Online monitor for generator carbon brush wear

A monitor and generator technology, applied in motor generator connectors, circuits, current collectors, etc., can solve the problems of collector ring loss, the possibility of missing reading if not carefully observed, and increasing the workload of inspection personnel. The effect of preventing the contact resistance from increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

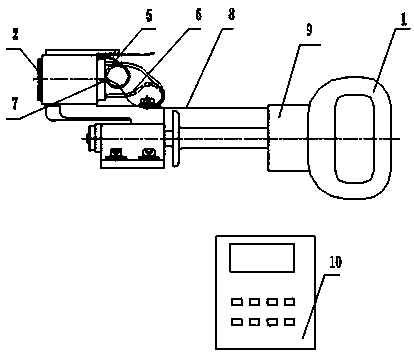

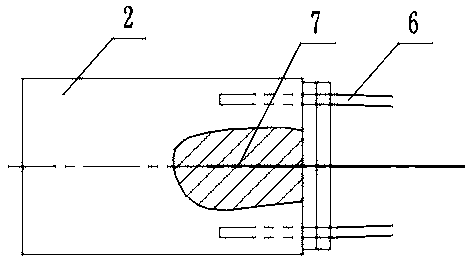

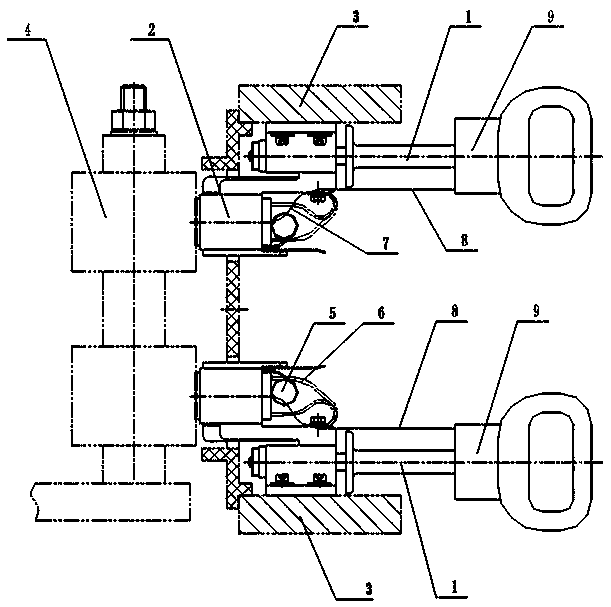

[0028] Such as figure 1 , 2 As shown in , 3, this embodiment provides the generator carbon brush wear online monitor of the first embodiment, including a brush holder 1, a carbon brush 2 is arranged on the brush holder 1, and the brush holder 1 is usually detachable. A conductive circuit is formed between the carbon brush 2 and the conductive ring 3, and the front end of the carbon brush 2 is in contact with the collector ring 4 to form a conductive circuit. The rear end of the carbon brush 2 is provided with a spring 5 to provide spring force; ) on the carbon brush 2, protruding from the rear end of the carbon brush 2; the rear end of the carbon brush 2 is pre-embedded with the brush 6, and the brush 6 is generally a braided soft copper wire, and the end of the brush 6 is provided with a fixed block to install the carbon brush 2 At this time, put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com