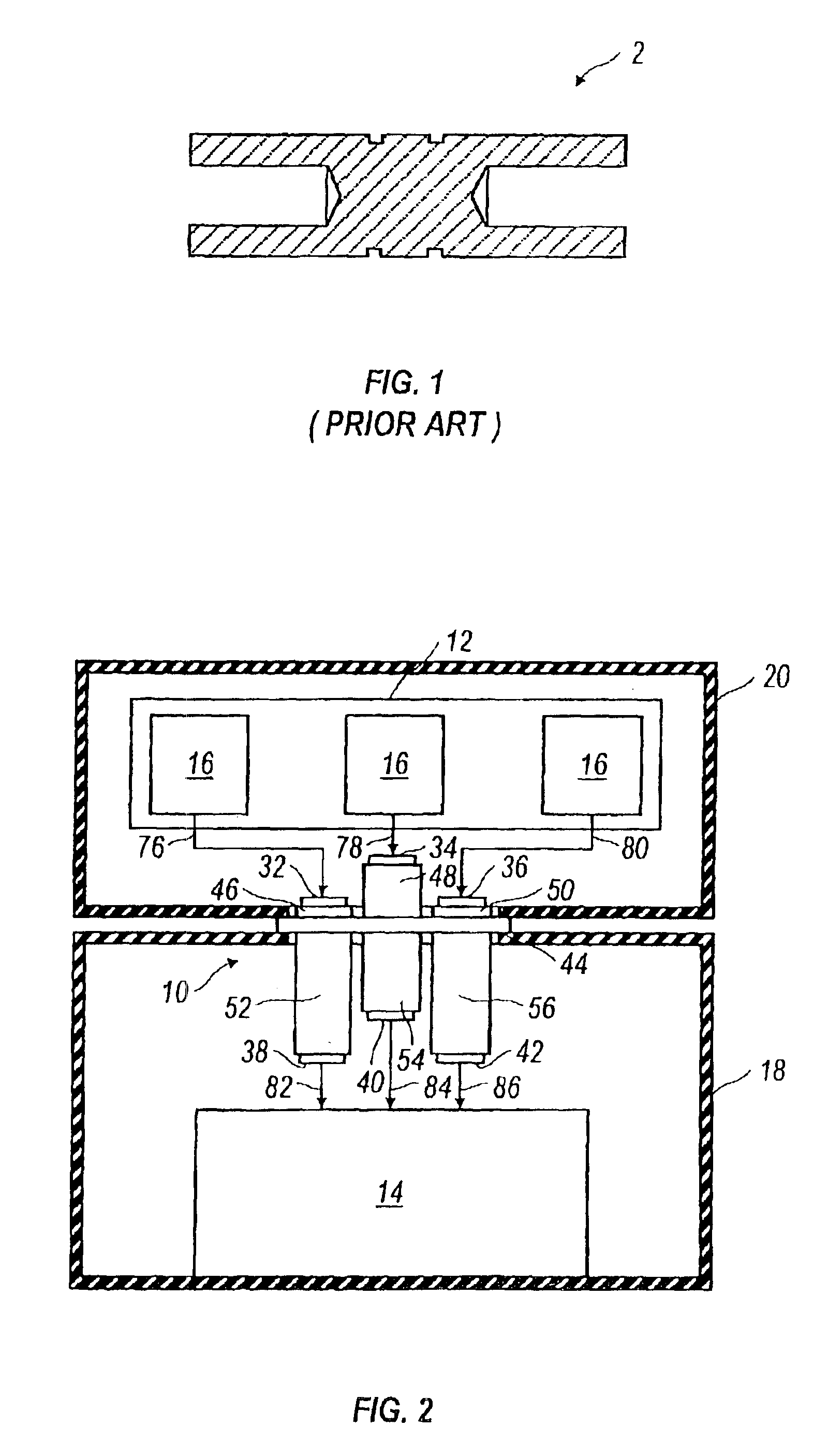

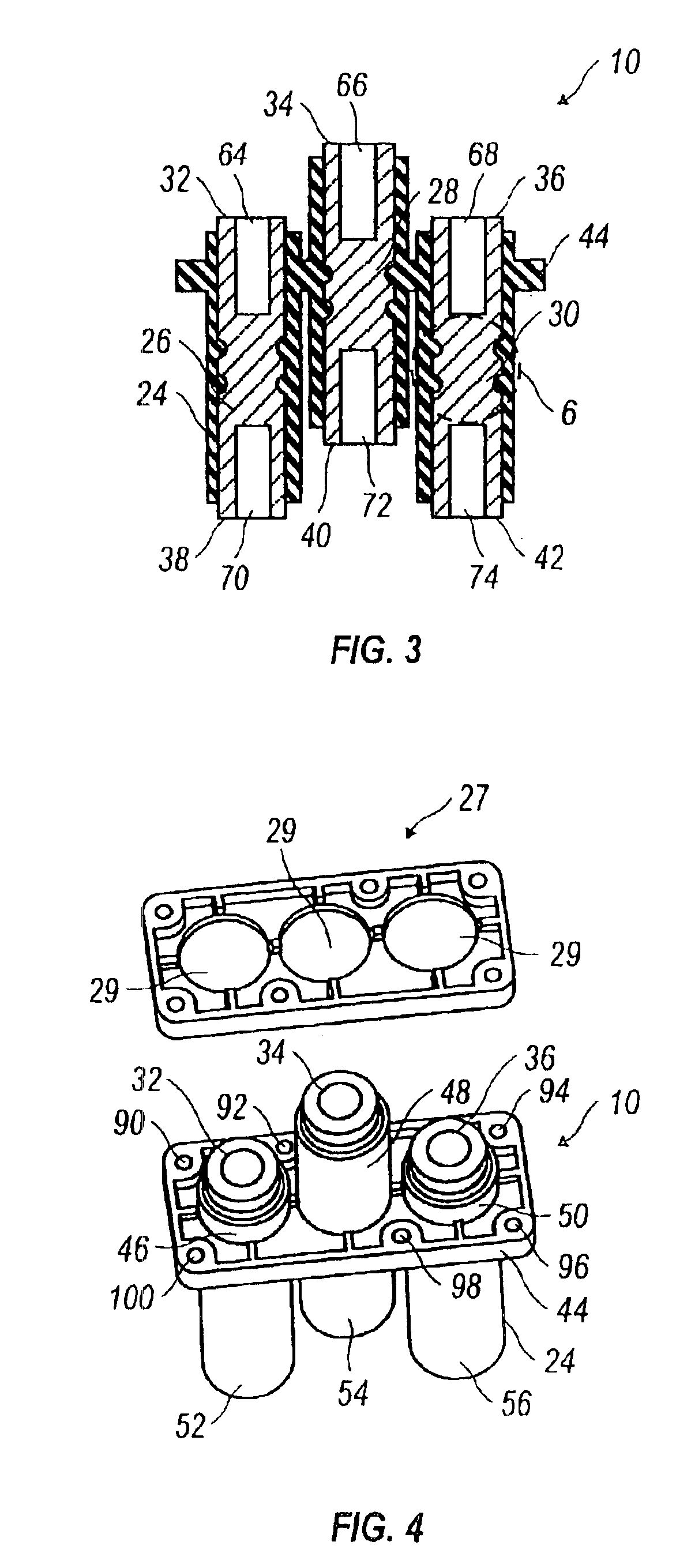

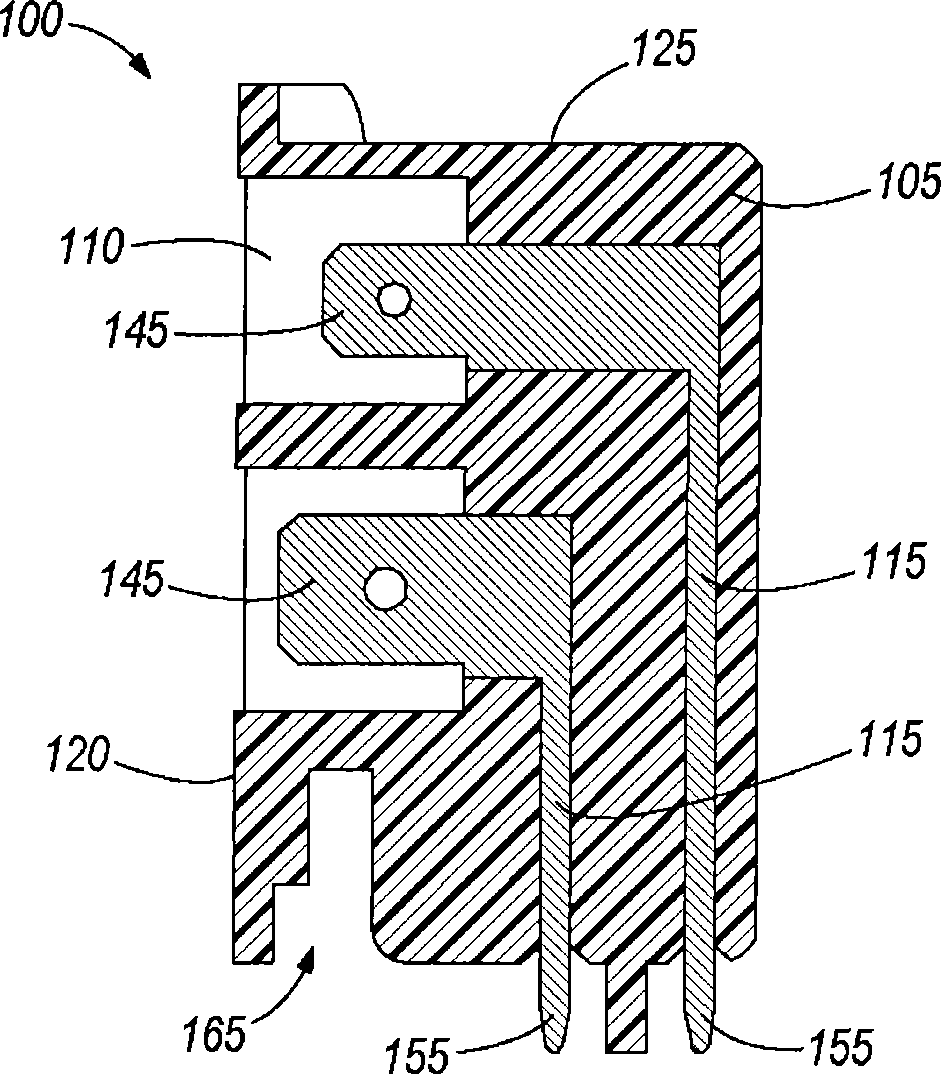

Three-phase connector for electric vehicle drivetrain

InactiveUS6890218B2Accurate isolationLow costElectric discharge tubesCoupling contact membersDrivetrainEngineering

A three-phase connector carries all three phases in one connector and keeps the phases properly isolated from each other and the motor case. The three-phase connector has metal connector components that are spaced from one another and supported in a nylon over molding covering each of the connector components, except for upper and lower exposed ends of the connector components, which are each drilled and tapped to receive bolts. First and second connector components extend above and below a flange of the three-phase connector with their respective exposed upper and lower ends offset in different planes than the exposed upper and lower ends of the third connector component.

Owner:SIEMENS VDO AUTOMOTIVE CORP

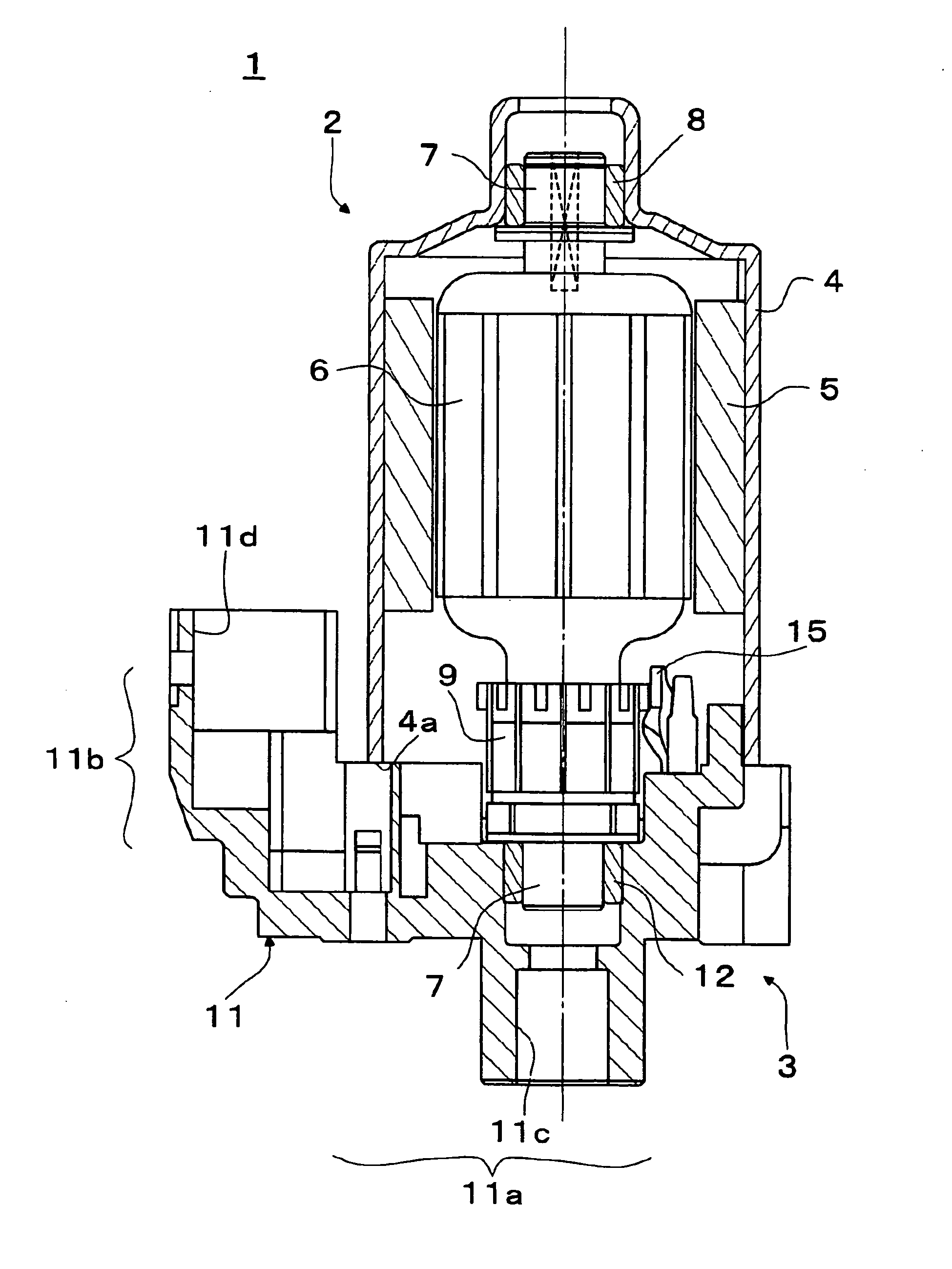

Electric motor

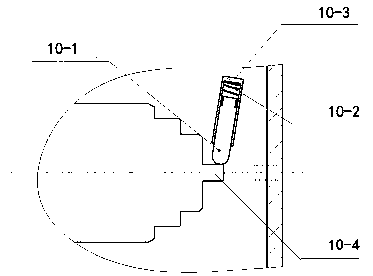

InactiveUS20080284272A1Simple structureRemove limitVehicle connectorsRotary current collectorEngineeringAbutment

In a terminal of an electric motor, a branch projects from a terminal connection on a side opposite from an extension. A projecting end side of the branch extends in an installation direction of the terminal, which is a direction for installing the terminal to a housing. The terminal is tiltable about a portion of the extension, which serves as a fulcrum, to cause abutment of the branch against a wall surface of the housing when the terminal connection receives a force in a direction opposite from the installation direction.

Owner:DENSO CORP

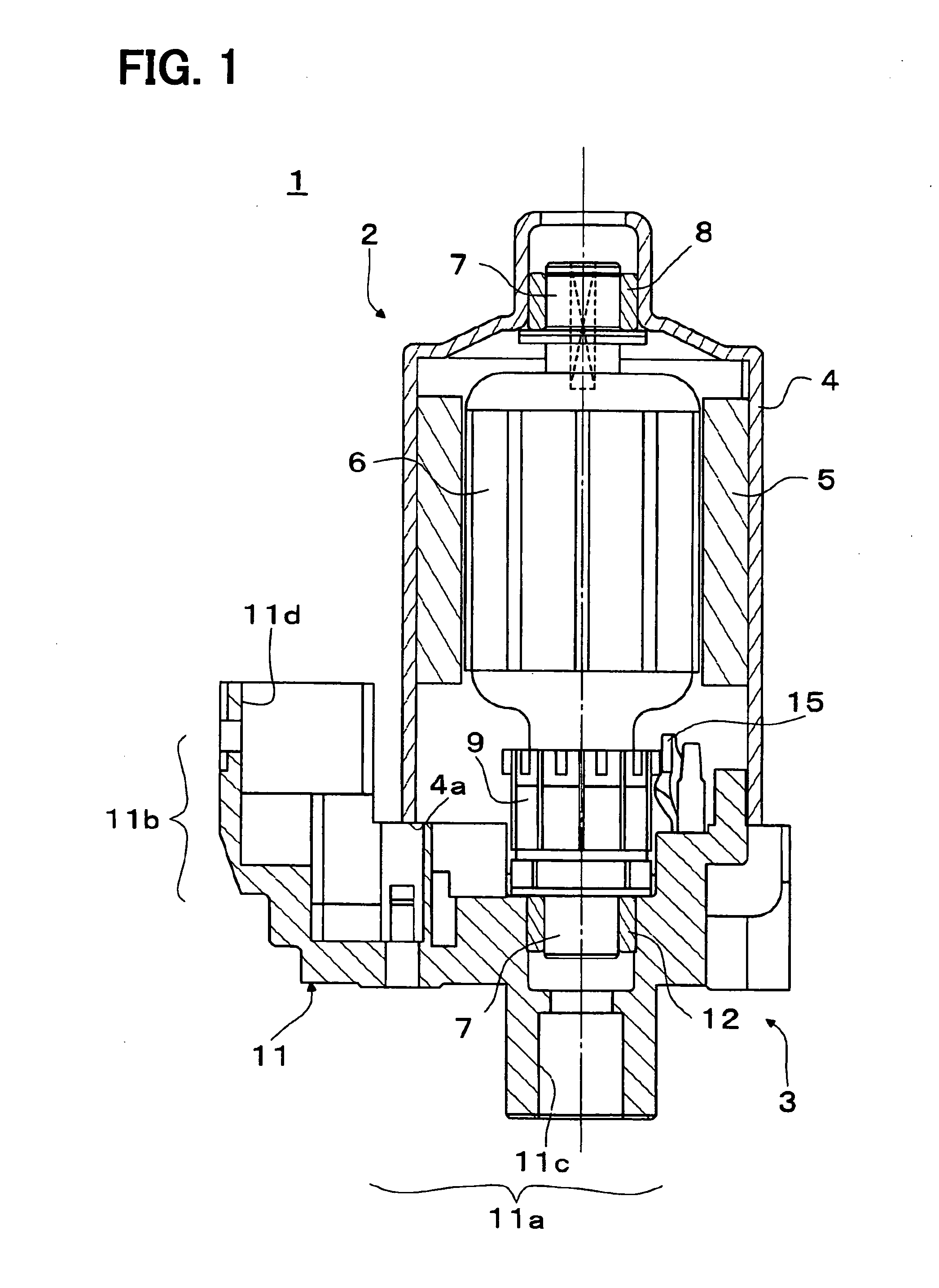

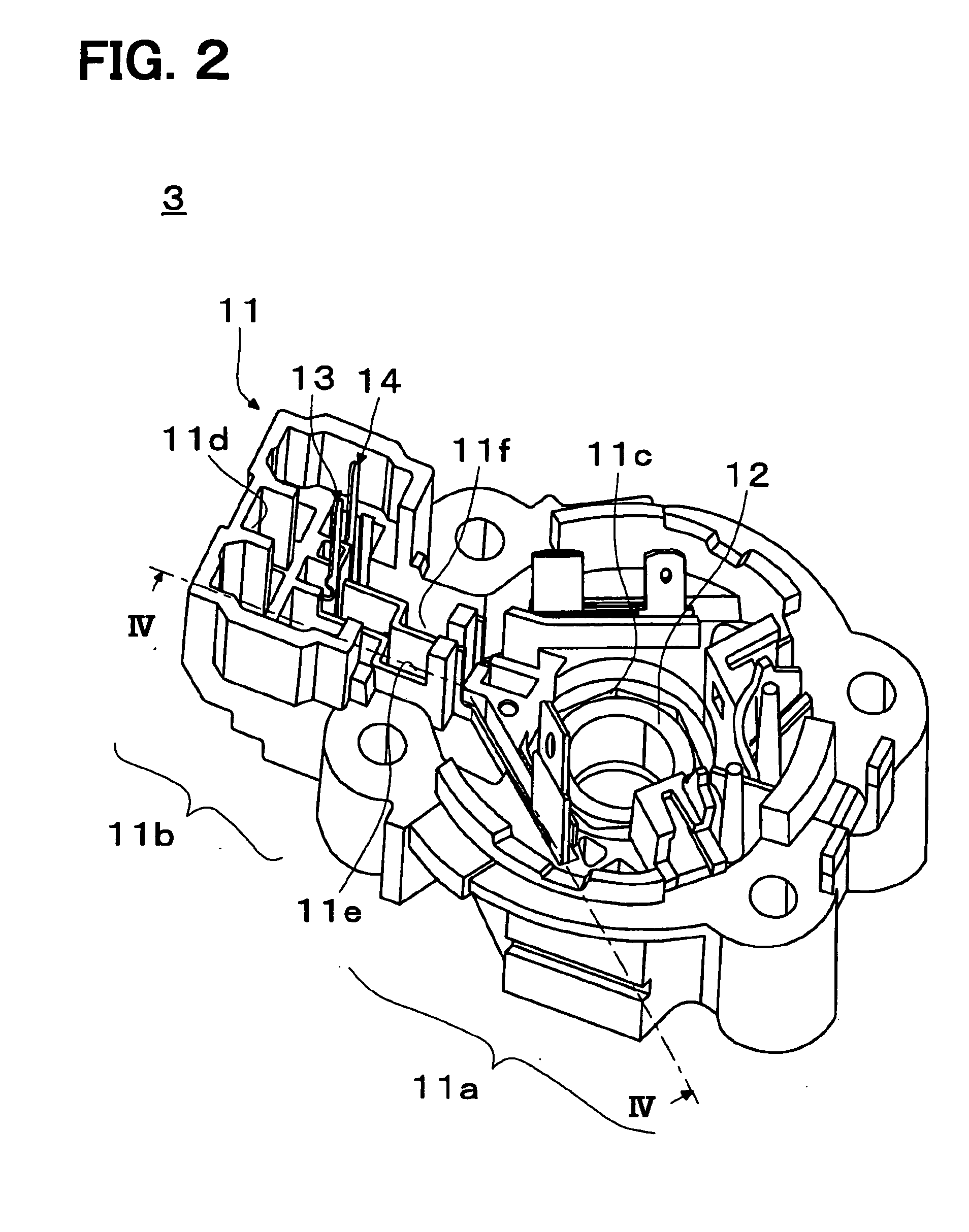

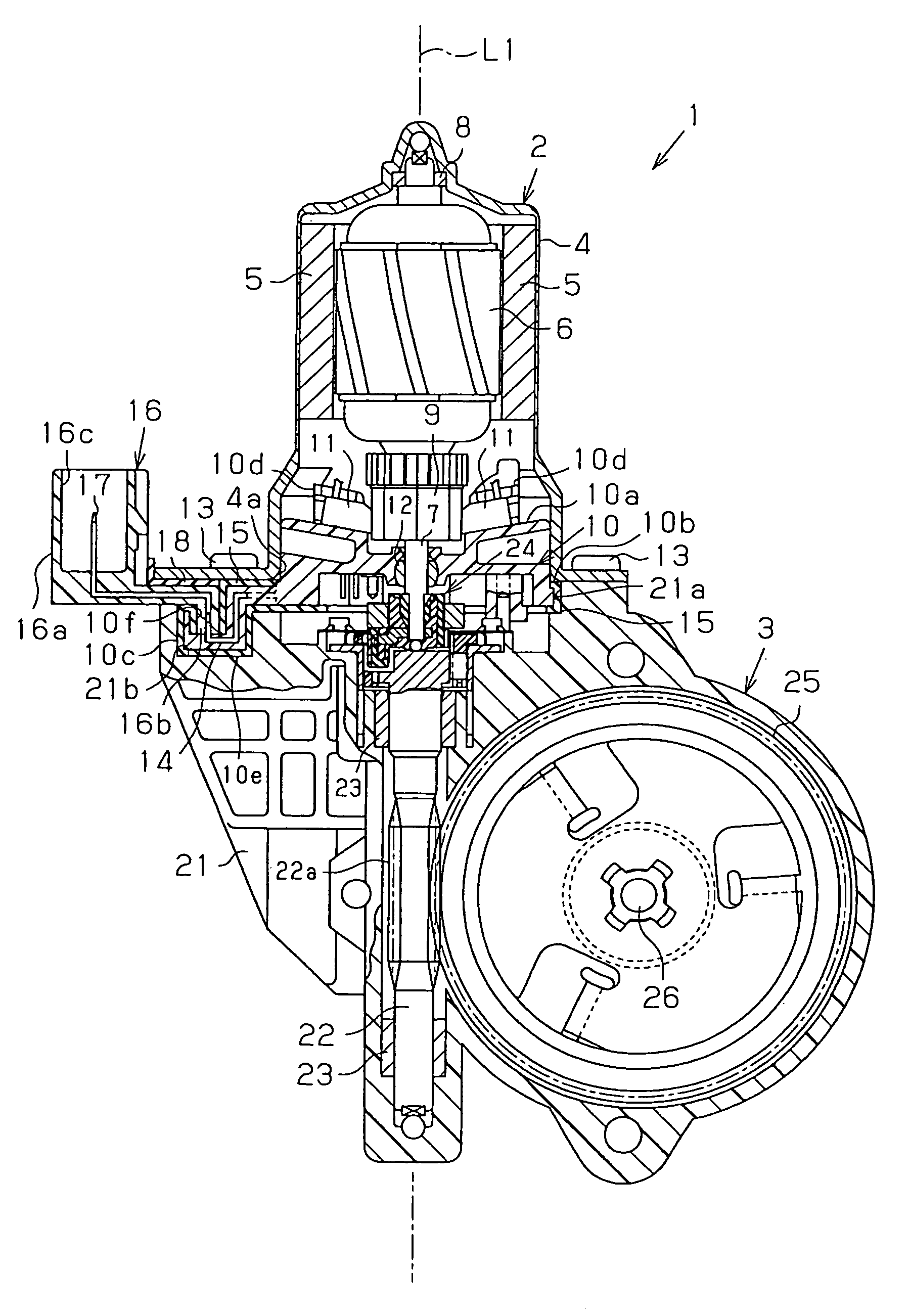

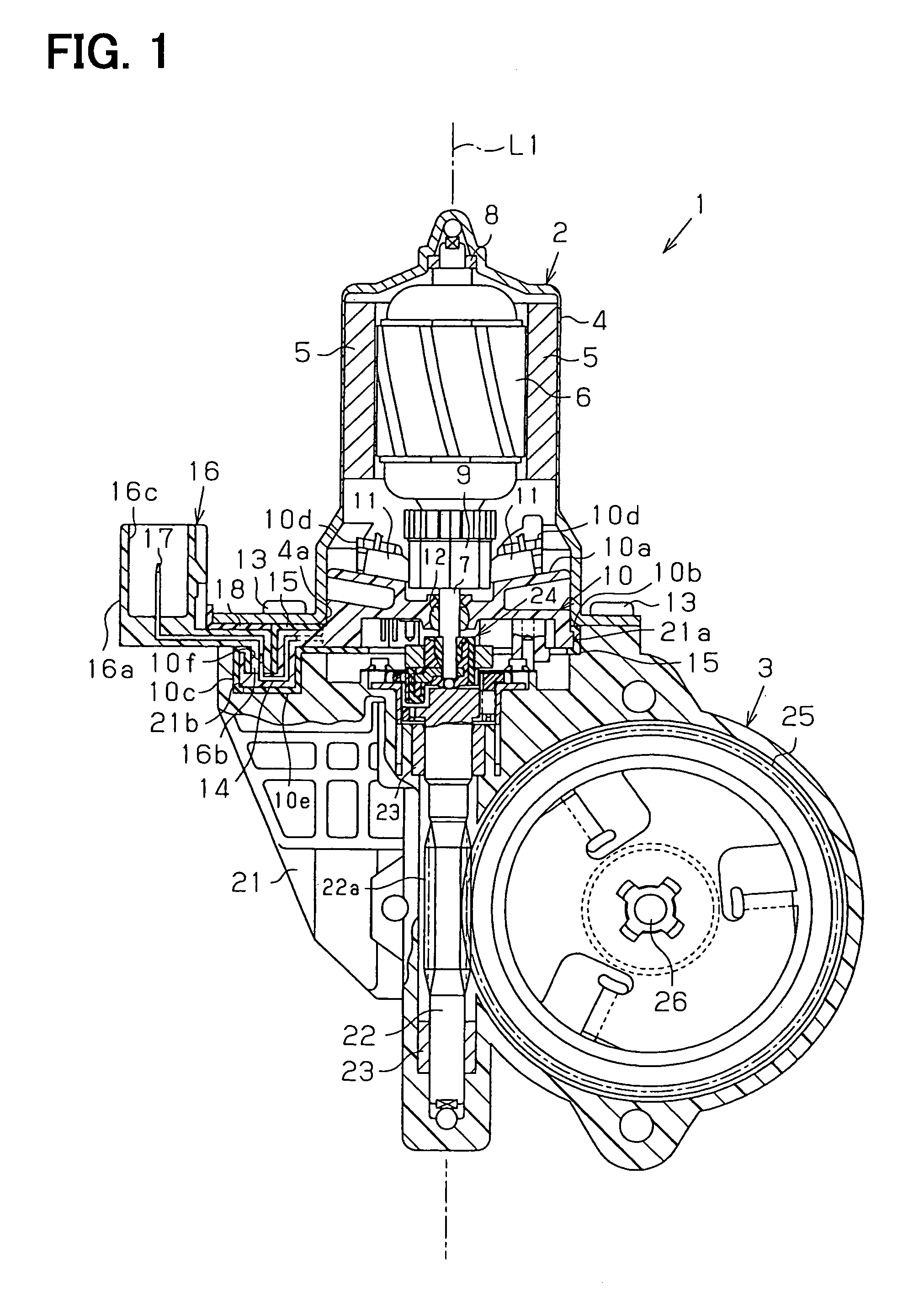

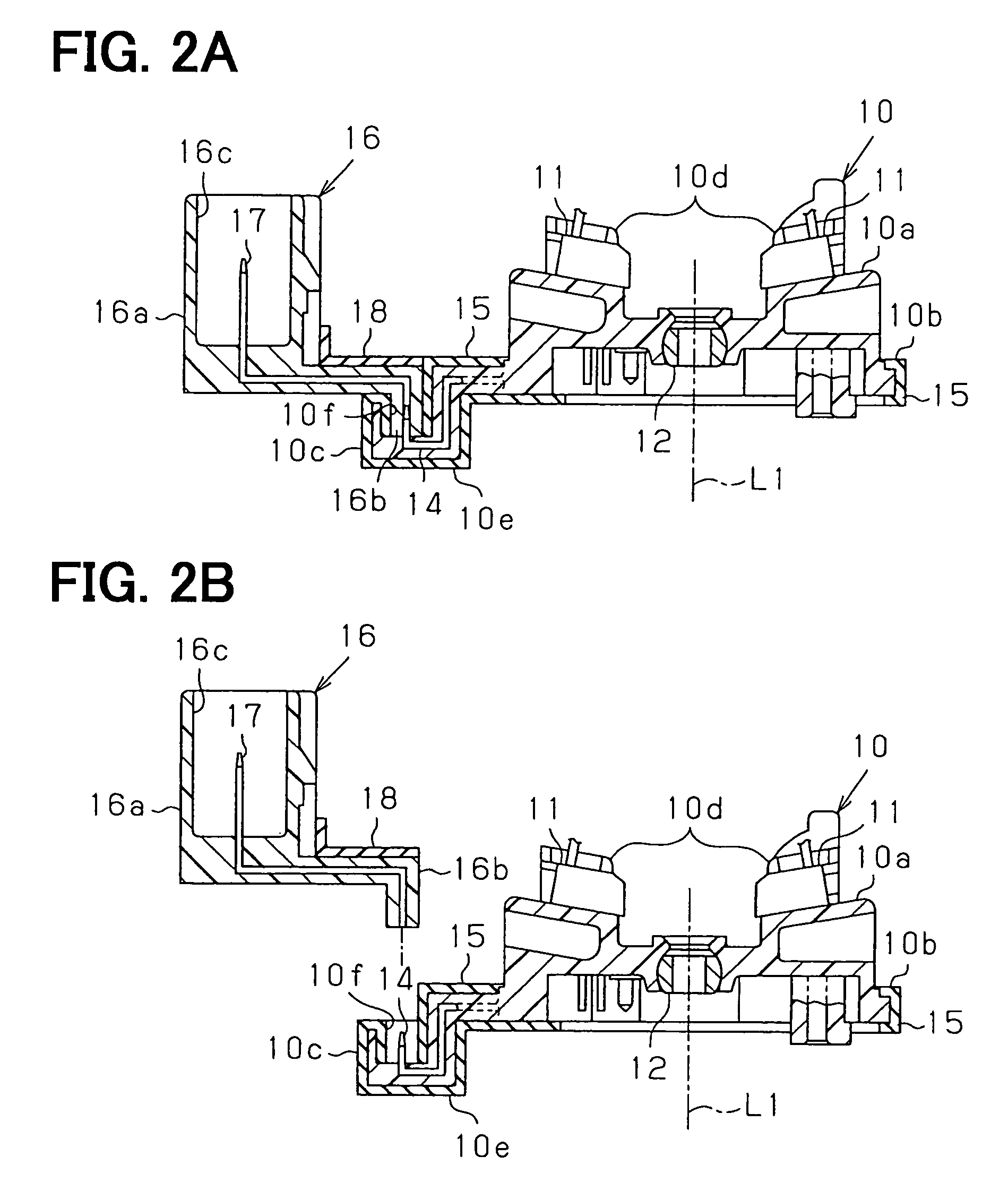

Motor and method for manufacturing motor

InactiveUS7109617B2Reduce wasteAssociation with control/drive circuitsRotary current collectorEngineeringElectrical and Electronics engineering

A holder-side connecting portion 10c provided on a brush holder 10 and a connector-side connecting portion 16b provided on a connector portion 16 are electrically and mechanically connected with each other. The holder-side connecting portion 10c and the connector-side connecting portion 16b are clamped between a yoke housing 4 and a gear housing 21. For this reason, the connecting portions 10c and 16b for connecting the brush holder 10 and the connector portion 16 are prevented from being externally exposed. As a result, the insulation of the connecting portions 10c and 16b can be secured without complicating the construction of the connecting portions 10c and 16b by applying a special seal or the like to the connecting portions 10c and 16b.

