Carbon brush grinding equipment and utilization method thereof

A grinding and carbon brush technology, applied in brush manufacturing, motor-generator connectors, etc., can solve the problems of affecting the use of carbon brushes, too deep grinding of carbon brushes, and not having a good buffer mechanism, so as to protect the carbon brushes. , to avoid the effect of grinding precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

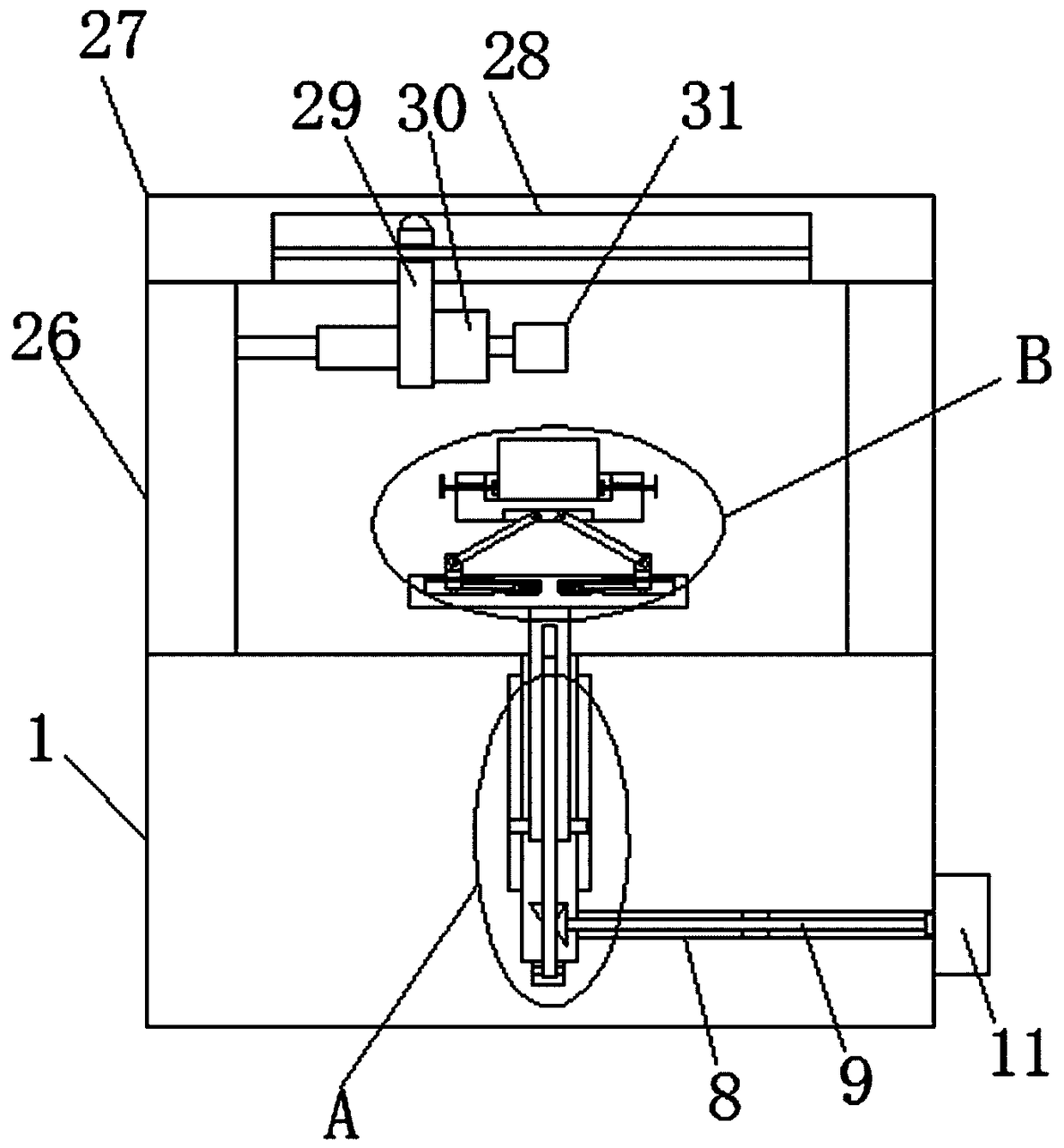

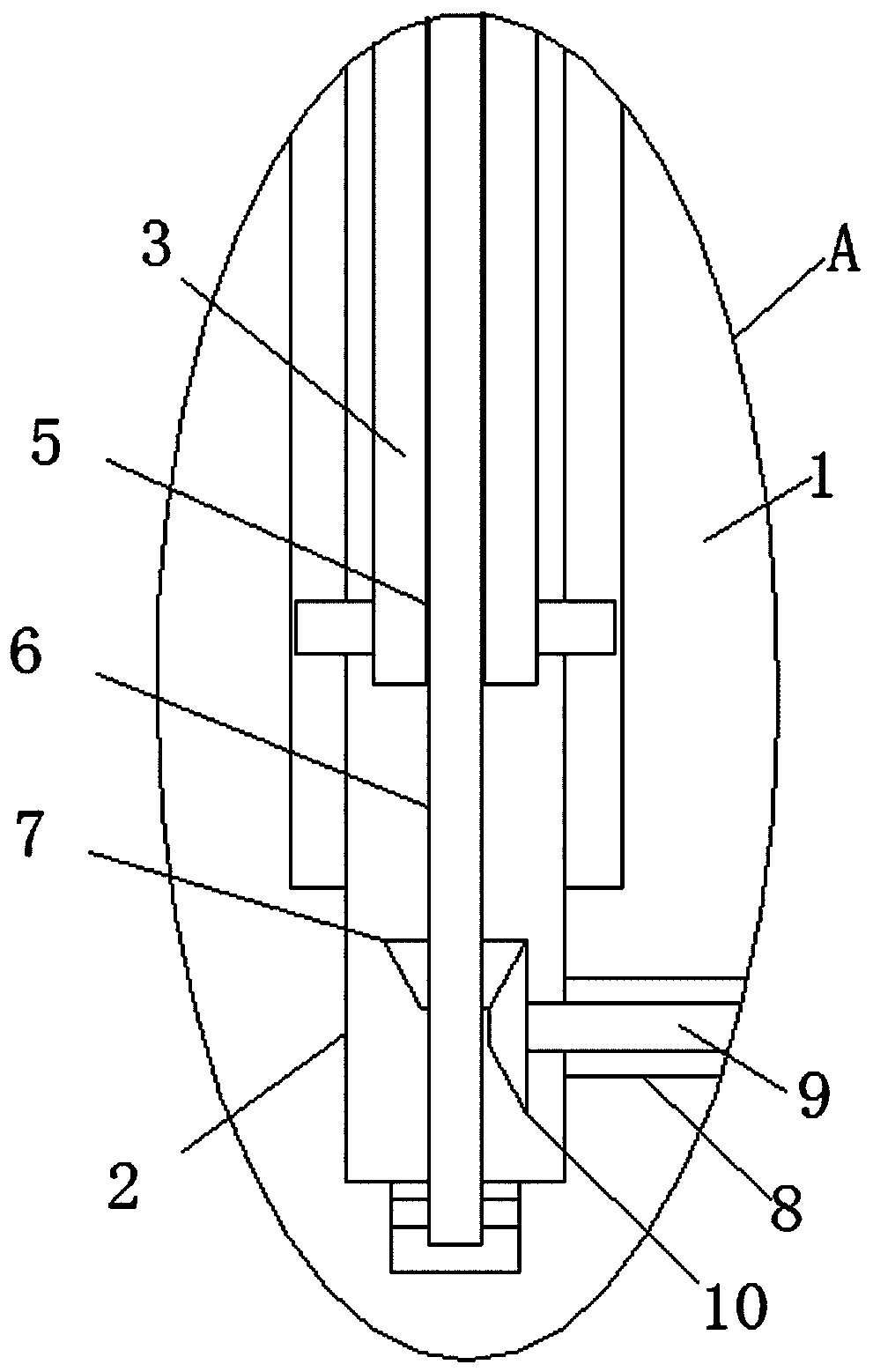

