Patents

Literature

62results about How to "Desired effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

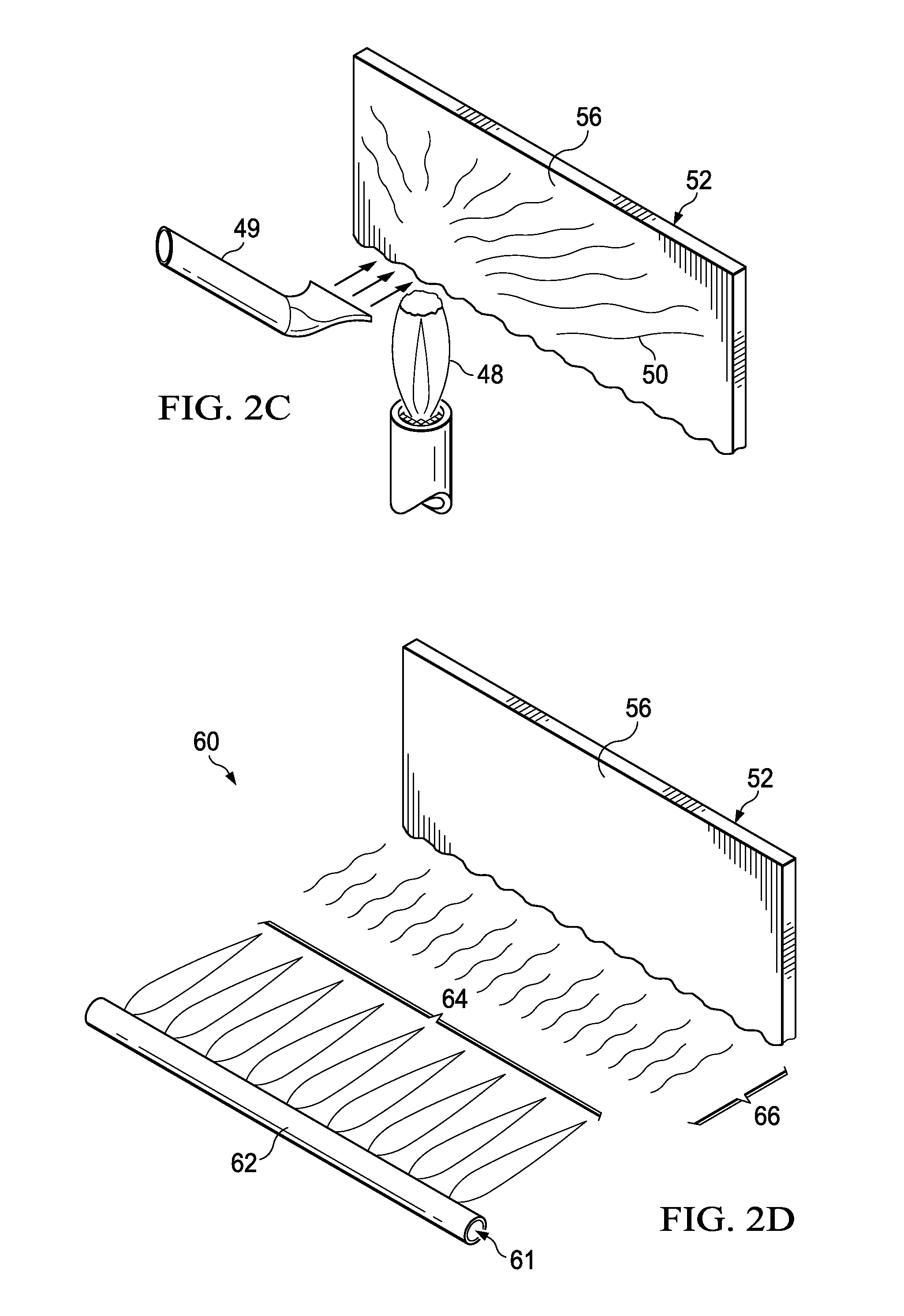

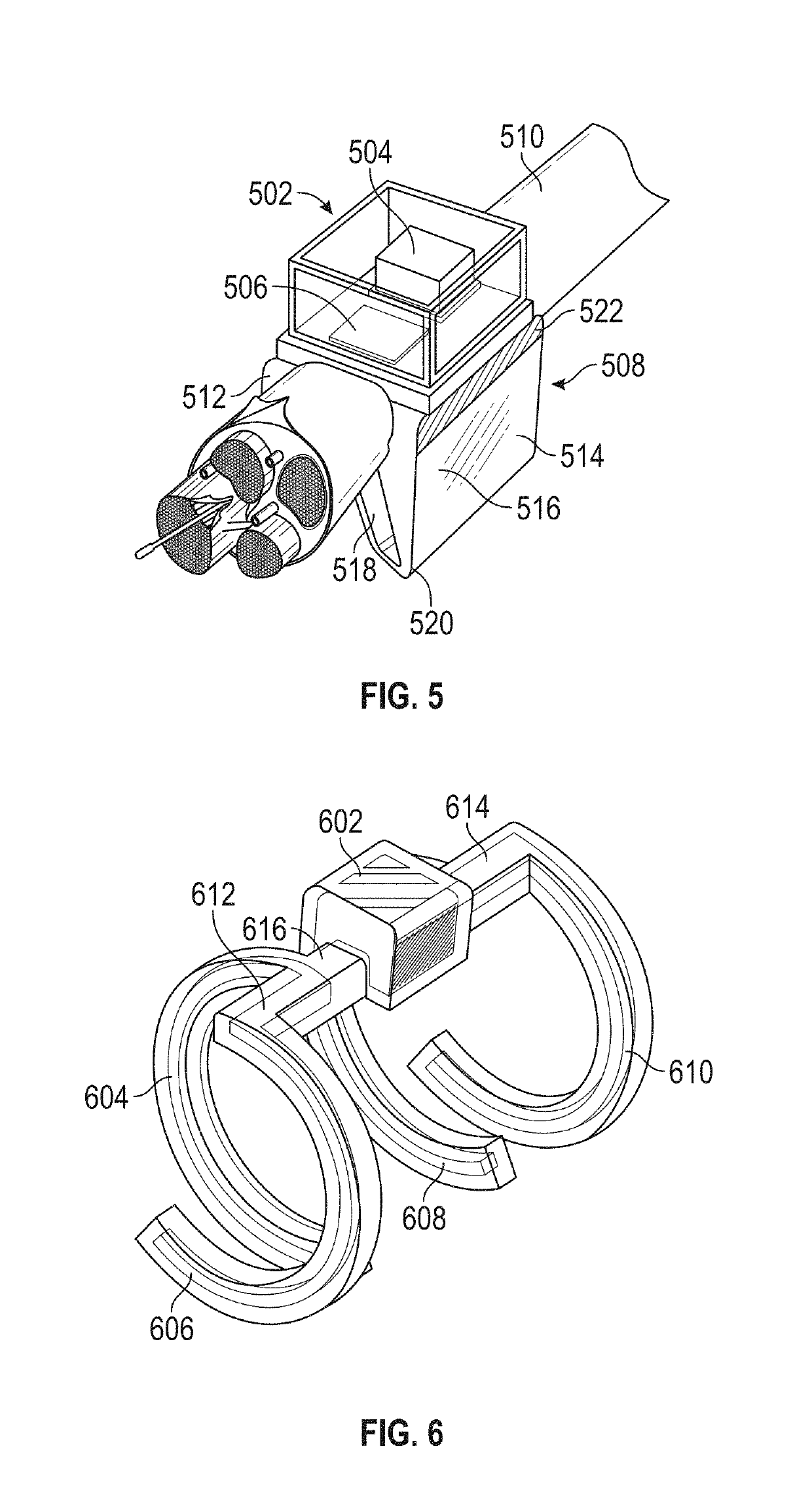

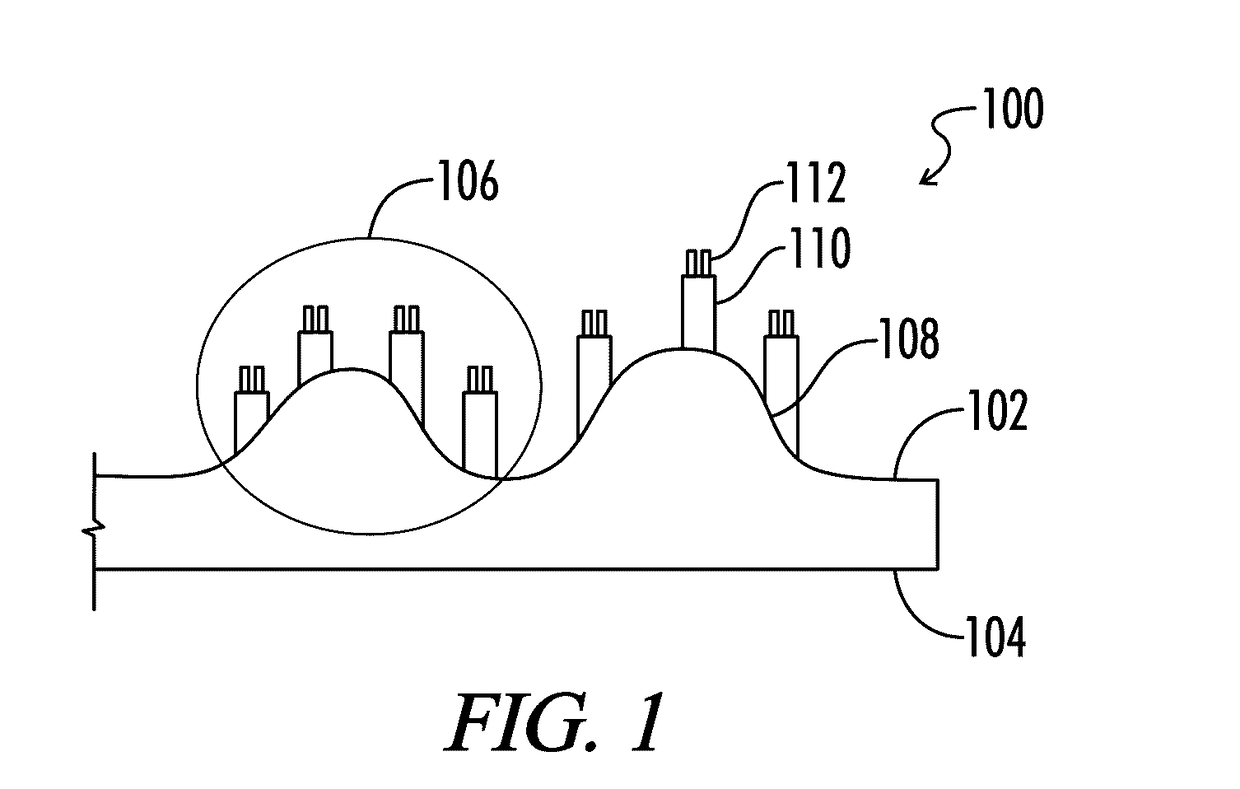

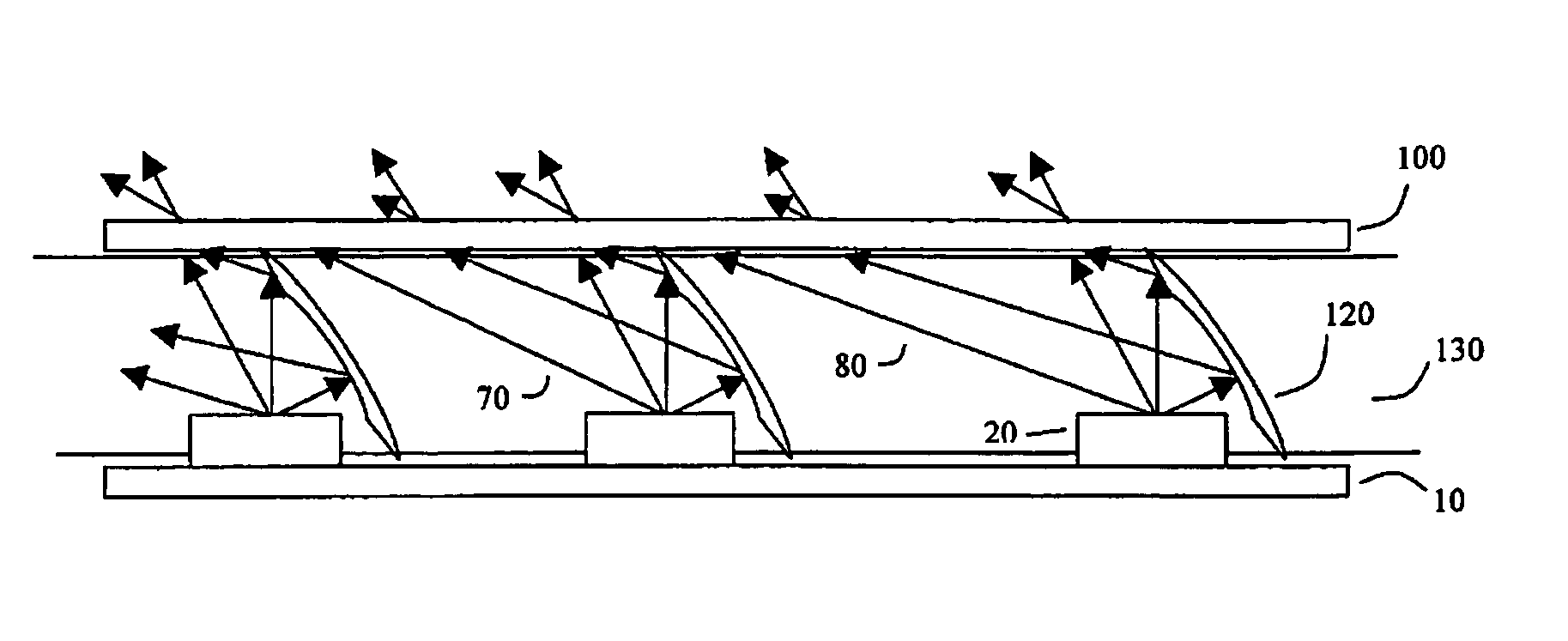