Owner:DENSO CORP

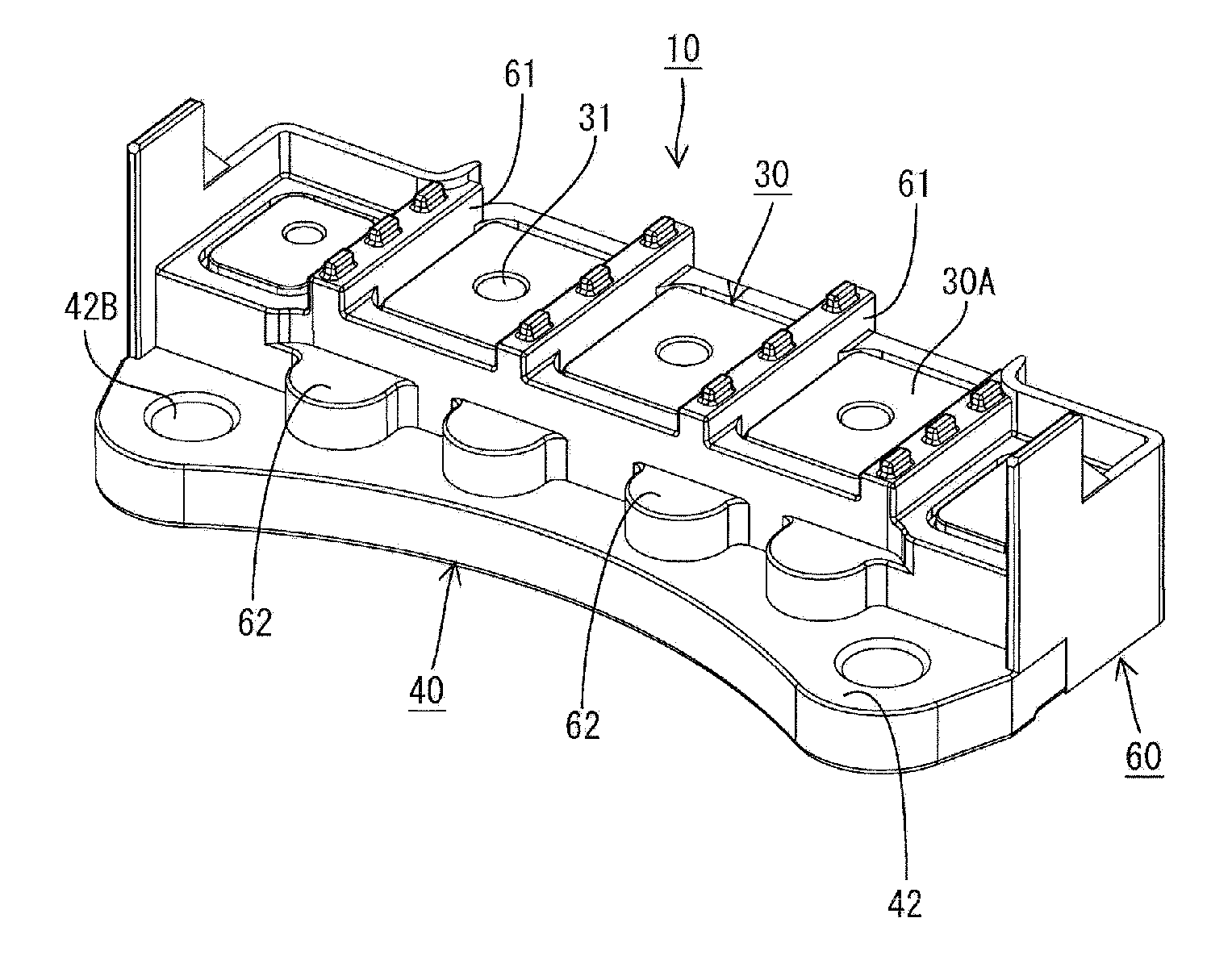

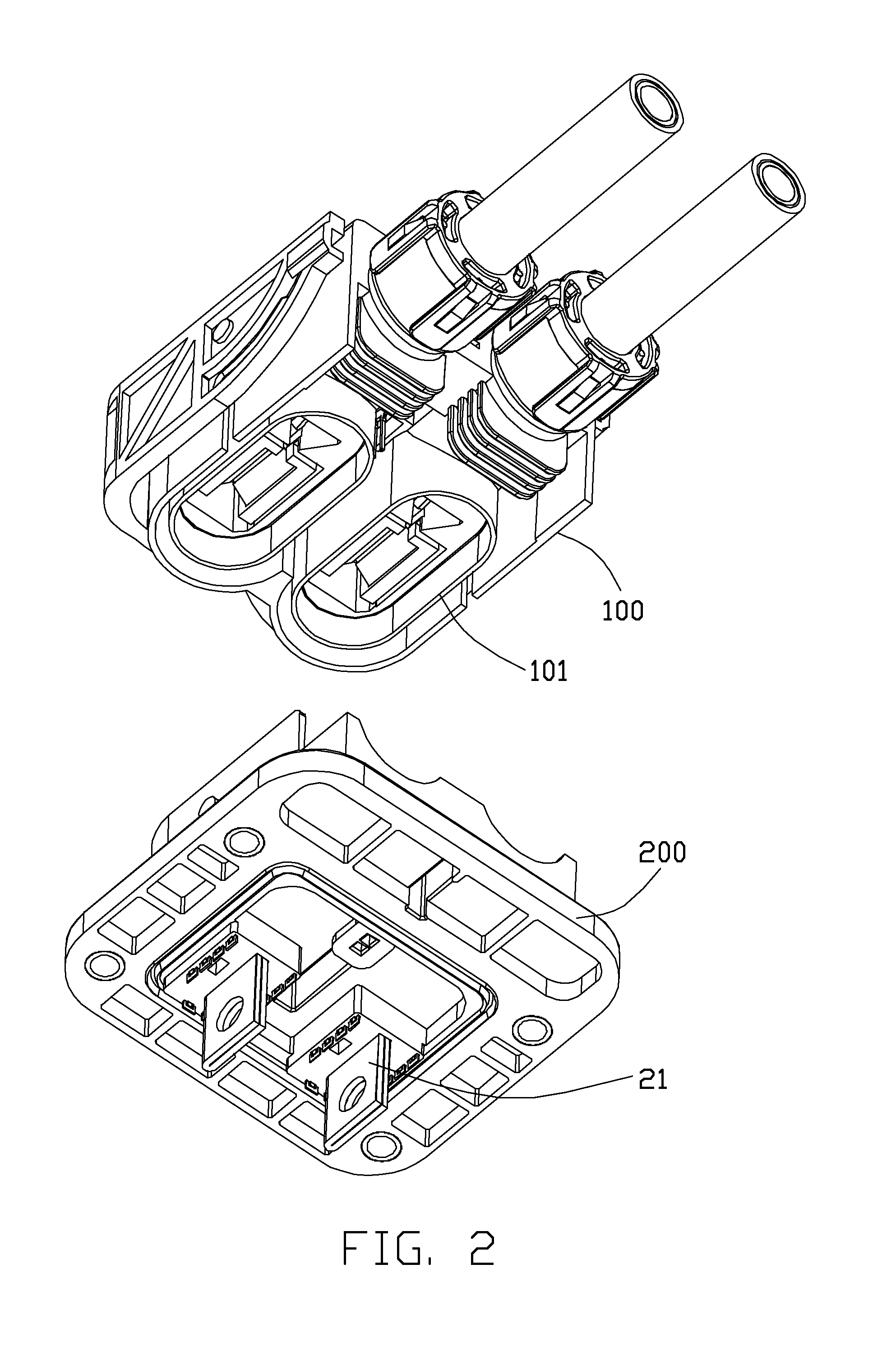

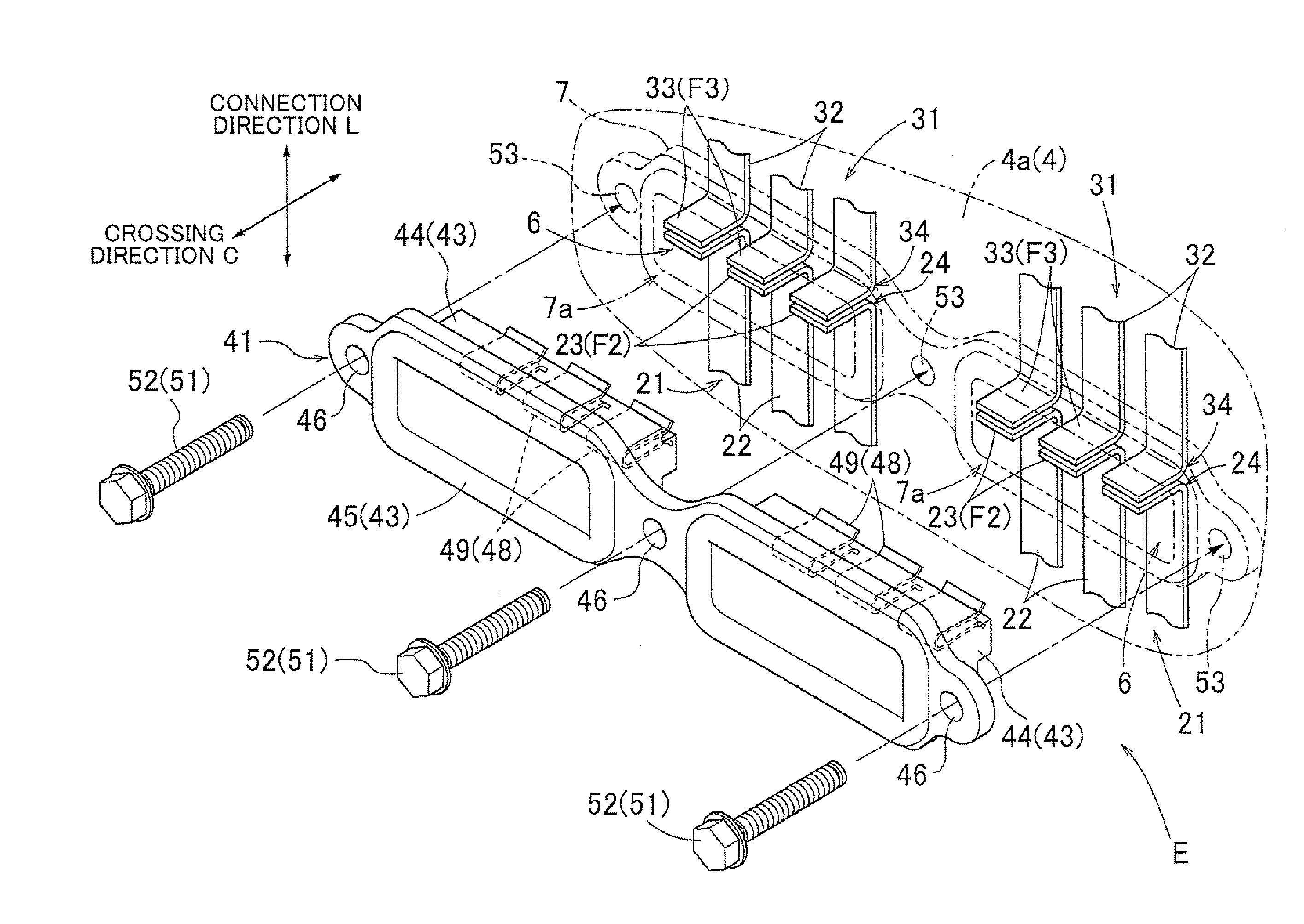

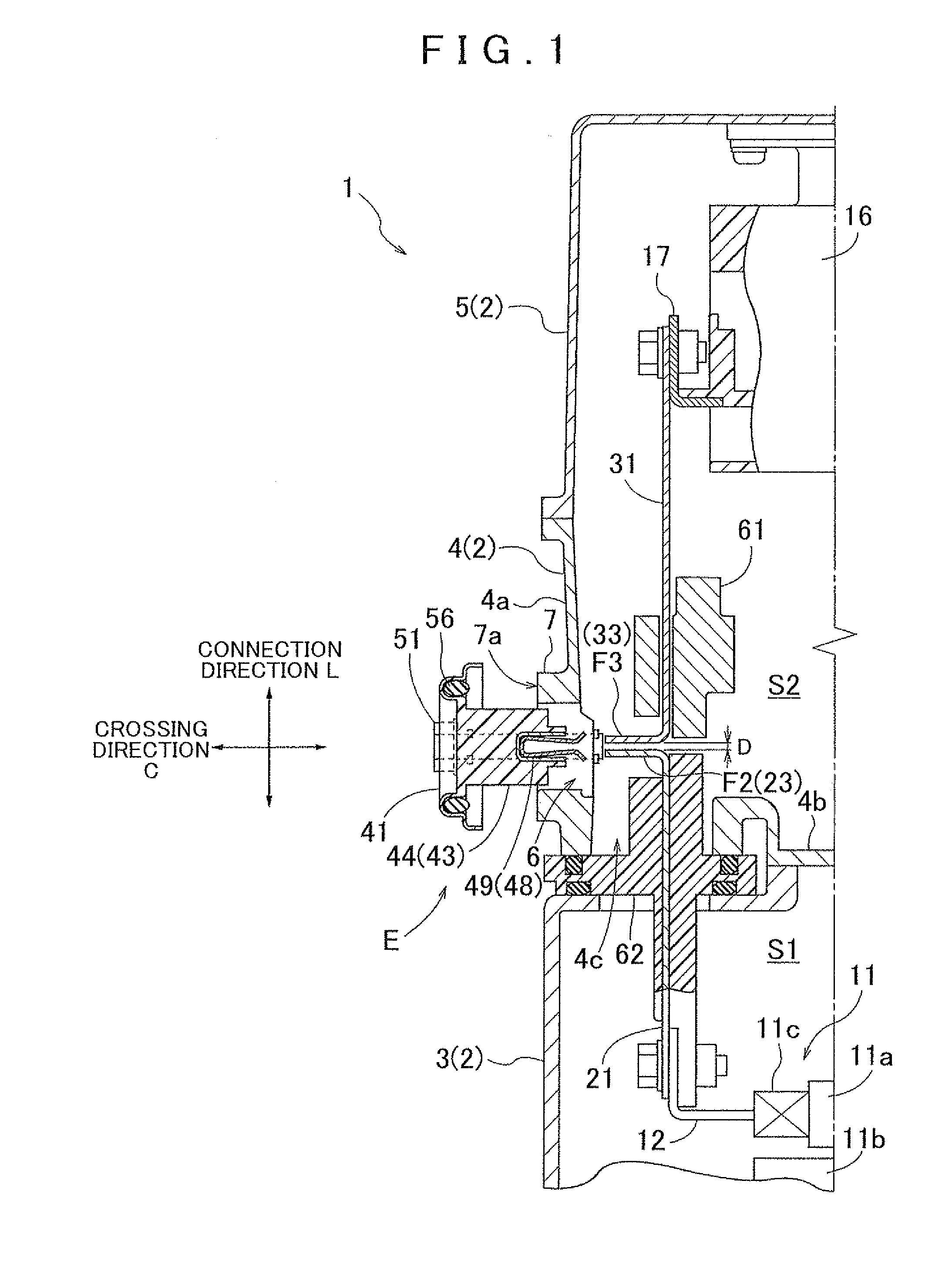

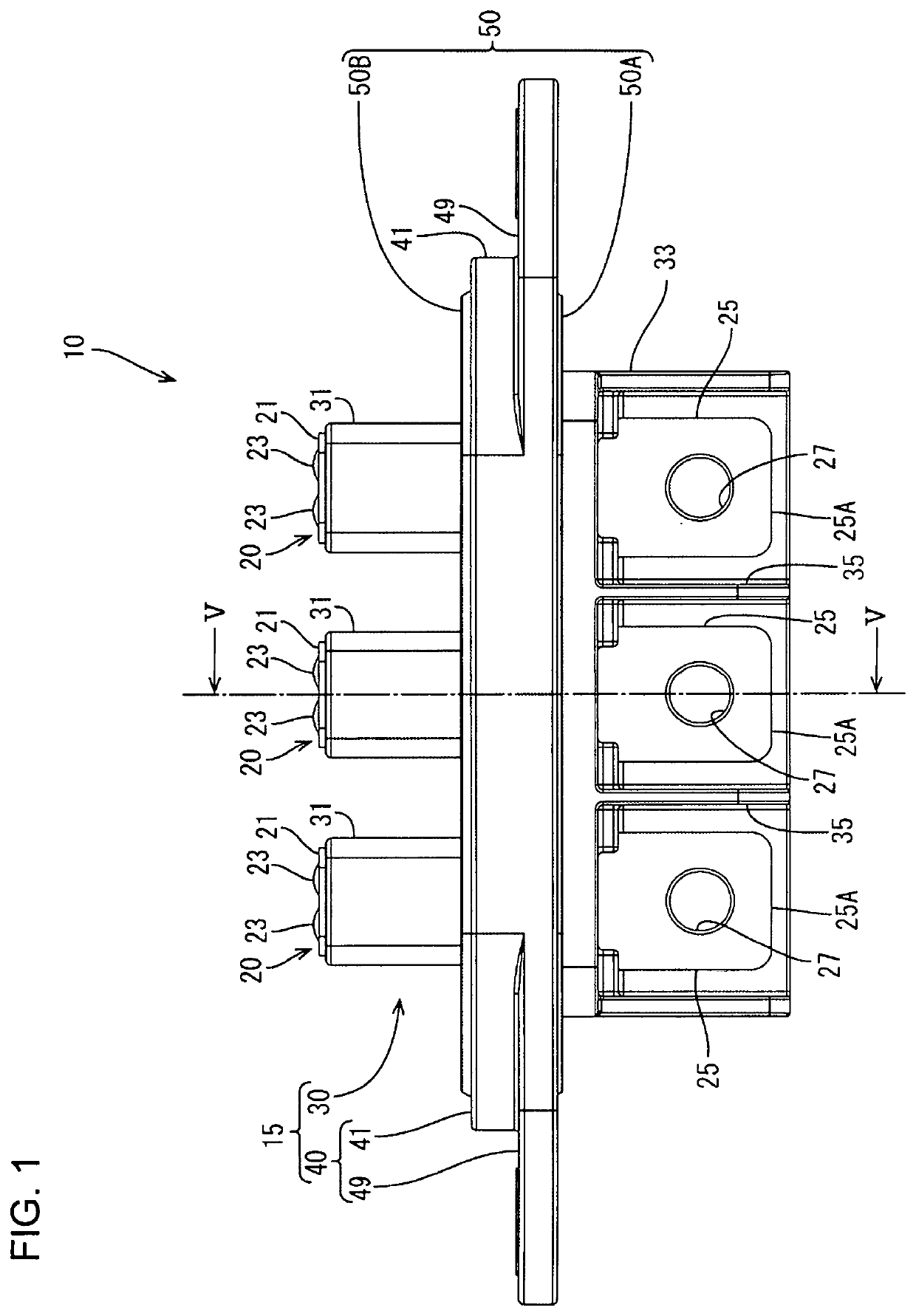

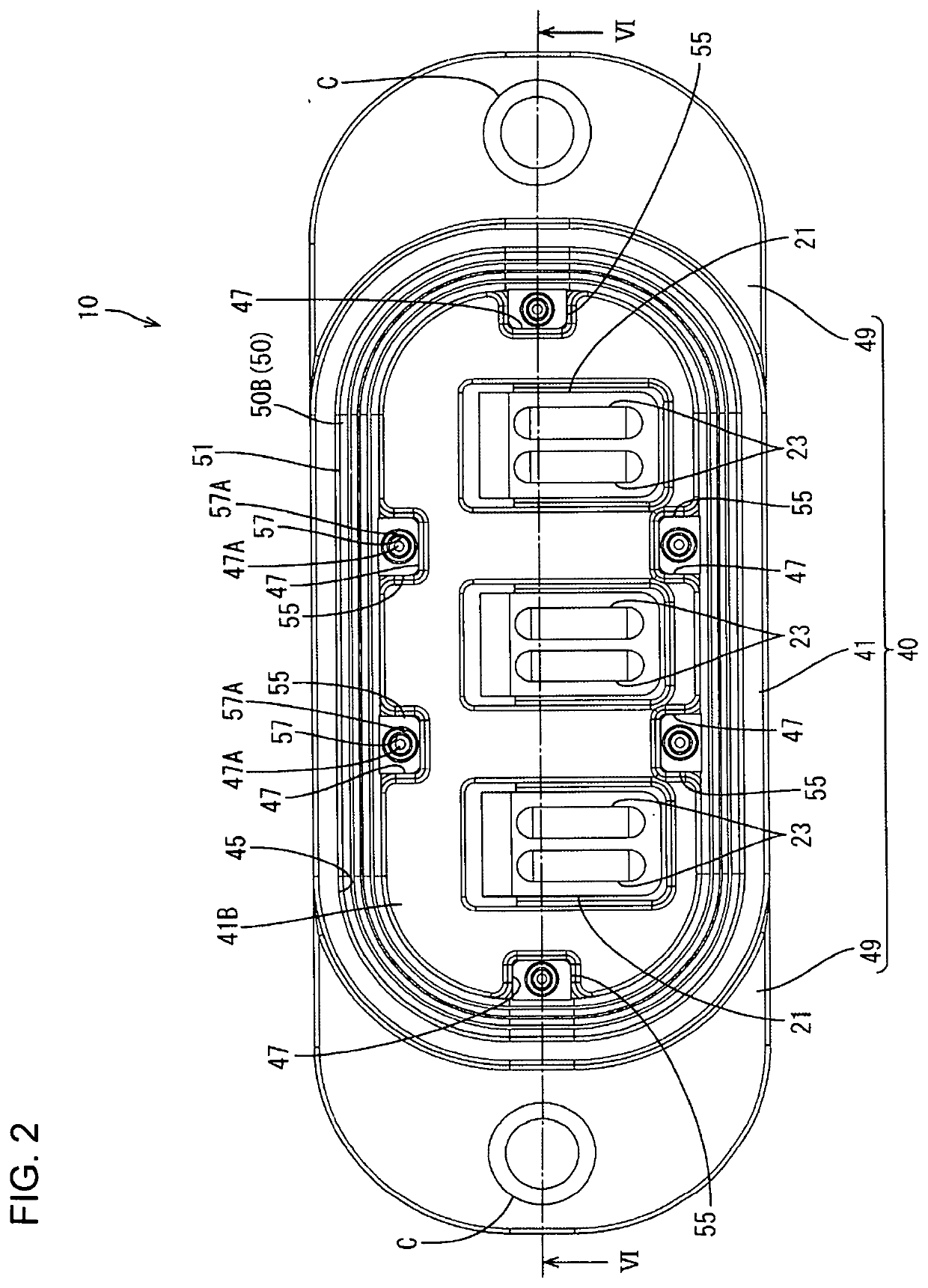

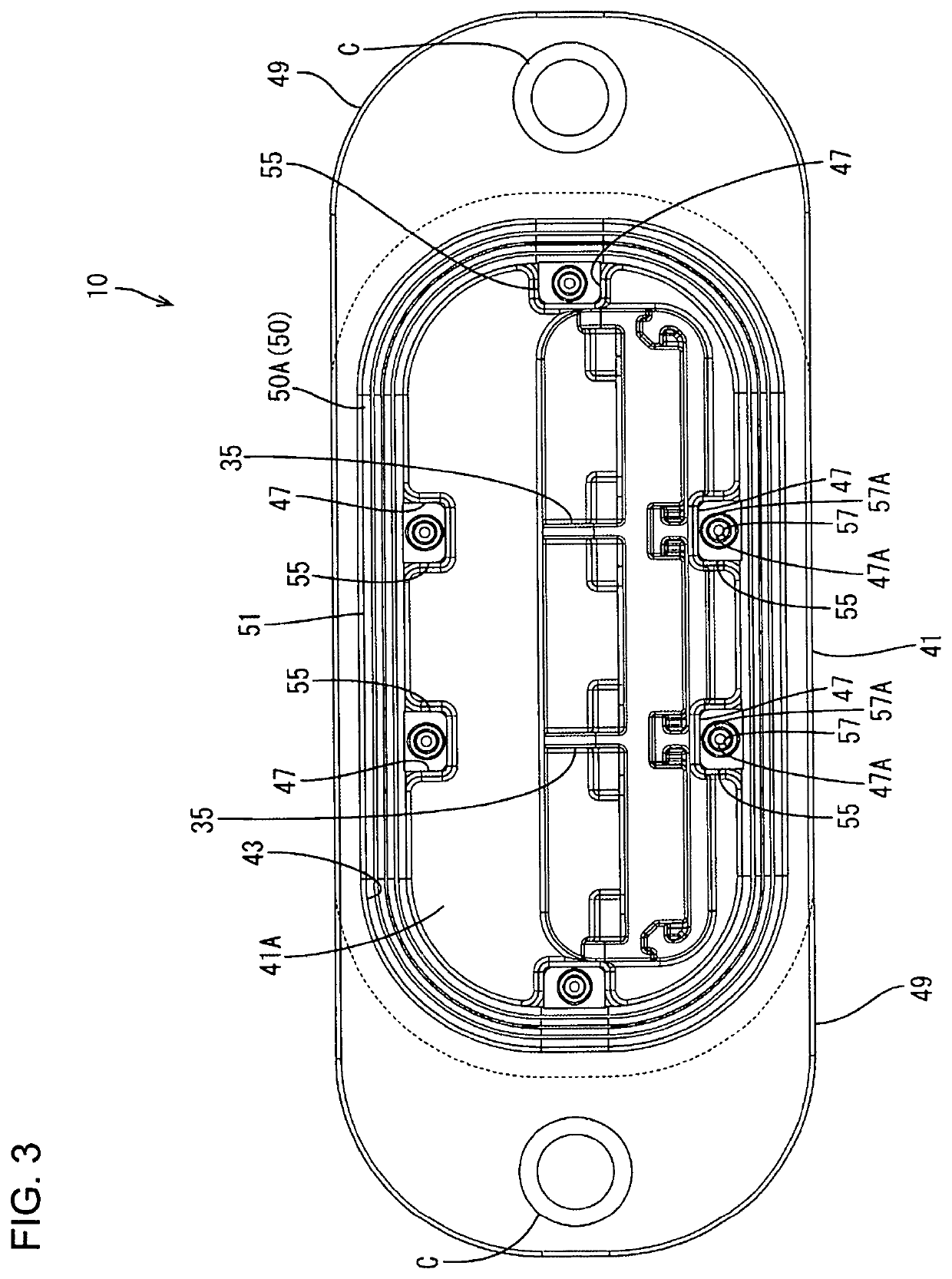

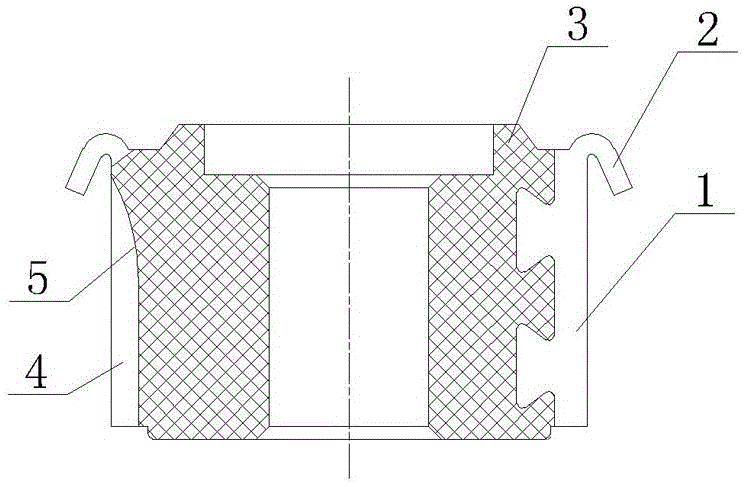

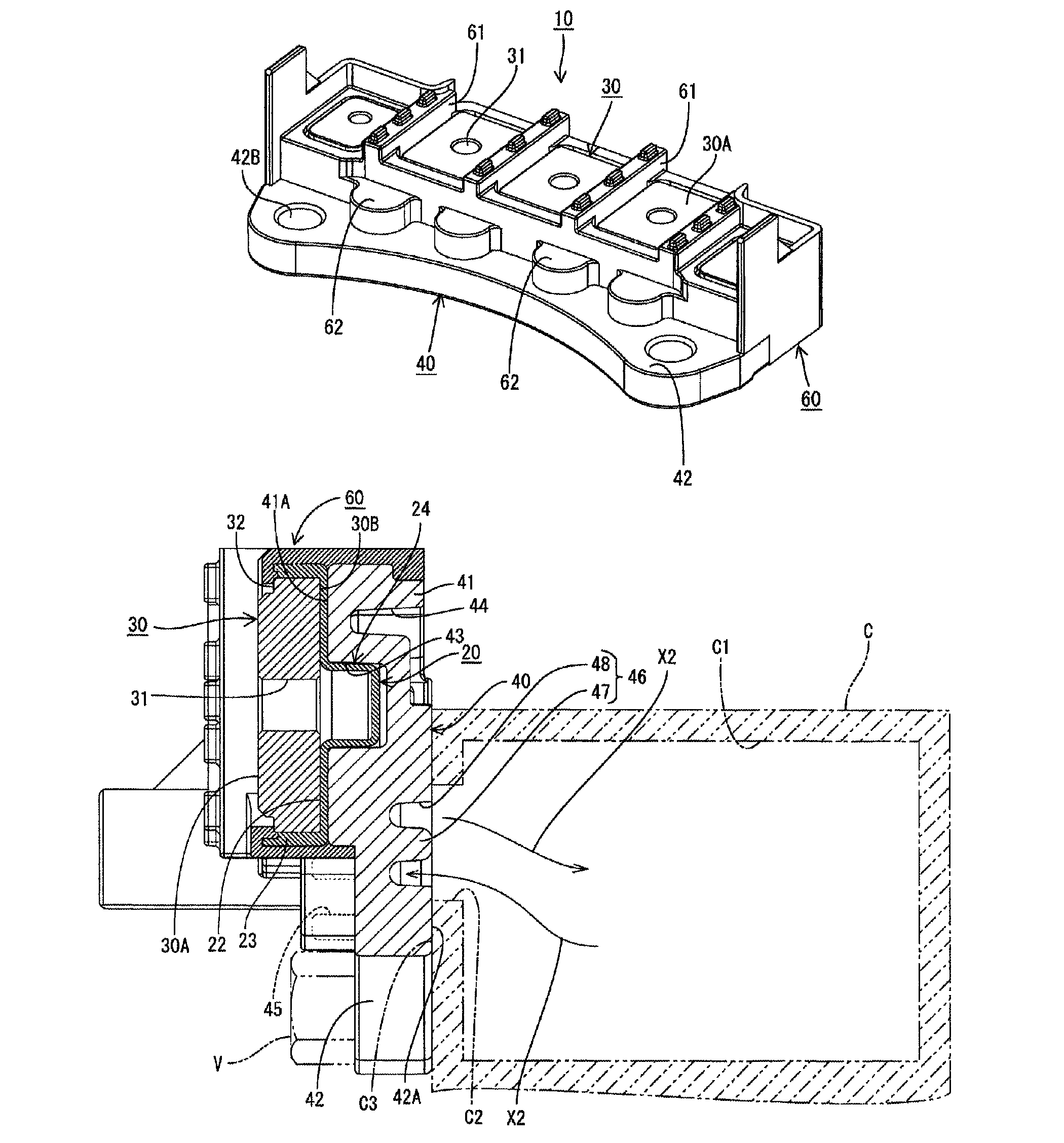

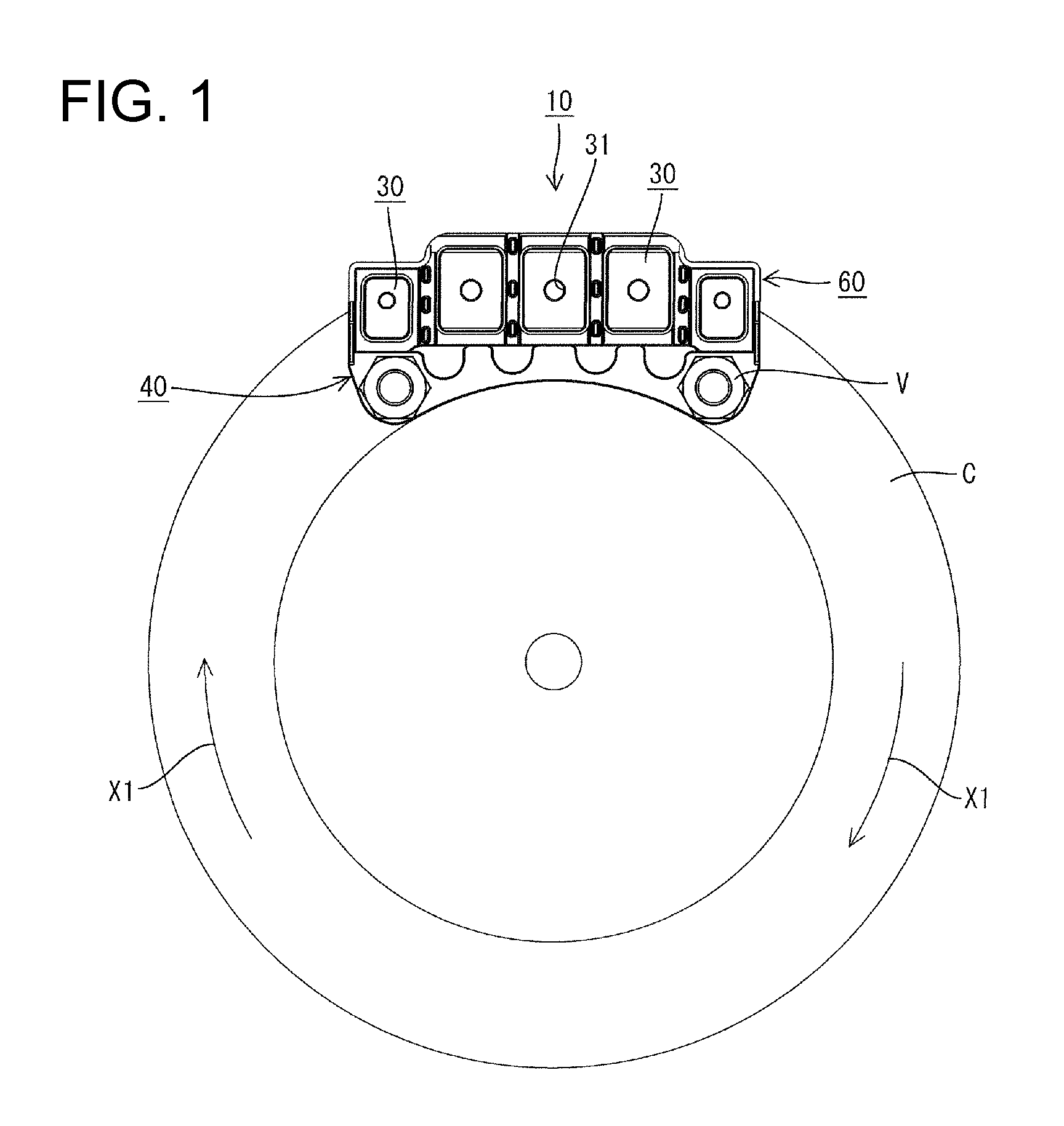

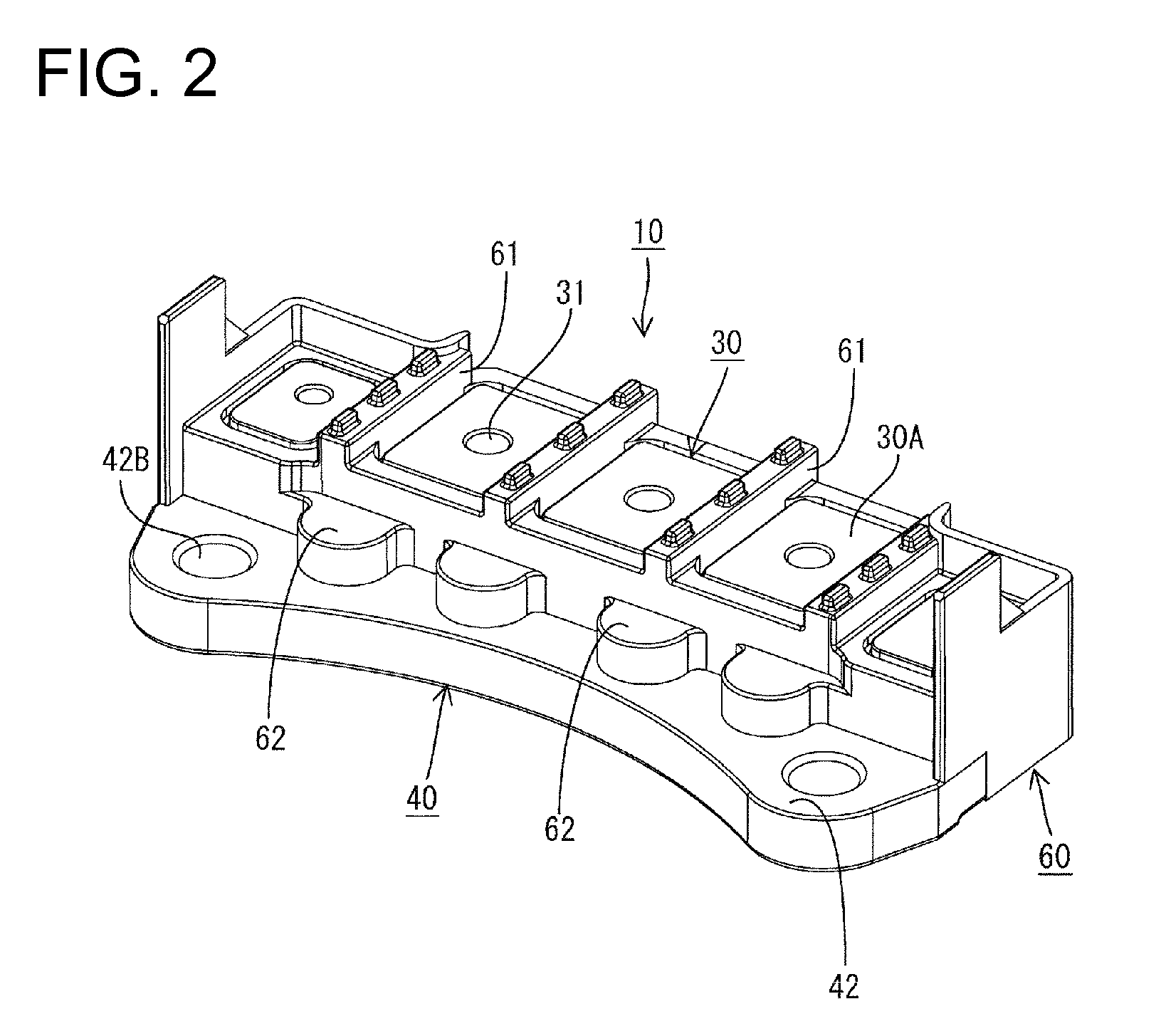

Terminal block and motor provided therewith

ActiveUS20120223601A1Improve heat transfer performanceHeat radiationElectrically conductive connectionsDynamoelectric machine connectorsBusbarEngineering

A terminal block (10) to be fixed to a motor case (C) which houses a motor body and includes a coolant flow path (C1) and adapted to fasten busbars by tightening bolts includes nuts (30) for tightening the bolts, and a heat sink (40) made of aluminum die-cast and held in close contact with the nuts (30) via an insulation plate (20) behind the nuts (30). The heat sink (40) includes a heat radiating portion (46) which comes into contact with cooling water passing in the coolant flow path (C1) of the motor case (C).

Owner:SUMITOMO WIRING SYST LTD

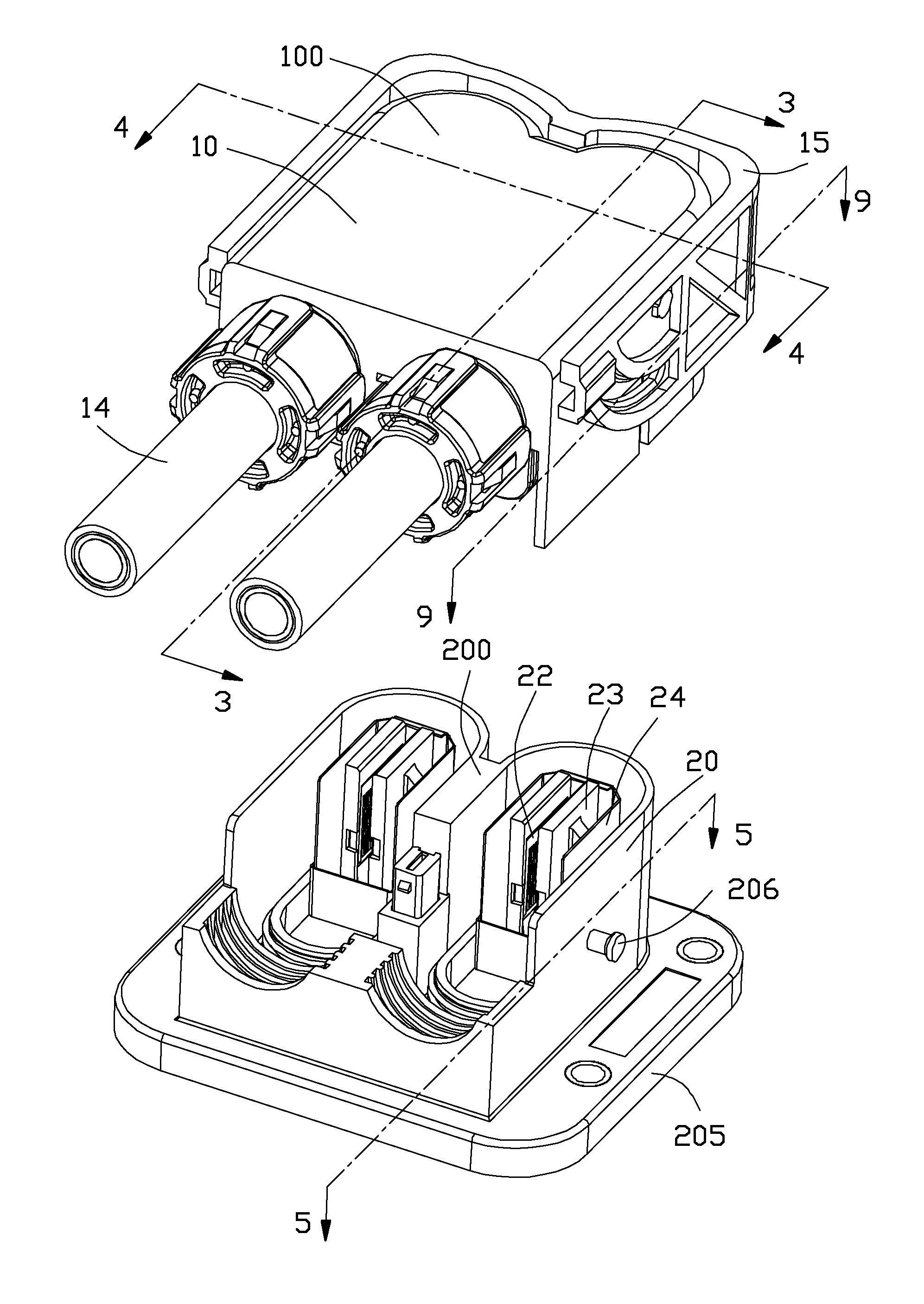

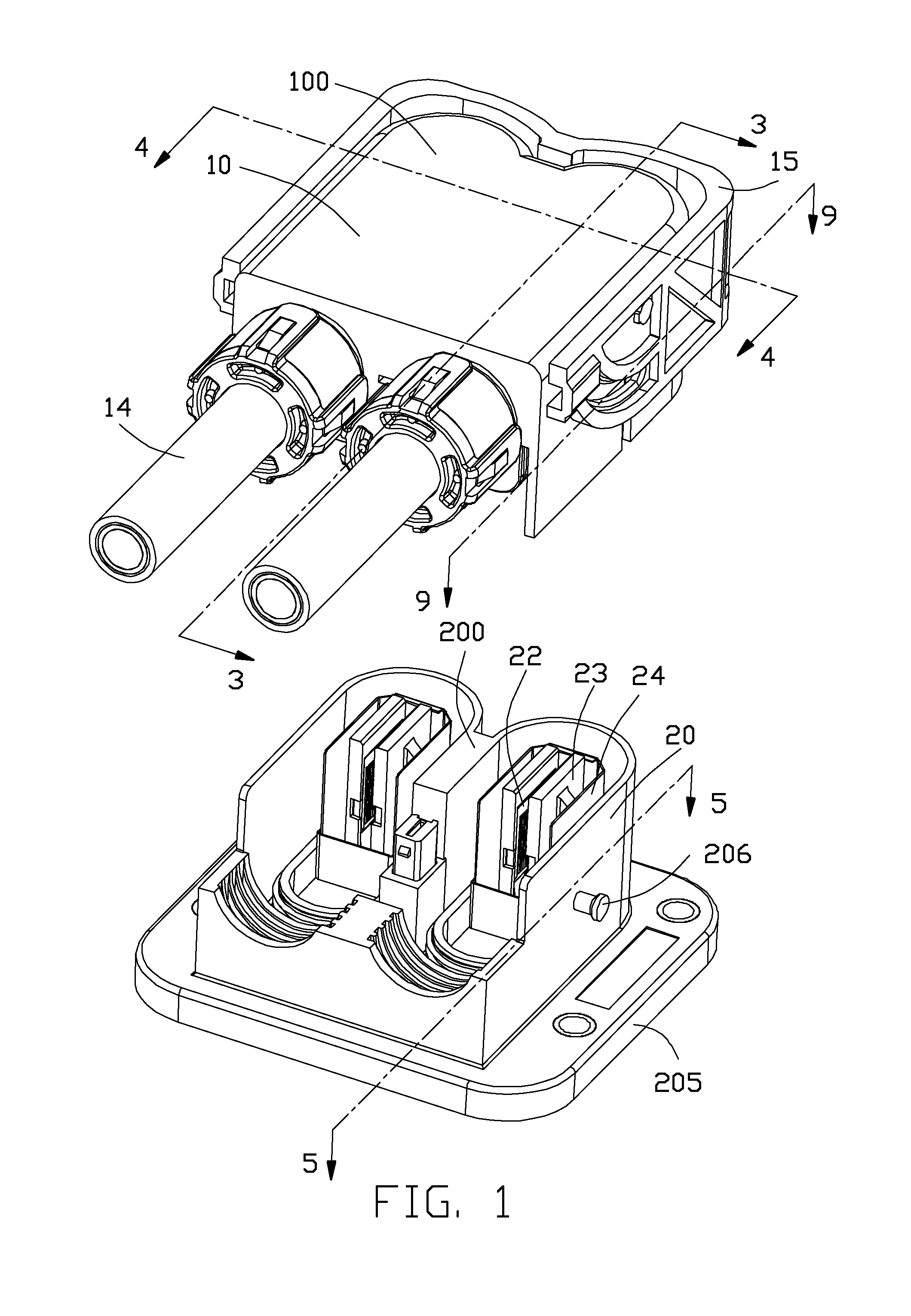

Connector assembly with reliable electrical connection

ActiveUS9559467B1Vehicle connectorsDynamoelectric machine connectorsElectrical connectionEngineering

An connector assembly includes a male connector (100) having a male housing (10) and a plurality of male contacts (12); and a female connector (200) for mating with said male connector including a female housing (20) and a plurality of female contacts (21) retained in said female housing. Each female contact defines a pair of mating plates (211) spaced away from each other for said male contact locating therebetween. Each pair of said mating plates (211) have a pair of spring leaves (22) connecting therewith and defining a plurality of spring fingers (221) resiliently clamping the corresponding male contact (12) therebetween.

Owner:FOXCONN INTERCONNECT TECH LTD

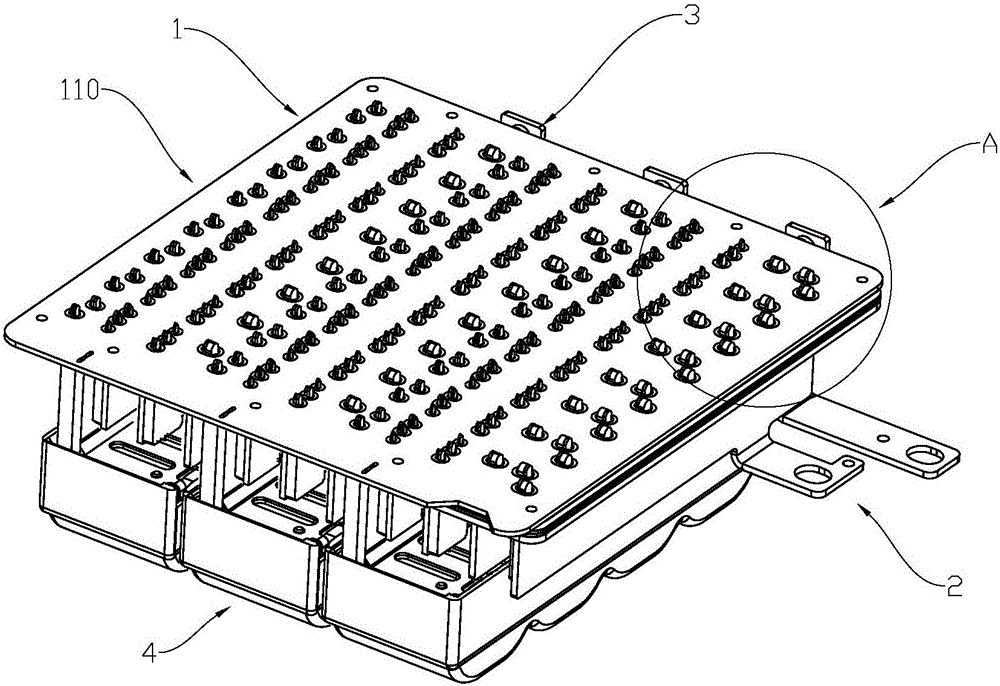

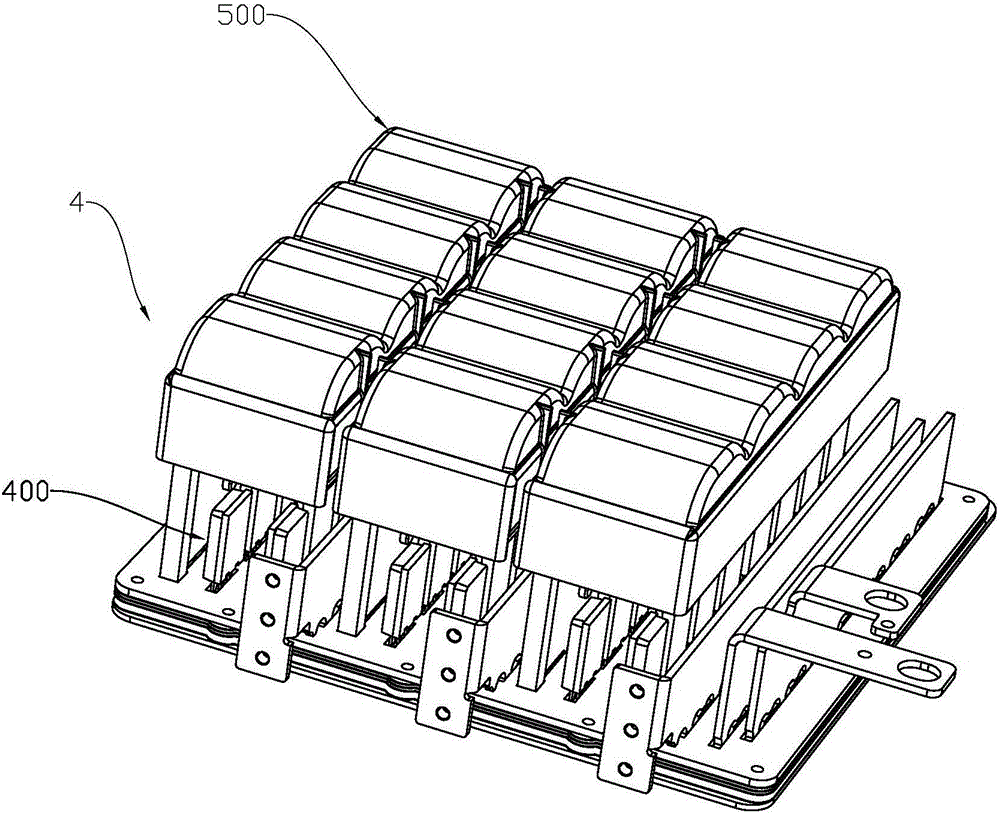

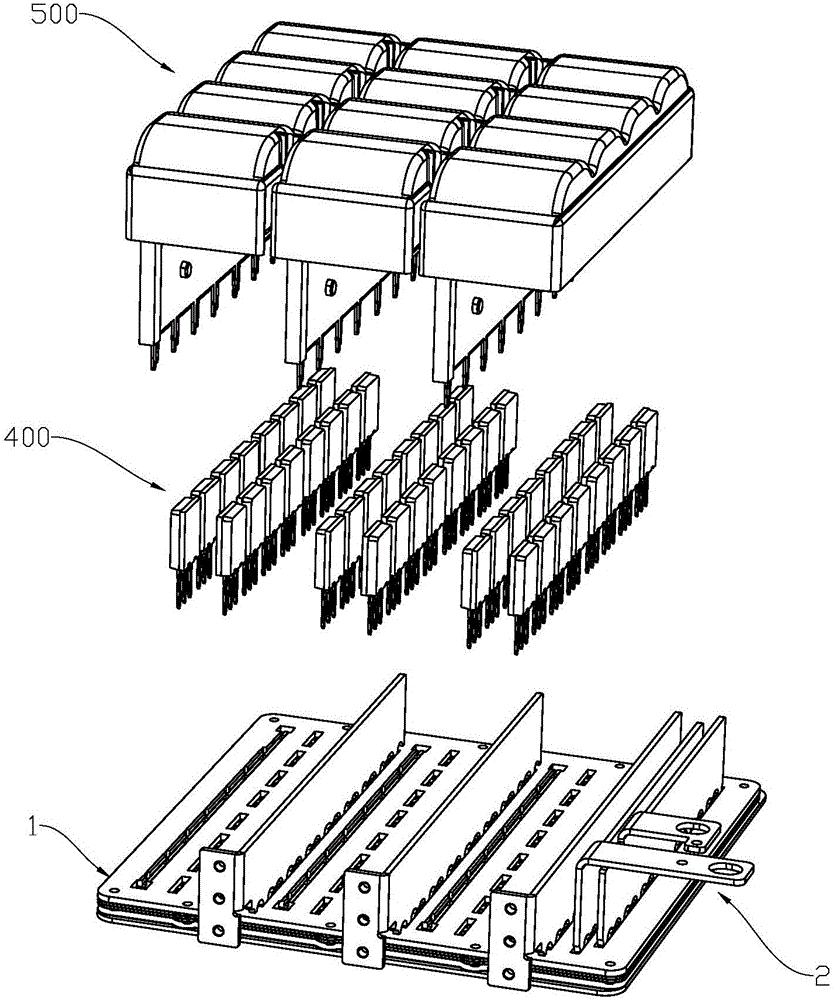

