Tensile test device

A technique for tensile testing and installation, applied to measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem of inability to parallel the vertical direction of the pin 104, deformation or crooked of the pin 104, and damage to the electronics Problems such as component appearance, to avoid damage to electronic components, to achieve reliable results, to improve the efficiency of the production process and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail with the help of the following specific examples and accompanying drawings.

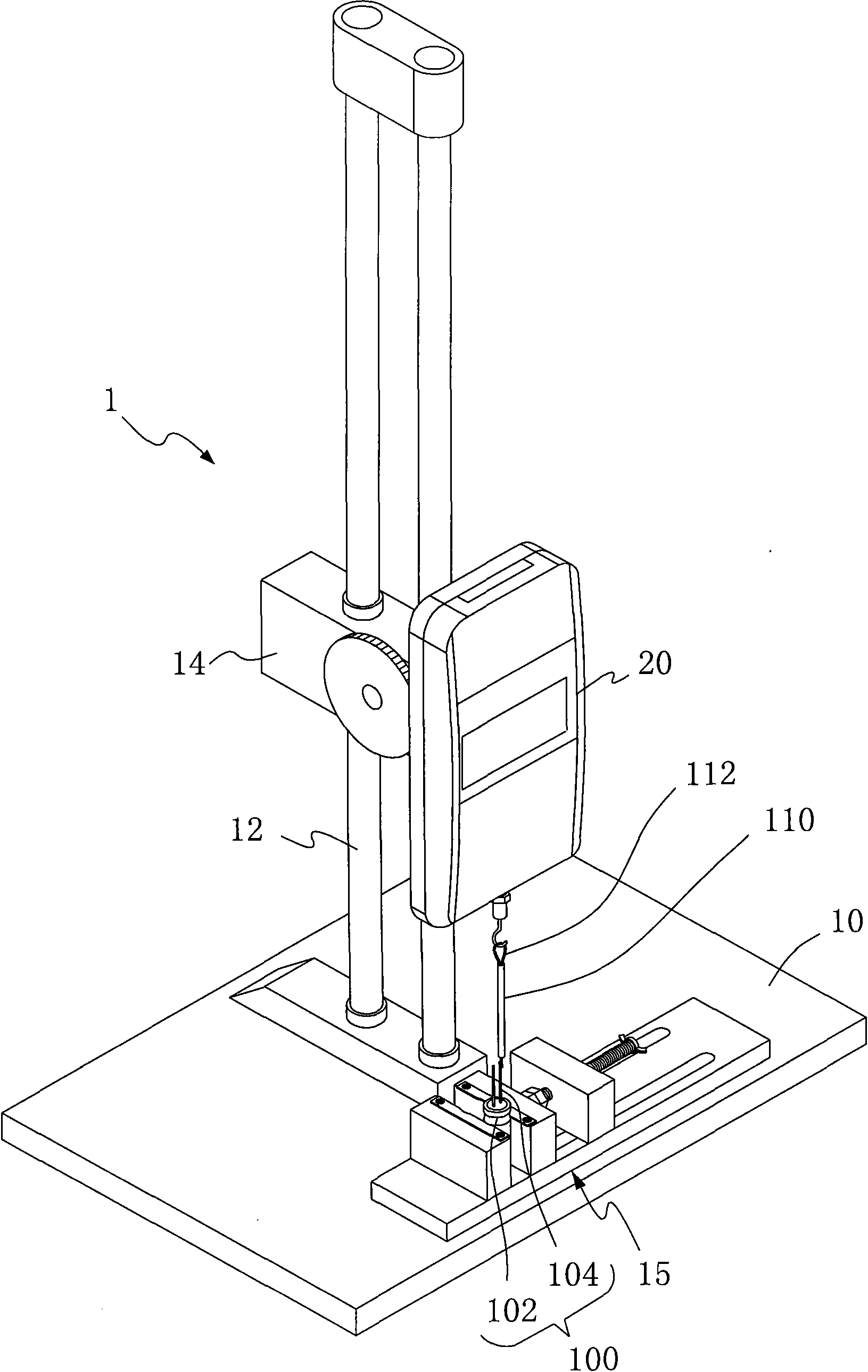

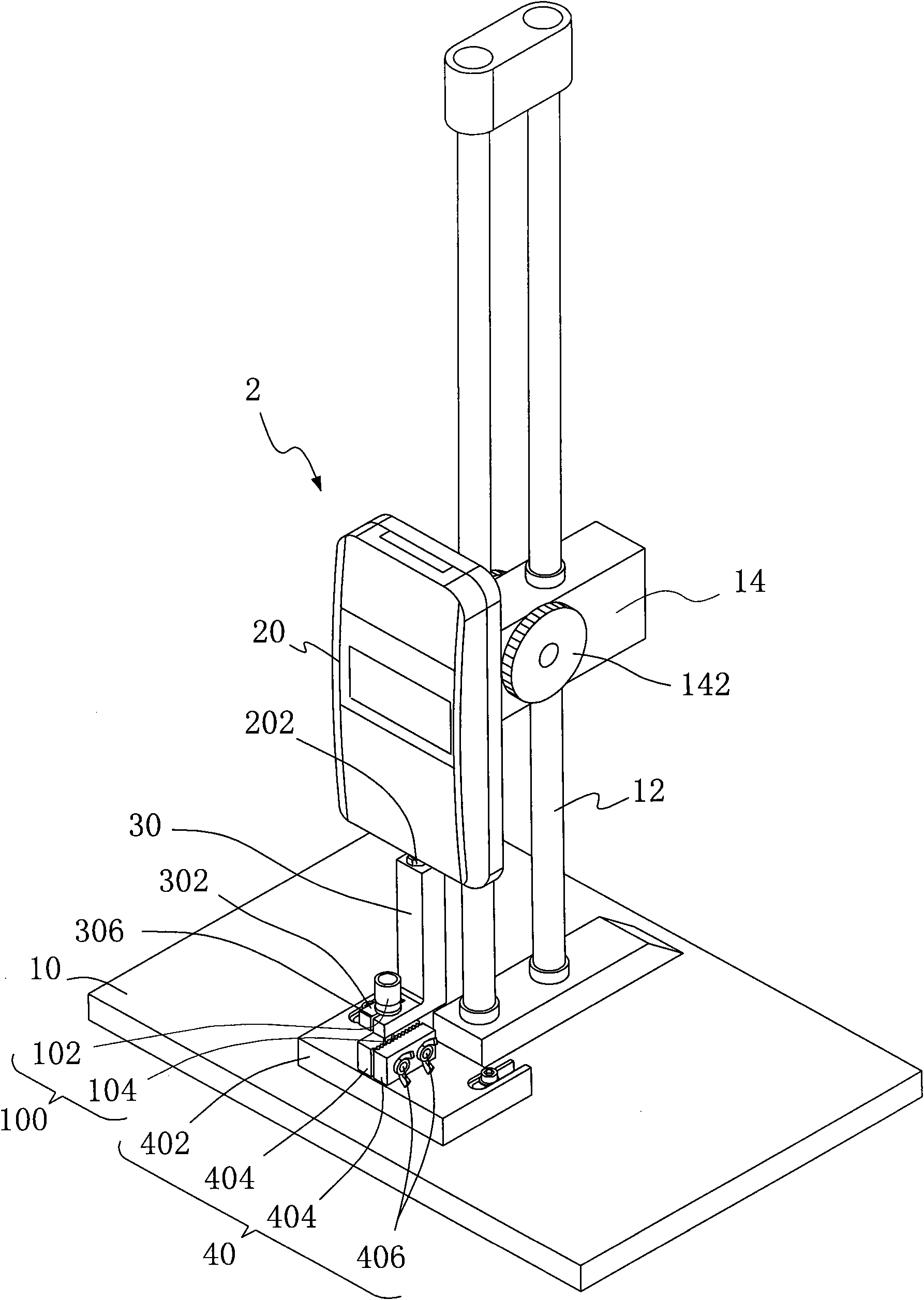

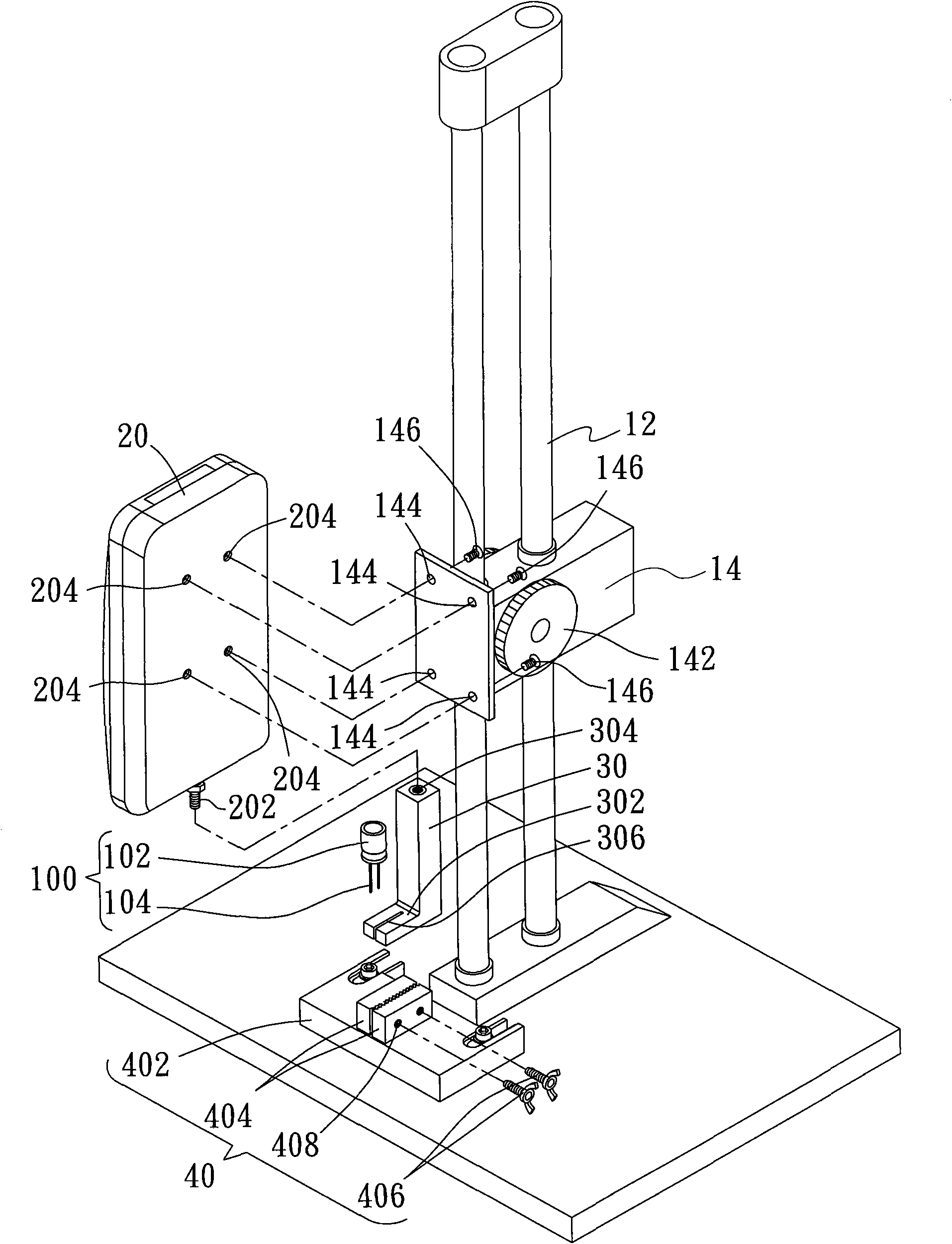

[0058] refer to figure 2 , is a three-dimensional schematic diagram of a tensile test device according to an embodiment of the present invention. The tensile test device 2 is used to conduct a tensile test of the electronic component 100 to test the bonding strength between the body 102 and the pin 104 . At figure 2 Among them, the tensile test device 2 includes a base 10, a push-pull force gauge 20, a hanger 30 and a clamp 40; wherein, the base 10 has a support frame 12 and a mounting portion 14 located on the support frame 12, and the push-pull force gauge 20 is installed on the installation part 14 and has a stretching part 202; the hanger 30 is connected to the stretching part 202 for hanging the body 102 and exposing the pins 104 towards the base 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com