Brush apparatus for an electric machine and electric machine

A brush device and brush technology are used in electromechanical devices, starting devices with mechanical power storage, and motor starting for engines, etc., which can solve problems such as starter failures and achieve the effect of preventing damage or danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

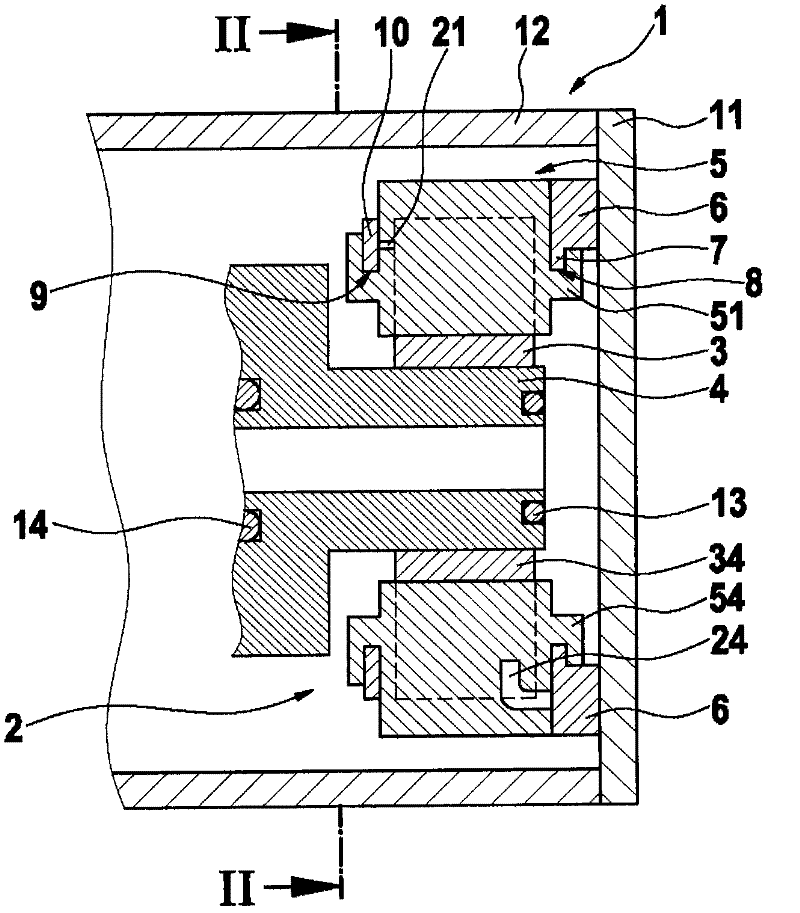

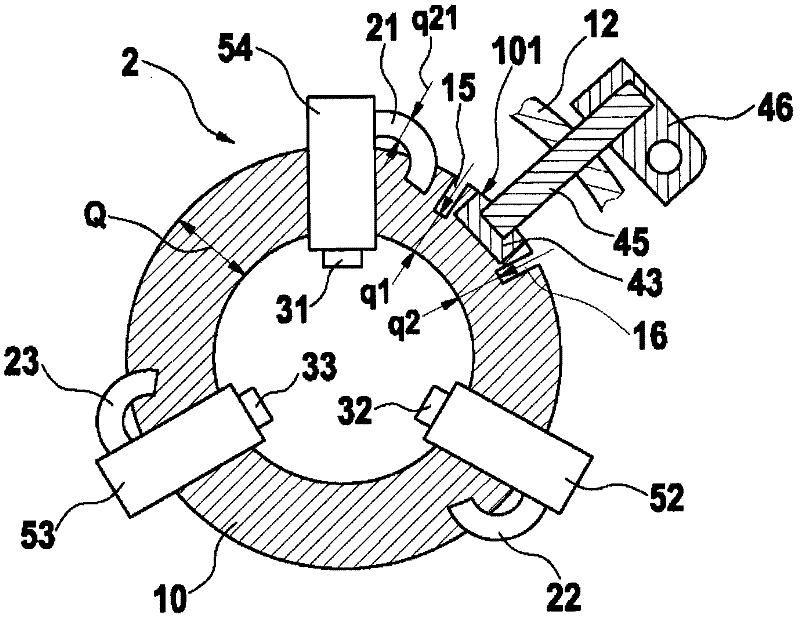

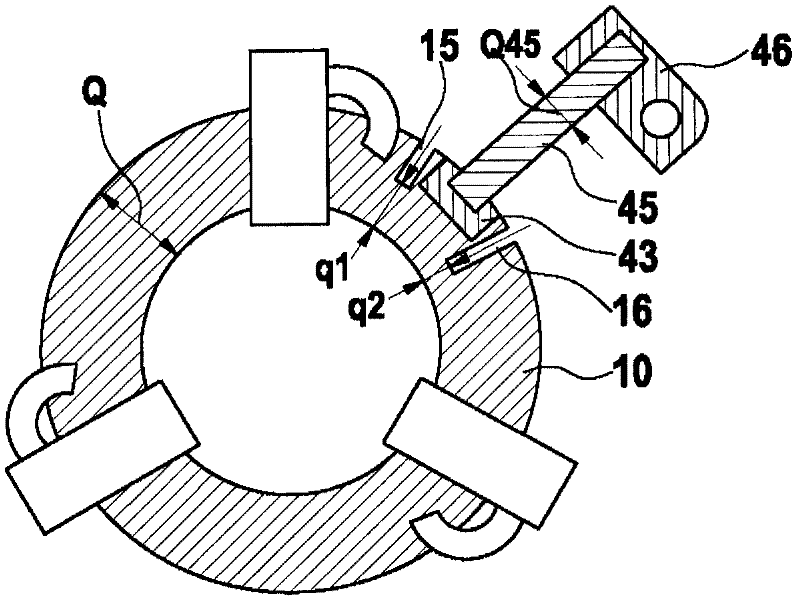

[0036] figure 1 A partial axial cross-section of an electric machine 1 with a brush arrangement 2 is shown. The brush arrangement 2 is constructed with brush pairs, wherein figure 1 Two brushes 3 , 34 are shown, which run on the commutator 4 . Springs, not shown, are pretensioned in the brush holder 5 to press the brushes 3 against the commutator 4 . The brush holder 5 is fixed on the brush plate 6 .

[0037] figure 1 It is shown that the brush holder 5 is fastened via an undercut to the brush plate 6 via a so-called groove-spring connection. The annular projection 7 of the brush plate 6 engages in the groove 8 of the brush holder 5 . As a result, the brush holder 5 is fixed on the brush plate 6 on the axial end side. On the opposite axial end side, the brush holder 5 , 54 is inserted into the annular busbar 10 with the groove 9 . The bus bar 10 thus serves as a second fastening element for holding the brush holder 5 . The bus bar 10 is connected to a starter relay, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com