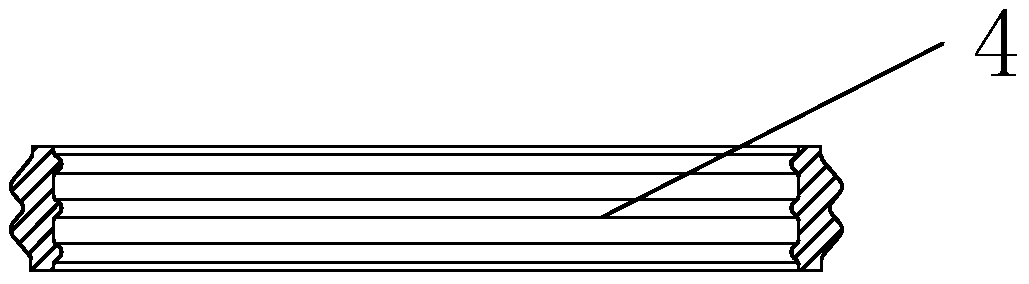

AC motor controller, and laminated busbar assembly and manufacturing method thereof

ActiveCN105680266AIncrease productivityImprove scalabilityCoupling device connectionsAC motor controlPower flowBusbar

The invention provides an AC motor controller, and a laminated busbar assembly and a manufacturing method thereof. The AC motor controller comprises the laminated busbar assembly, a controllable switch device assembly and a filter device assembly; the laminated busbar assembly comprises laminated substrates, an anode current metal board, a cathode current metal board and an output current metal board; in the plug piece soldering process, the AC motor controller can be processed by enabling a first pin of the anode current metal board, a second pin of the cathode current metal board, a third pin of the output current metal board, the controllable switch device assembly and the filter device assembly to penetrate a pad hole group and carrying out once soldering, and the production efficiency is high; and the laminated busbar assembly which is arranged in the modularized manner is high in the expansibility and widely suitable for other electric control devices.

Owner:ZHUHAI ENPOWER ELECTRIC

Electrical connection device

InactiveUS20110065298A1Low costEasy to replace partsAssociation with control/drive circuitsWindingsElectricityEngineering

The present invention relates to an electrical connection device that connects a rotating electrical machine and an inverter within a housing. The electrical connection device is configured with a first bus bar connected to a terminal of the rotating electrical machine such that the first bus bar that is insulated from the housing, and a second bus bar that is connected to a terminal of the inverter device such that the second bus bar is also insulated from the housing. An insulating connection member is configured to connect the first bus bar and the second bus bar. The first bus bar and second bus bar are housed within the housing such that they face each other to form a gap between them. The connection member is configured to pass through a wall of the housing so as to electrically connect the first and second bus bars.

