AC motor controller, and laminated busbar assembly and manufacturing method thereof

A technology of laminated busbars and components, applied in the direction of AC motor control, motor generator connectors, electrical components, etc., can solve the time-consuming and time-consuming insertion process, poor scalability of transmission substrate busbars, and difficulty in improving substrate assembly Processing production efficiency and other issues, to achieve the effect of wide use, optimization of process, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] AC Motor Controller Example:

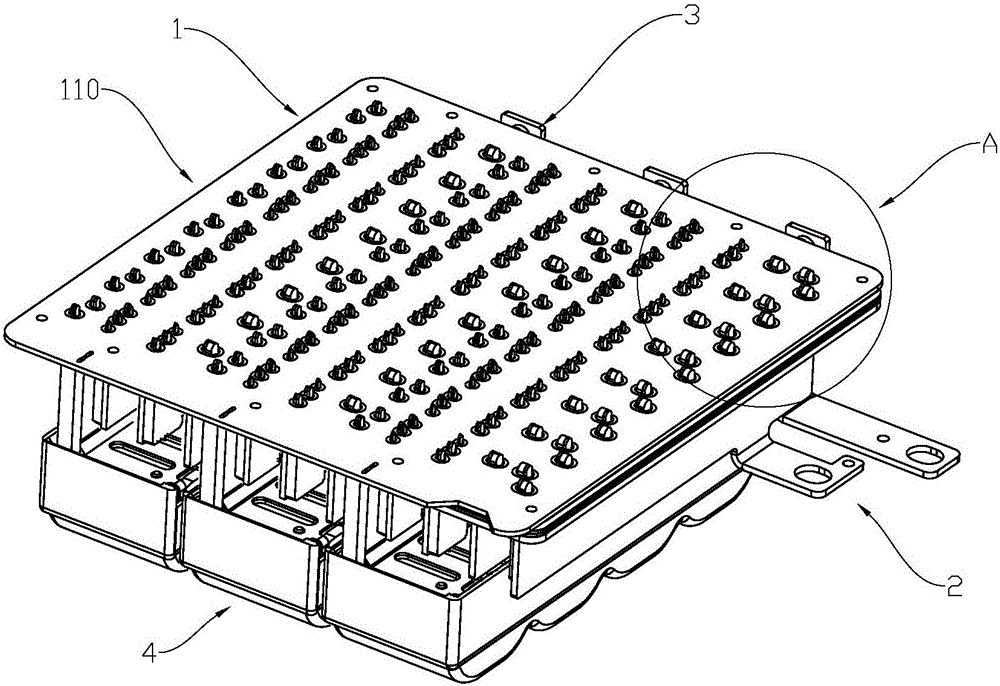

[0045] Such as figure 1 as shown, figure 1 It is a structural diagram of an AC motor controller, and the AC motor controller includes a laminated busbar assembly 1 , an input manifold 2 , an output manifold 3 and circuit devices 4 . The role of the AC motor controller is to convert the input DC current into an AC current output through a controllable switching device such as a power tube, so as to meet the power demand of the drive motor.

