Automatic shifter for generator carbon brush assembly

An automatic movement and generator technology, applied in the direction of motor generator connectors, electrical components, circuits, etc., can solve the problem of increasing the friction coefficient, increasing the wear of brushes and collector rings, and reducing the use of brushes and collector rings. life and other issues, to achieve the effect of preventing carbon brushes from overheating and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

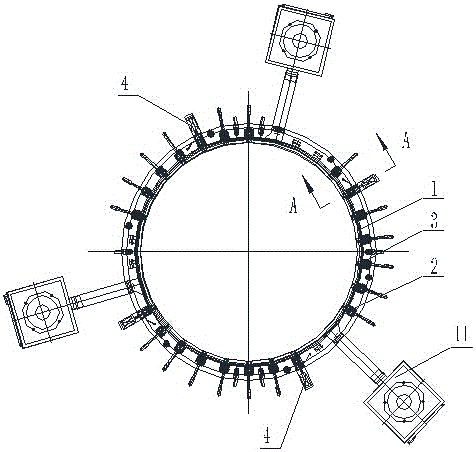

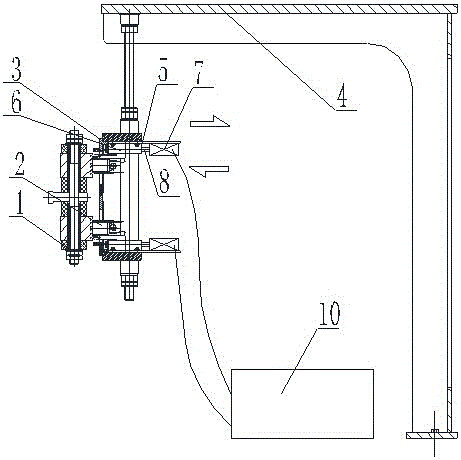

[0018] see Figure 1 to Figure 2 , an automatic moving device for a generator carbon brush assembly, comprising a collector ring 1, a carbon brush 2, a conductive ring 3, and a support cover 4, and the collector ring 1 is connected to the conductive ring 3 through a carbon brush 2 to form a conductive path, specifically The front end of the carbon brush 2 is in contact with the collector ring 1, and the braid of the carbon brush 2 is fixed on the conductive ring 3; the carbon brush 2 is set on the support cover 4, and the carbon brush 2 and the conductive ring 3 are supported on the support cover 4.

[0019] The improvement of the present invention is that a guide rail 5 is provided on the support cover 4, the brush holder 6 is slidably arranged on the guide rail 5, and slides on the guide rail 5 (upper side, lower side or bottom surface of the guide rail 5);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com