Owner:AISIN AW CO LTD

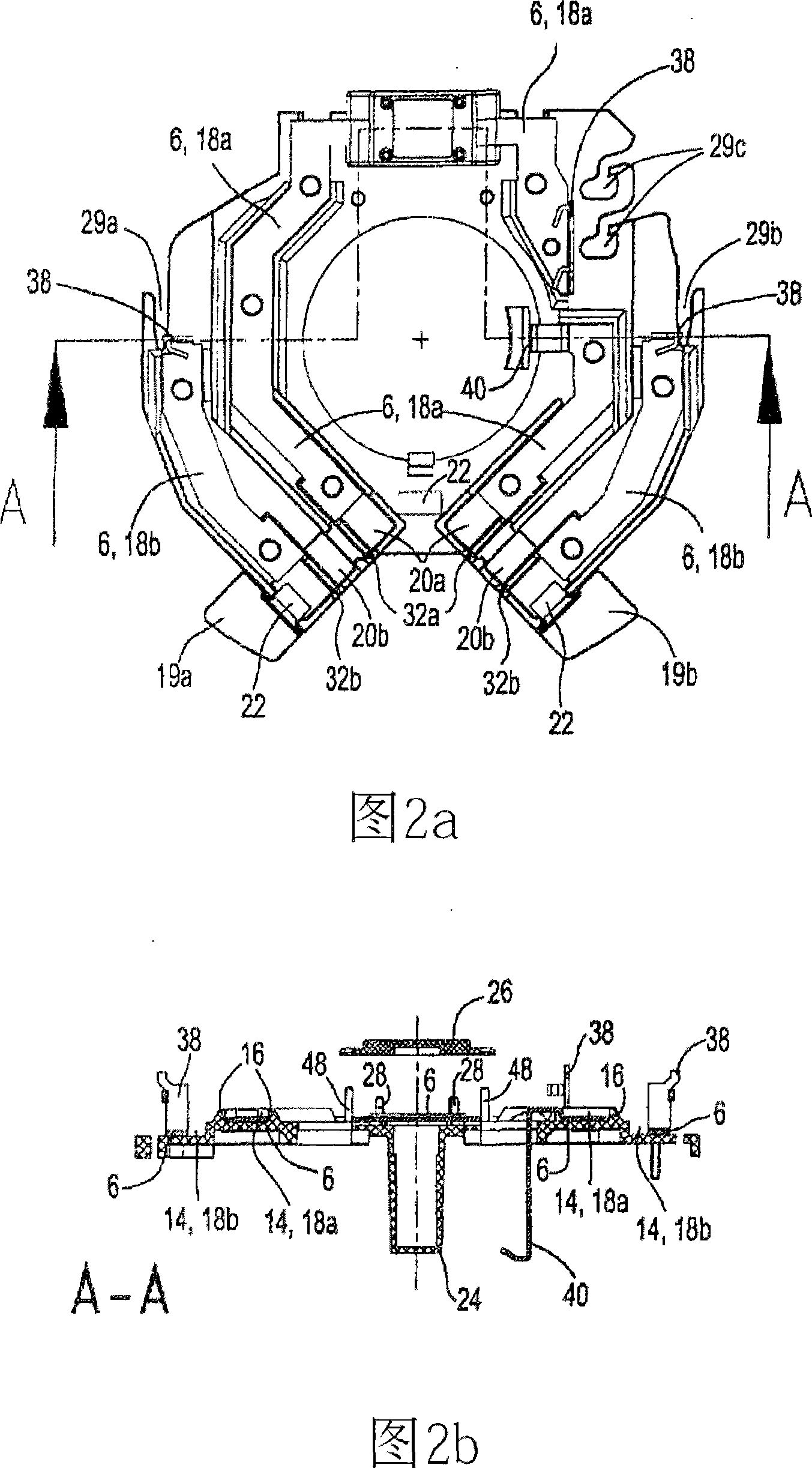

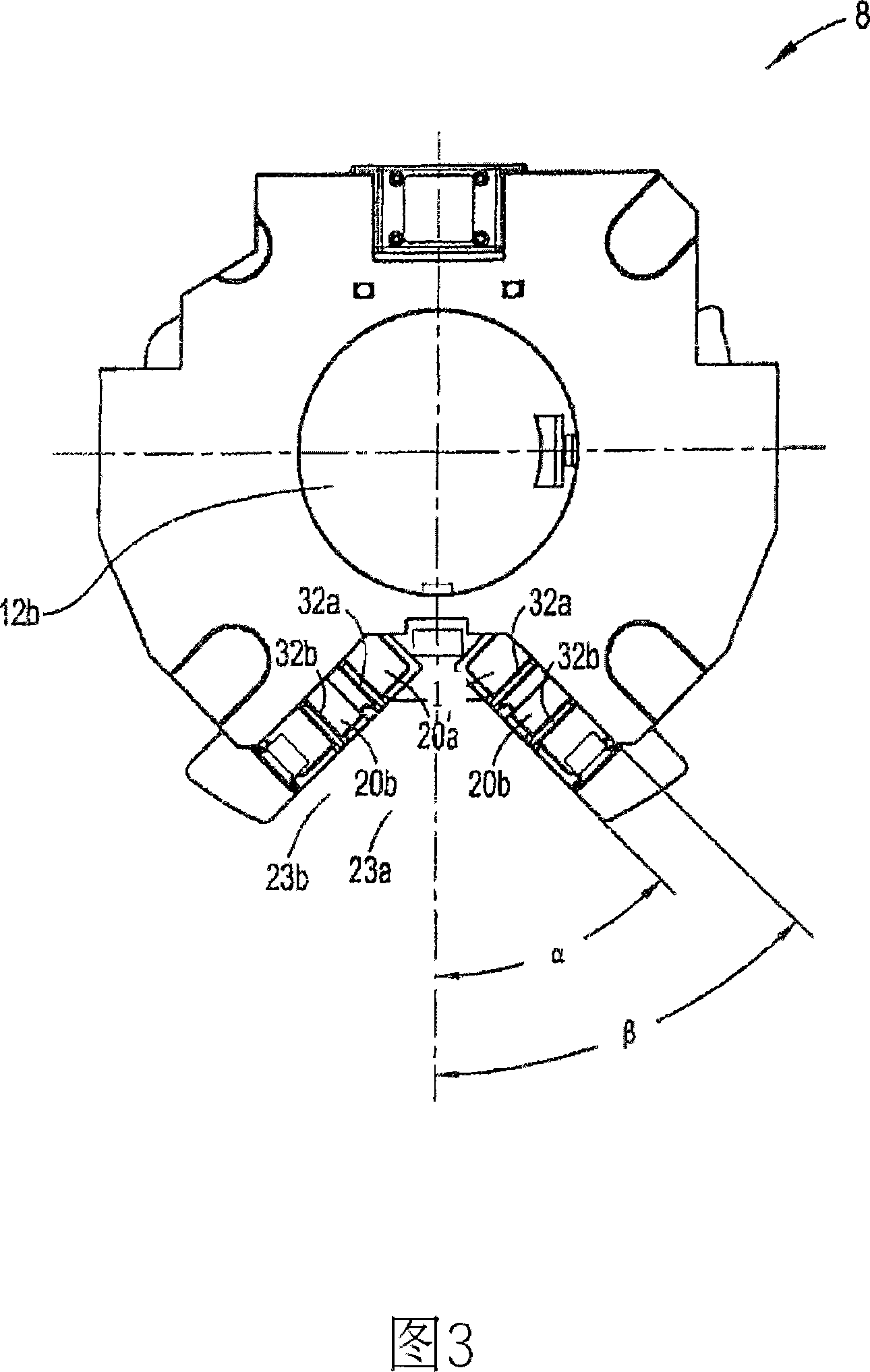

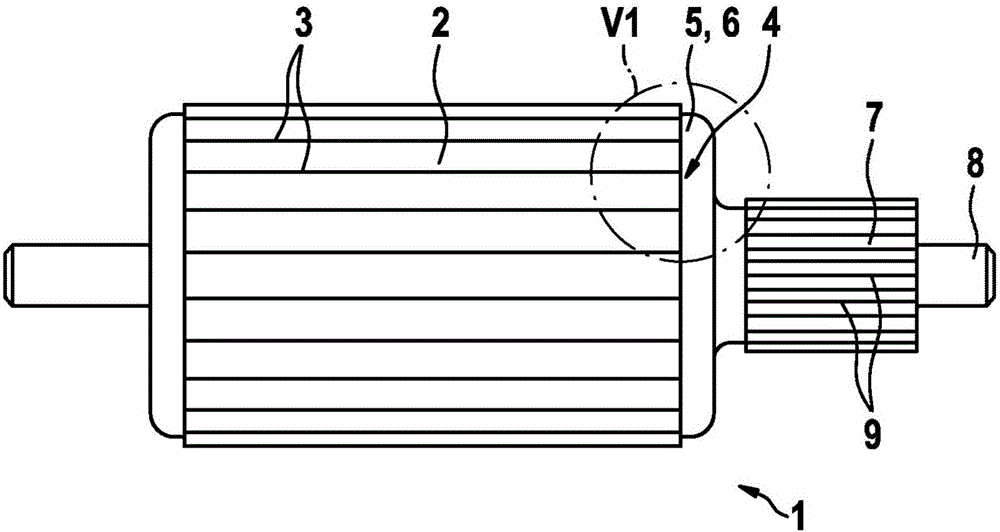

Brush apparatus for an electric machine and electric machine

ActiveCN102460909AIncrease temperatureReduce external temperatureVehicle connectorsPower operated startersBusbarElectric machine

The invention relates to an electric machine (1), especially a starter for an internal combustion engine, comprising a commutator (4) and a brush apparatus (2), brushes (3) being arranged on the commutator (4) in such a manner that at least one pair of brushes can rotate off-set from each other, every brush (3) being held in a brush holder (5), every brush holder (5) being fastened to an axial face on a brush plate (6), every brush (3) being alternately switchable in series either with a negative pole or a positive pole by a current conducting device (18, 19) to give a pair of brushes, and the brush plate (6) with connecting leads (24, 25, 26) leading to brushes (3) on the negative pole side and a busbar (10) with connecting leads (21, 22, 23) leading to brushes (3) on the positive pole side forming a respective current conducting device (18, 19). In order to protect the brush apparatus (2) from thermal overloads in an easy manner, at least one current conducting device (18, 19) is designed to have a unit for reducing heat dissipation.

Owner:SEG AUTOMOTIVE GERMANY GMBH

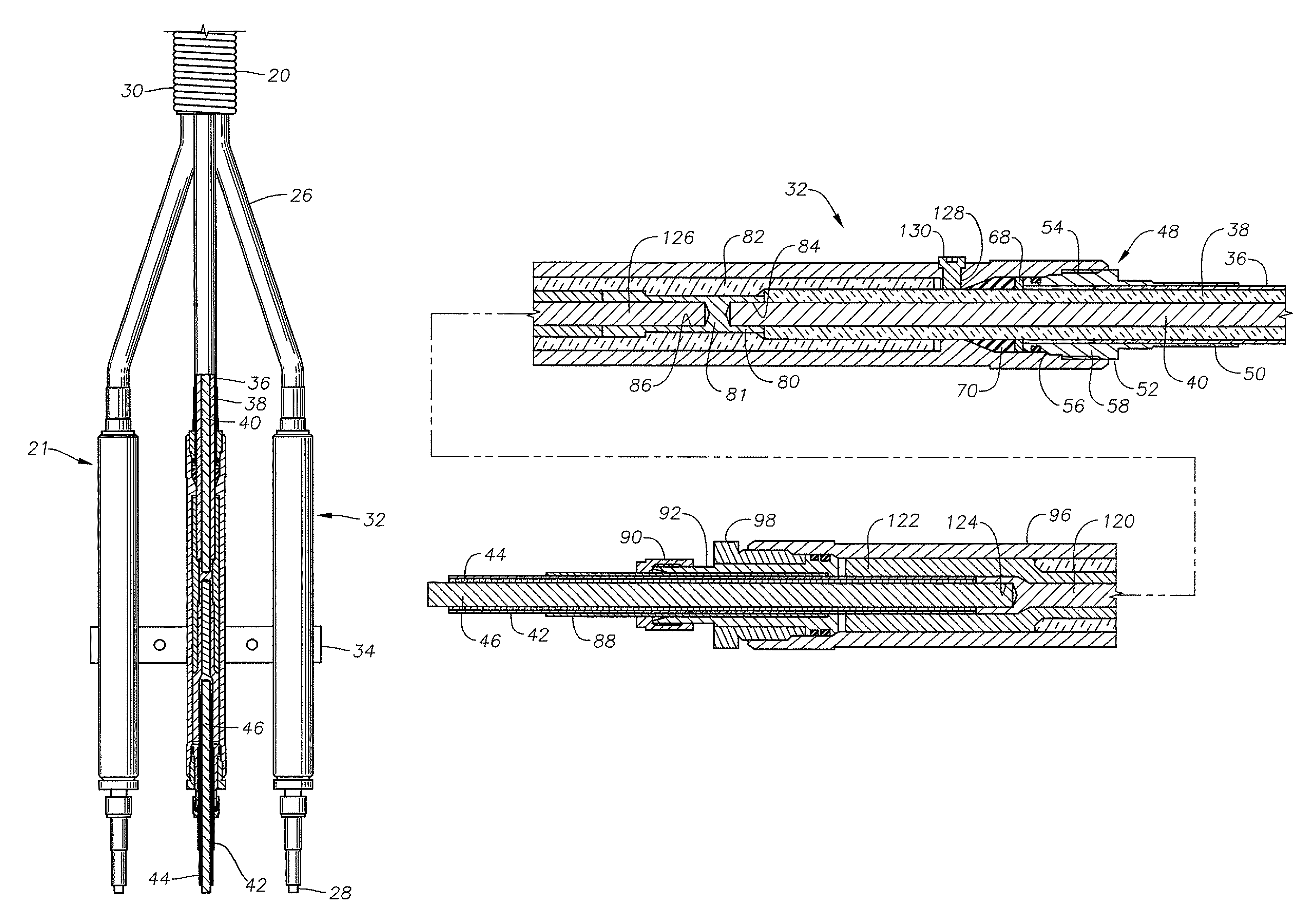

High voltage mechanical splice connector

ActiveUS8382508B1Firmly connectedQuick connectionEngagement/disengagement of coupling partsElectrically conductive connectionsElectricityMechanical splice

An electrical power assembly comprises a motor lead with individual metal sheathed conductors, a power cable with individual metal sheathed conductors and a splice connector for connecting each of the conductors. Each splice connector has a tubular metal fastener body with an upward facing shoulder at an upper end and a downward facing shoulder at a lower end. A metal nut assembly is fixed to one of the power cable conductors with a downward facing shoulder in metal-to-metal sealing engagement with the upward facing shoulder of the fastener body. A metal coupler fixed to one of the motor lead conductors with an upward facing shoulder in metal-to-metal sealing engagement with the downward facing shoulder of the fastener body. Contacts electrically connect one of the motor lead conductors to one of the power cable conductors within the fastener body. An elastomeric seal disposed between the nut assembly and the fastener body, has expansion relief voids operable to collapse and relieve stresses exerted by the seal when the seal undergoes thermal expansion.

Owner:BAKER HUGHES INC

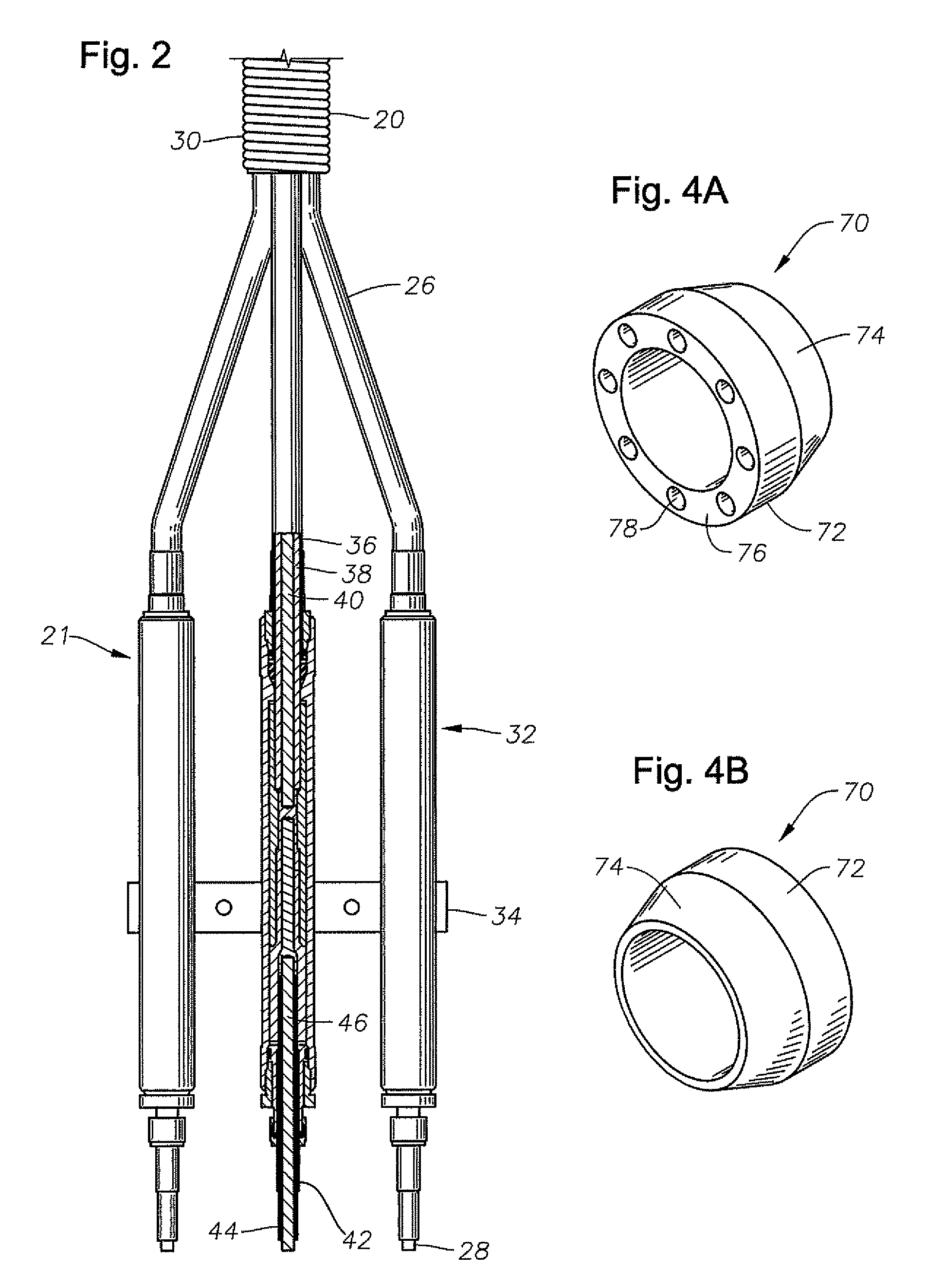

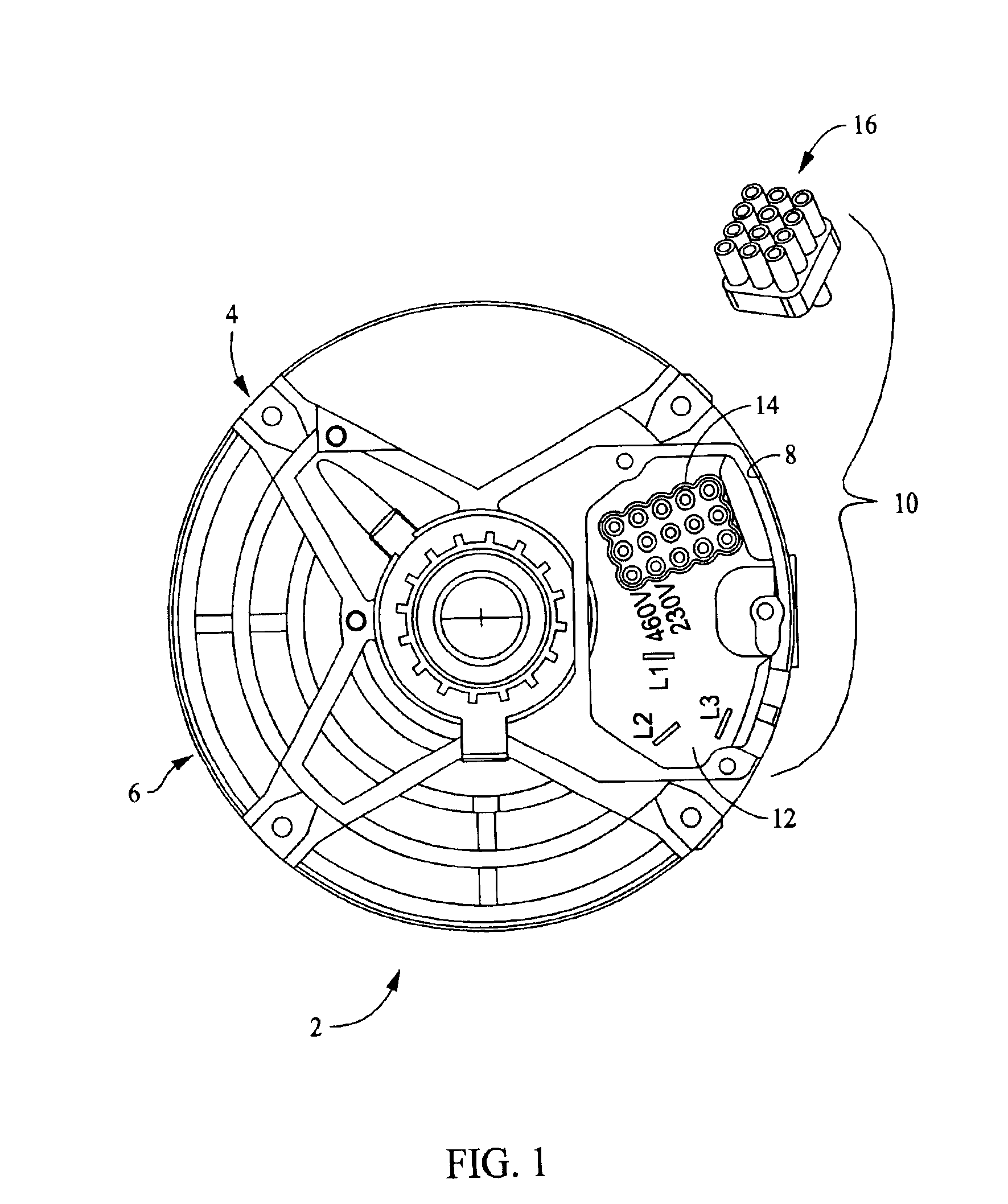

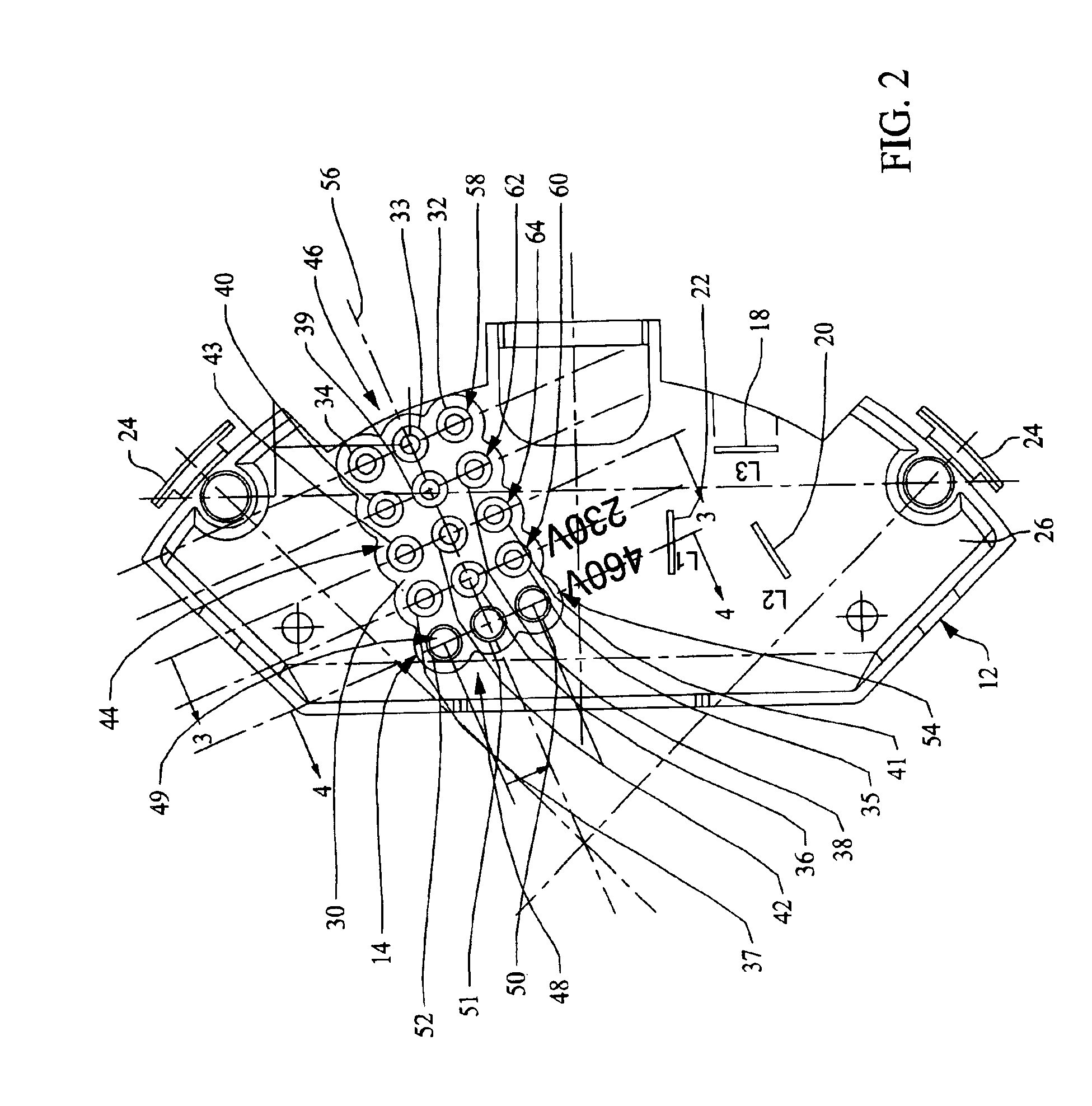

Methods and systems for electric motor voltage change

InactiveUS6879070B2Coupling device connectionsElectrically conductive connectionsElectricityEngineering

A terminal board assembly for a multi-voltage device. The terminal board assembly includes a terminal board including a terminal block. The terminal board is configured for attachment to the multi-voltage device. The terminal block is configured to electrically couple with an electrical power source and the multi-voltage device. The assembly also includes a plug that is configured for insertion within the terminal block. The terminal block is configured to receive the plug in at least one of a first inserted position and a second inserted position. The orientation of the plug relative to the terminal block is the same in the first inserted position as in the second inserted position. The terminal block is configured to transfer a first voltage to the multi-voltage device when the plug is attached to the terminal block in the first inserted position. The terminal block is configured to transfer a second voltage to the multi-voltage device when the plug is attached to the terminal block in the second inserted position.