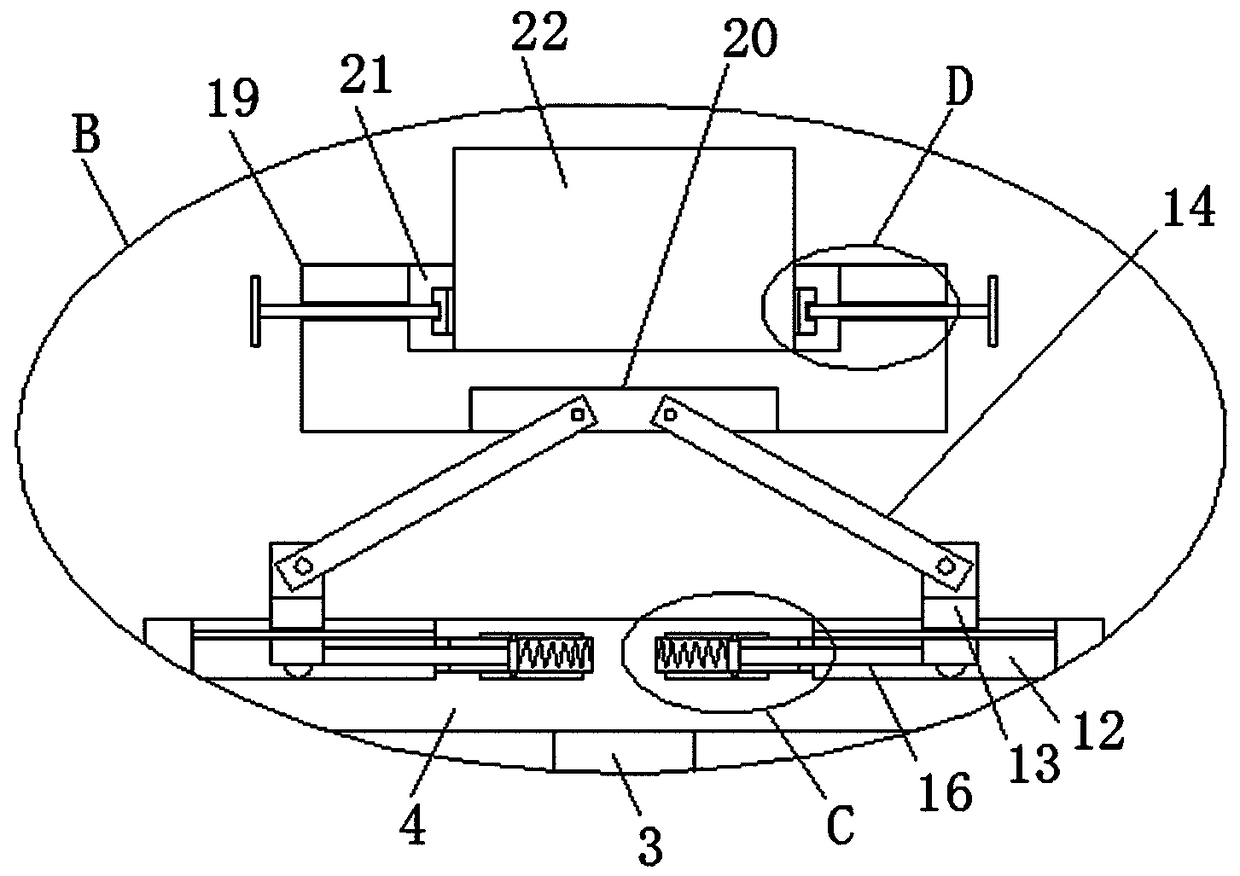

[0030] refer to Figure 1-5In this embodiment, a carbon brush grinding processing equipment is proposed, including a base 1, a first groove 2 is opened on the top of the base 1, a sliding rod 3 is slidably installed in the first groove 2, and the top of the sliding rod 3 Extending to the outside of the first groove 2, and fixedly installed with the first fixing seat 4 located above the base 1, the bottom end of the slide bar 3 is provided with a first screw hole 5, and a first screw rod is arranged in the first screw hole 5 6. The first screw 6 is threadedly connected with the first screw hole 5, the bottom end of the first screw 6 extends outside the first screw hole 5, and is rotatably mounted on the bottom inner wall of the first groove 2, the first screw A fixed sleeve on the rod 6 is provided with a first gear 7 located below the slide rod 3, and a through hole 8 is provided on one side of the inner wall of the first groove 2, and a rotating shaft 9 is installed in the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com