Derusting device for inner wall of hollow steel pipe

A technology of hollow steel pipe and rust remover, which is applied in the direction of grinding machines, grinding machine parts, metal processing equipment, etc., can solve the problems of low grinding efficiency, easy to grow rust, inflexibility, etc., and achieve low grinding efficiency and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

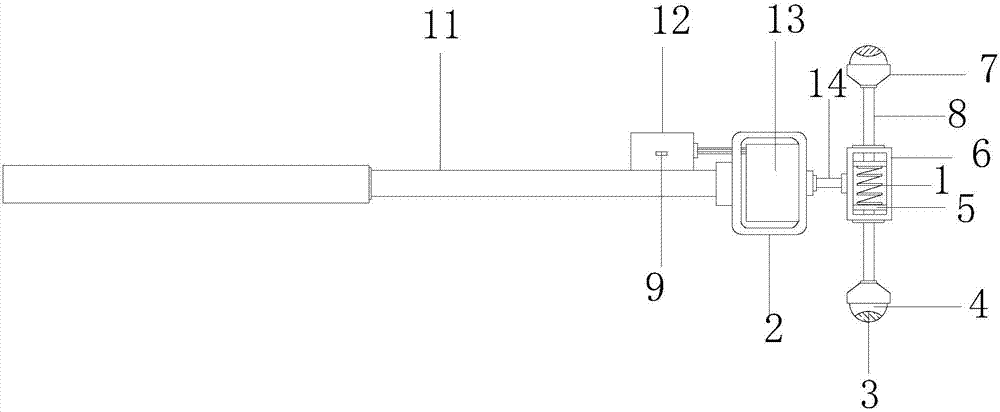

[0012] Such as figure 1 As shown, the rust remover for the inner wall of the hollow steel pipe includes a handle 11, and a casing 2 is fixedly installed on the head of the handle 11. An installation chamber is arranged in the casing 2, and a drive motor 13 is installed in the installation chamber to drive Motor 13 is controlled by a motor controller 12, and motor controller 12 is installed on the handle 11, and motor controller 12 is built-in lithium battery, and it is whole drive motor power supply, is also provided with the button 9 that controls motor switch usefulness, drive motor 13 The motor shaft 14 passes through the casing 2 and extends out of the casing 2. A rotary box 6 is fixedly installed on the motor shaft of the drive motor 13. A buffer cavity is arranged in the rotary box 6. The two ends of the rotary box A telescopic grinding mechanism is arranged respectively, and the two grinding mechanisms are pressed against the inner wall of the steel pipe.

[0013] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com