Owner:GENERAL ELECTRIC CO

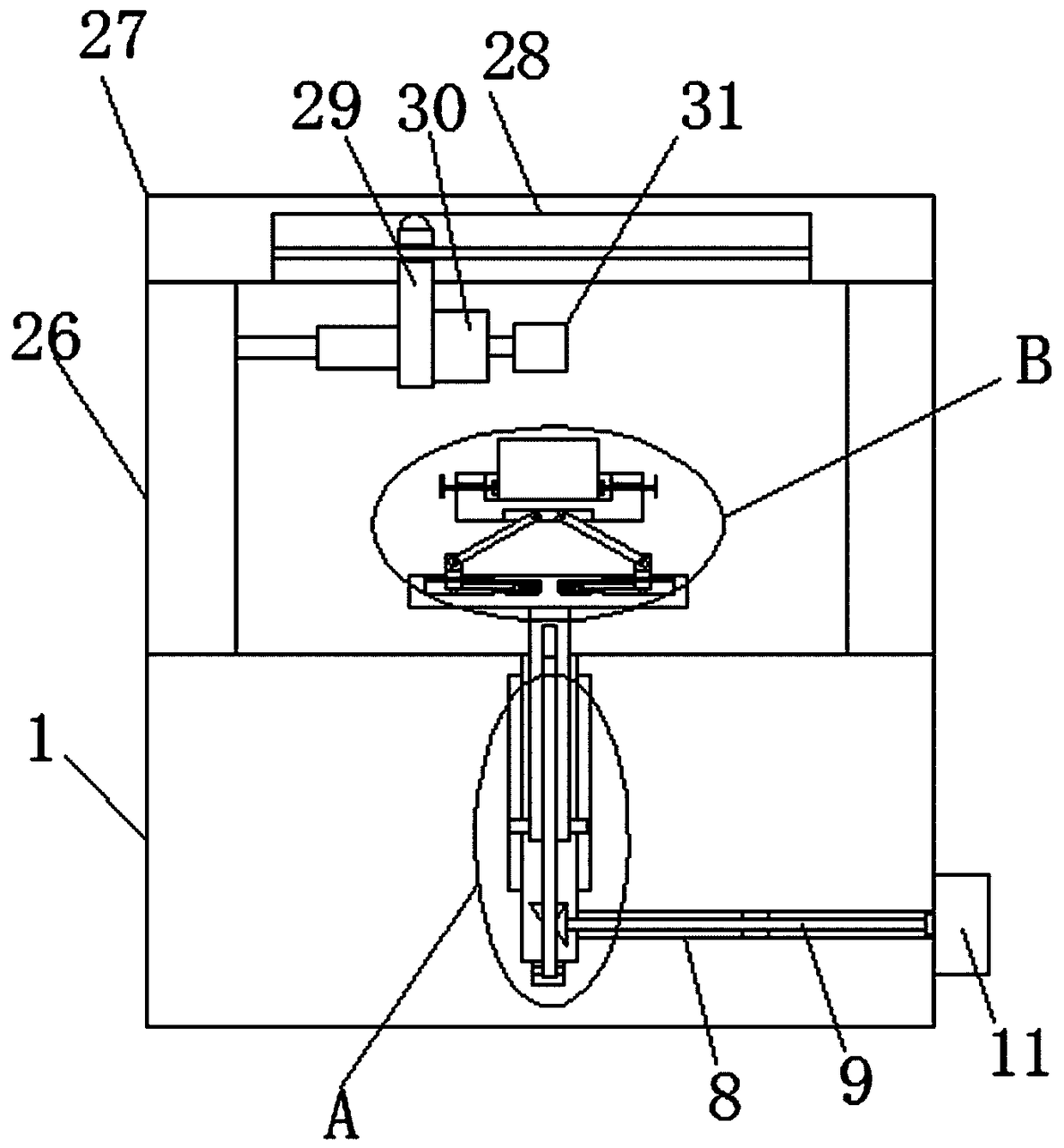

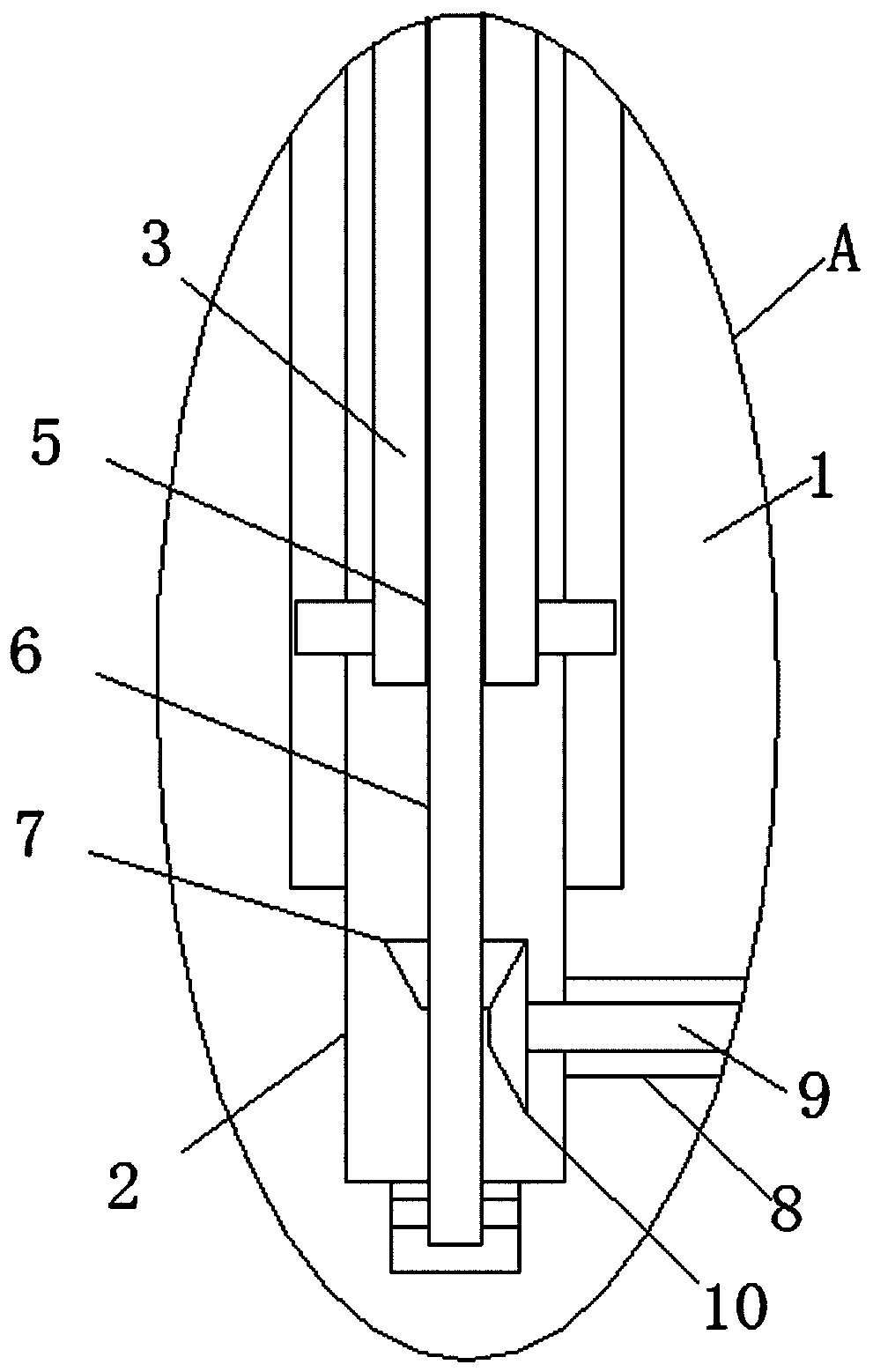

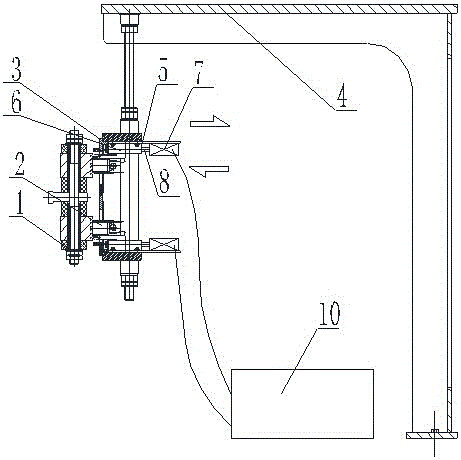

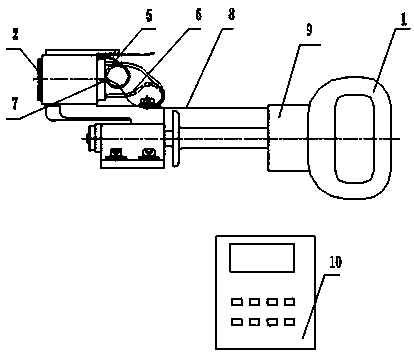

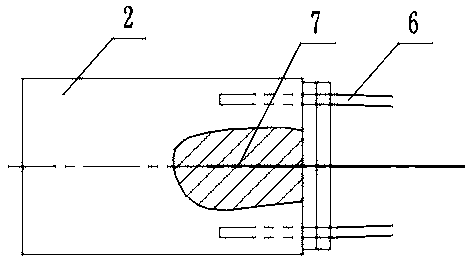

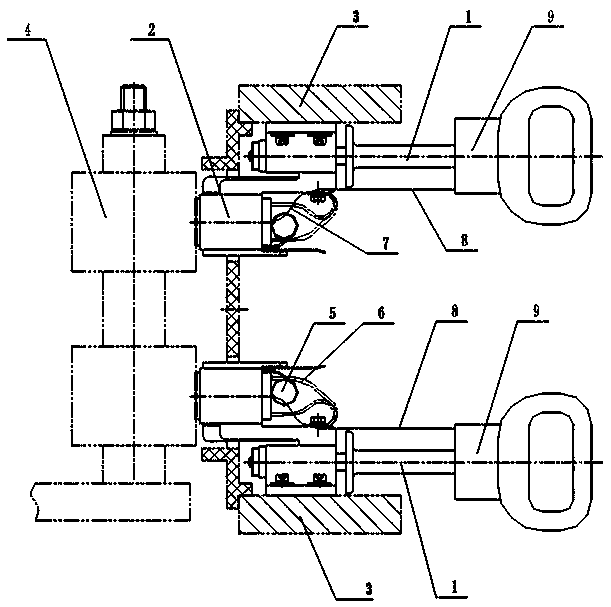

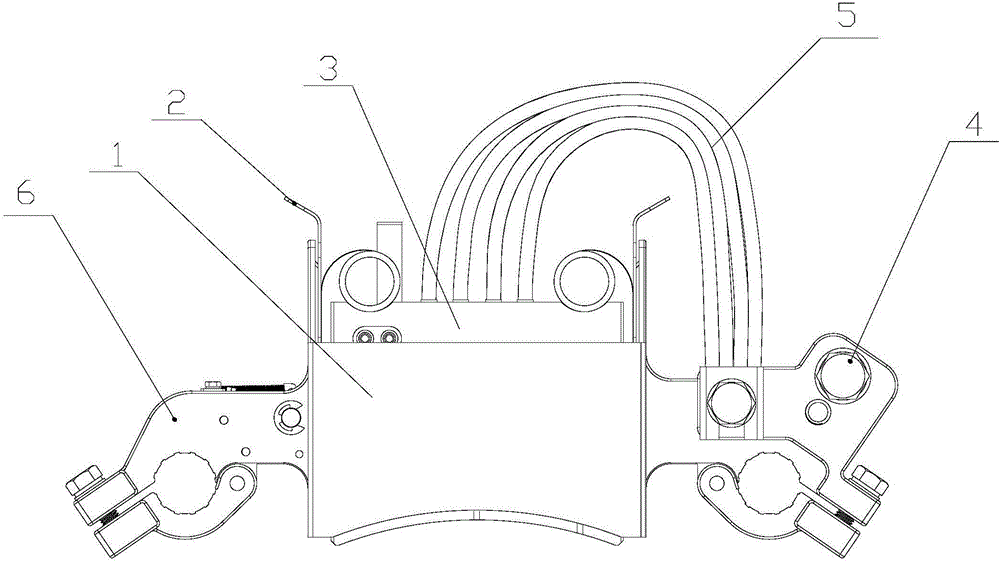

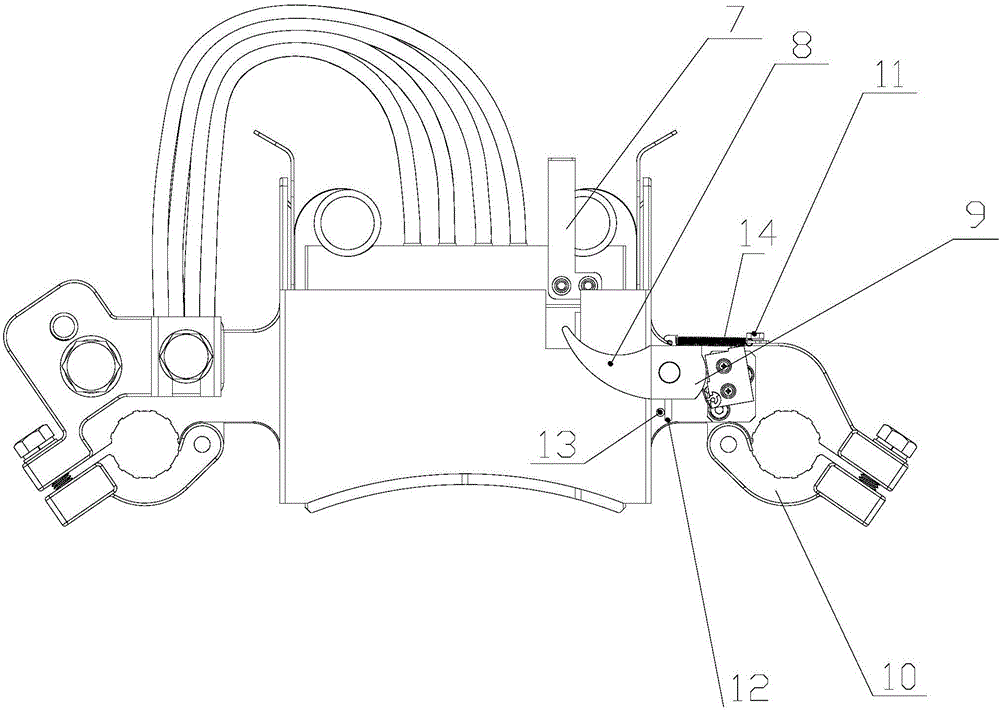

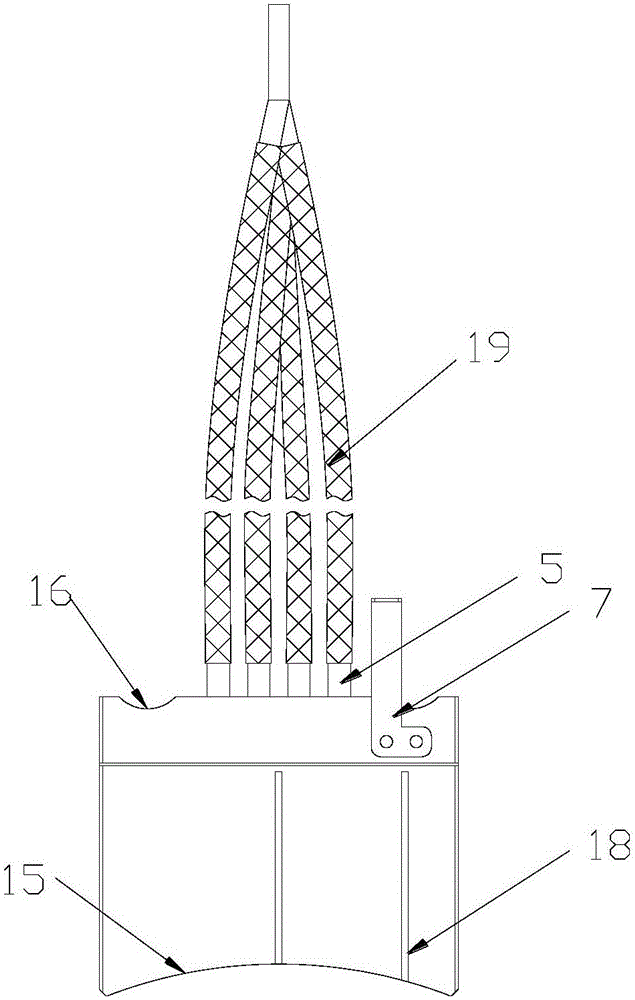

Carbon brush grinding equipment and utilization method thereof

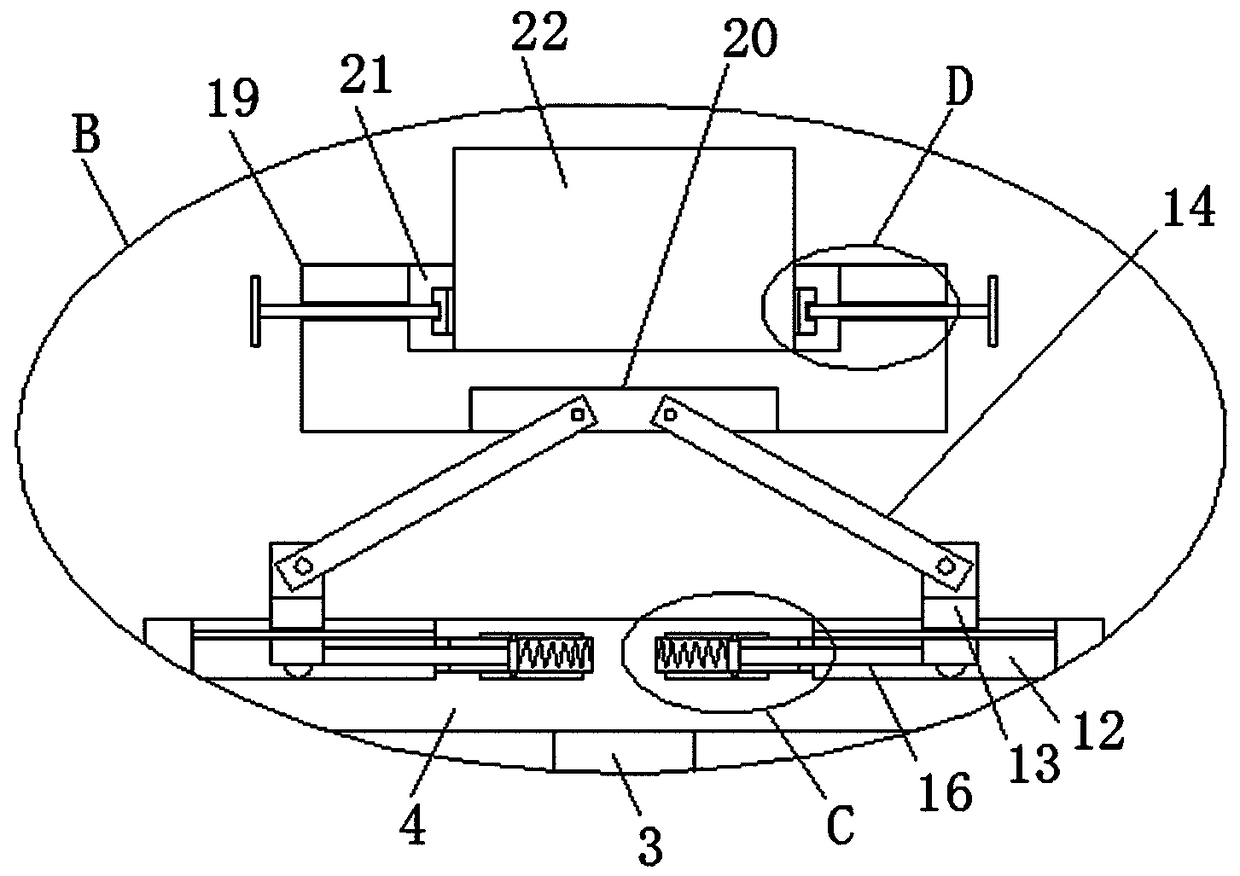

PendingCN108418078AAchieve grindingAchieve protectionDynamoelectric machine connectorsBrushes manufactureEngineeringScrew thread

The invention discloses carbon brush grinding equipment and a utilization method thereof. The carbon brush grinding equipment comprises a base, the top of the base is provided with a first groove, a slide rod is slidably mounted in the first groove, the top end of the slide rod extends out of the first groove to allow fixed mounting of a first fixing seat above the base, the bottom end of the slide rod is provided with a first screw hole, and a first screw rod in threaded connection with the first screw hole is arranged in the first screw hole. The bottom end of the first screw rod extends outof the first screw hole and is rotationally mounted on the bottom inner wall of the first groove, a first gear below the slide rod fixedly sleeves the first screw rod, and the inner wall of one sideof the first groove is provided with a through hole. The carbon brush grinding equipment is simple in structure, reasonable in design, high in automation degree, convenient and quick in carbon brush grinding, convenient for operators to use and effective in carbon brush protection, and carbon brush grinding precision or carbon brush damages caused by excessive grinding can be avoided.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

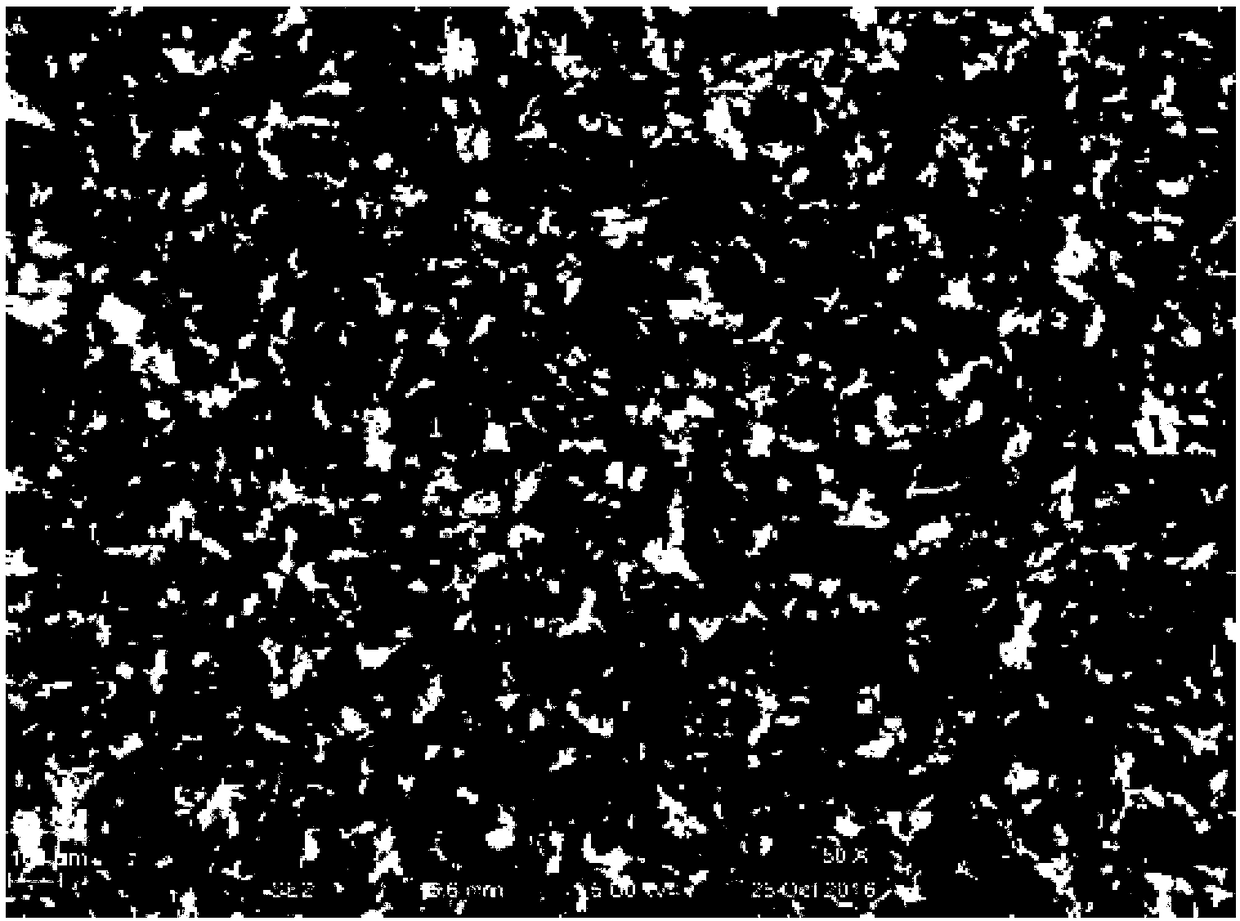

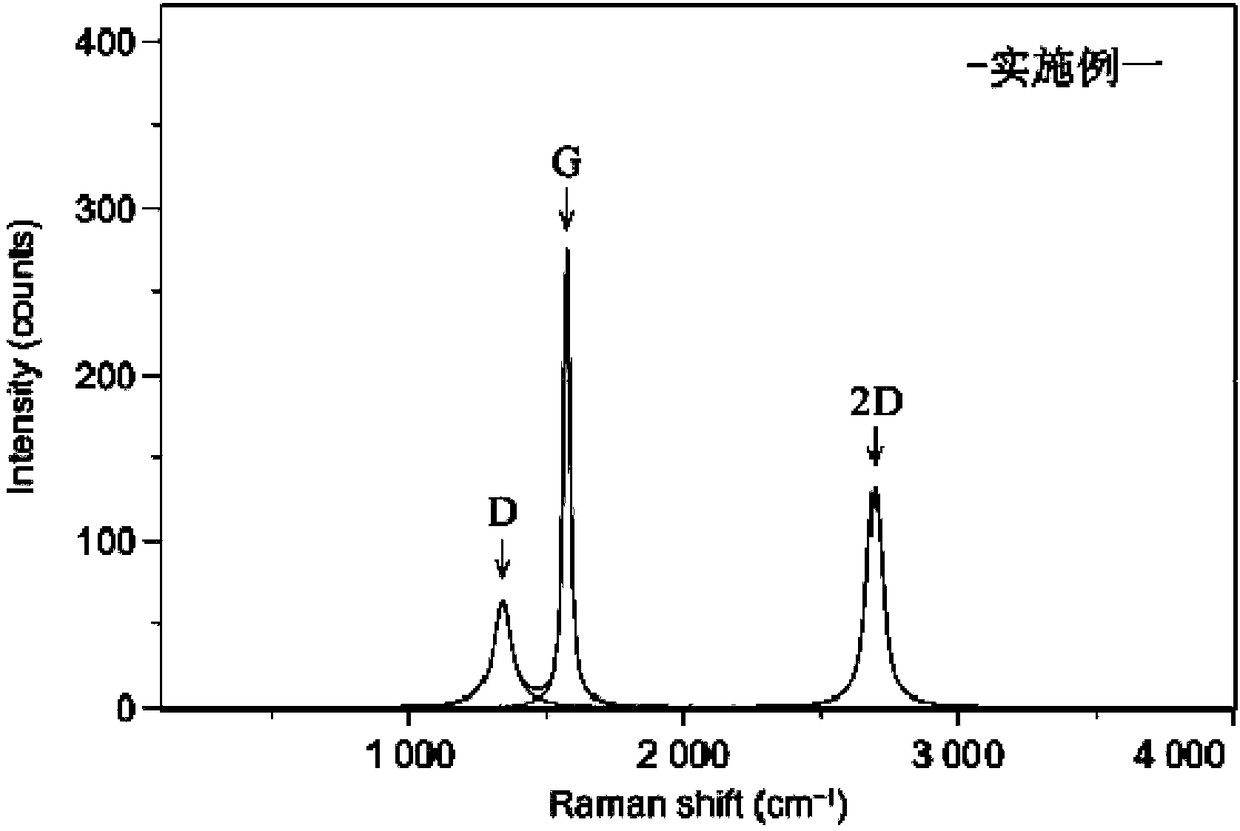

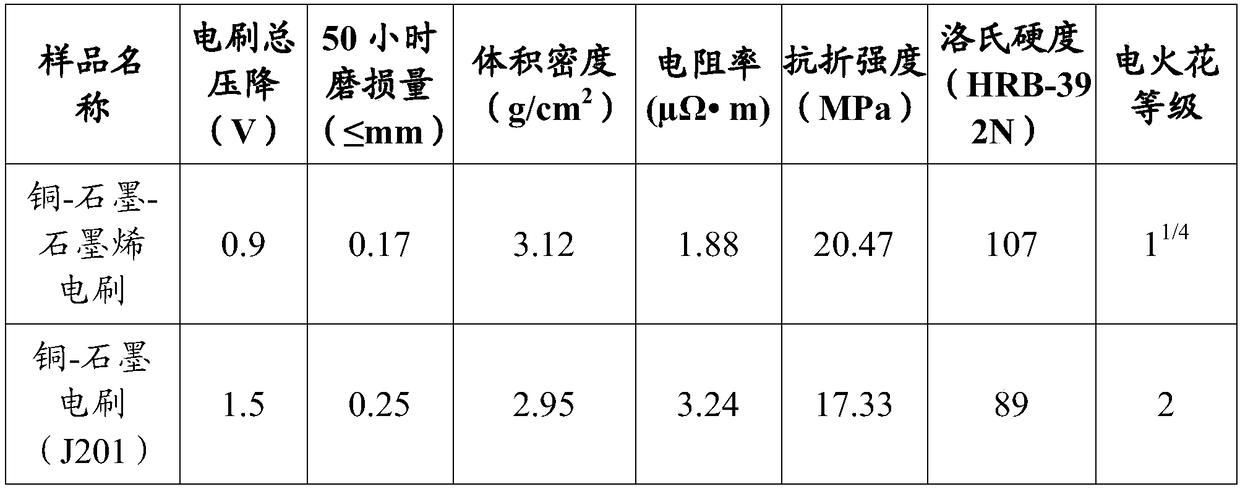

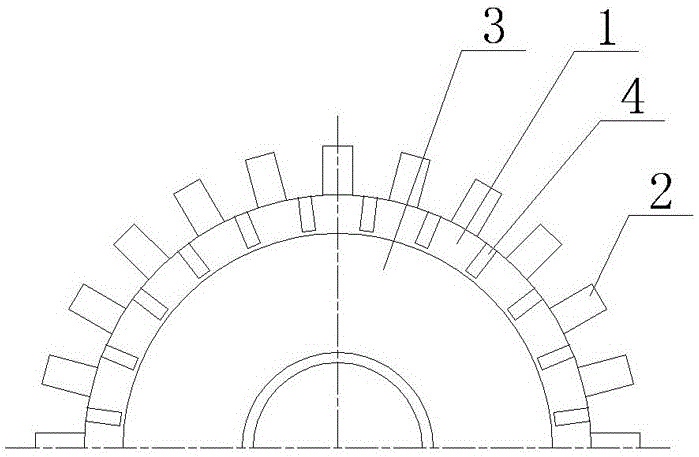

Copper-graphite-graphene brush and preparation method thereof

ActiveCN108512006AGood electrical performanceImprove mechanical propertiesRotary current collectorDynamoelectric machine connectorsSlurryElectrical performance

The invention discloses a copper-graphite-graphene brush and a preparation method thereof. The copper-graphite-graphene brush comprises 35-80% of copper powder, 10-60% of graphite powder, 0.5-30% of graphene powder and 0-20% of thermosetting resin by mass. According to the preparation method, a graphene slurry, graphene-copper composite powder, first graphene-copper-graphite composite powder, second graphene-copper-graphite composite powder, and a copper-graphite-graphene brush are obtained sequentially. The preparation method is low in cost and simple in operation and can realize automatic continuous stable large-scale production. The prepared copper-graphite-graphene brush is low in resistivity, electric spark and friction coefficient, and high in wear resistance; and compared with a traditional brush product, the electrical performance, mechanical performance and service life of the brush are improved greatly.

