Motor for removing electric corrosion of bearing

A technology of electro-corrosion and bearings, applied in the direction of motor-generator connectors, circuits, electrical components, etc., can solve the problems of high application cost, low versatility, and electro-corrosion application process of motor bearings, and achieve low maintenance cost and versatility Strong, low friction and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

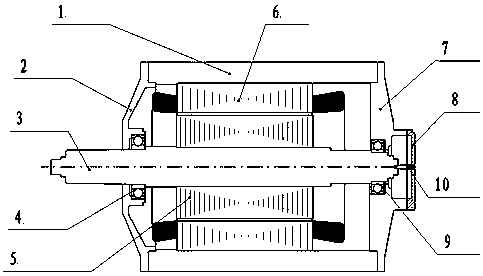

[0034] Such as figure 1 As shown, the motor for eliminating electric corrosion of bearings according to the present invention includes a housing 1 and a motor stator 6 inside it, a motor rotor 5, and a rotating shaft 3, and the two ends of the housing are respectively equipped with a first end cover 2 and a second end cover. Cover 7, one end of the rotating shaft 3 fits through the first end cover 2 through the first bearing 4, the other end of the rotating shaft 3 fits with the second end cover 7 through the second bearing 9, and the second end cover 7 is externally fixed There is a cover plate 8 , and the end surface of the other end of the rotating shaft is electrically connected with the cover plate 8 through an elastic component 10 .

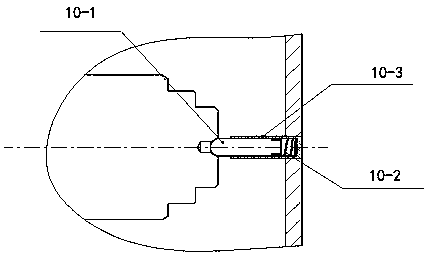

[0035] Such as figure 2 Said, the elastic assembly 10 includes a thimble 10-1, a spring 10-2 and a syringe 10-3, one end of the syringe 10-3 is fixed to the cover plate 8, and the spring 10-2 is placed in the syringe 10-3 Inside, one end...

Embodiment 2

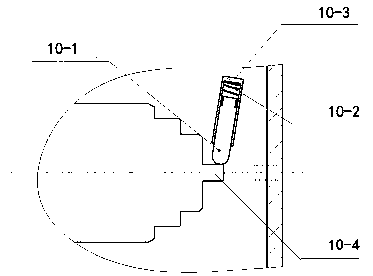

[0039] Such as image 3 As shown, the elastic assembly 10 of this embodiment also includes a thimble 10-1, a spring 10-2 and a needle cylinder 10-3. The difference from Embodiment 1 is that the end surface of the rotating shaft in contact with the thimble 10-1 is processed with a very small The outer diameter of the boss 10-4, the thimble is in radial contact with the boss.

Embodiment 3

[0041] Such as image 3 As shown, the elastic component 10 of this embodiment adopts a spring piece 10 - 5 , one end of the spring piece 10 - 5 is in contact with the cover plate 8 , and the other end is in contact with the end surface of the rotating shaft 3 . The included angle α between the spring leaf 10-5 and the cover plate 8 is larger before the cover plate is installed than after installation, which is equivalent to the principles of embodiments 1 and 2, and the spring leaf can be adjusted to compensate for position changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com