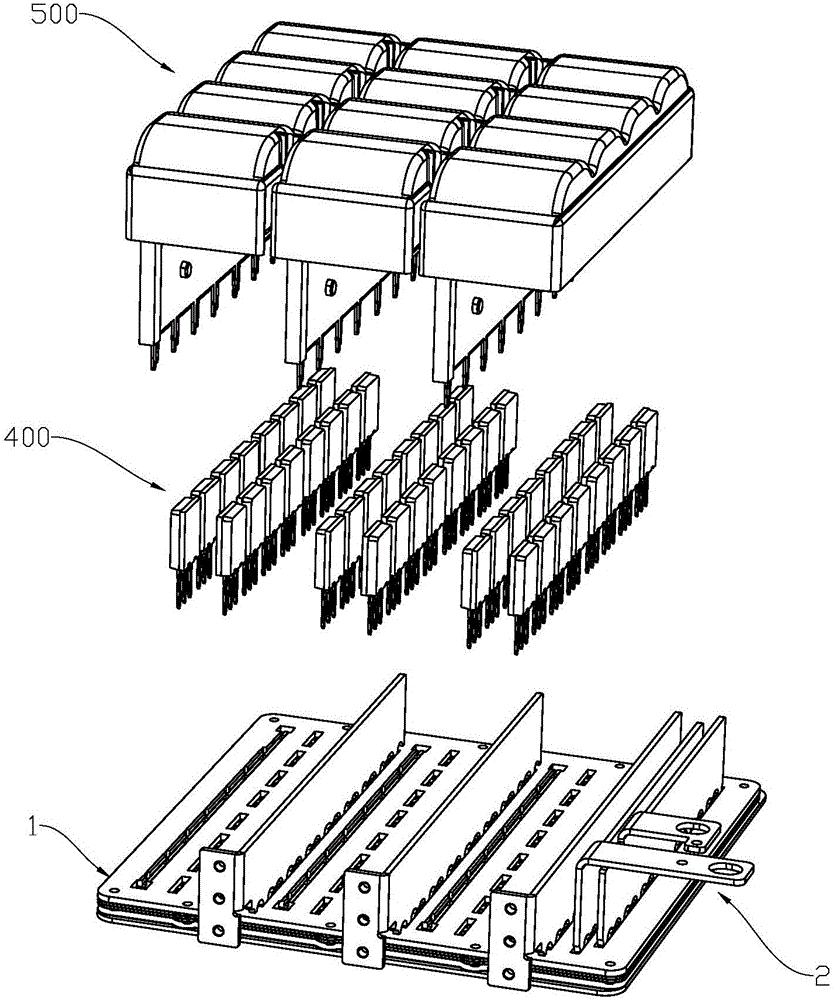

[0046] Among them, the difference between the laminated busbar assembly 1 in this embodiment and the existing busbars is that the laminated busbar assembly is arranged by stacking multiple metal plates, and the pins on each metal plate pass through the pins of other metal plates. The avoidance hole finally reaches the pad hole group position of the substrate.

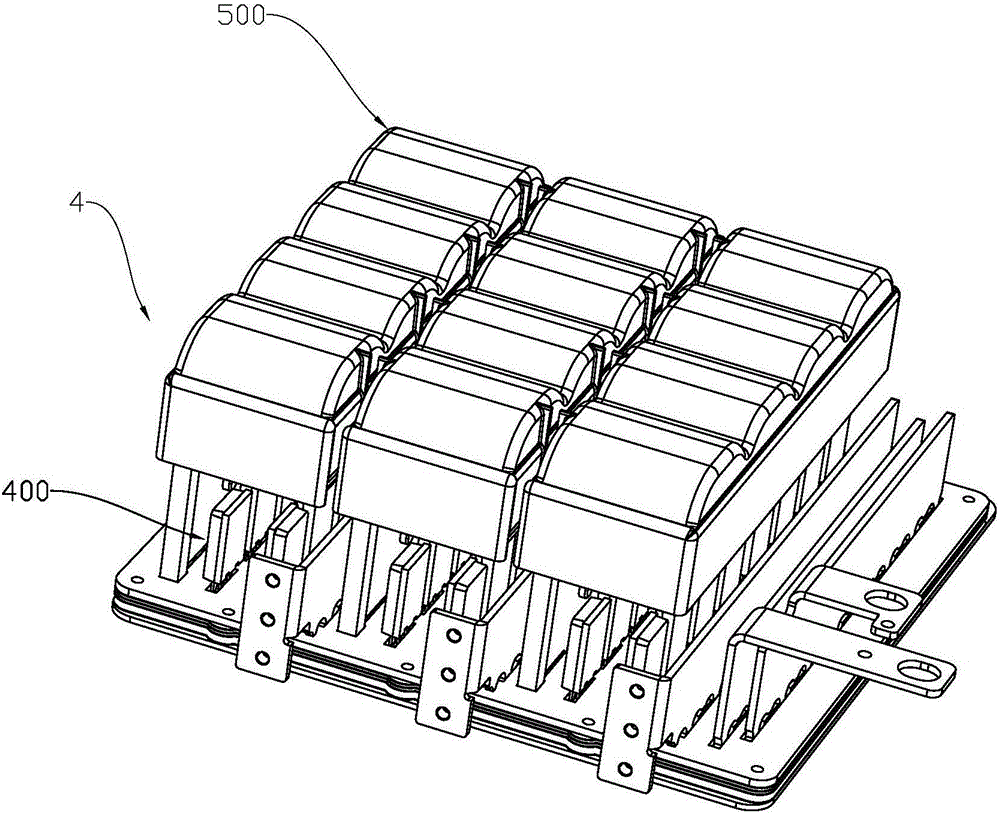

[0047] Such as figure 2 as shown, figure 2 It is a structural diagram of another angle of the AC motor controller, the circuit device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com