Owner:SHANGHAI SIMBATT ENERGY TECH CO LTD +1

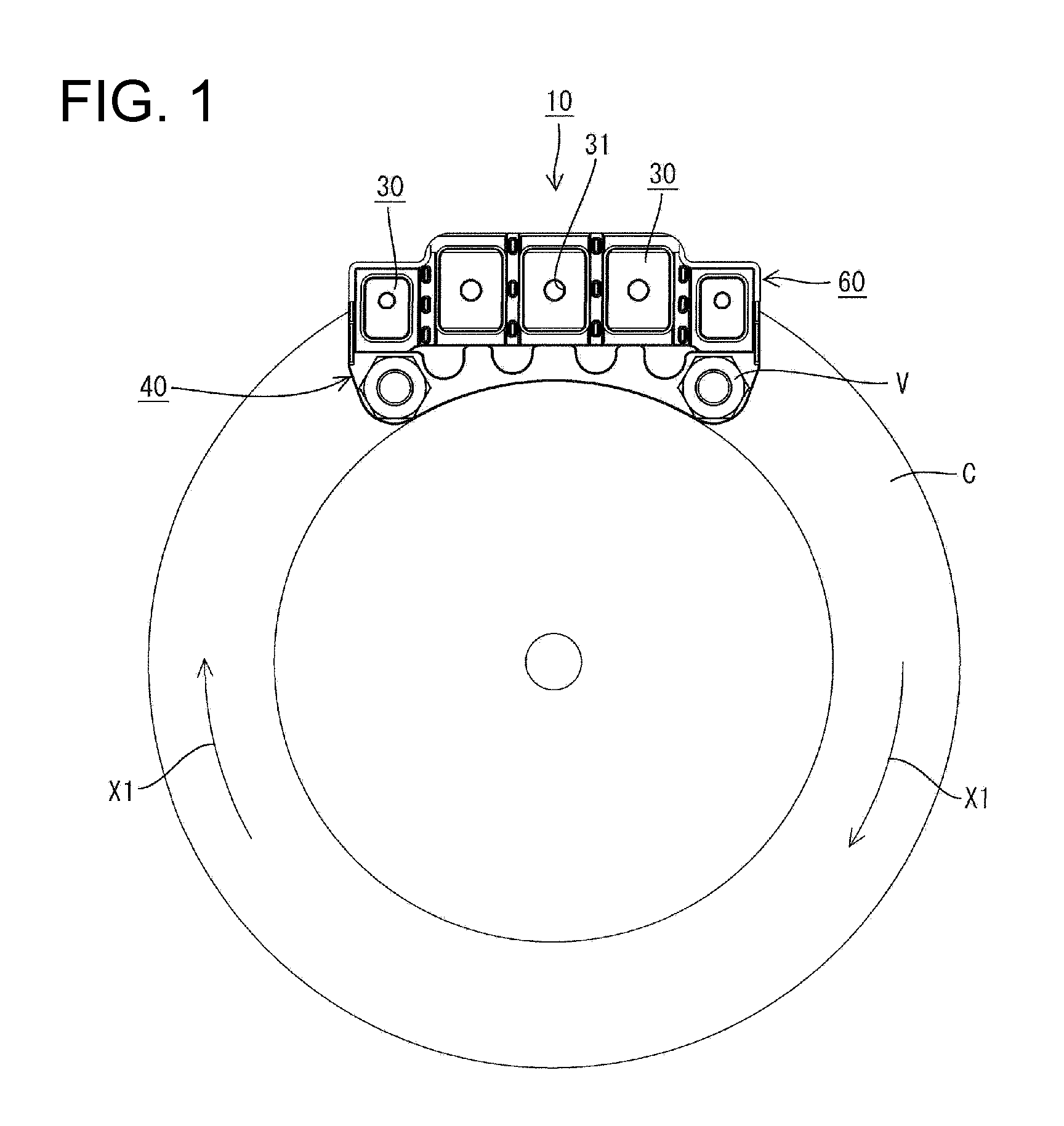

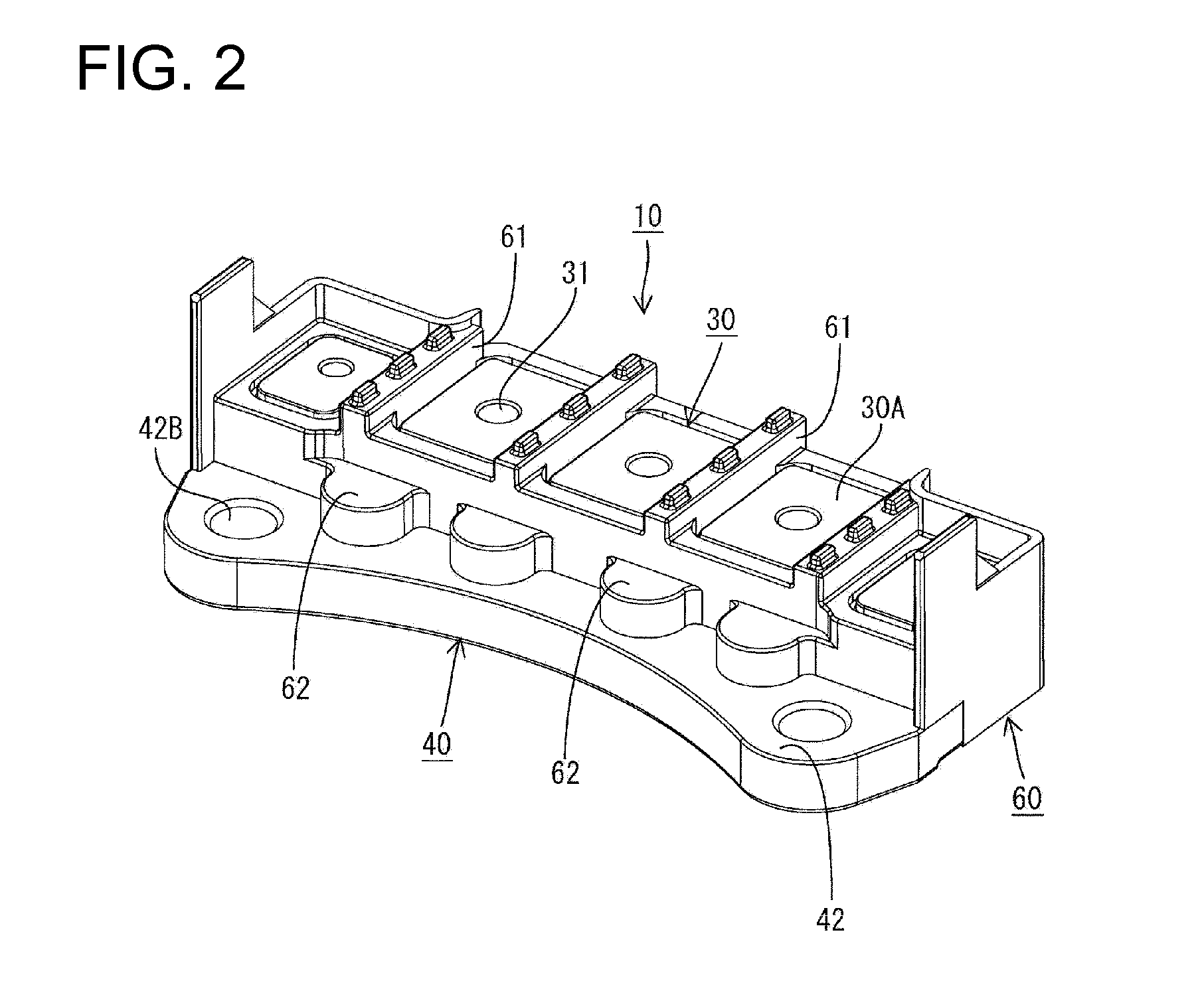

Connector

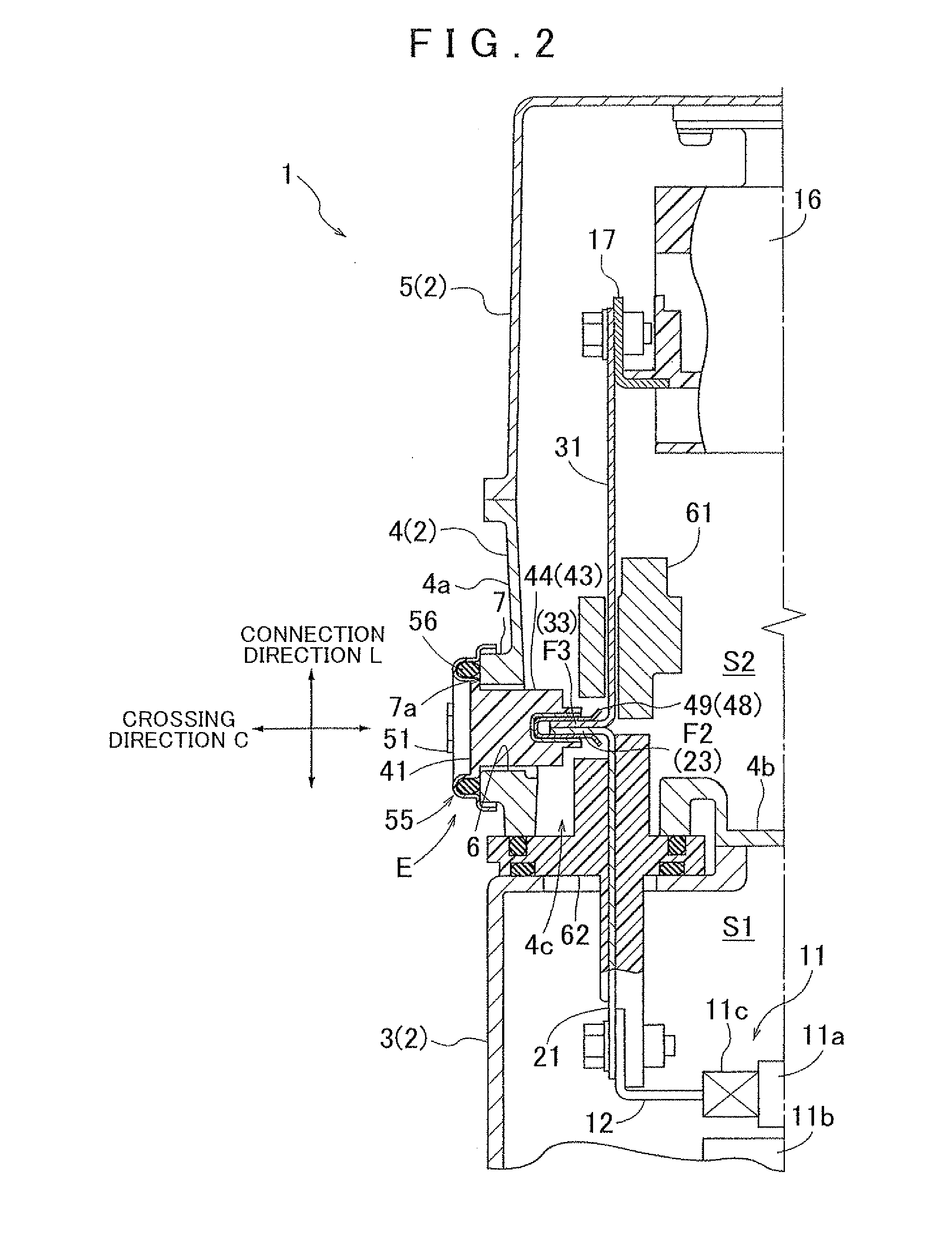

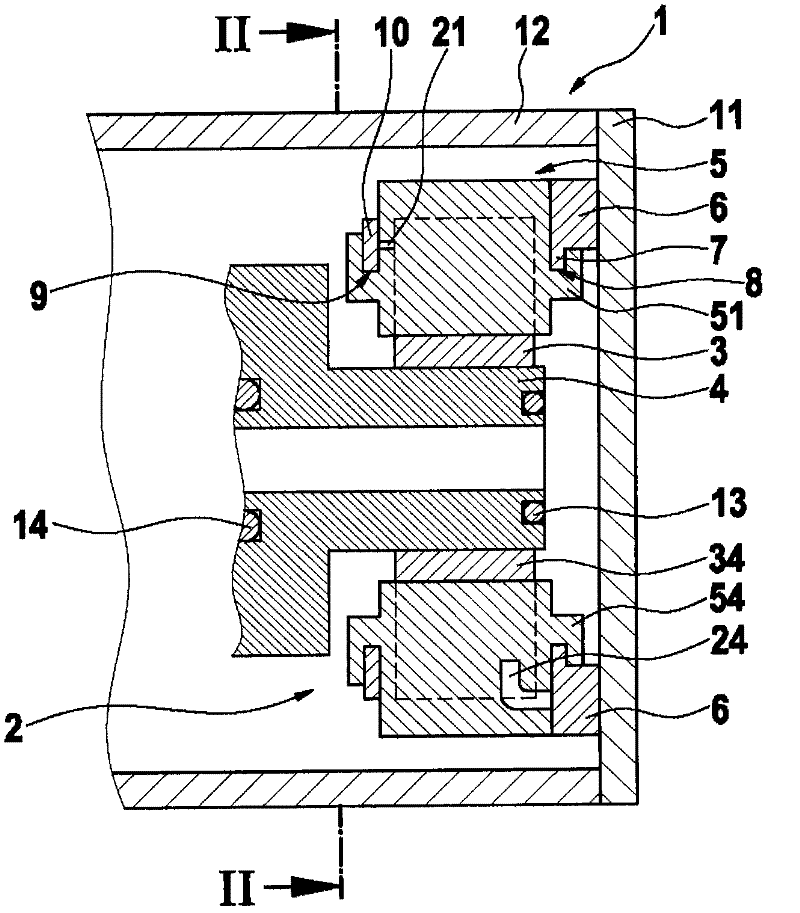

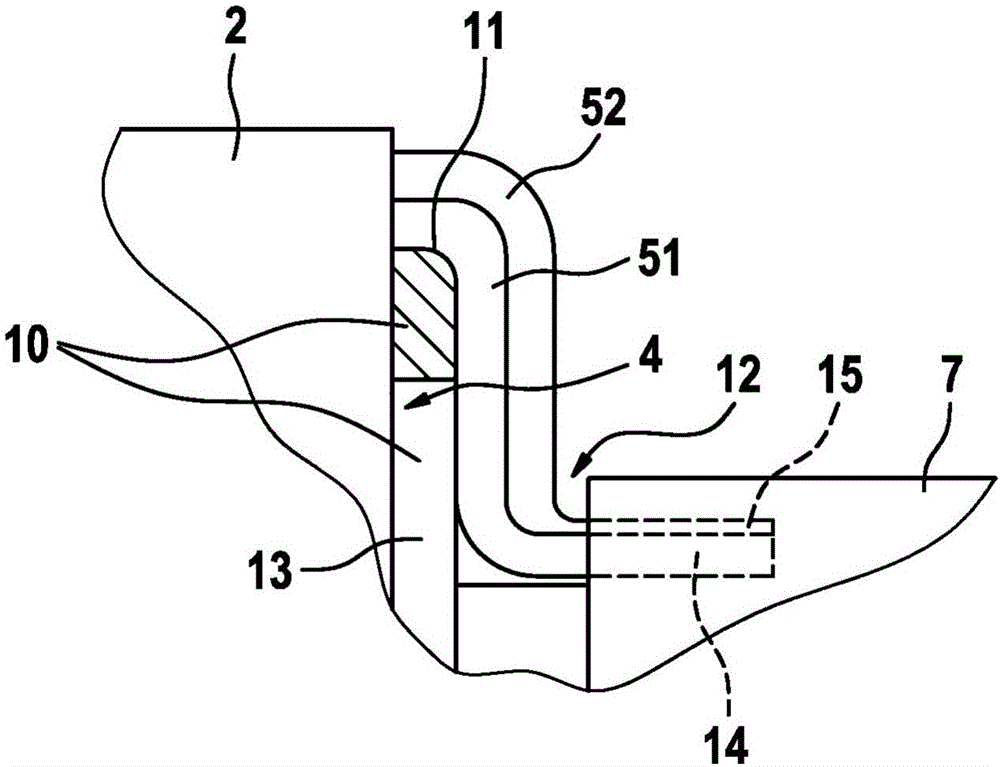

ActiveUS20190379154A1Cheap productionEnsure sealing performanceSecuring/insulating coupling contact membersCouplings bases/casesEngineeringFlange

A connector (10) in a first device is connected to a mating connector (80) in a second device while overlapping and fixing the devices. The connector (10) includes a terminal holding portion (30) to hold terminals (20). A flange (40) on an outer periphery of the terminal holding portion (30) is sandwiched between cases (60, 90) of the devices. A first seal (50A) is mounted on a surface of the flange (40) facing the first device and seals between an outer surface of the case (60) of the first device and the flange (40), and a second seal (50B) is mounted on a surface of the flange (40) facing the second device and seals between an outer surface of the case (90) of the second device and the flange (40). Mounted positions of the seals (50A, 50B) are aligned in an overlapping direction of the first and second devices.

Owner:AUTONETWORKS TECH LTD +2

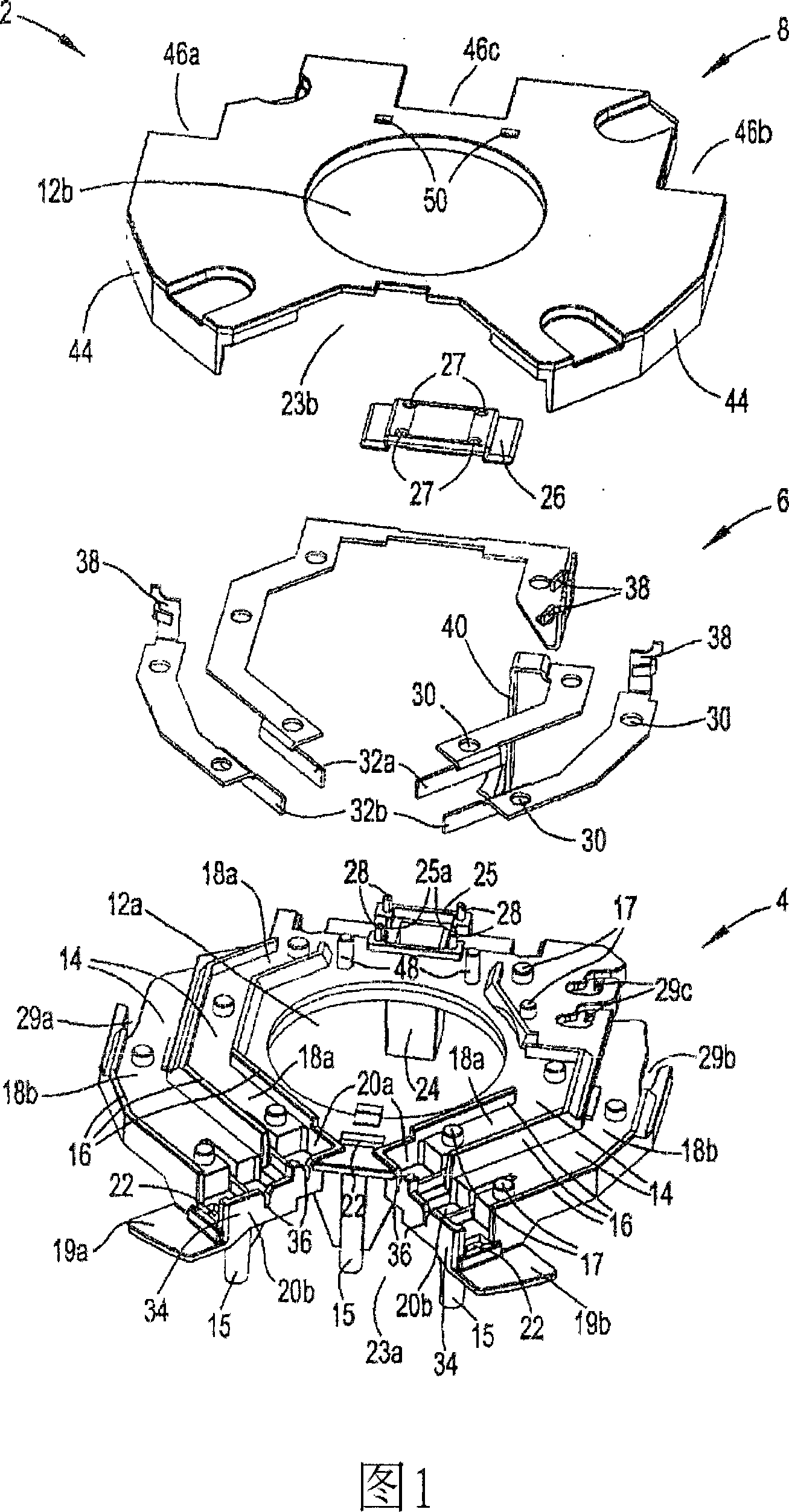

Connecting device for an electric motor

ActiveCN101248557AReduced seriesWindingsDynamoelectric machine connectorsElectrical conductorEngineering

The invention relates to a connecting device (2) for an electric motor, particularly an external rotor motor, to connect ends of a stator winding to a connecting lead (65). Said connecting device (2) is composed of a wiring plate (4) which is arranged on a plane extending in a radial direction relative to the stator axis and within a circumferential circle defined by a stator diameter, and which is provided with terminal areas for contacting the connecting lead (65) as well as shaped strip conductor guides (14) and strip conductors (6) with terminal lugs (38) for contacting the stator winding. A plug element (10) is provided which can be pre-assembled on the connecting lead (65) and comprises insulation displacement contacts (68) that contact the connecting lead (65). The plug element (10) can be mounted on the wiring plate (4) parallel to the stator axis such that the insulation displacement contacts (68) contact the terminal areas of the strip conductors (6) embodied as contacting sections (32a, 32b).

Owner:EBM PAPST MULFINGEN GMBH & CO KG

Interface connector for a motor and a motor incorporating the interface connector

InactiveCN101447628AAssociation with control/drive circuitsSecuring/insulating coupling contact membersEngineeringConductive materials

The present invention relates to an interface connector for a motor and a motor incorporating the interface connector. The present invention discloses an interface connector for use with an electric motor. The interface connector comprises a body made of insulating materials and conductors made of conducting materials. One side of the body has a plurality of recessed openings, and the conductors are imbedded in the body such that a conductor is individually located within a respective recessed opening, although there may be a greater number of recessed openings than conductors.

Owner:REGAL BELOIT EPC

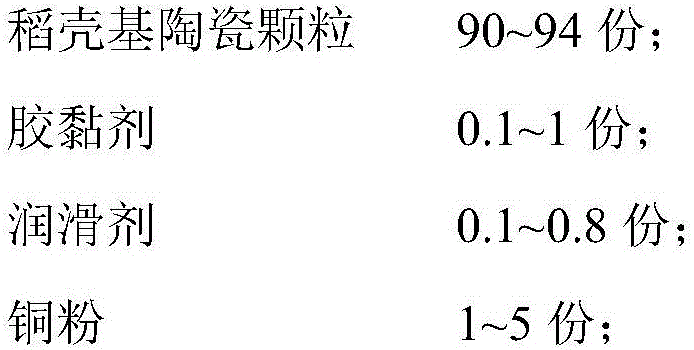

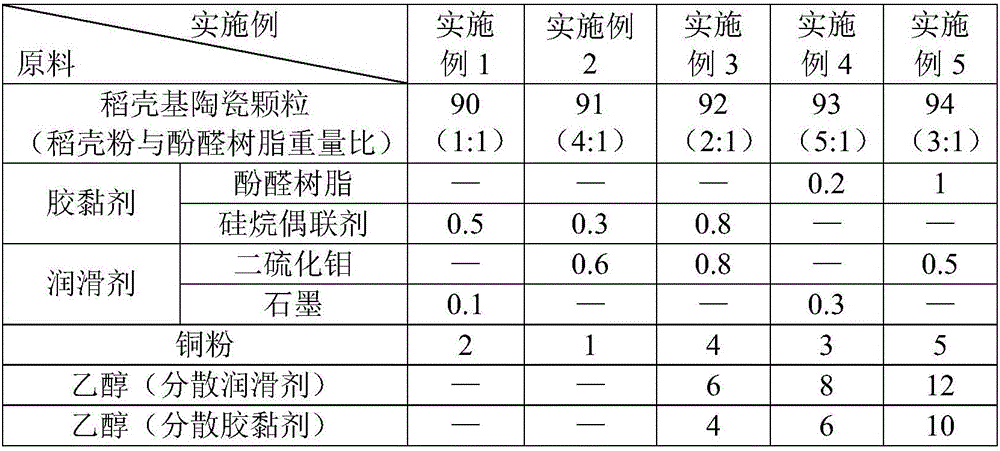

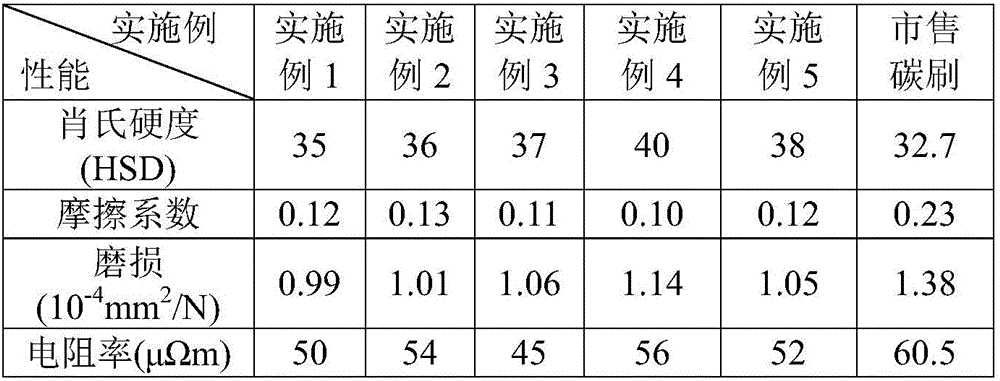

Method for manufacturing motor brush by rice hull

ActiveCN106207692ALow resistivityGood reversing performanceRotary current collectorDynamoelectric machine connectorsAdhesiveCarbonization

The invention discloses a method for manufacturing a motor brush by a rice hull, and relates to the technical field of the preparation of the motor brush. Preparation materials comprise 90-94 parts of rice hull base ceramic particles, 0.1-1 part of adhesive, 0.1-0.8 part of lubricating agent, 1-5 parts of copper powder and the like, wherein the rice hull base ceramic particle is obtained in a way that rice hull powder and phenolic resin are subjected to high-temperature carbonization after being mixed evenly at the ratio of 1-5:1. From the comprehensive utilization of the rice hull, the rice hull (powder) and a phenolic resin high-temperature carbonization product-rice hull ceramic particle are used as the body material of the brush, raw materials including a certain quantity of solid lubricating agent, adhesive, copper powder and the like are used as auxiliary materials, and all materials are evenly stirred and are subjected to compression moulding and calcination to obtain the motor brush. The method is suitable for manufacturing various classes of motors of brush components, and a preparation process is simple and easy in implementation and is safe and environmentally friendly. The prepared motor brush has the advantages of being low in specific resistance, good in commutation, electrical conductivity and thermal conductivity, excellent in abrasion performance and decay resistance, long in service life, good in self-lubricating property and the like, and the combination property of the prepared motor brush is obviously superior to the combination property of a traditional brush.

Owner:HEFEI UNIV

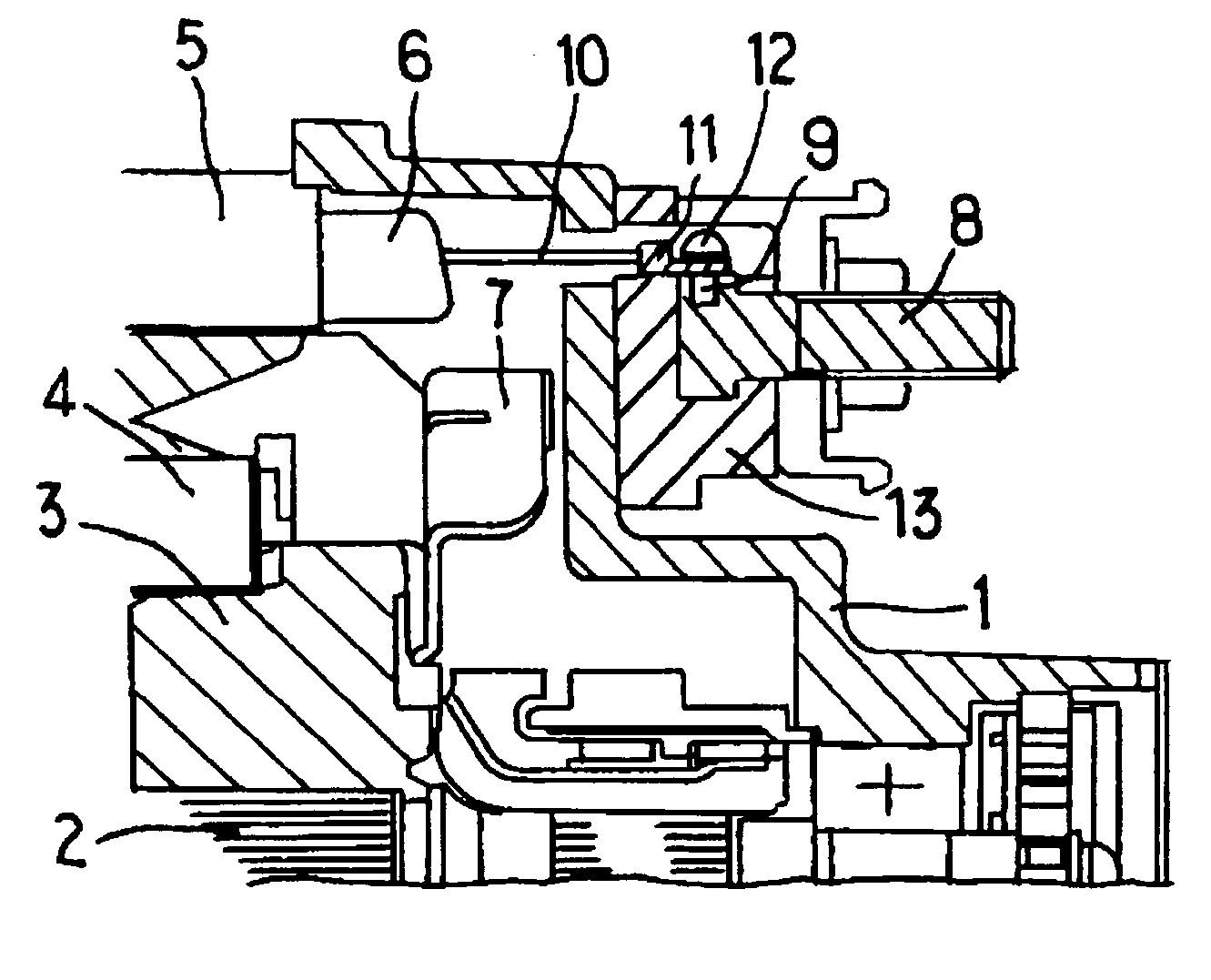

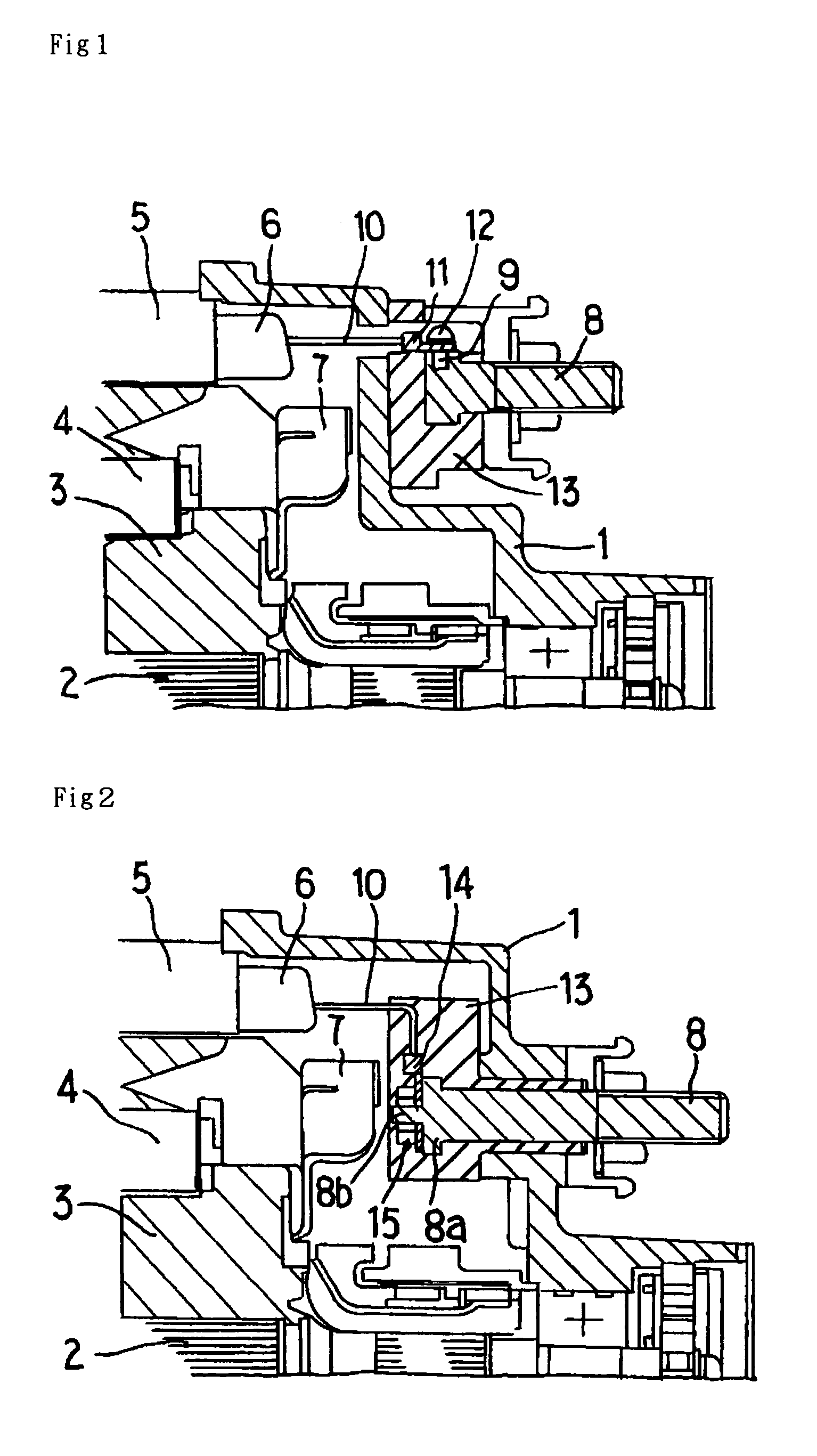

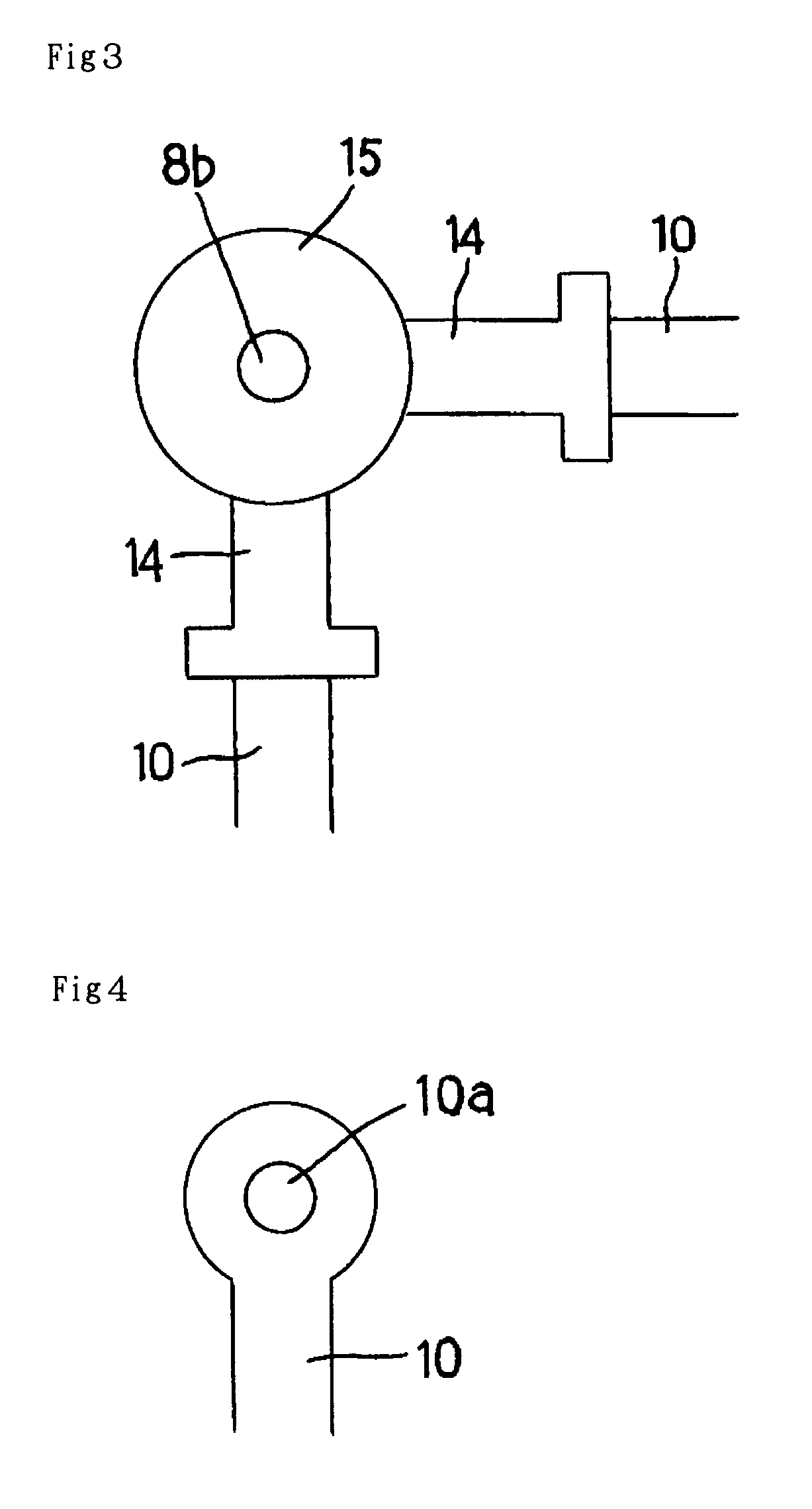

Electric rotating machine for vehicle

InactiveUS6963150B2Increase resistanceImprove efficiencySoldered/welded conductive connectionsMagnetic circuit stationary partsThree-phaseEngineering

Reductions in cost and manufacturing processes are achieved by interposing a single metallic terminal between a lead wire of a stator and a three-phase output terminal. A rotor 3 is fixed onto a rotating shaft 2 disposed rotatably in a housing 1, and a stator core 5 is disposed opposite to the rotor 3. A stator winding 6 is wound around the stator core 5 and a lead wire 10 of the stator winding 6 is connected to a head portion 8a of a three-phase output terminal 8 through a single metallic terminal by a screw 12.

