Soybean milk machine

A soymilk machine and machine head technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of unfavorable coarse to fine grinding, difficult to clean, and the grinding speed cannot be accelerated, and achieves easy processing and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

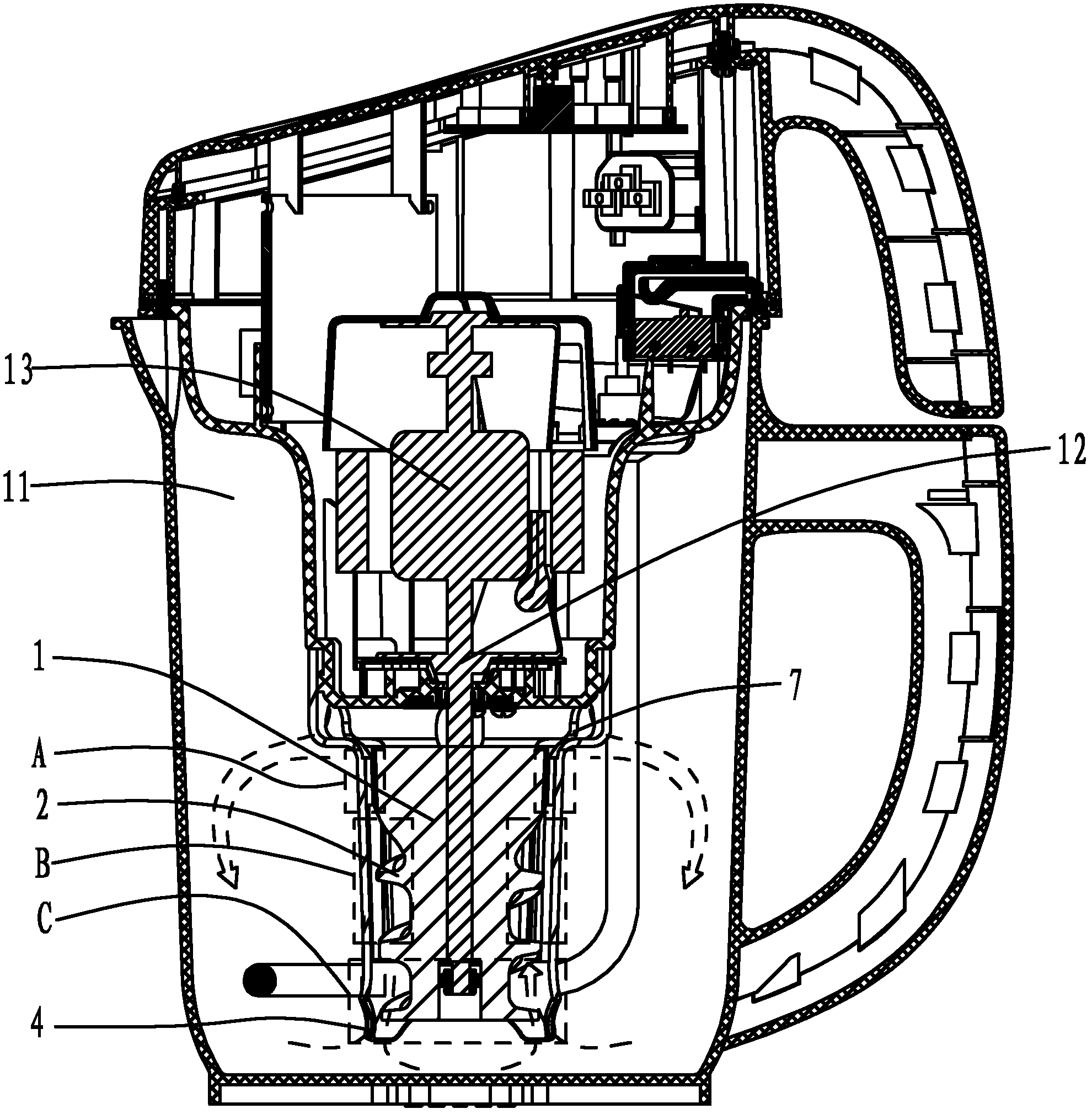

[0062] See attached Figure 1~12 , attached Figure 14~15 , attached Figure 18 , a soybean milk machine, comprising a cup body 11, a machine head buckled on the cup body 11, a motor 12 arranged in the machine head and an output shaft 13 connected with the motor 12, a liquid flow is provided at the lower part of the machine head The driving device 2 and the grinding device, the liquid flow driving device 2 is arranged below the grinding device.

[0063] The liquid flow driving device 2 is a thread that can generate liquid flow driving when rotating. The grinding device at least includes a dynamic grinding head 1 and a static grinding head 4 that are combined inside and outside each other and correspond in shape and structure. The working of the dynamic and static grinding heads On the surface, there are respectively movable grinding teeth 3 and static grinding teeth 5 corresponding in structure.

