Cutting board grinding device

A cutting board and grinding mechanism technology, which is applied in the direction of grinding drive devices, grinding machines, grinding slides, etc., can solve the problems of workers' hand cuts, affecting the effect of cutting board use, unevenness, etc., and achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

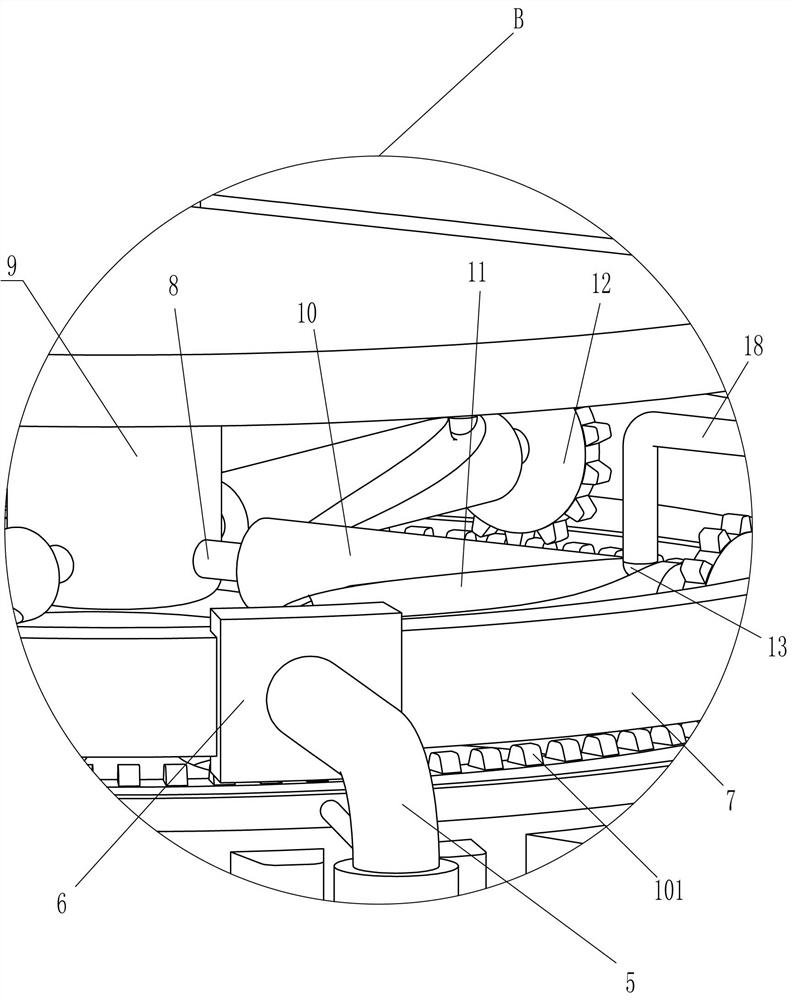

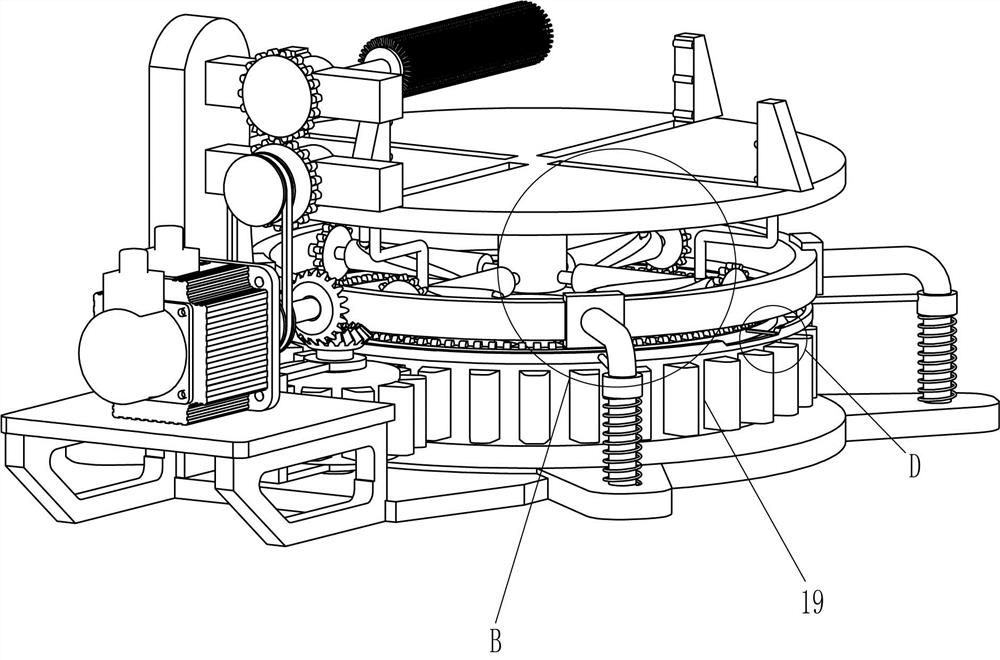

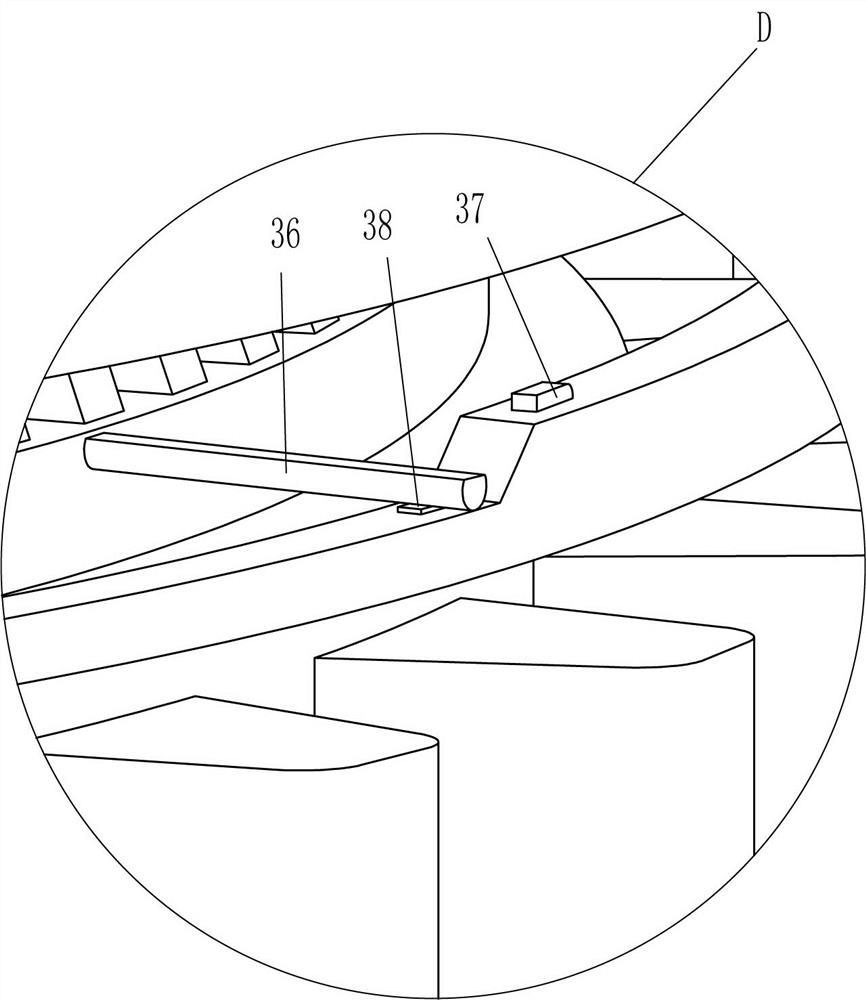

[0032] A cutting board grinding device, such as Figure 1-7 As shown, it includes a base 1, a mounting frame 2, a placement plate 3, a grinding mechanism, a clamping and rotating mechanism, and a driving mechanism. The top of the tight rotating mechanism is connected with a placement plate 3, the top of the mounting frame 2 is provided with a grinding mechanism, and the front side of the top of the base 1 is equipped with a driving mechanism, which is connected in transmission with the clamping rotating mechanism, and the driving mechanism is connected in transmission with the grinding mechanism.

[0033] When the worker needs to polish the chopping board, the worker first puts the chopping board flat on the placement board 3, and after the worker puts the cutting board flat on the placement board 3, the worker can start the drive mechanism to rotate clockwise, and the clockwise rotation of the drive mechanism will Drive the clamping and rotating mechanism to clamp the cutting...

Embodiment 2

[0035] A cutting board grinding device, such as Figure 1-7 As shown, the grinding mechanism includes a steel brush cylinder 4, the second gear 25, the third gear 26, the second pulley 28 and a flat belt 29. Above the tightening mechanism, the front end of the steel brush cylinder 4 is welded with a third gear 26, and the top of the mounting frame 2 front side is rotatably provided with a second gear 25, the second gear 25 is located below the third gear 26, and the second gear 25 and The third gear 26 is engaged, and the front side of the second gear 25 is fixedly connected with a second pulley 28 , and the second pulley 28 is connected to the driving mechanism through a flat belt 29 .

[0036] When the driving mechanism rotates clockwise, the clockwise rotation of the driving mechanism will drive the second pulley 28 to rotate clockwise through the flat belt 29, and the clockwise rotation of the second pulley 28 will drive the second gear 25 to rotate clockwise, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com