Ornament punching device

A technology for stamping devices and accessories, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high noise, difficult mold replacement, slow processing speed of punching machines, etc., so as to reduce noise and energy loss and achieve mechanical mass production. the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

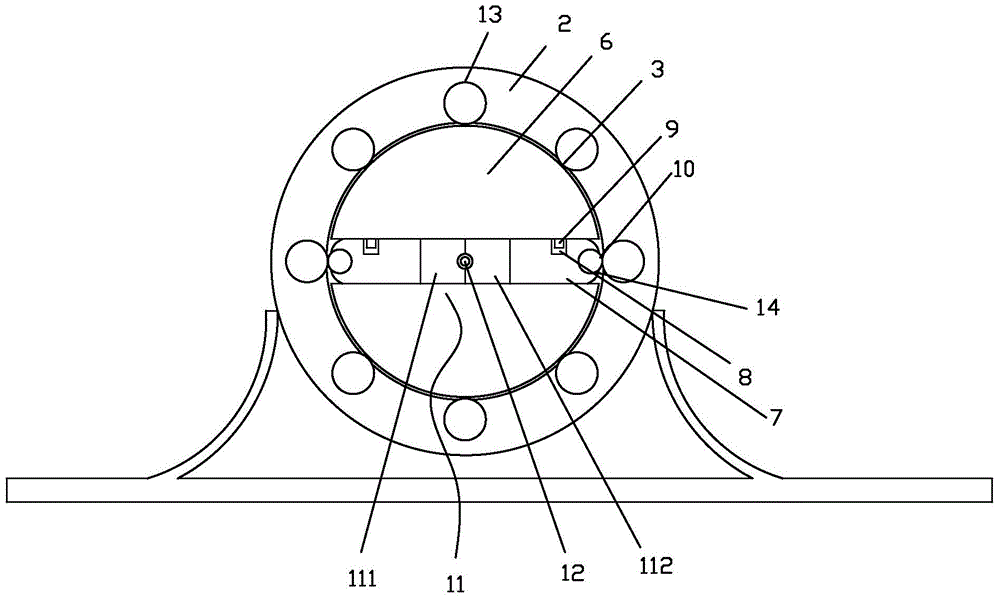

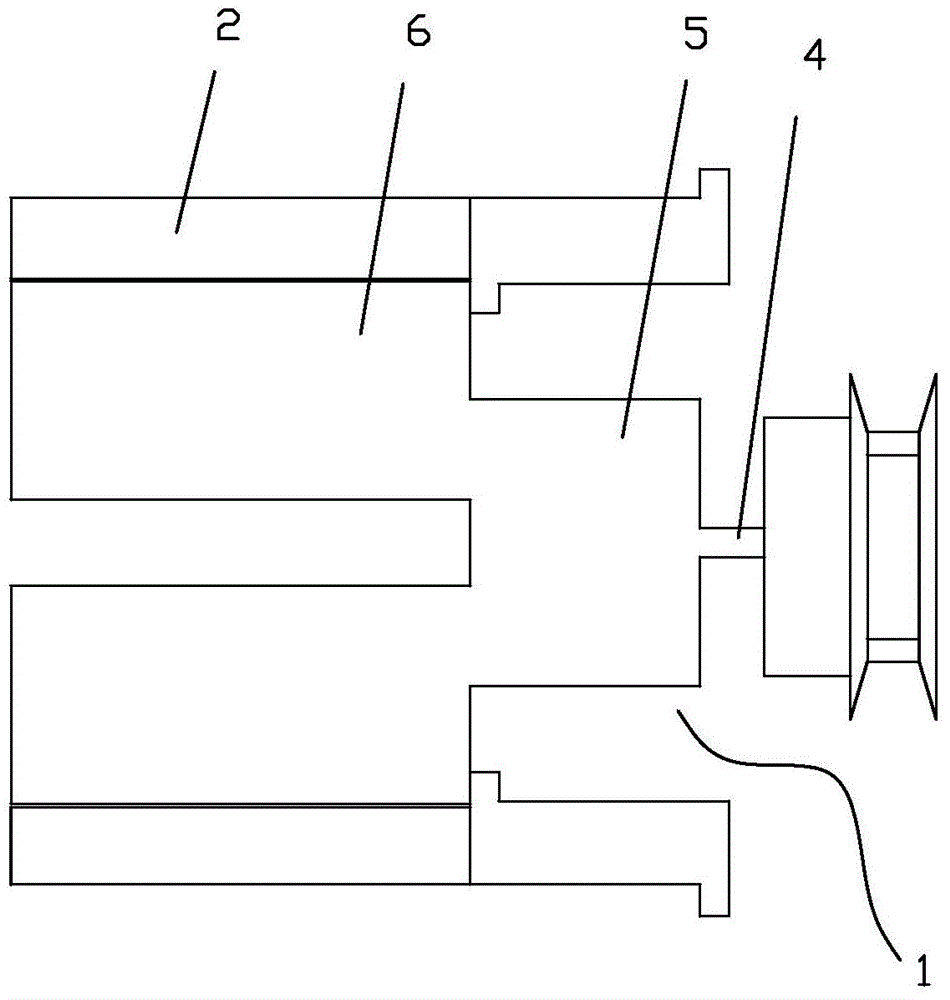

[0018] Such as figure 1 with figure 2 A jewelry stamping device shown includes a driving wheel 1 and a driven wheel 2, the driving wheel 1 is located inside the driven wheel 2, and the driven wheel 2 is fixed on the base. The inner wall of the driven wheel 2 is provided with a cylindrical cavity with a notch, and a first cylinder 13 is inserted in the cylindrical cavity with a notch, and a part of the first cylinder 13 protrudes from the notch to form a thimble 3, and the thimble 3 Correspondence in pairs. The driving wheel 1 includes a drive shaft 4 , a transmission shaft 5 and a rotating shaft 6 . A hammer 7 is arranged in the rotating shaft 6, and the hammer 7 is provided with a groove 8, and the width of the groove 8 is 5mm. The width is 3 mm, and the top of the hammer 7 is provided with a cylindrical cavity with an opening, and the cylindrical cavity with an opening is inserted into a second cylinder 14 , and a part of the second cylinder 14 protrudes from the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com