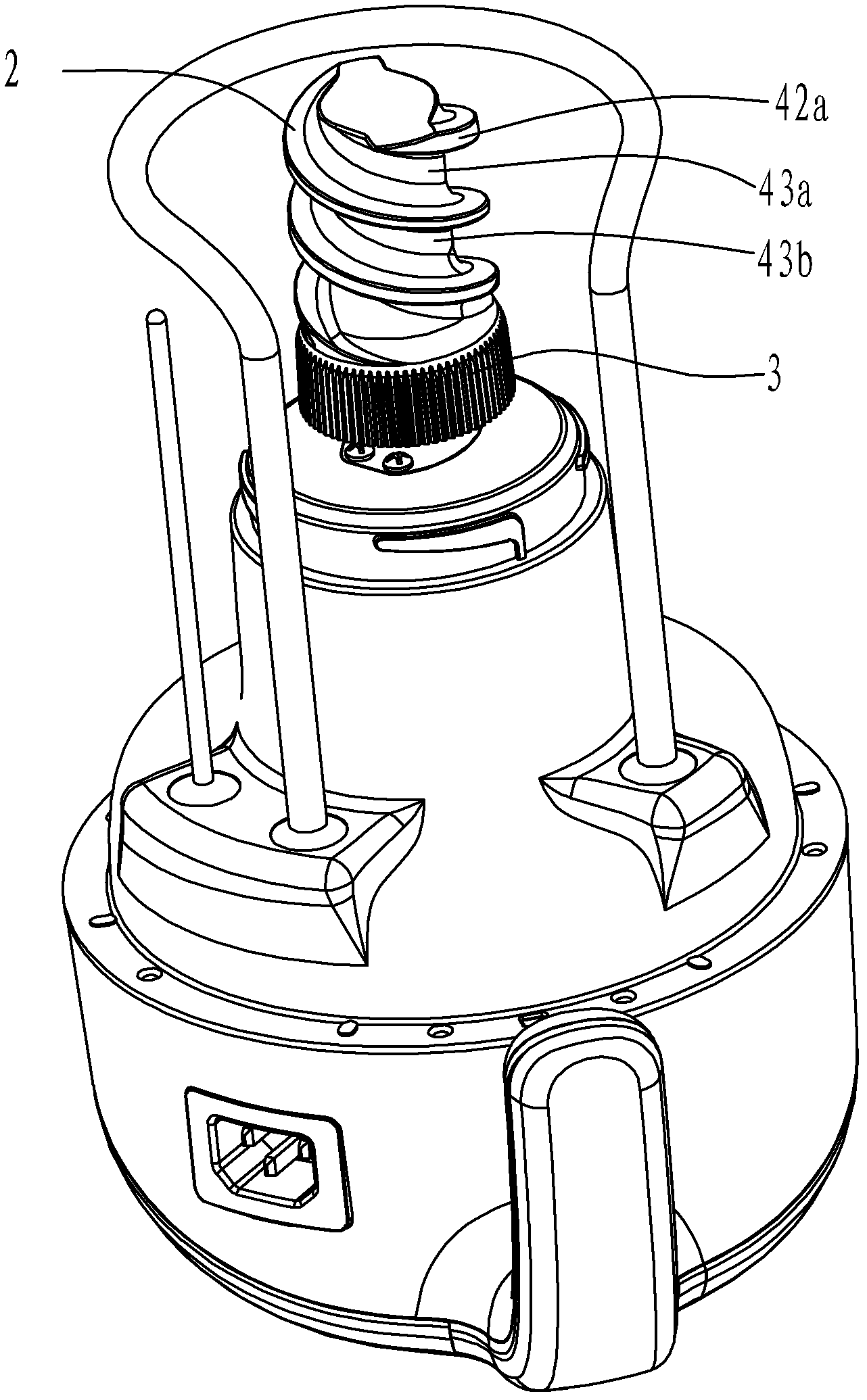

[0064] The trajectory of the thread of the liquid flow driving device 2 is ro...

Embodiment 2

[0085] See attached Figure 16~17 , in this embodiment, the screw thread of the movable grinding head 1 is different from that of the first embodiment, and has the same technical effect as that of the first embodiment in other places, which will not be repeated here.

[0086] In this embodiment, the thread of the movable grinding head 1 is a single-thread design, that is, only one thread in the same screw goes up the rod, and the single-thread pitch ST-D2 of the first thread 42 is 10~ 50. The height ST-H of the thread of the liquid flow driving device 2 is 5-45 mm. Considering the size of the material and the manufacturing process, the optimal thread distance ST-D2 is 40 mm, and the thread height ST-H is 20 mm.