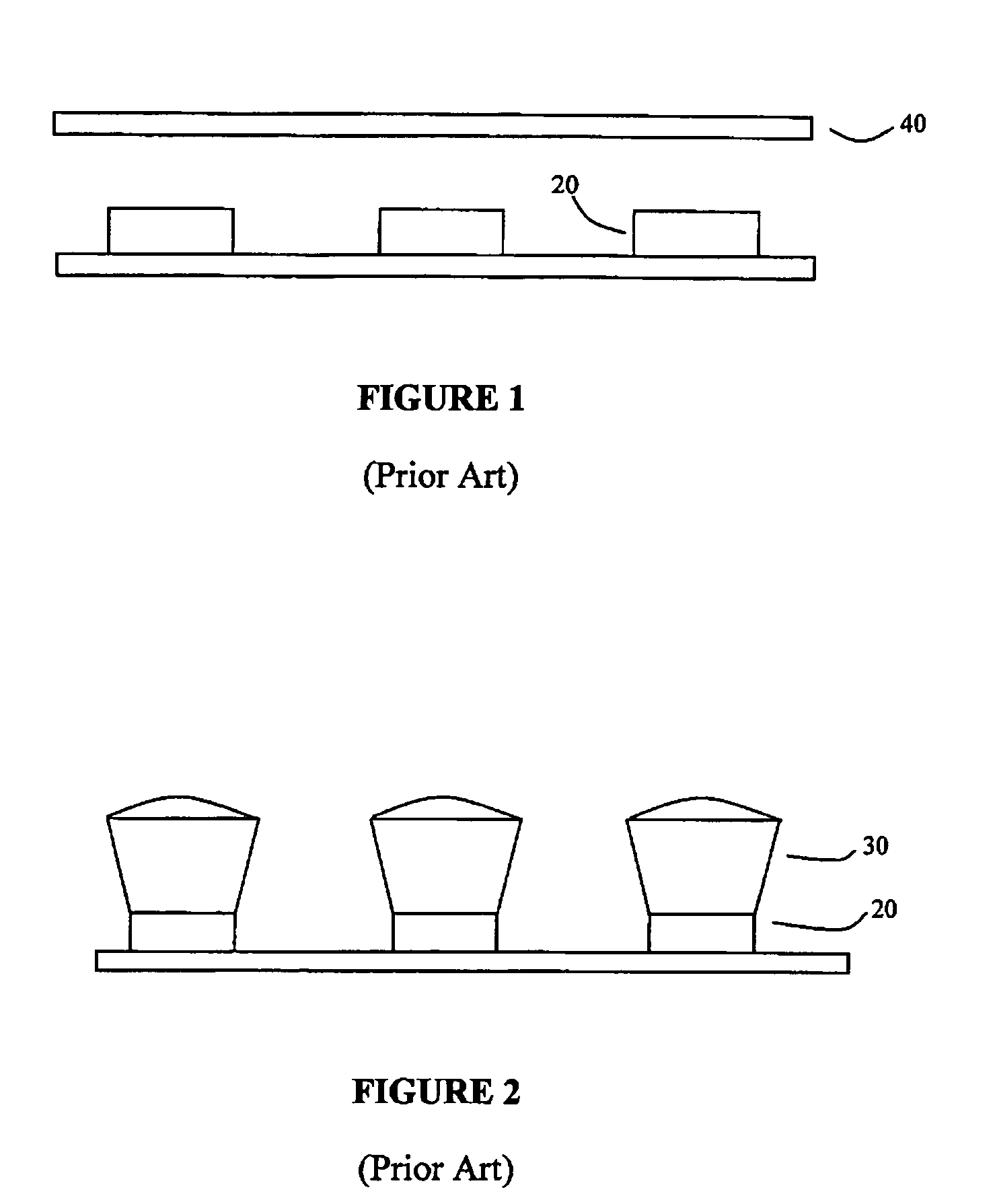

System and method for manipulating illumination created by an array of light emitting devices

ActiveUS7182480B2Desired effectNon-electric lightingPoint-like light sourceDiffusionMacroscopic scale

