Method for manufacturing motor brush by rice hull

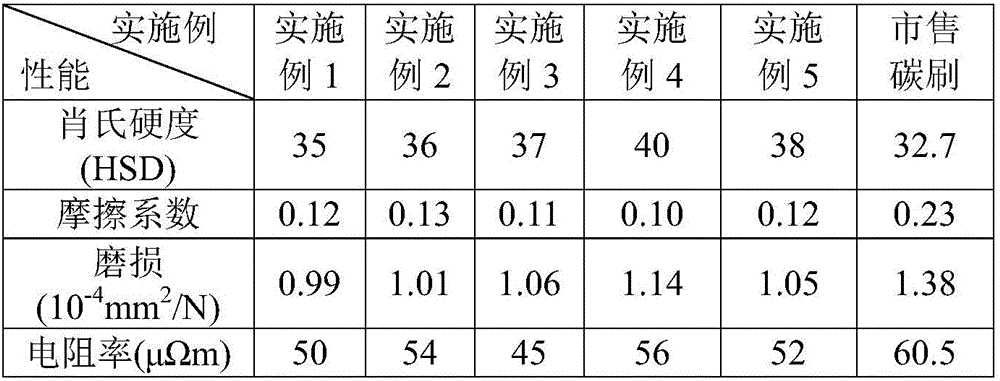

A technology of brushes and rice husks, applied in the direction of motor generator connectors, circuits, collectors, etc., can solve the problems of short service life and poor wear resistance, and achieve long service life, excellent wear resistance and corrosion resistance, and replacement good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

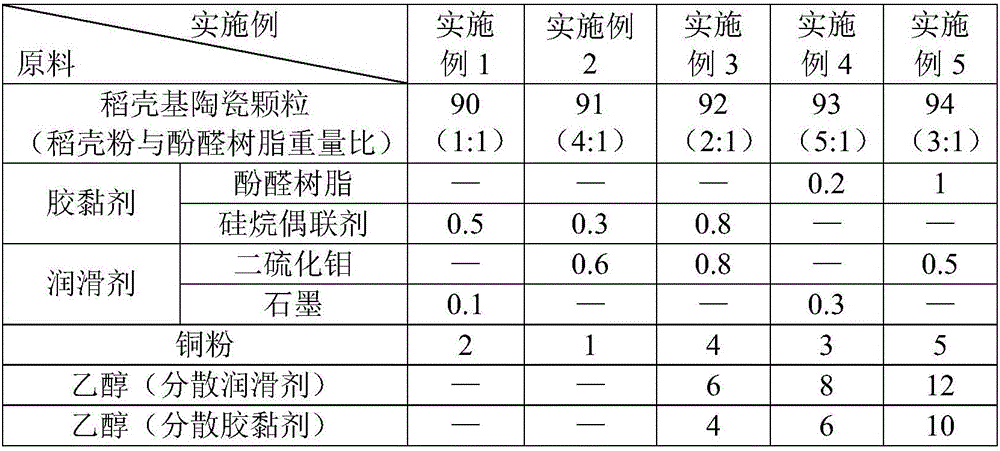

Embodiment 1

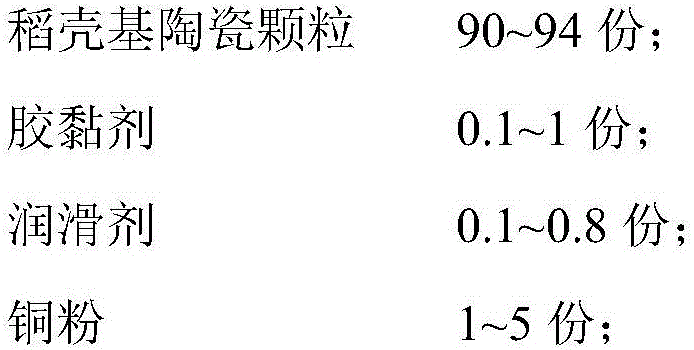

[0023] The method for preparing a motor brush by using rice husks, the steps are as follows:

[0024] ①. Blend rice husk powder and phenolic resin, stir evenly, transfer to a quartz boat, and carbonize at 900°C for 2 hours under the protection of nitrogen to obtain rice husk-based ceramic particles.

[0025] ② Stir graphite and silane coupling agent evenly; then add copper powder, continue stirring evenly, mix with rice husk-based ceramic particles, stir evenly, and set aside.

[0026] ③. Pour the uniformly mixed powder into a cold-pressed mold, press it under a pressure of 30Mpa, then move it into a tube furnace, and calcinate it at 900°C for 2 hours in a nitrogen atmosphere to obtain a motor brush.

Embodiment 2

[0028] The method for preparing a motor brush by using rice husks, the steps are as follows:

[0029] ①. Blend rice husk powder and phenolic resin, stir evenly, transfer to a quartz boat, and carbonize at 900°C for 2 hours under the protection of nitrogen to obtain rice husk-based ceramic particles.

[0030] ② Stir molybdenum disulfide and silane coupling agent evenly; then add copper powder, continue stirring evenly, mix with rice husk-based ceramic particles, stir evenly, and set aside.

[0031] ③. Pour the uniformly mixed powder into a cold-pressed mold, press it under a pressure of 30Mpa, then move it into a tube furnace, and calcinate it at 900°C for 2 hours in a nitrogen atmosphere to obtain a motor brush.

Embodiment 3

[0033] ①. Blend rice husk powder and phenolic resin, stir evenly, transfer to a quartz boat, and carbonize at 900°C for 2 hours under the protection of nitrogen to obtain rice husk-based ceramic particles.

[0034] ②. Add ethanol to molybdenum disulfide, ultrasonically disperse evenly, then add copper powder, continue stirring evenly, and set aside.

[0035] ③. Add ethanol to the silane coupling agent, ultrasonically disperse evenly, and set aside.

[0036] ④. Mix the system obtained in steps ② and ③, and after stirring evenly, add rice husk-based ceramic particles, stir evenly, and set aside.

[0037] ⑤. Pour the uniformly mixed powder into a cold-pressed mold, press it under a pressure of 30Mpa, then move it into a tube furnace, and calcinate it at 900°C for 2 hours in a nitrogen atmosphere to obtain a motor brush.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com