Owner:MITSUBISHI ELECTRIC CORP

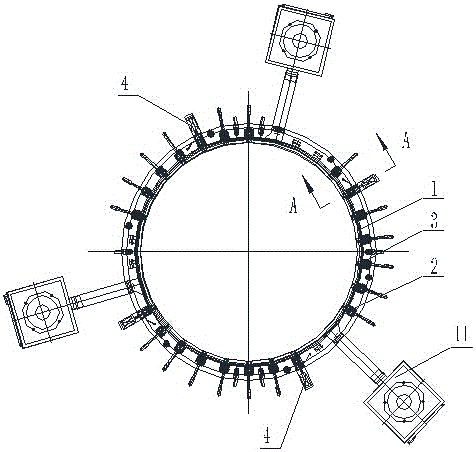

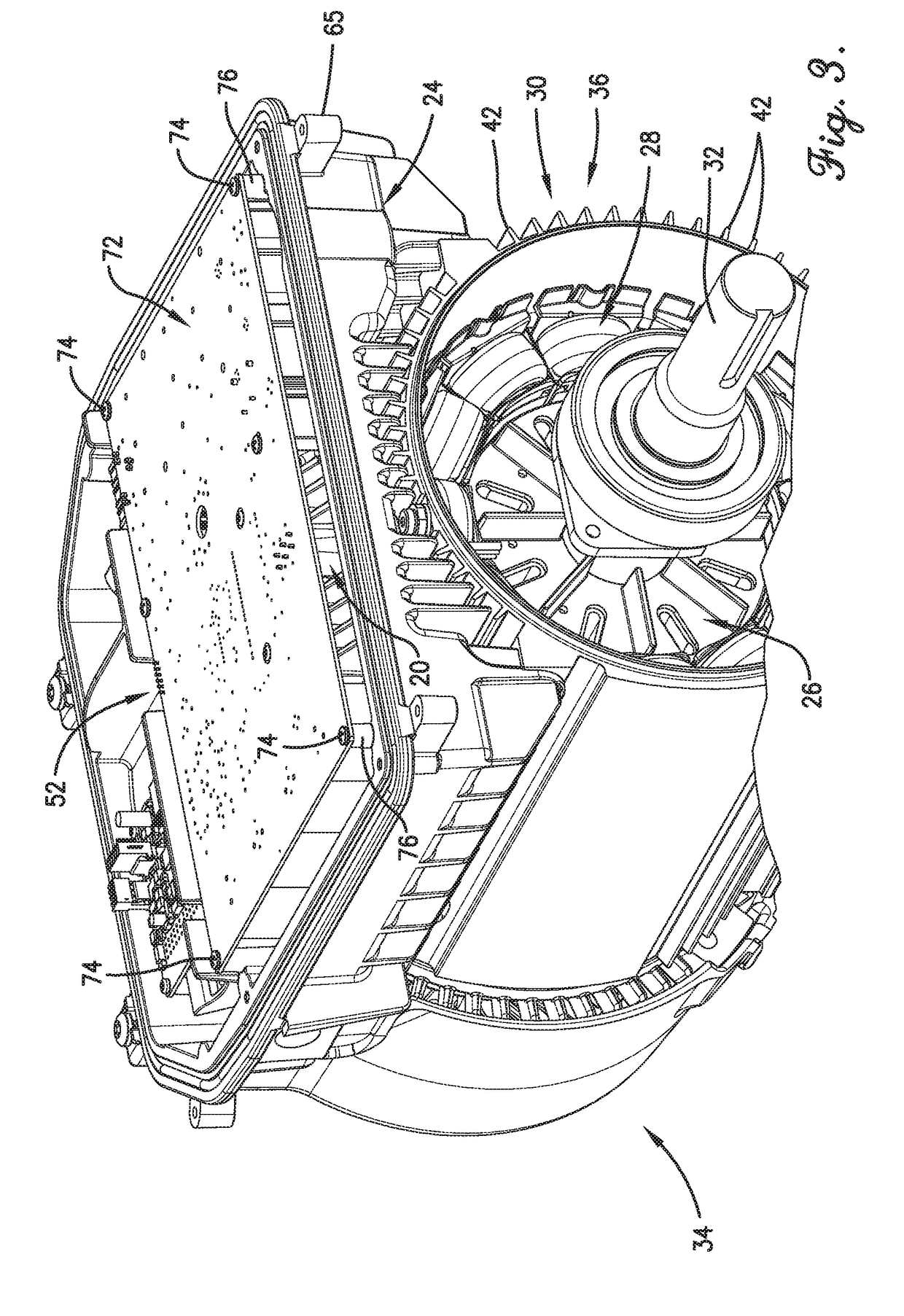

Automatic shifter for generator carbon brush assembly

ActiveCN106159625AAdjustable temperatureAvoid overall overheatingRotary current collectorDynamoelectric machine connectorsMotor driveProgrammable logic controller

The invention discloses an automatic shifter for a generator carbon brush assembly, comprising a collector ring, carbon brushes and a conductive ring; the collector ring is electrically connected with the conductive ring through the carbon brushes, and the carbon brushes and the conductive ring are supported on the support shell; the automatic shifter is characterized in that a guide rail is arranged on the support shell, and brush handles is slidably disposed in the guide rail; one end of every brush handle is connected with a servo motor, and the other end of every brush handle is connected with the corresponding carbon brush; when rotating, the servo motor drives the brush handles to reciprocate, the brush handles drive the carbon brushes to come into no contact by leaving the collector ring or to come into connection by approaching the collector ring. Under control of a PLC (programmable logic controller), according to measured current of the brushes or measured temperatures of the carbon brushes, the quantity of the brushes in contact with the collector ring is automatically adjusted, and the carbon brush assembly is shifted side to side to contact or leave the collector ring so as to adjust the temperatures of the brushes; superheating of the carbon brushes can be effectively prevented, and safety hazards can be effectively eliminated; current density of the brushes can also be automatically adjusted, and a unit is imparted better safety and operational stability.

Owner:重庆华能水电设备制造有限公司

Online monitor for generator carbon brush wear

PendingCN108879272AContinuous monitoring of wearAvoid lossRotary current collectorDynamoelectric machine connectorsElectrical resistance and conductanceWireless transmission

The invention discloses an online monitor for generator carbon brush wear. Pre-embedded wires, the front end of which is embedded inside a carbon brush, are arranged on the carbon brushes; the distance from the front end of the pre-embedded wires to the front end of the carbon brushes is less than the distance from the front end of brush cords to the front end of the carbon brushes; the embedded wires are connected to signal collection devices via signal wires, and the signal collection devices are connected to an alarm device by way of wired connection or wireless transmission; and the signalwhich is processed and sent is collected by the signal collection devices, so as to control the alarm device to issue an alarm signal. The online monitor for generator carbon brush wear of the invention can continuously monitor the wear condition of the carbon brushes during the use of the generator; when the carbon brushes are worn to a certain value, an electric signal is generated and is promptly issued; and thereby the damage of the collector ring, caused by the direct contact of the copper conductive brushes and the surface of the collector ring, is effectively prevented, and the temperature rise caused by the rise of contact resistance formed by the surface damage of the collector ring is further prevented.

Owner:重庆华能水电设备制造有限公司

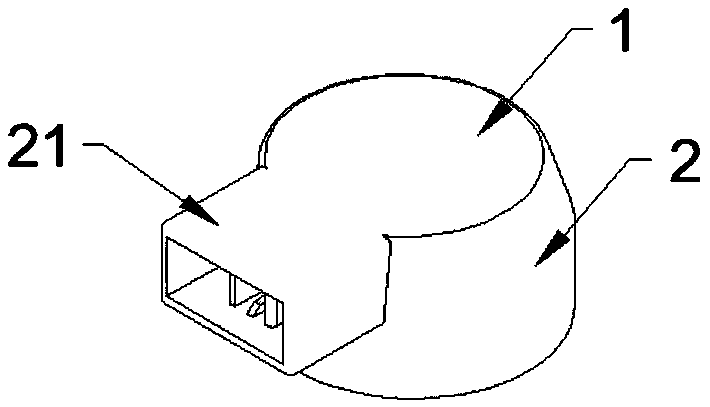

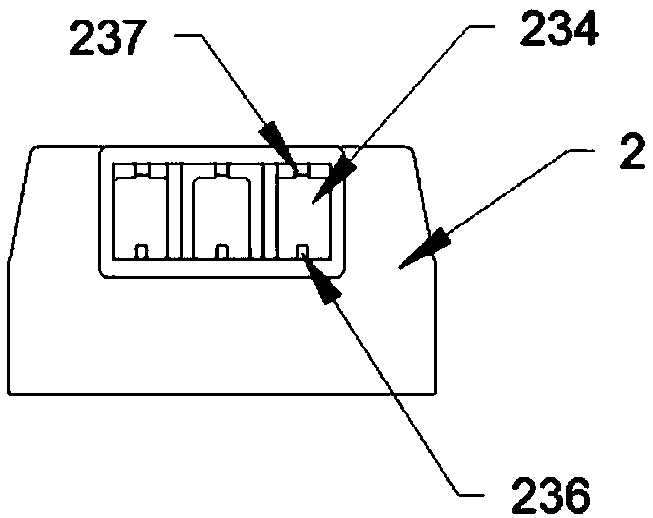

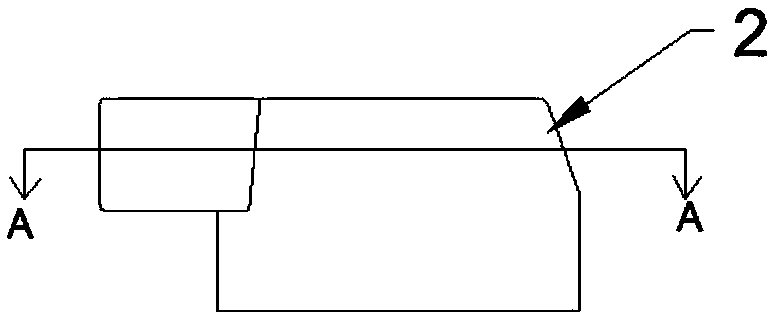

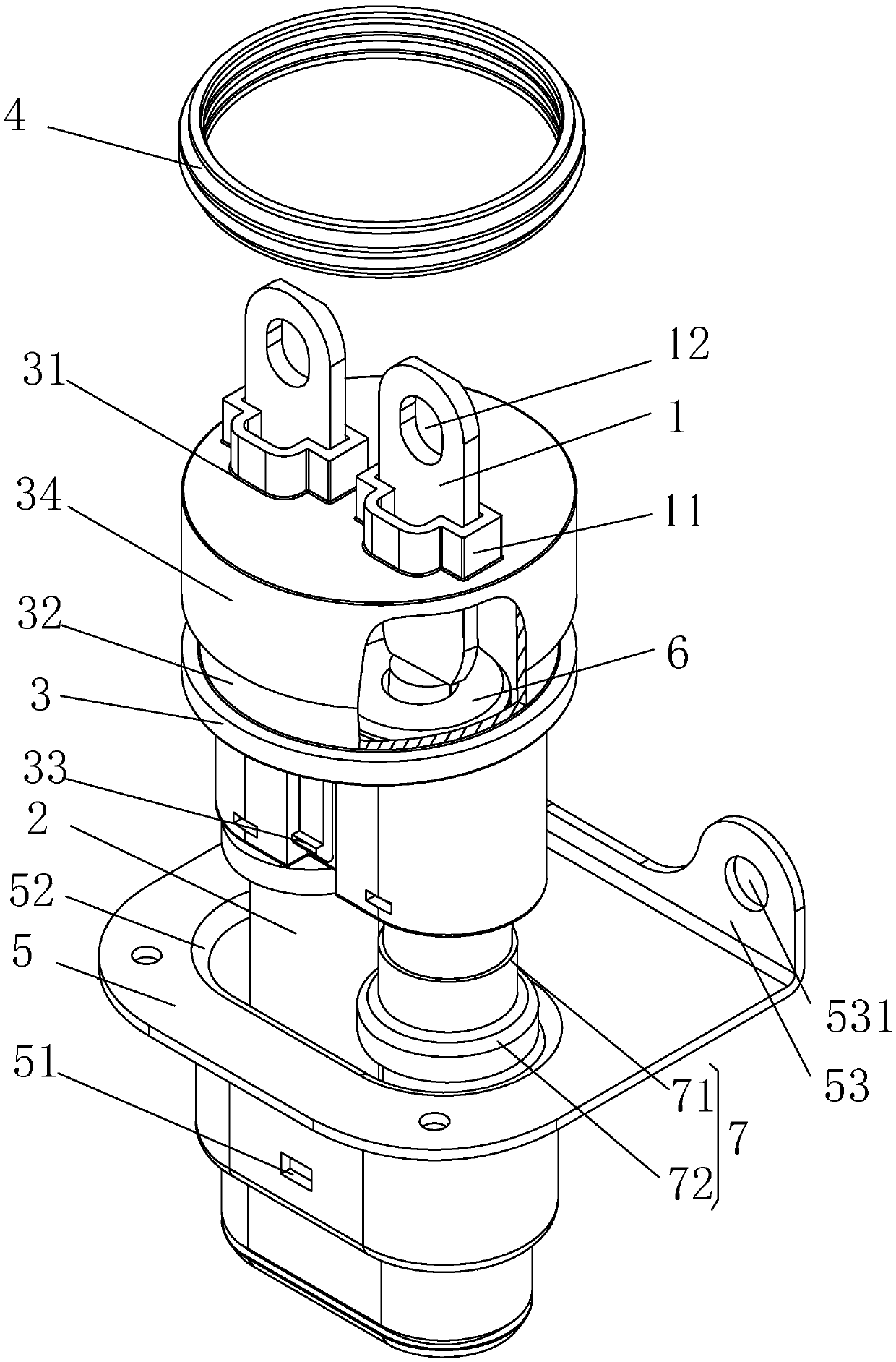

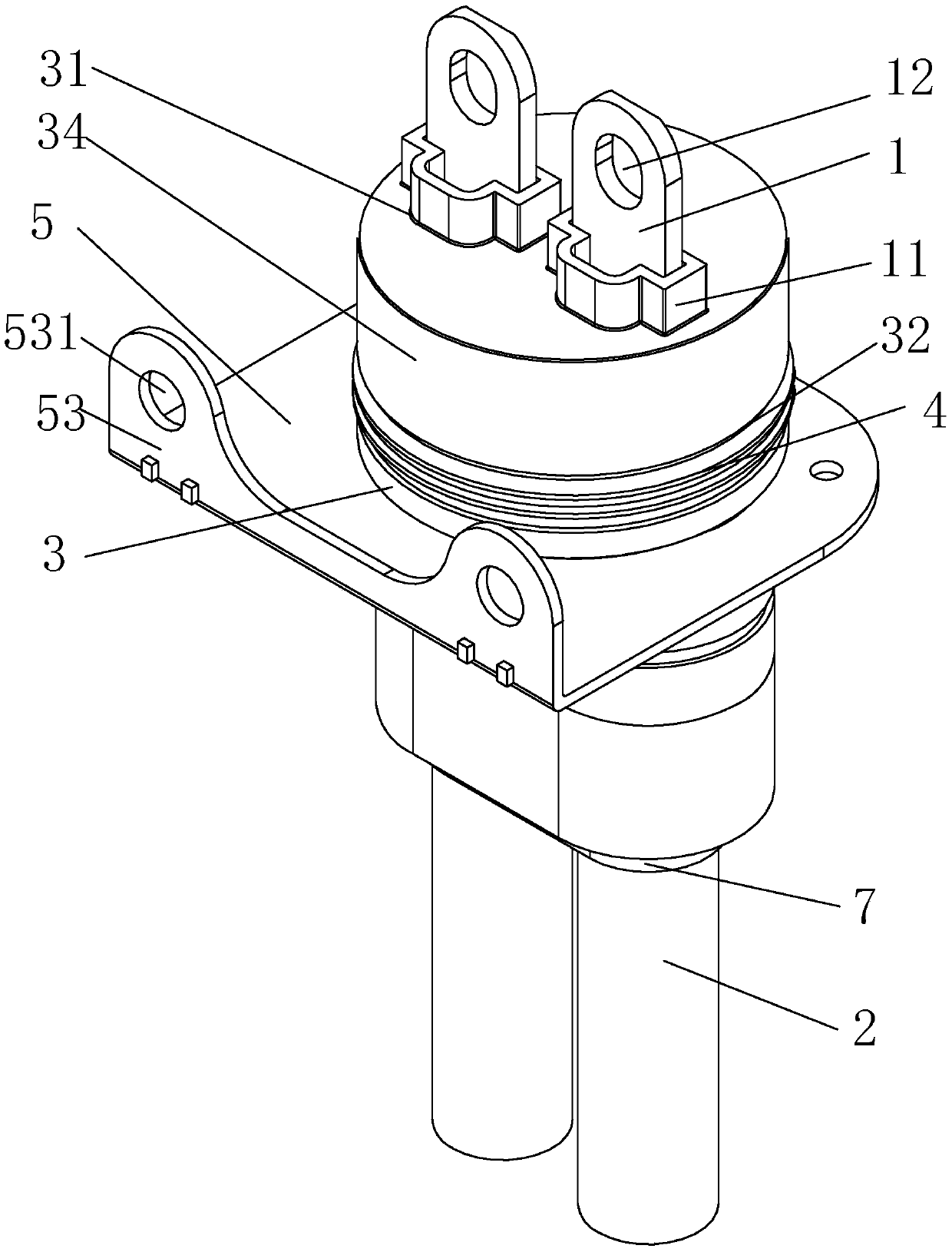

Terminal post sealing cover, upper cover assembly and compressor

PendingCN110854559AEasy to installQuick connectionElectrically conductive connectionsPositive displacement pump componentsStructural engineeringTop cap

The invention relates to a terminal post sealing cover, an upper cover assembly and a compressor. The terminal post sealing cover comprises a top cover and a side wall extending from the top cover toone end; The side wall comprises a accommodating part for accommodating a connection terminal and a terminal post, and a fixing part for sleeving the outer periphery of the terminal post fixing base and interfering and fixing with the outer periphery of the terminal post fixing base; The accommodating part is provided with a fixing structure for inserting and fixing the connection terminal; The fixing structure is provided with a through hole used for the terminal post to penetrate and enabling the penetrating terminal post to contact and connect with the connection terminal. The fixing part and the terminal post fixing base are interference-fixed so that the installation of the terminal post sealing cover and the terminal post fixing base is facilitated, the sealing between the terminal post sealing cover and the terminal post fixing base is realized, materials are saved, costs are saved and the production efficiency is improved. Besides, the terminal post is enabled to pass through the through hole and contact and connect with the connection terminal in the fixing structure, thus facilitating the rapid connection between the connection terminal and the terminal post and further improving the production efficiency.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

Motor controller connector assembly for new energy source automobile

InactiveCN105576424ASimple structureEasy to assembleVehicle connectorsCouplings bases/casesRubber ringNew energy

The invention provides a motor controller connector assembly for a new energy source automobile and belongs to the technical field of interface standard connector parts of a motor controller. The motor controller connector assembly comprises a wiring terminal, a cable, a plastic body, a waterproof sealing ring, a metal fixed shell, a rubber ring and a shielding ring, wherein one end of the wiring terminal is connected with the cable; a wiring terminal containing hole is formed in the middle of the plastic body; the other end of the wiring terminal penetrates through the wiring terminal containing hole from bottom to top; an embedding groove is formed in one side, close to the wiring terminal, of the plastic body around the periphery; a clamping pin is arranged on one side, close to the cable, of the plastic body; the waterproof sealing ring is embedded into the embedding groove; the metal fixed shell is provided with a bayonet; the metal fixed shell sleeves the plastic body; the bayonet is correspondingly adapted to the clamping pin; the rubber ring sleeves the cable and is close to the wiring terminal; and the shielding ring sleeves the cable and is close to the bottom of the plastic body. The motor controller connector assembly has the advantages of convenience for assembling, high connection strength, reliability in contact and difficulty of loosening; the waterproof sealing property is high; and a detachable structure is adopted so that the motor controller connector assembly can be conveniently used for the second time.

Owner:SUZHOU CABLEPLUS ELECTRIC

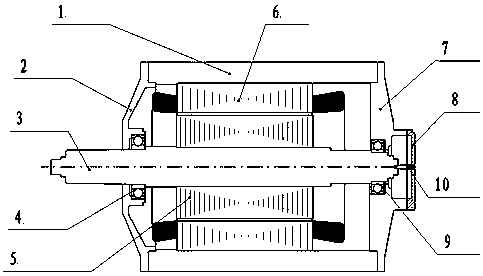

Motor for removing electric corrosion of bearing

PendingCN107681836AImprove general performanceWith layout spaceCoupling contact membersDynamoelectric machine connectorsElectric machineStructural engineering

The invention discloses a motor for removing the electric corrosion of a bearing, and the motor comprises a housing, a motor stator, a motor rotor and a rotating shaft, wherein the motor stator, the motor rotor and the rotating shaft are located in the housing. Two ends of the housing are respectively provided with a first end cover and a second end cover. One end of the rotating shaft adaptivelypasses through the first end cover through a first bearing, and the other end of the rotating shaft is adapted to the second end cover through a second bearing. The exterior of the second end cover isfixedly provided with a cover plate, and the end face of the other end of the rotating shaft is electrically connected with the cover plate through an elastic assembly. The cover plate is also electrically connected with the second end cover, the housing, and the first end cover. The elastic assembly comprises an ejector pin, a spring, and a needle cylinder. The exterior of the second end cover is fixedly provided with a cover plate, and one end of the needle cylinder is fixed with the cover plate. The spring is placed in the needle cylinder, wherein one end of the ejector pin stretches intothe needle cylinder to make contact with the spring, and the other end of the ejector pin makes contact with the end face of the rotating shaft. The motor is high in universality, is simple in installation, is low in cost, is long in service life, is reliable in structure, and is low in maintenance cost.

Owner:HEFEI JUYI POWER SYST CO LTD

Integration carbon brush device for aerogenerator

ActiveCN106059170AFix uneven pressureReduce incidenceRotary current collectorDynamoelectric machine connectorsBrush deviceEngineering

The present invention discloses an integration carbon brush device for an aerogenerator. The device comprises a carbon brush and a brush box; the carbon brush is fixed in the brush box; the carbon brush includes a carbon brush body; the brush box includes a brush box body, and a first fixed assembly and a second fixed assembly extending outwards are respectively arranged at two sides of the brush box body; the brush box body is provided with a through hole, one end of the carbon brush body is extended from the through hole to touch the surface of a conducting ring, and other end of the carbon brush body is fixed with a lead; the carbon brush body is provided with pressure grooves at two sides of the lead, an opening joint is arranged at the rear end of the lead, and the opening joint is fixed at the first fixed assembly; constant pressure springs are respectively arranged at the two sides of the top of the brush box body, and the constant pressure springs are embedded into the pressure grooves; and a contact point switch stop hook is fixed at the side surface of the carbon brush body, and the contact point switch stop hook is arranged at the lower portion of the pressure grooves. The integration carbon brush device for an aerogenerator employs an integrated carbon brush to take place of the multi-carbon brush combination structure in the prior art so as to solve the uneven pressure and reduce the incidence rate of faults such as high temperature, sparking and the burning of the surface of a conducting ring.

Owner:摩腾科技(上海)有限公司

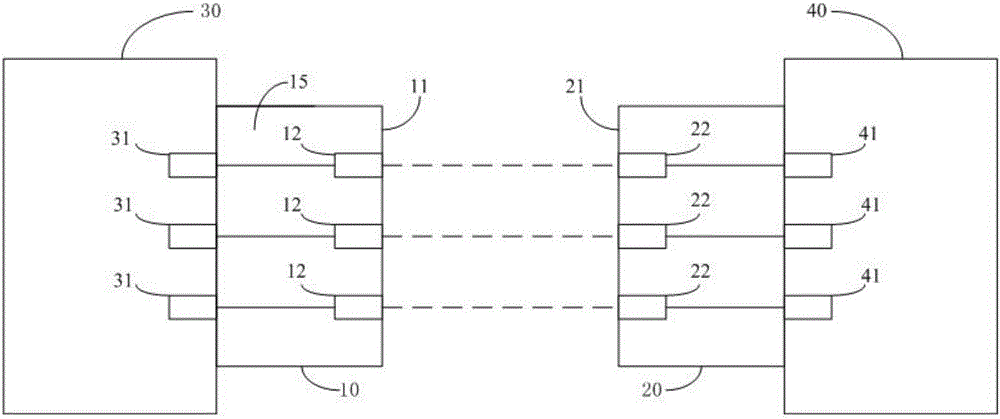

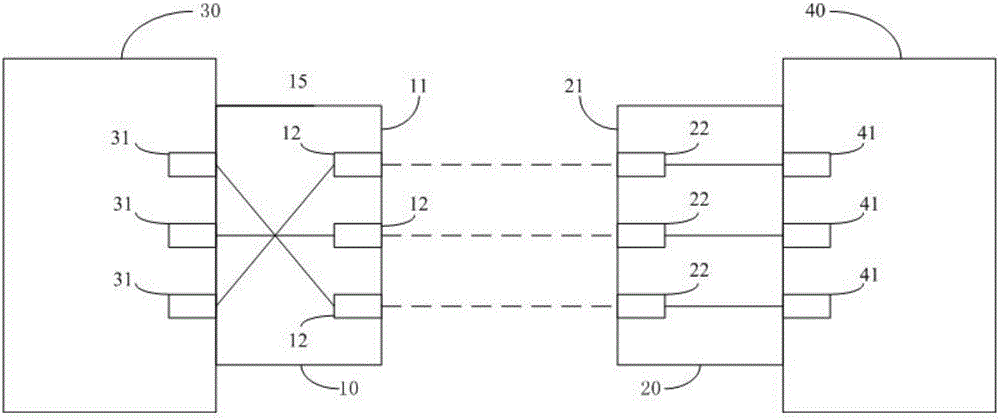

Connector of electronic speed regulator and motor, power system and unmanned aerial vehicle

InactiveCN106716742AImprove assembly efficiencyImprove accuracyEmergency protective circuit arrangementsCoupling contact membersElectricityOutput device

The invention provides a connector of an electronic speed regulator and a motor. The connector of an electronic speed regulator and a motor comprises an output device (10) used for being electrically connected to three output terminals (31) of an electronic speed regulator (30), wherein the output device (10) comprises a first bearing portion (11) and three output connecting portions (12) used for respectively outputting three-phase driving signals of the motor, the three output connecting portions (12) are fixedly connected to be an integral body through the first bearing portion (11), so that relative positions of the three output connecting portions (12) are fixed; and an input device (20) used for being electrically connected to three input terminal (41) of the motor (40), wherein the input device (20) comprises a second bearing portion (21) and three input connecting portions (22) used for respectively inputting three-phase driving signals of the motor, the three input connecting portions (22) are fixedly connected to be an integral body through the second bearing portion (21), so that relative positions of the three input connecting portions (22) are fixed, and the three input connecting portions (22) are used for being respectively connected with the three output connecting portions (12) to electrically connect the input device (20) and the output device (10).

Owner:SZ DJI TECH CO LTD

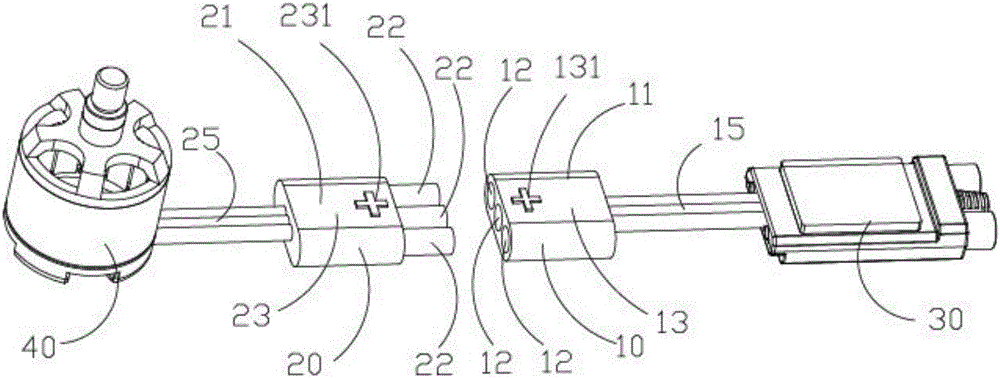

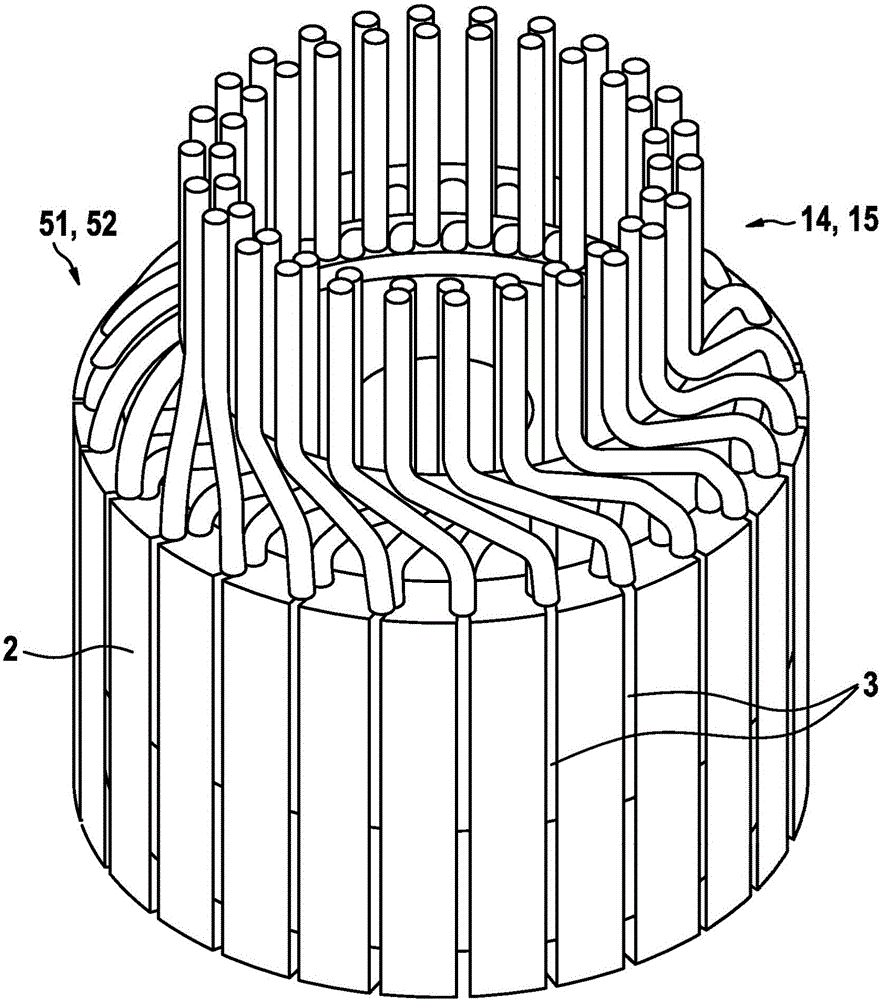

Method and rotor for producing a short winding head

ActiveCN105706343AShort structure lengthReduce weightWindingsRotary current collectorElectrical conductorRadial position

The invention relates to a method and a rotor for producing a short winding head (6), in which conductor sections (5) of a rotor winding, emerging on the front side from the base body (2) of a rotor (1), are bent in the direction of a commutator (7). The conductor ends (14, 15) of the conductor sections (51, 52), which are aligned parallel to the axis, are placed in a second inner radial position from an original first outer radial position. Conductor sections (51) leading to the conductor ends (14) are bent over a bending edge (11) of a bending ring (10) placed on the front side on a base body (2) and are aligned at least approximately parallel to the front side (4) of the base body (2).