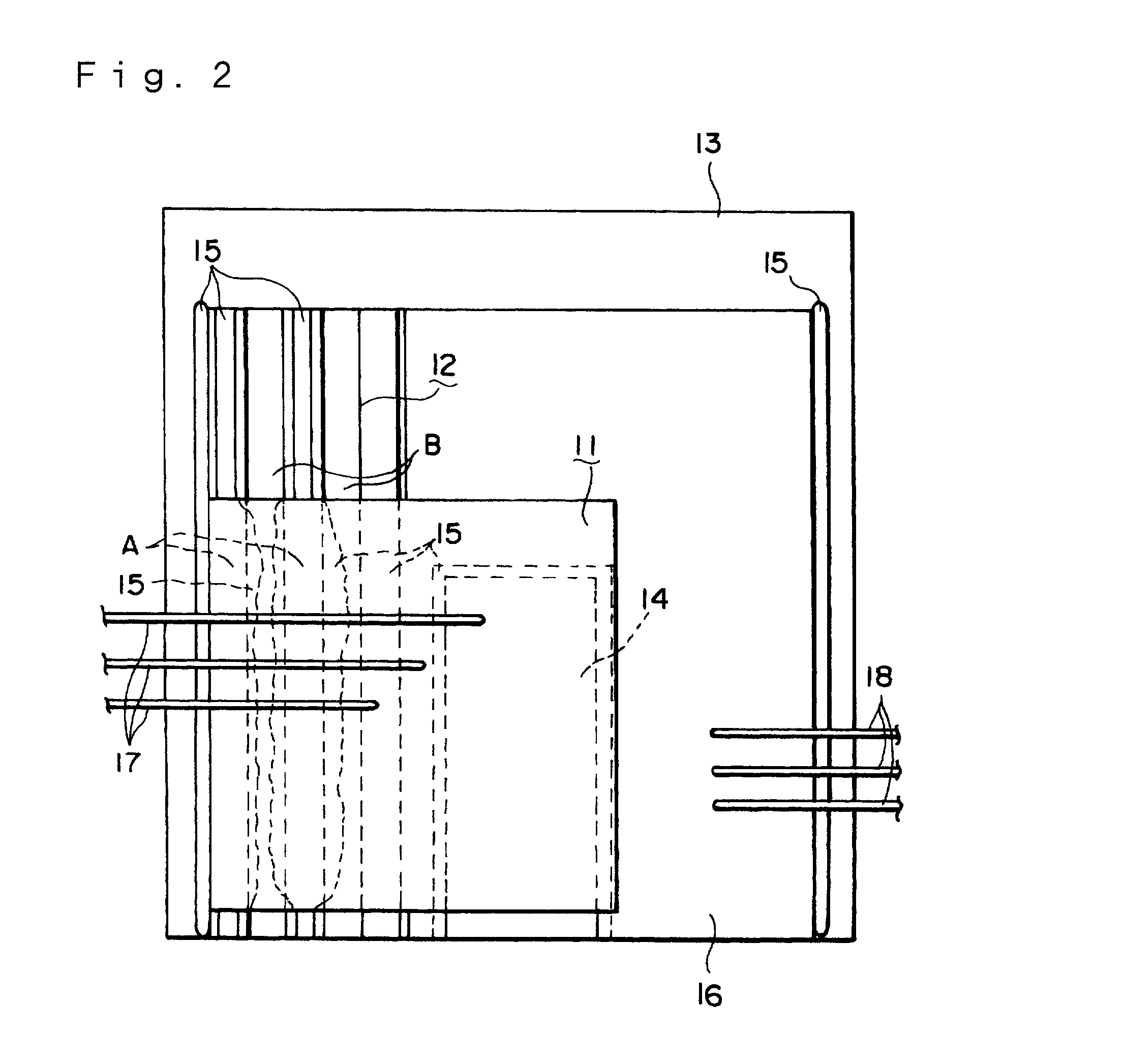

The present invention provides an illumination optical system that enables the direction and mixing of light from light emitting devices. The optical system comprises a plurality of light emitting devices that are spatially arranged in an array, wherein this array comprises one or more sections, such that the light emitting devices in a particular section emit light within a predetermined wavelength range. Through the use of a combination of macroscopic and microscopic optical systems, the illumination created by the array can be manipulated such that a desired illumination distribution is created. The macroscopic optical system provides a means for redirecting the illumination in one or more desired directions, wherein this redirection is provided by a collection of appropriately shaped and positioned reflective optics. Subsequent to its interaction with the macroscopic optical system, the illumination is manipulated by a microscopic optical system that enables the diffusion of the illumination in a predetermined manner, while retaining the desired angular distribution of the illumination created by the macroscopic optical system. Through the appropriate design and orientation of both the macroscopic and microscopic optical systems, a desired illumination effect can be created.

