Copper-graphite-graphene brush and preparation method thereof

A technology of graphene and graphene powder, which is applied in the manufacture of brushes, circuits, collectors, etc., can solve the problems of poor mechanical performance, no electrical performance, high resistivity of brushes, etc., and achieve the use effect and life improvement, continuous The effect of stable mass production and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the copper-graphite-graphene brush in this embodiment has low energy consumption and a simple process. It can realize automatic, continuous and stable large-scale production by using multiple mechanical devices. The production cost is low, and it has broad market application prospects.

[0054] In the copper-graphite-graphene electric brush prepared through the above steps, each composition is as follows: copper powder, the mass fraction is 35-80%, graphite powder, the mass fraction is 10-60%, graphene powder, the mass fraction is 0.5% ~30%, thermosetting resin, mass fraction is 0~20%, additive, mass fraction is 0~2.44%.

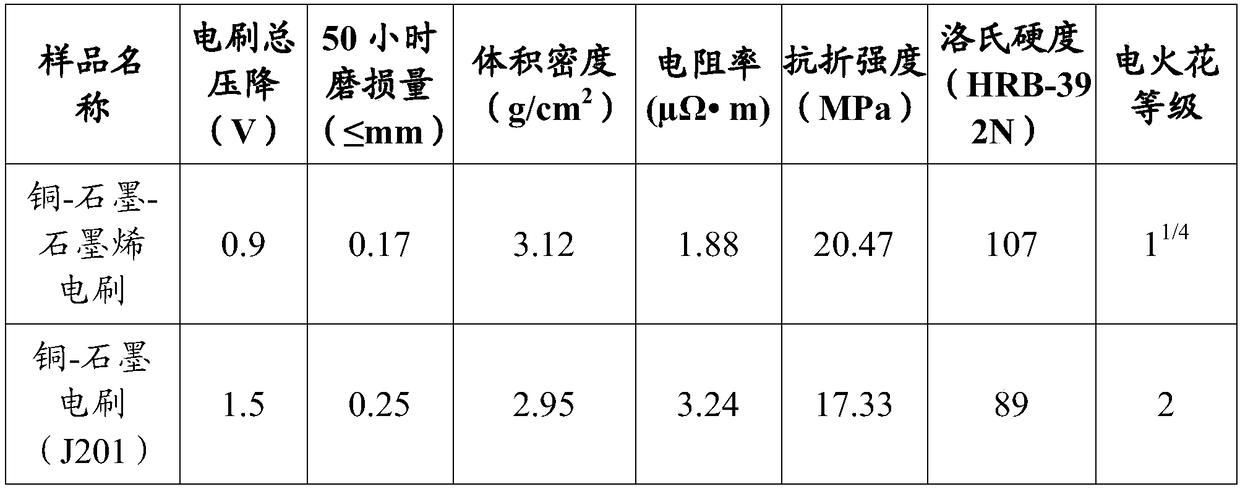

[0055] The copper-graphite-graphene brush prepared in this example uses graphene as the reinforcement of the copper-based composite material, which improves the conductivity, wear resistance, voltage drop and spark level of the existing copper-graphite brush , the copper-graphite-graphene brush in this embodiment has excellen...