Owner:SEG AUTOMOTIVE GERMANY GMBH

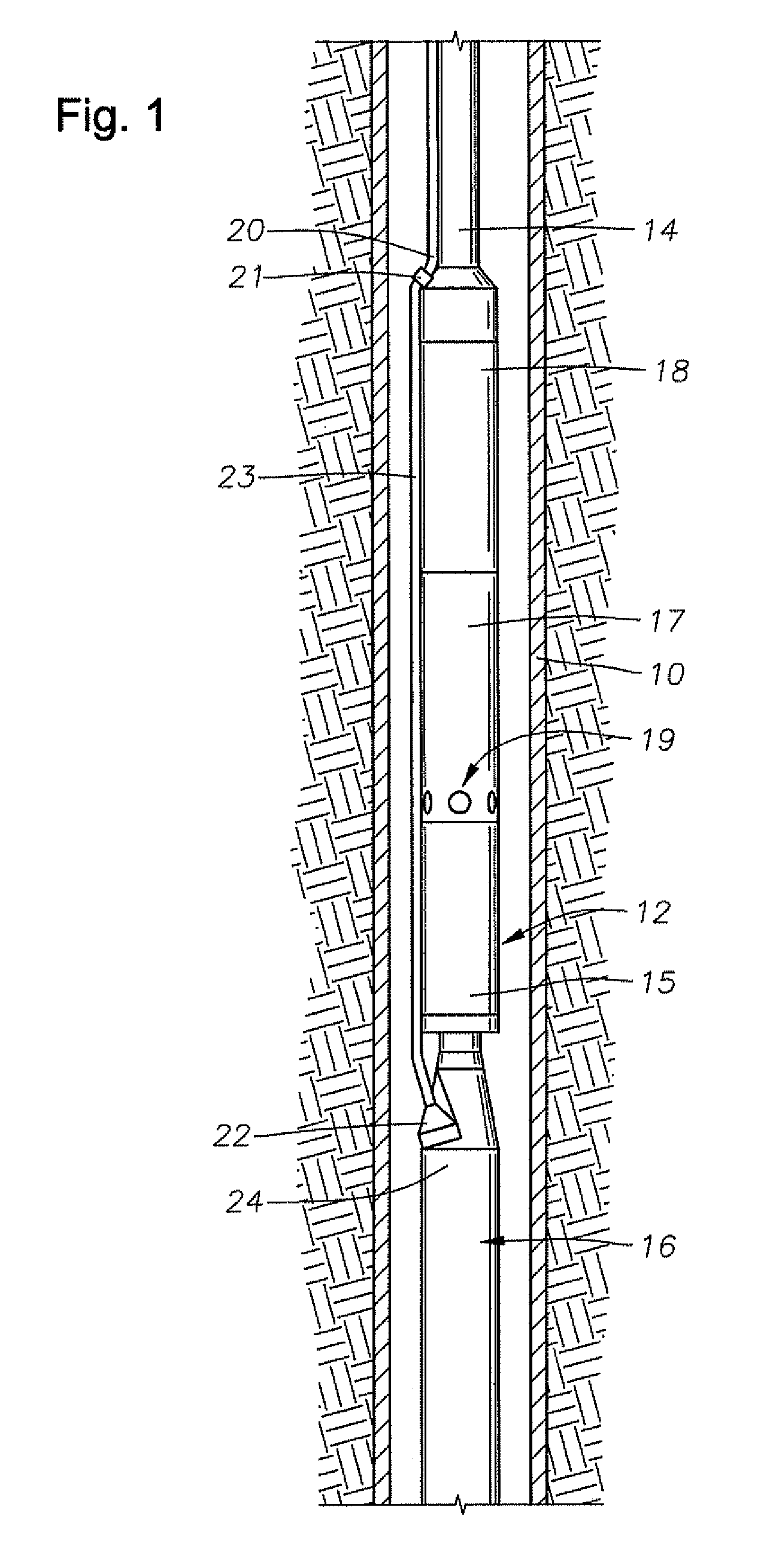

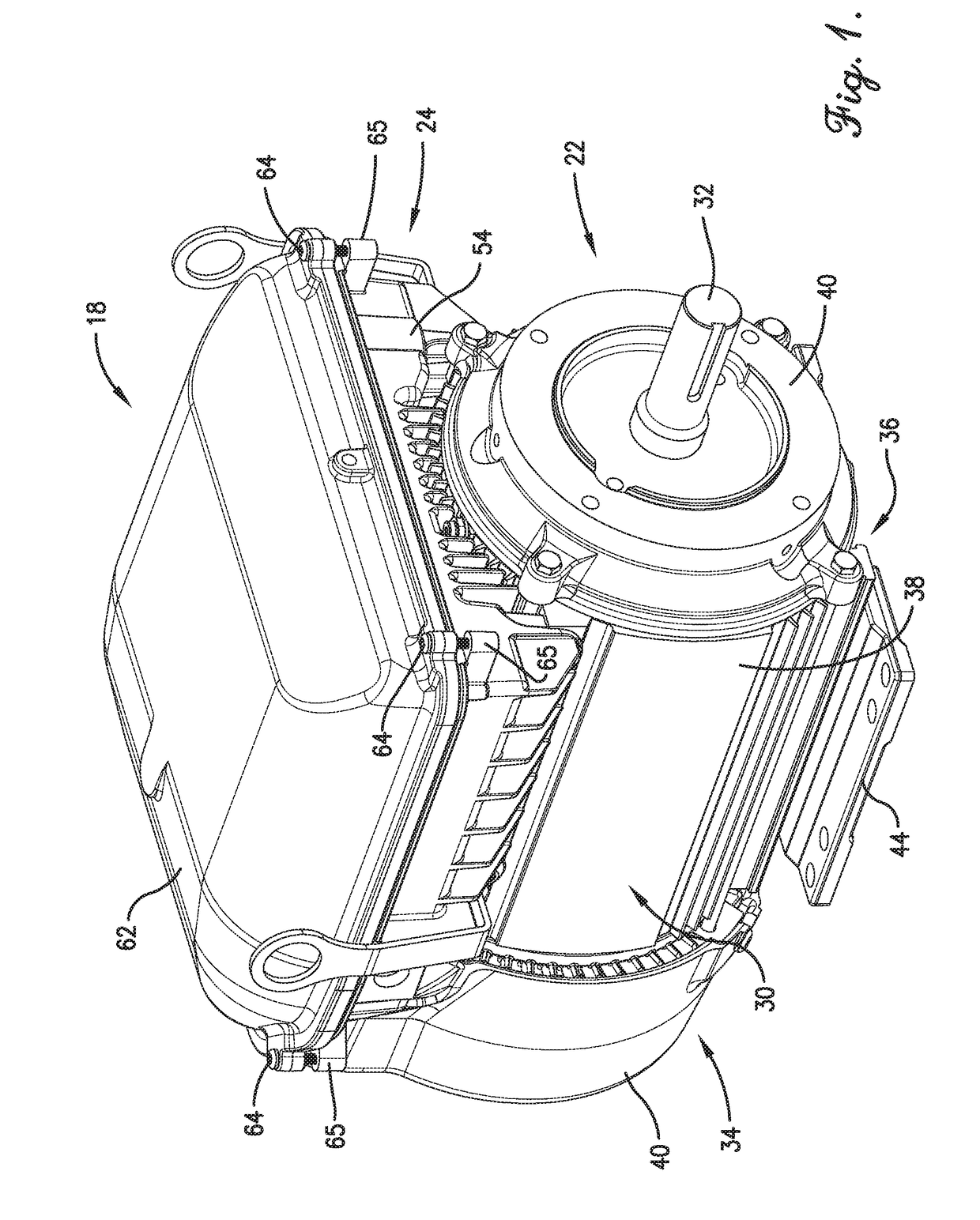

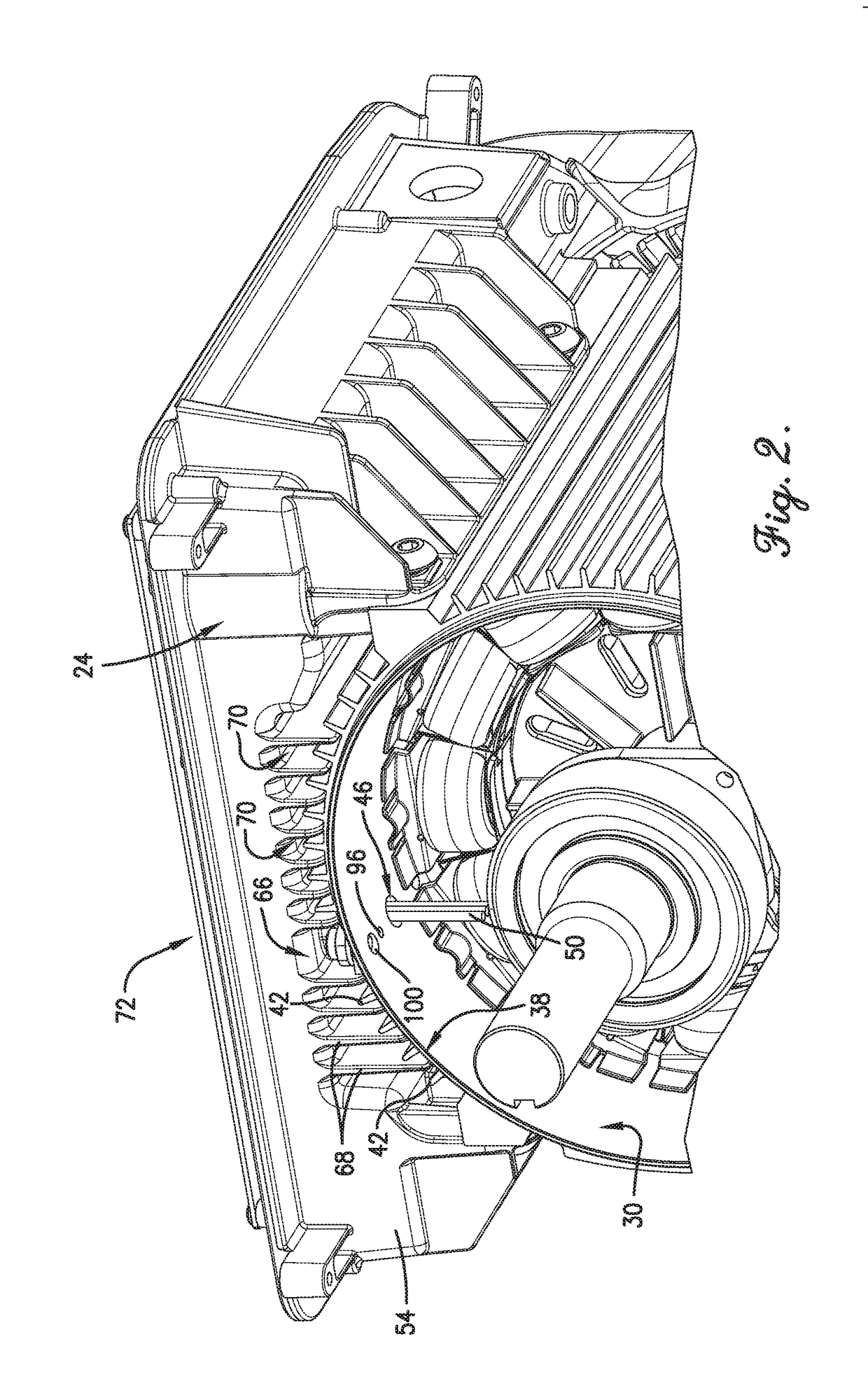

Motor lead connector for ingress protected motor

ActiveUS20180358860A1Association with control/drive circuitsCouplings bases/casesEngineeringElectric motor

An electric motor having a rotor, a stator, a case at least partially enclosing the rotor and the stator, and a lead connector. The lead connector includes a body having a base, a terminal end, and an intermediate portion extending between the base and the terminal end. The lead connector also includes a first sealing interface extending substantially circumferentially about the intermediate portion and a second sealing interface abutting the case.

Owner:NIDEC MOTOR CORP

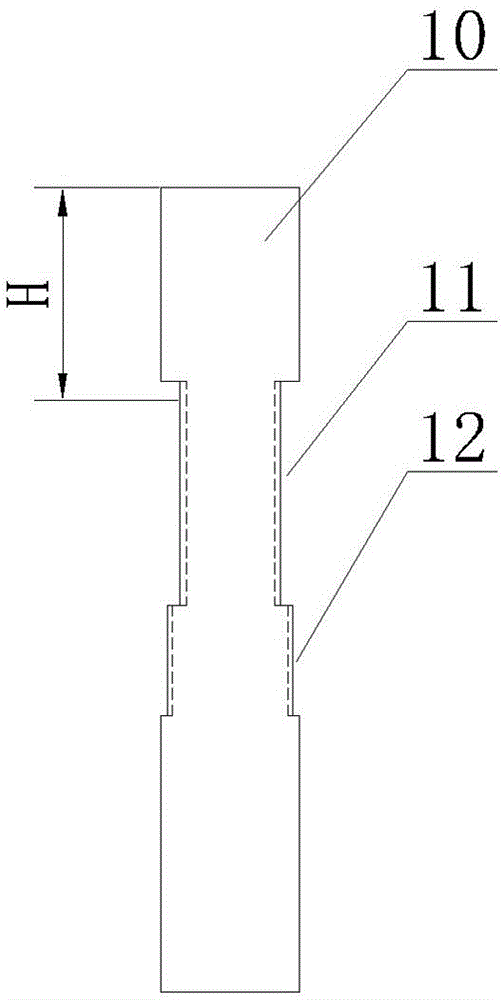

Hook-shaped commutator

ActiveCN106451001AJob impactImprove bonding fastnessRotary current collectorDynamoelectric machine connectorsPunchingMilling cutter

The invention discloses a hook-shaped commutator composed of a bakelite powder base and commutating copper sheets. The hook-shaped commutator is characterized in that insulation between the commutating copper sheets is carried out by milling insulating grooves with a circular milling cutter between, the tops of the insulating grooves is subjected to arc transition so as to be prevented from being pierced; the commutating copper sheets are elongated bodies before the insulating grooves are milled and hooks are formed; the outer side of each elongated body is an arc surface, the height of the top, where a hook is to be formed, of the elongated body is H; the middle positions of the left and right sides of the elongated body are provided with connected upper and lower punching notches respectively, the distance between the top of the upper punching notch and the top of the elongated body is less than H; the width of the lower punching notch is narrow; the width of the upper punching notch is wide; the upper punching notch has a punching slope in the radial direction, the punching slopes of adjacent elongated bodies define a tapered mouth with an inward large end. The hook-shaped commutator prevents glue from entering the insulating grooves, enables high-quality production and high mechanical strength, and facilitates automatic insertion and mass production.

Owner:ZHEJIANG SONGPU COMMUTATOR

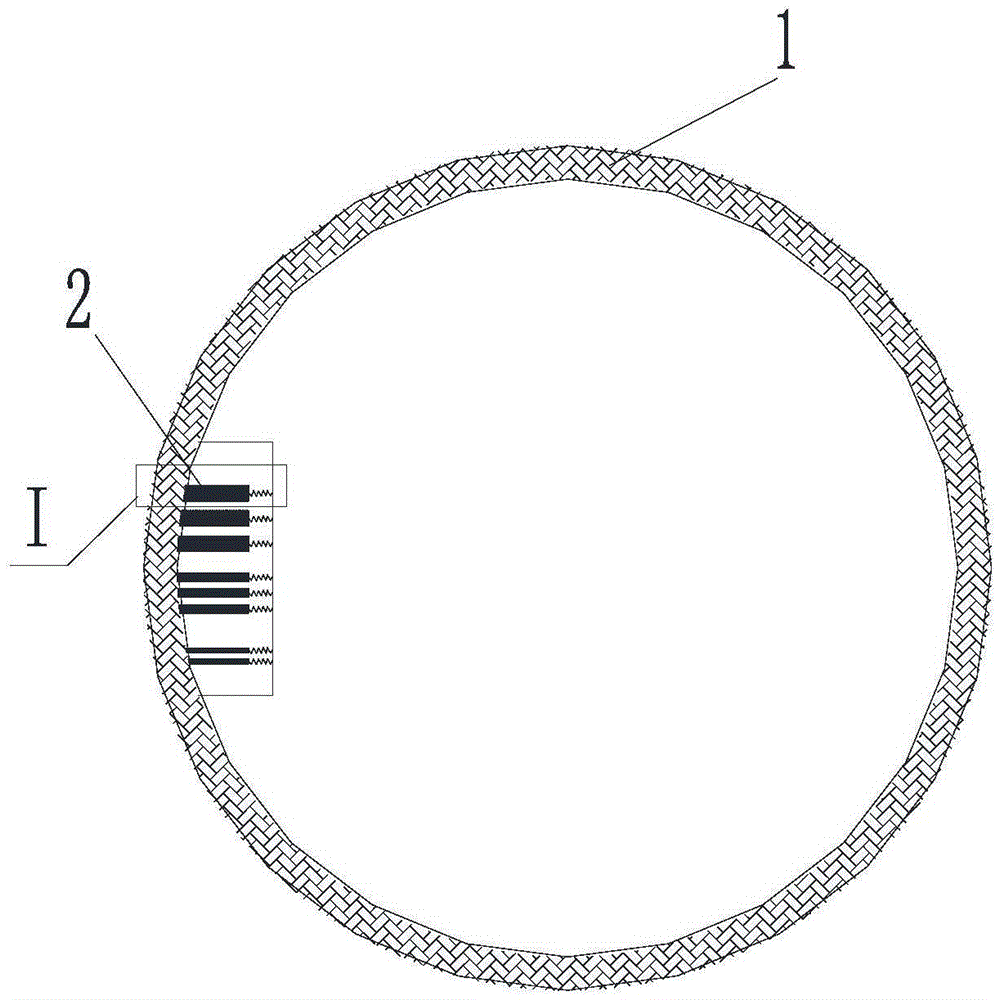

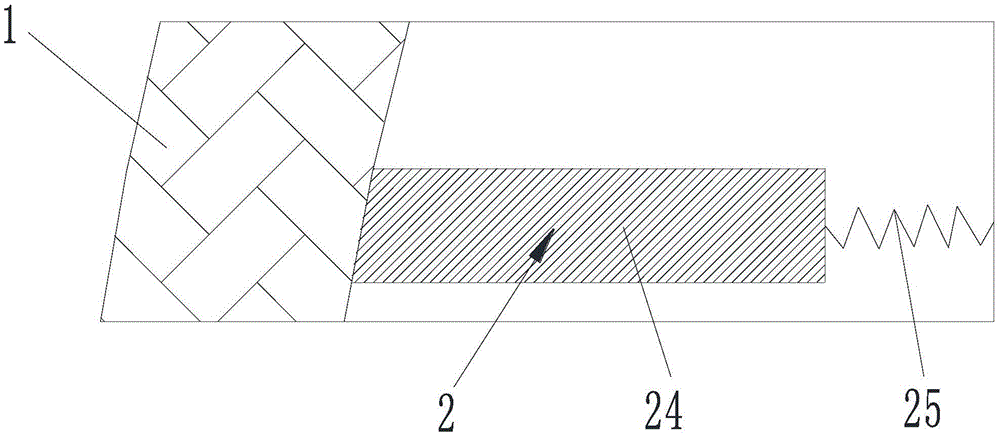

Cable twist-preventing structure for cables of wind generating set, and wind driven generator

ActiveCN105649898APhenomena that affect workImprove reliabilityRotary current collectorFinal product manufactureWind drivenNacelle

The invention provides a cable twist-preventing structure for cables of a wind generating set, and a wind driven generator. The cable twist-preventing structure comprises a circular-ring-shaped current collecting guide rail and a current collecting slider; the circular-ring-shaped current collecting guide rail is arranged horizontally, and the current collecting slider is connected to the current collecting guide rail and capable of sliding along the current collecting guide rail; the cables in the wind generating set include a cabin cable arranged in a cabin and a tower barrel cable arranged in a tower barrel; the current collecting guide rail is connected with the cabin cable, while the current collecting slider is connected with the tower barrel cable. Alternatively, the current collecting guide rail is connected with the tower barrel cable, while the current collecting slider is connected with the cabin cable. By using the cable twist-preventing structure for the cables of the wind generating set, unlimited rotation of the cabin can be realized, and the adaptability to wind directions can be enhanced; meanwhile, a yaw angle detector and a yaw protector are not required, and therefore, not only is the manufacturing cost reduced, but also the reliability of the set during operation is enhanced.

Owner:XINJIANG GOLDWIND SCI & TECH

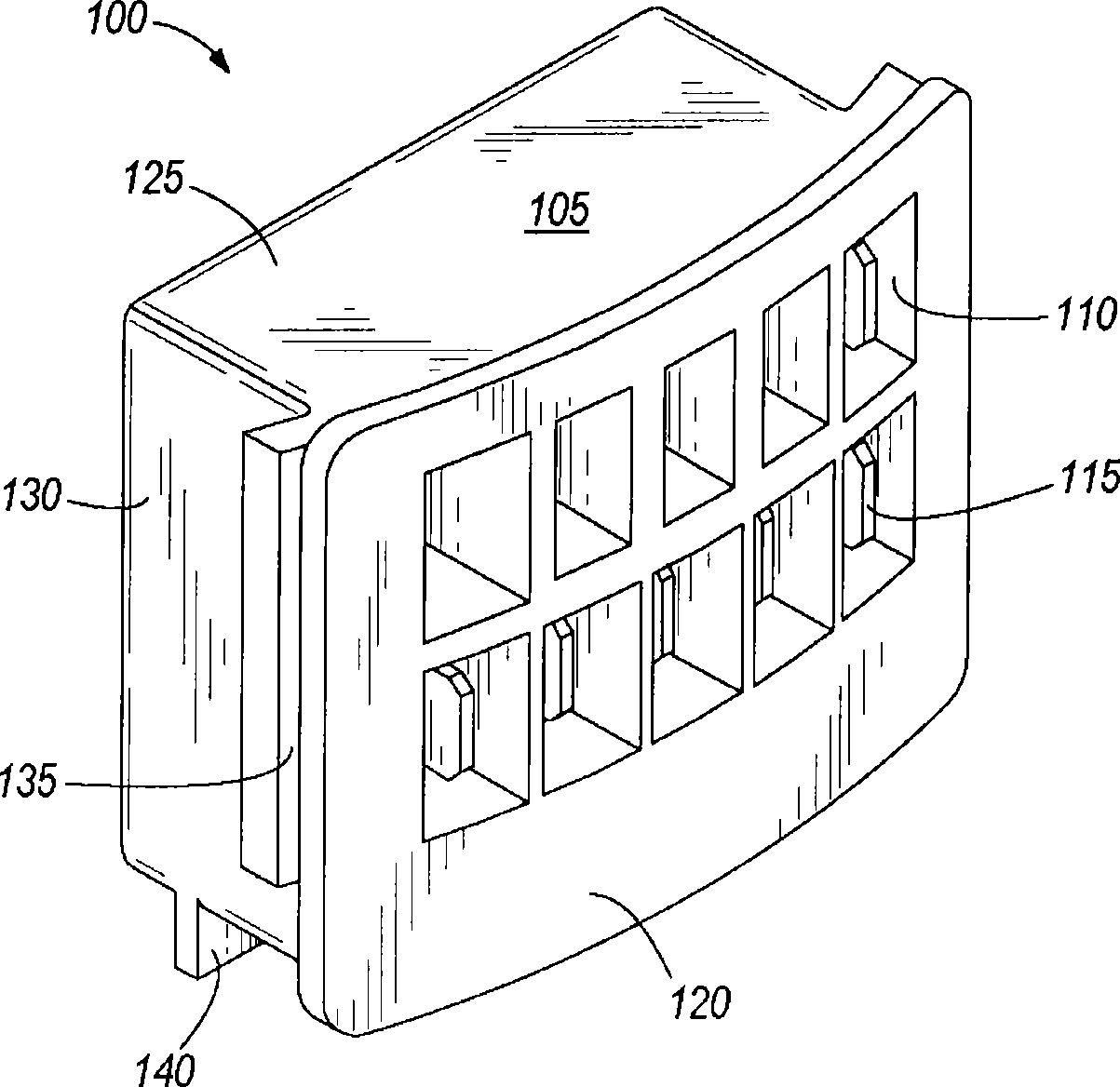

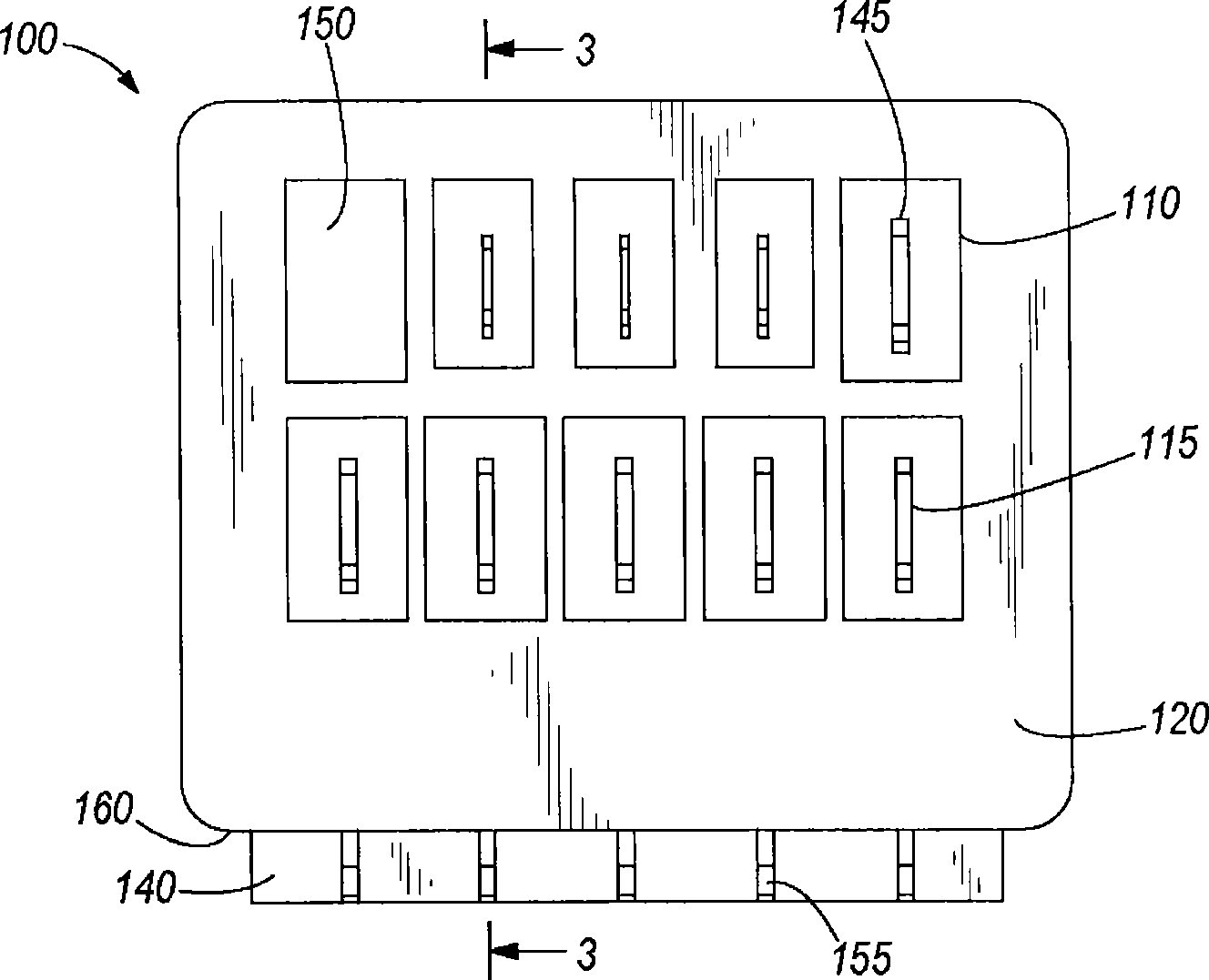

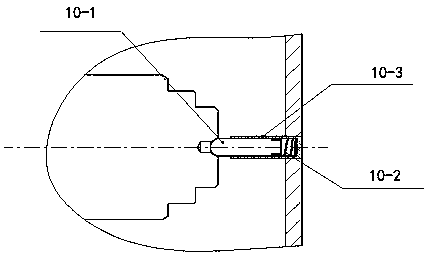

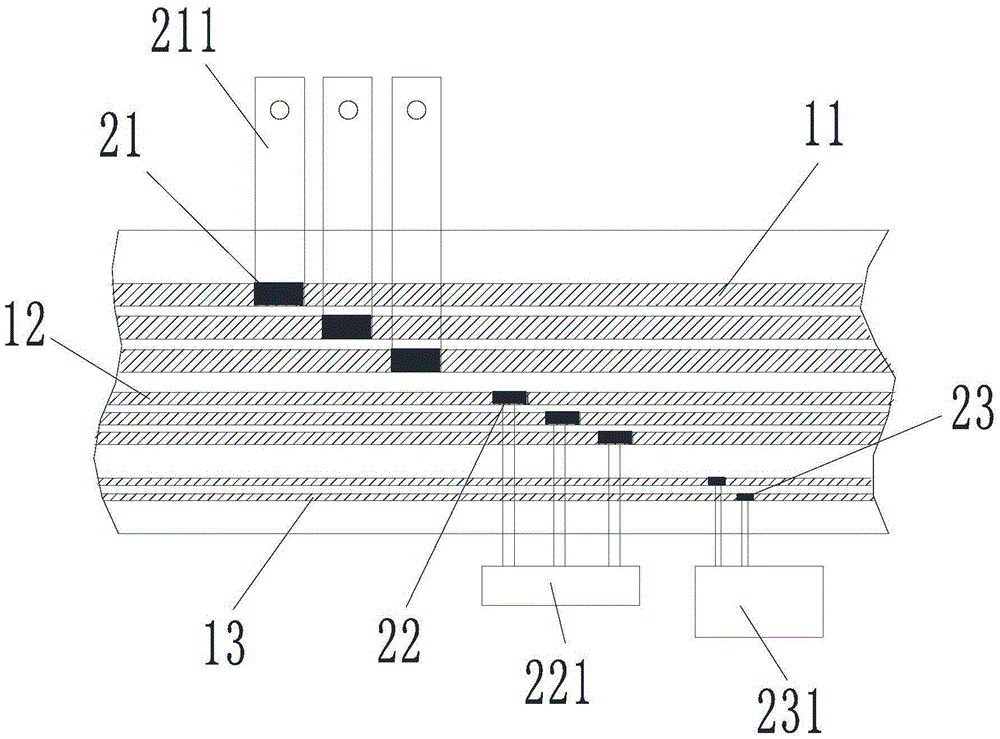

Terminal block with integral heat sink and motor provided therewith

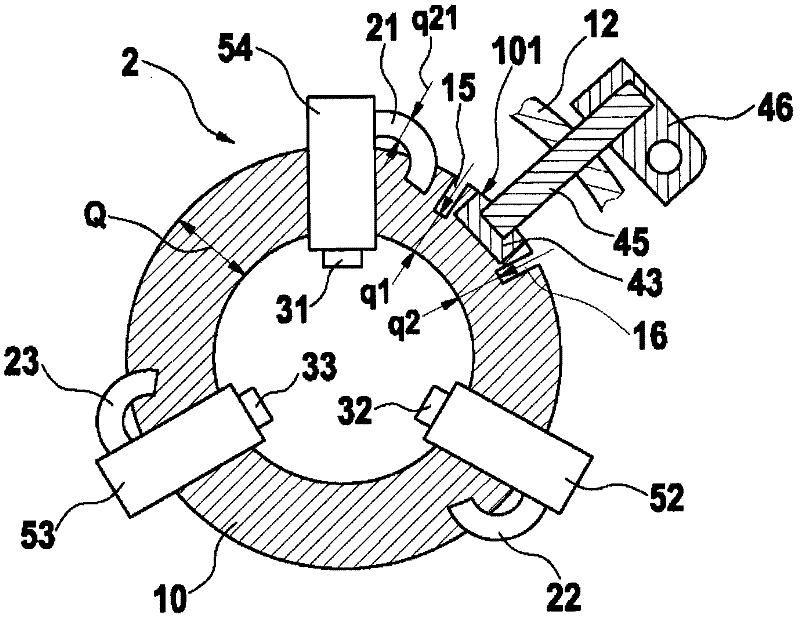

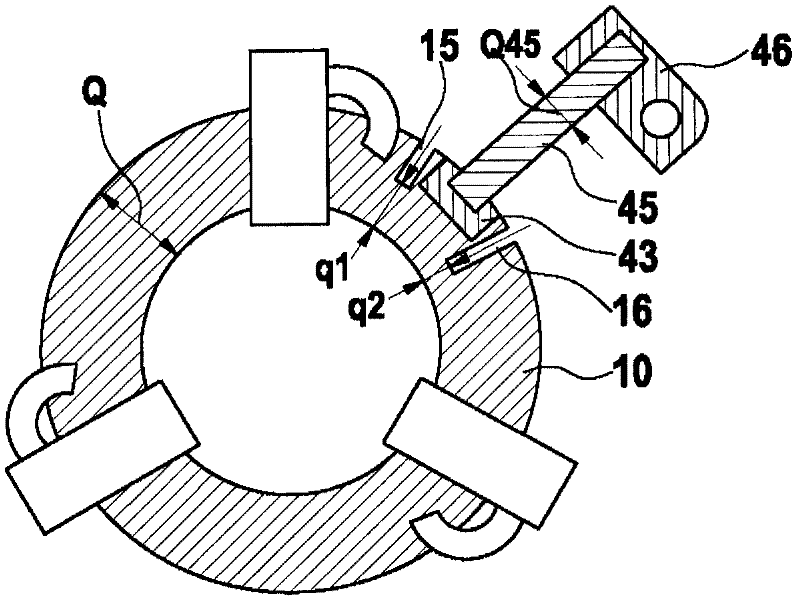

ActiveUS9105990B2Improve heat transfer performanceHeat radiationIndirect heat exchangersDynamoelectric machine connectorsBusbarCoolant flow

A terminal block (10) to be fixed to a motor case (C) which houses a motor body and includes a coolant flow path (C1) and adapted to fasten busbars by tightening bolts includes nuts (30) for tightening the bolts, and a heat sink (40) made of aluminum die-cast and held in close contact with the nuts (30) via an insulation plate (20) behind the nuts (30). The heat sink (40) includes a heat radiating portion (46) which comes into contact with cooling water passing in the coolant flow path (C1) of the motor case (C).

Owner:SUMITOMO WIRING SYST LTD

Lanthanum-oxide-doped modified copper-based graphite motor carbon brush and preparation method thereof

InactiveCN106384924AGood electrical propertiesImprove friction performanceRotary current collectorDynamoelectric machine connectorsMicrospherePorous carbon

The invention discloses a lanthanum-oxide-doped modified copper-based graphite motor carbon brush. The base material of the carbon brush includes natural flake graphite, porous carbon powder and copper powder, and bronze powder compound, and lanthanum oxide is added for modification so as to improve the sintering performance. In the preparation process, polydopamine is deposited on the surface of natural flake graphite and porous carbon for surface modification in order to improve the bonding force between the carbon material and other raw materials and improve the density of materials. Conductive silica sol mixed with carbon nano microspheres is used to replace the traditional resin adhesive in order to prevent particles from falling off and being worn. The finally prepared carbon brush material exhibits good electrical performance and friction performance, is of high hardness and good sliding performance, is not easy to crack, and has outstanding comprehensive performance.

Owner:阜阳市鼎铭汽车配件制造有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com