Suction nozzle for testing sorting machine

A technology for testing sorting machines and nozzle rods, applied in sorting and other directions, can solve problems such as low production efficiency, small bearing capacity of nozzle heads, and failure of suction nozzles to suck products, and achieve reduced maintenance costs, reasonable position settings, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

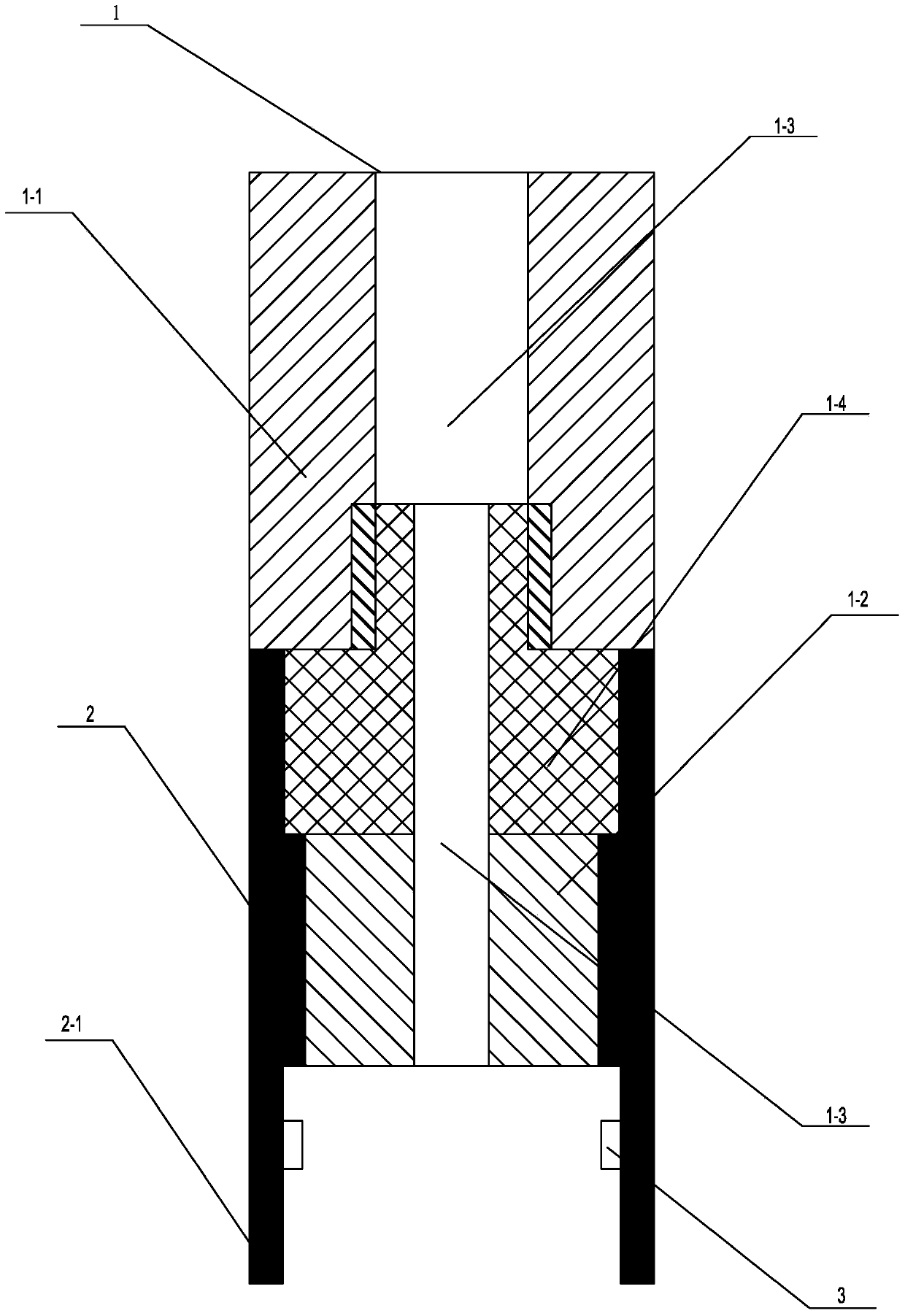

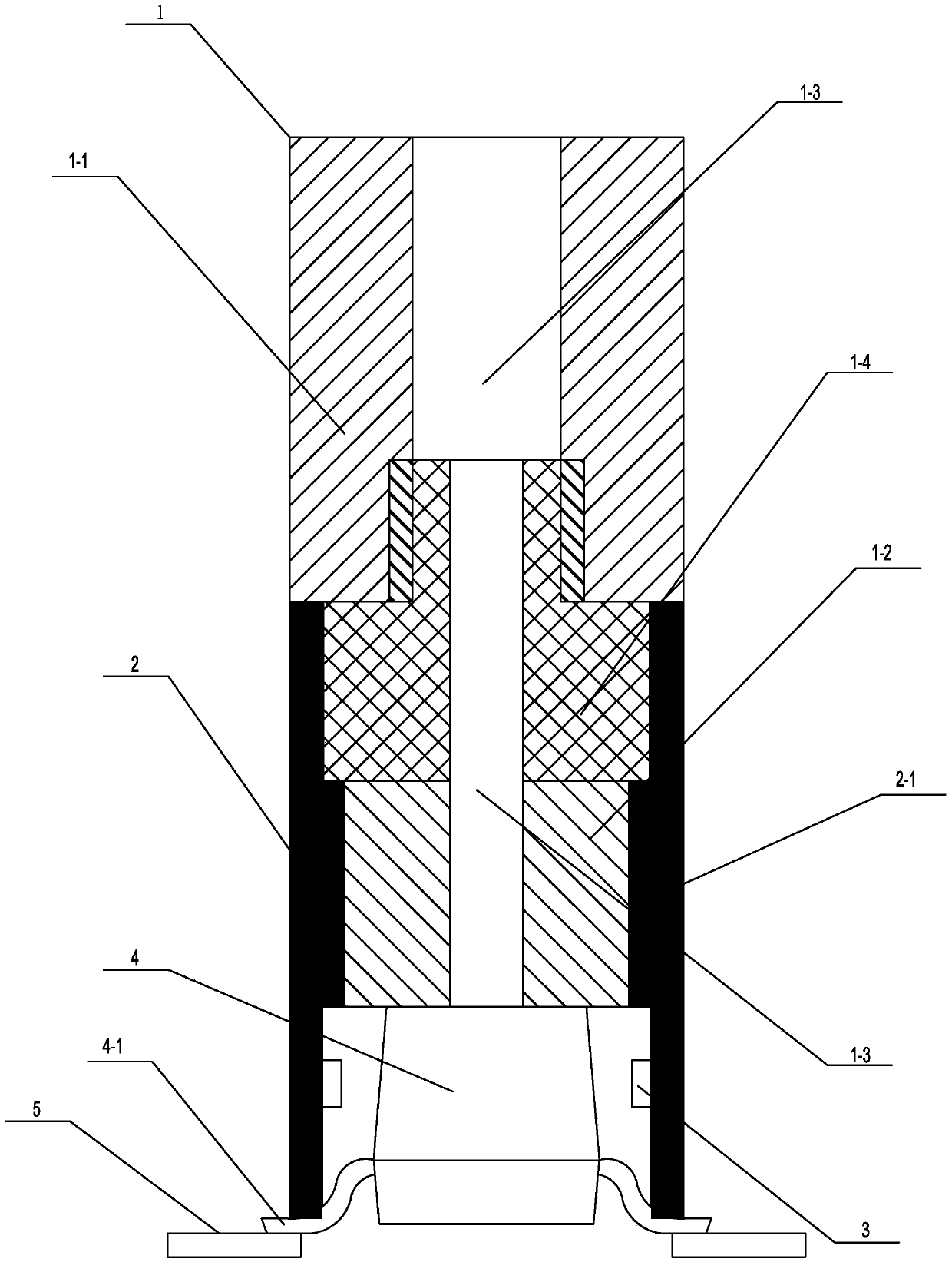

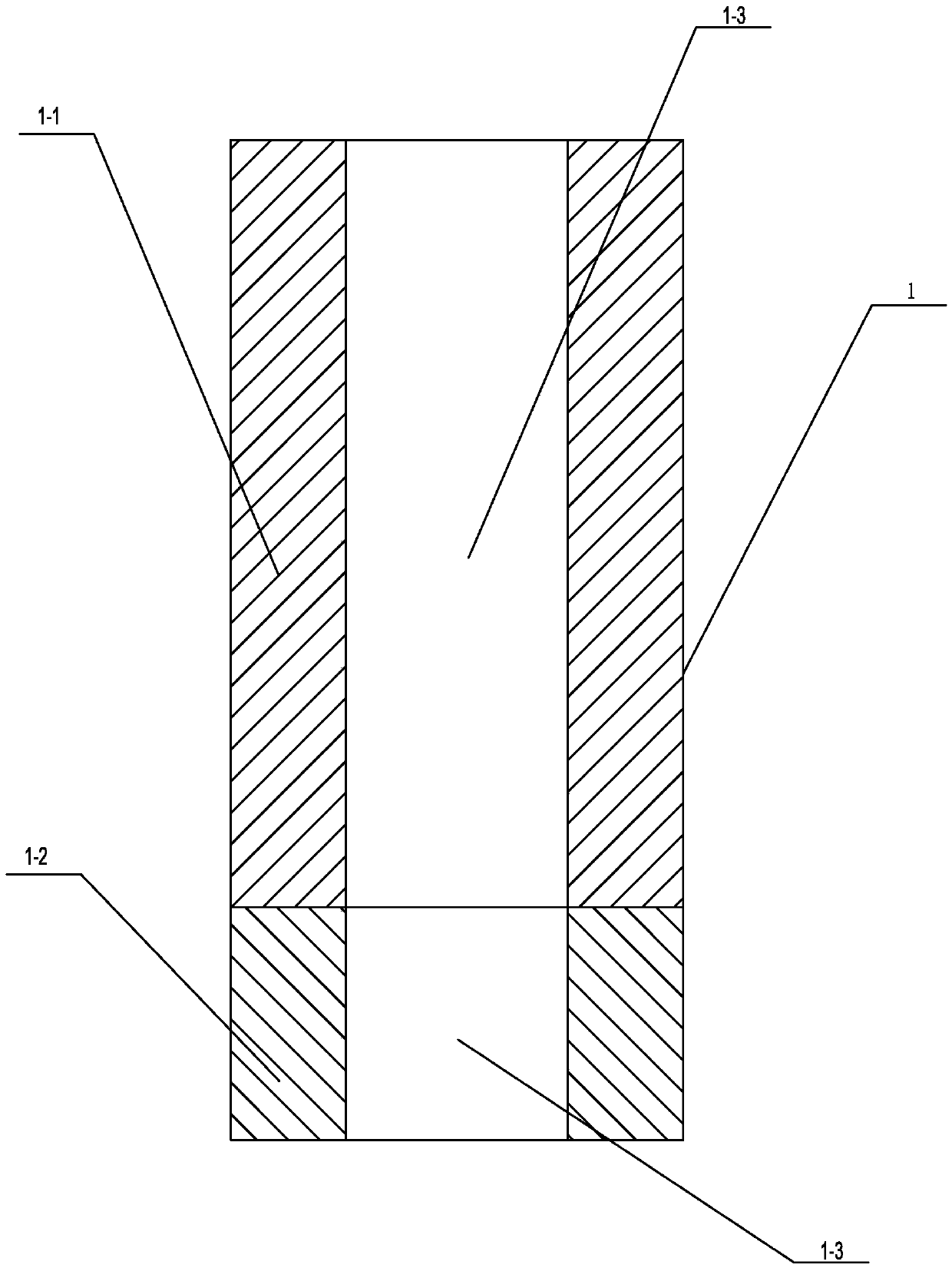

[0022] Such as figure 1 A specific embodiment of the present invention is proposed as shown, a suction nozzle for testing a sorting machine, including a nozzle body 1, and the nozzle body 1 includes a nozzle rod 1-1 and a nozzle head 1-2. The center of the nozzle rod 1-1 and the nozzle head 1-2 is provided with a vacuum flow channel 1-3, and they communicate with each other. The nozzle body 1 is provided with a detachable positioning protection device 2, the positioning protection device 2 includes positioning protection rods 2-1 arranged on both sides of the suction nozzle body 2 and set in a direction parallel to the suction nozzle body 1, the horizontal distance between the two positioning protection rods 2-1 is less than or equal to the two pins 4 of the semiconductor device 4 The distance between -1.

[0023] The positioning protection rod 2-1 is equipped with a pressure detection device 3, and the pressure detection device 3 is connected with the pushing mechanism of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com