Owner:SIGNIFY HLDG BV

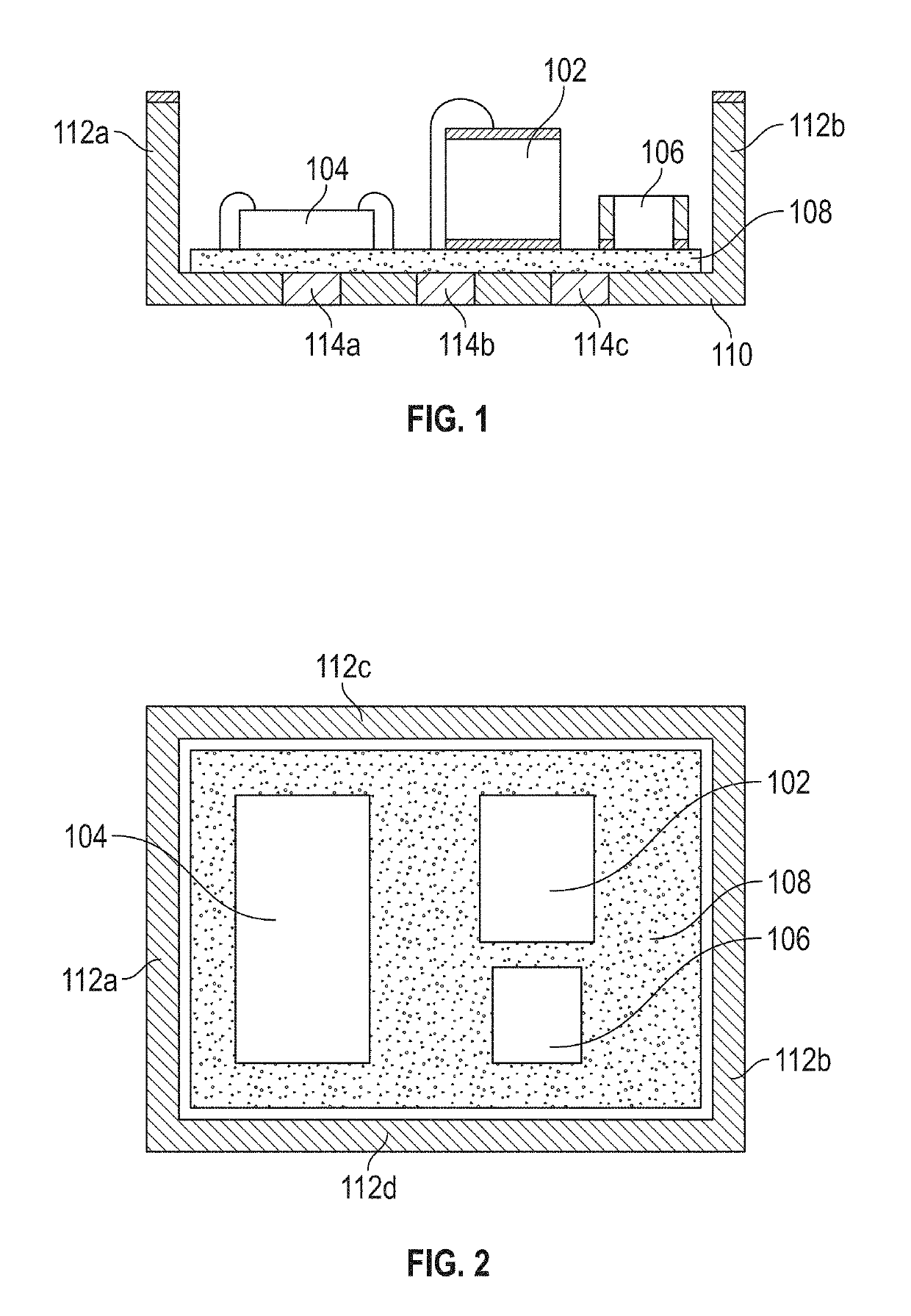

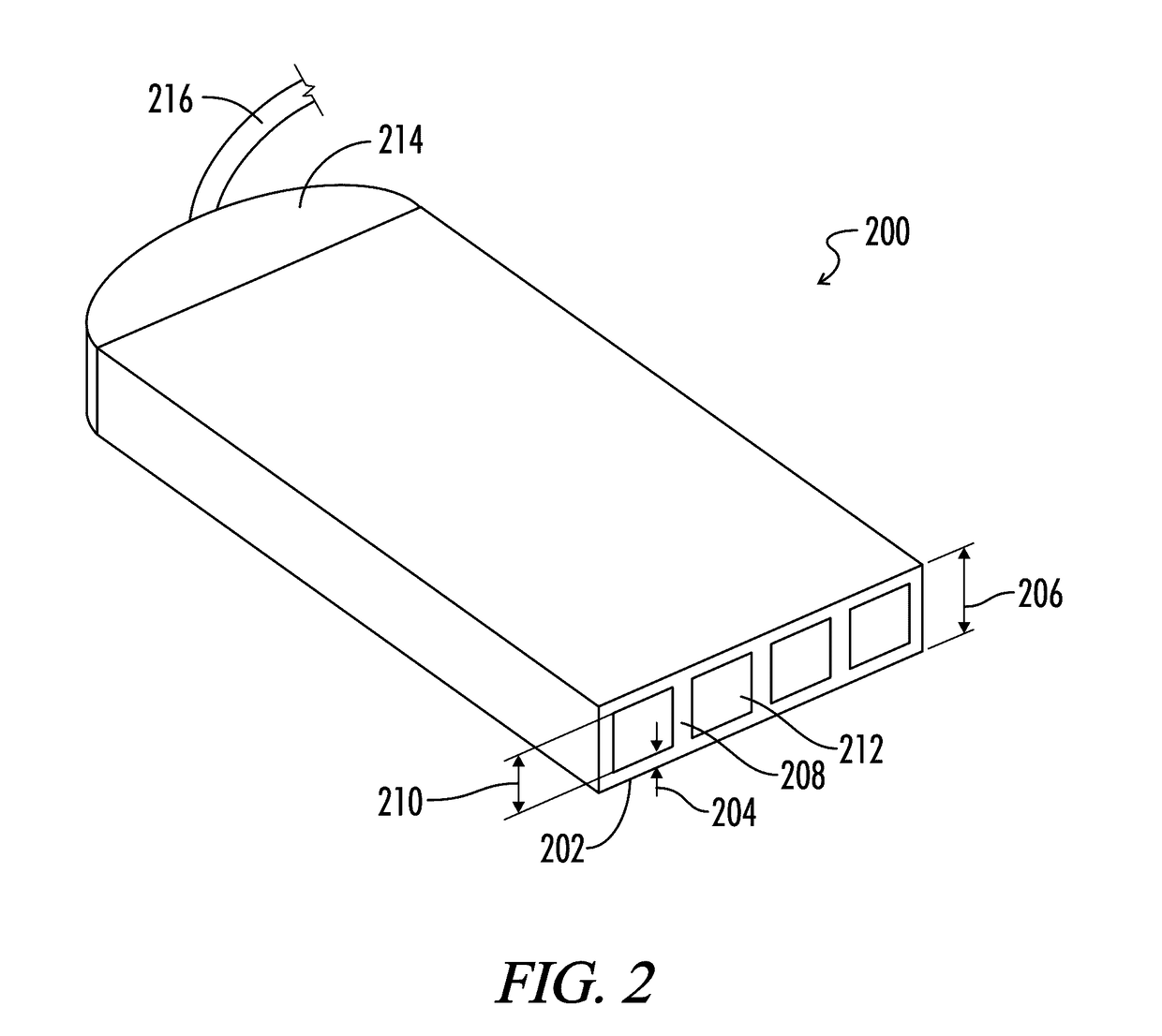

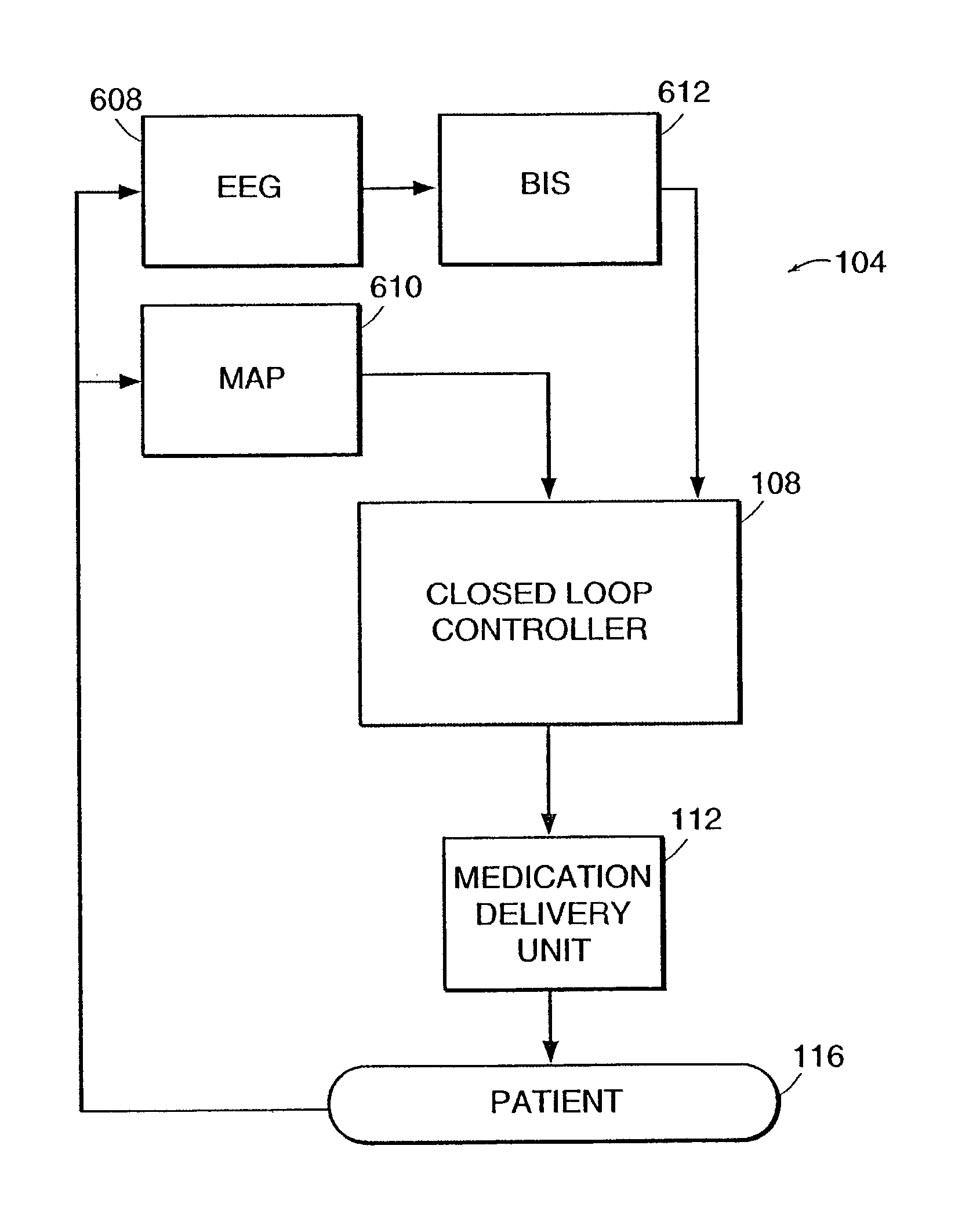

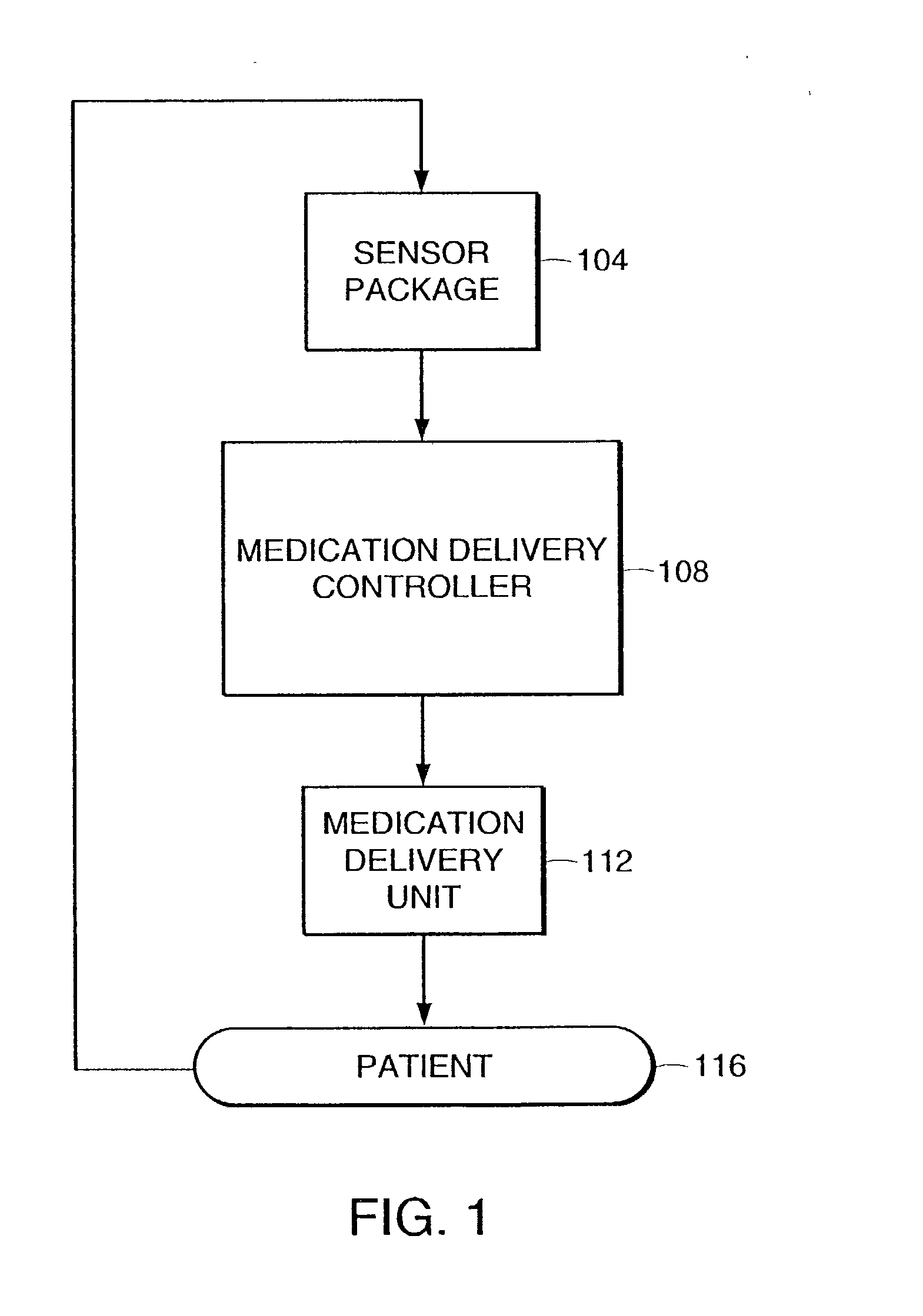

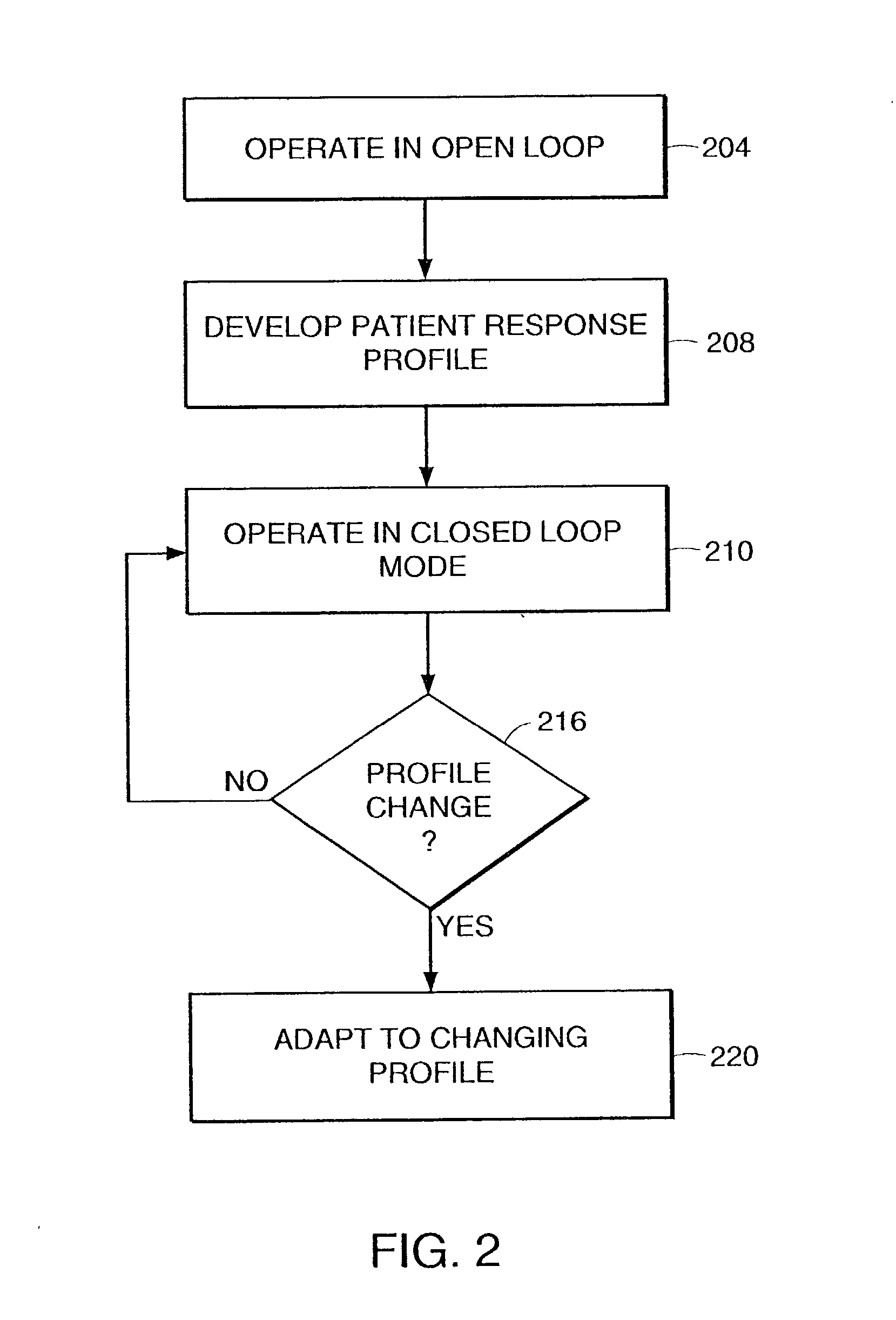

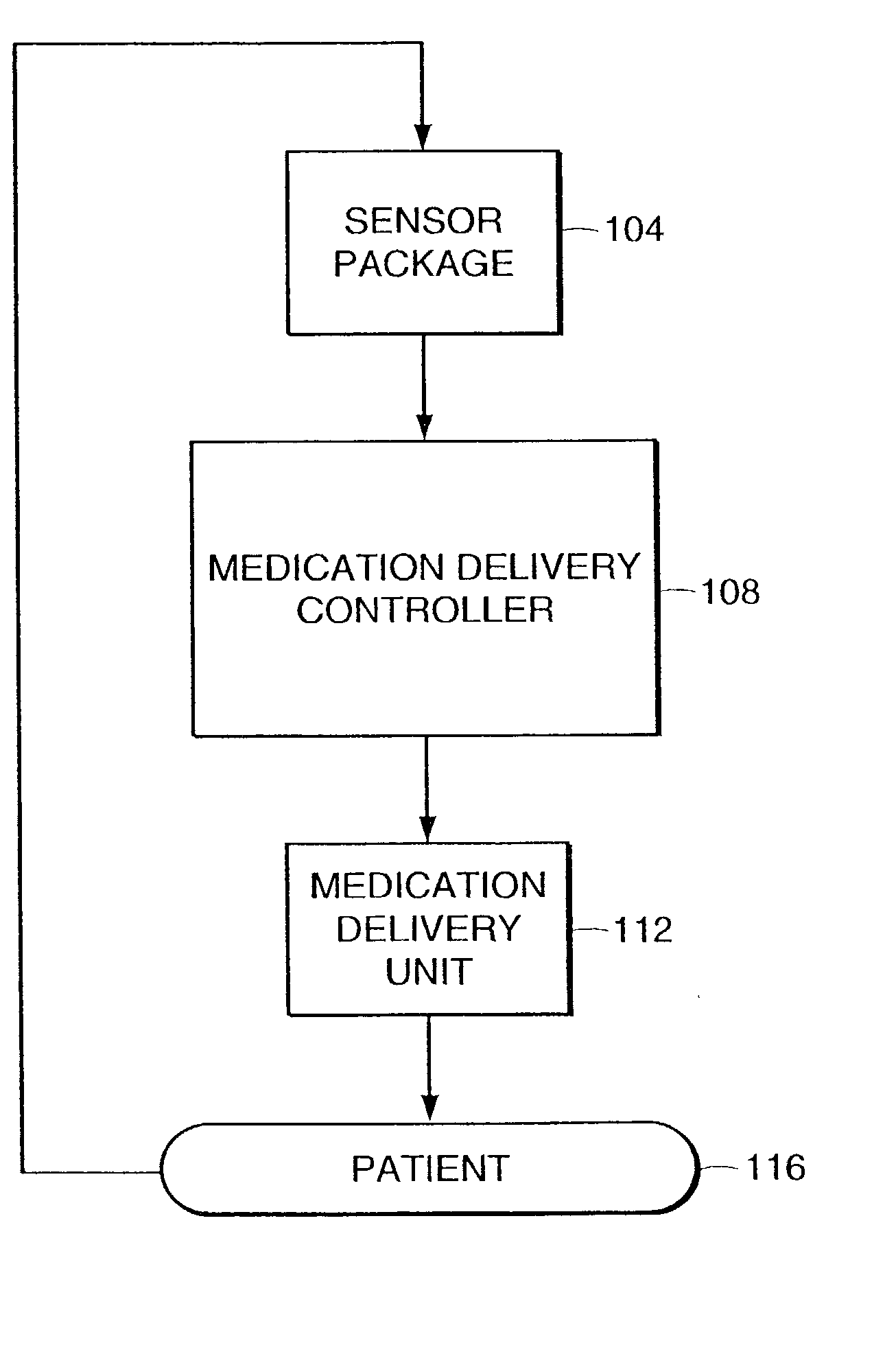

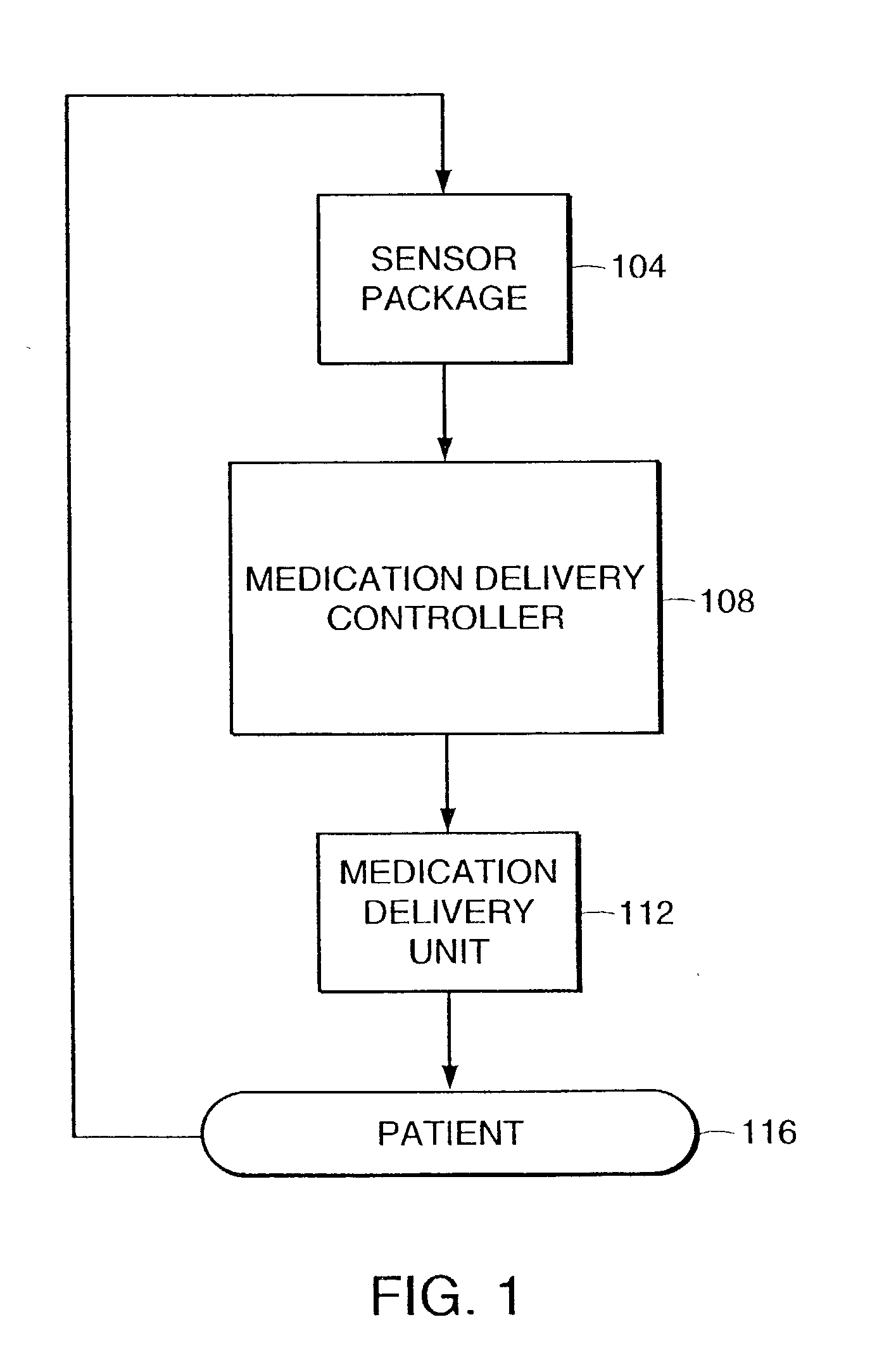

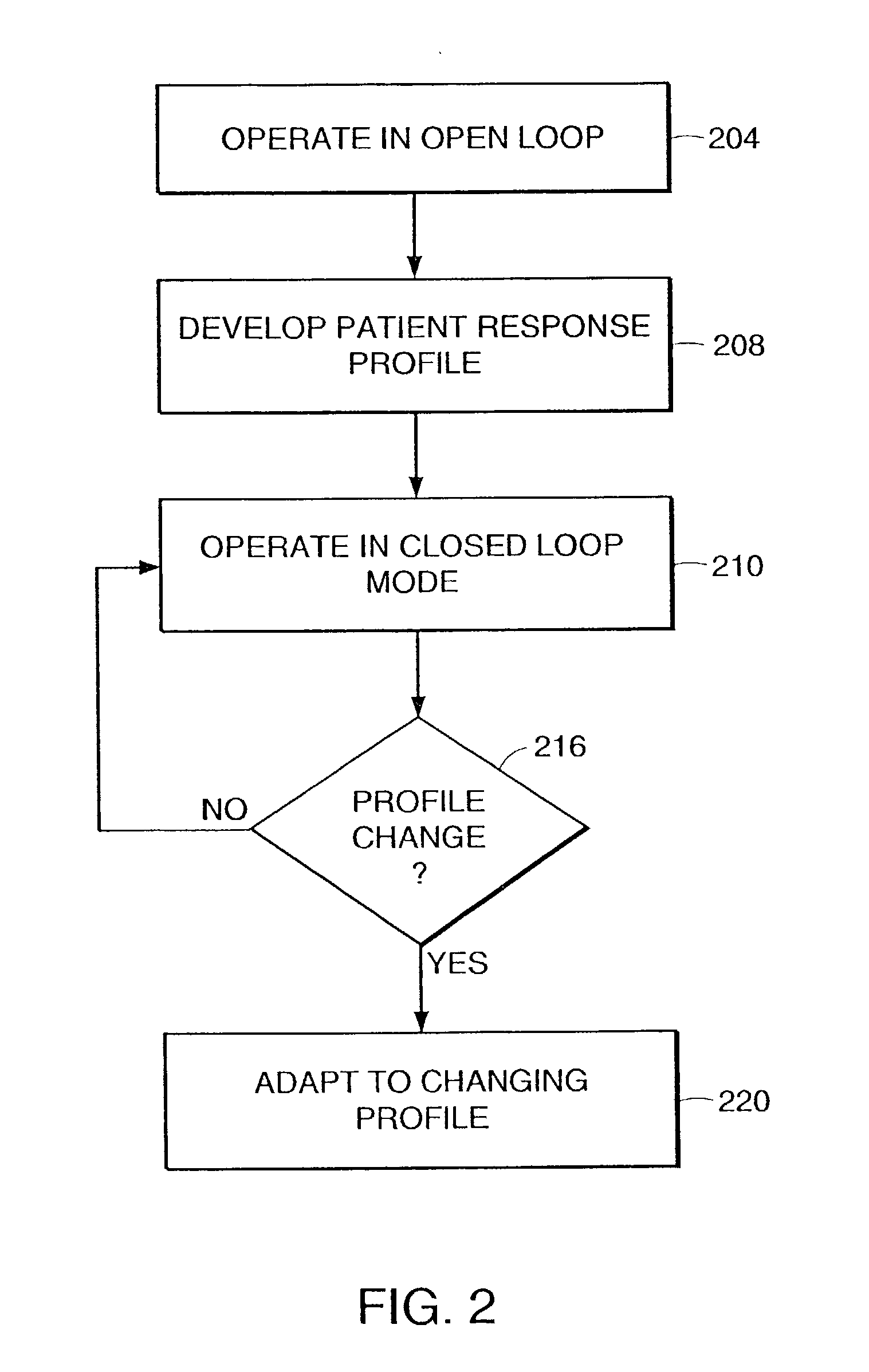

System and method for adaptive drug delivery

InactiveUS20030036744A1ChangeDesired effectMedical devicesPressure infusionIntensive care medicineGiven medications

A system and method for controlling the administration of medication to a patient utilizes