Embodiment 3

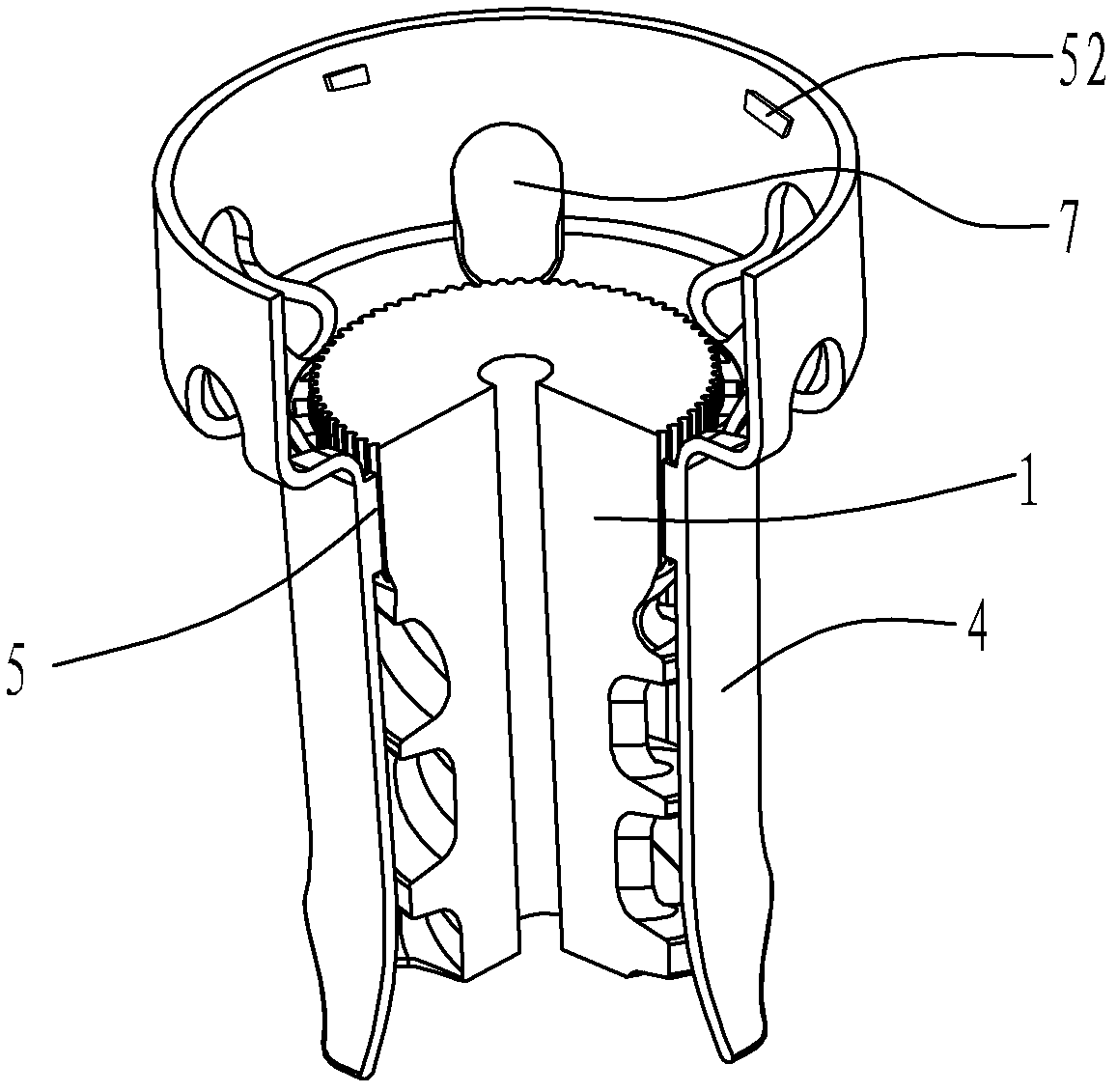

[0088] See attached Figure 19~30 , the dynamic grinding head 1 of this embodiment is different from that of Embodiment 1, and has the same technical effect as Embodiment 1 in other places, and will not repeat them here.

[0089] In this embodiment, in order to adapt to different appearance design requirements, and also to reduce the height of the entire grinding part, the movable grinding teeth 3 of the movable grinding head 1 are changed from roughly the same direction as the central axis of the screw to a roughly vertical direction, as shown in Figure 23 As shown, the angle e between the movable grinding teeth 3 and the central axis of the movable grinding head 1 is 0°~85°, so that the contact surface of the grinding part A formed by the moving grinding head 1 and the static grinding head 4 is larger, and at the same time, the height direction is saved. The space, comprehensive crushing effect and better circulating fluidity of soybean milk have an angle e of 75°.

[0090...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com