Embodiment 1

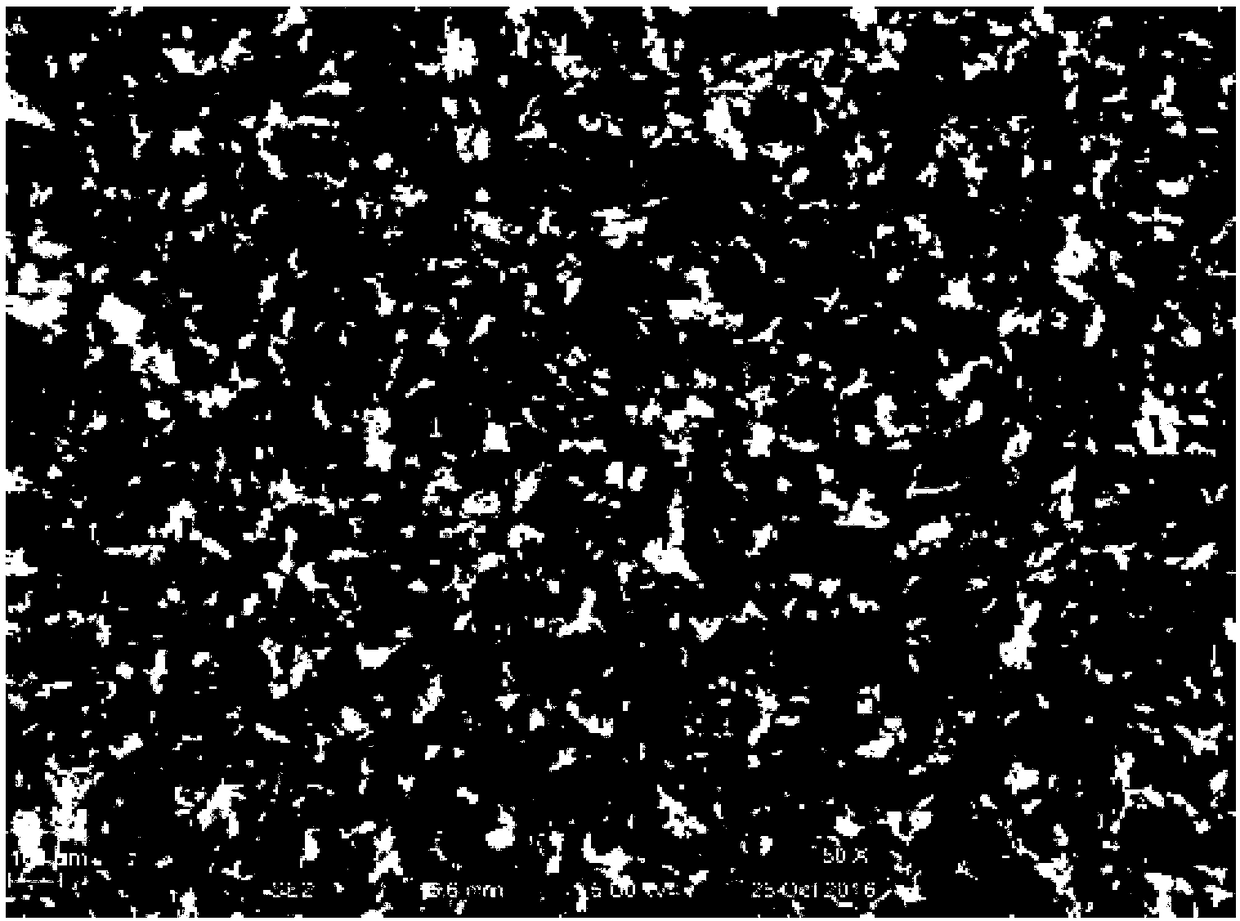

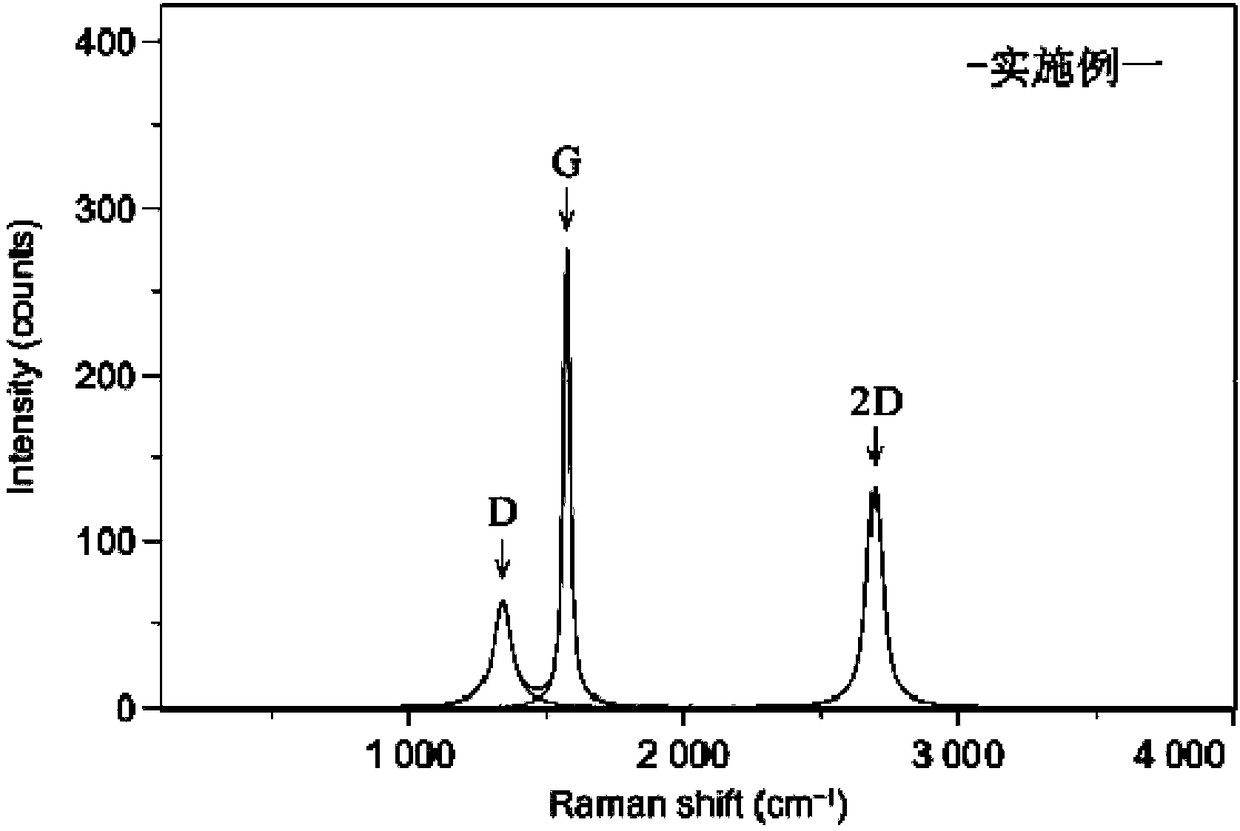

[0058] Step S1: The raw material graphene powder is obtained by processing graphene obtained by mechanical exfoliation, the number of graphene layers is 10, and the size of a single sheet is 0.1um. The specification of the prepared graphene powder is 500 mesh. The 1g of raw graphene powder is dispersed in 200ml of ethyl acetate by ultrasonic waves with an oscillation frequency of 20kHz to form a graphene slurry.

[0059] Step S2: Add the graphene slurry in step S1 to the mixer, and add 10 g of 200-mesh electrolytic copper powder to the mixer, and the mixer continues to work for 24 hours, so that the graphene slurry and copper powder can be mixed uniform. The mixed material output from the mixer was evaporated to dryness by freeze-drying at -40°C for a total of 10 hours to form a graphene-copper composite powder.

[0060] Step S3: Input the graphene-copper composite powder in step S2 into a planetary ball mill, and continue to add 9 g of 150-mesh flake graphite powder and 1 g ...

Embodiment 2

[0071] Step S1: The raw material graphene powder is obtained by processing graphene obtained by mechanical exfoliation, the number of graphene layers is 1 layer, and the size of a single sheet is 100um. The specification of the prepared graphene powder is 500 mesh. 1g of raw graphene powder is dispersed in 200ml of N,N-dimethylacetamide by ultrasonic waves with an oscillation frequency of 80kHz to form a graphene slurry.

[0072] Step S2: Add the graphene slurry in step S1 to the mixer, and add 14g of 300-mesh electrolytic copper powder to the mixer, and the mixer continues to work for 10 hours, so that the graphene slurry and copper powder can be mixed uniform. The mixed material output from the mixer was evaporated to dryness by freeze-drying at -50°C for a total of 24 hours to form a graphene-copper composite powder.

[0073] Step S3: Input the graphene-copper composite powder in step S2 into a planetary ball mill, and continue to add 5 g of flake graphite powder of 300 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com