adaptive feedback to achieve and maintain a target effect in said patient. A sensor package having one or more sensors is used to sense an attribute of the patient and to provide a parameter indicating the attribute being sensed. A medication delivery controller accepts one or more parameters from the sensor package and uses these parameters to determine the effect of a medication on a patient and the concentration level of medication that will achieve a desired effect. The medication delivery controller controls the medication delivery unit to deliver the medication at a rate determined to achieve said target concentration level of said medication in said patient. If the patient's response to a given medication changes as a result of external stimuli, the medication delivery controller can detect this change and determine a new concentration level of medication which will achieve the desired effect. The medication delivery controller can steer the medication delivery unit to administer an amount of medication to reach this new concentration level.

Owner:FRESENIUS VIAL

System and method for adaptive drug delivery

InactiveUS20030045858A1ChangeDesired effectMedical devicesPressure infusionIntensive care medicineGiven medications

A system and method for controlling the administration of medication to a patient utilizes adaptive feedback to achieve and maintain a target effect in said patient. A sensor package having one or more sensors is used to sense an attribute of the patient and to provide a parameter indicating the attribute being sensed. A medication delivery controller accepts one or more parameters from the sensor package and uses these parameters to determine the effect of a medication on a patient and the concentration level of medication that will achieve a desired effect. The medication delivery controller controls the medication delivery unit to deliver the medication at a rate determined to achieve said target concentration level of said medication in said patient. If the patient's response to a given medication changes as a result of external stimuli, the medication delivery controller can detect this change and determine a new concentration level of medication which will achieve the desired effect. The medication delivery controller can steer the medication delivery unit to administer an amount of medication to reach this new concentration level.

Owner:FRESENIUS VIAL

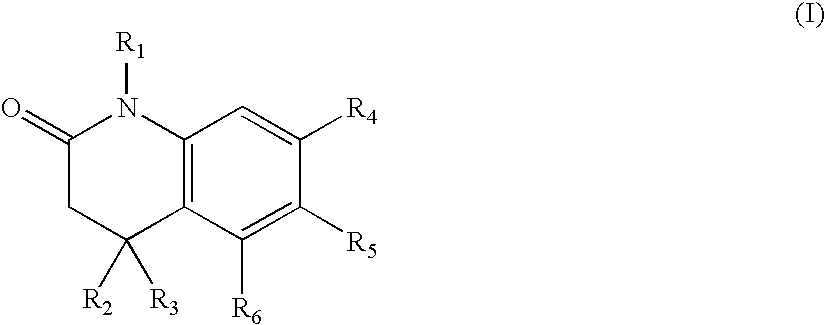

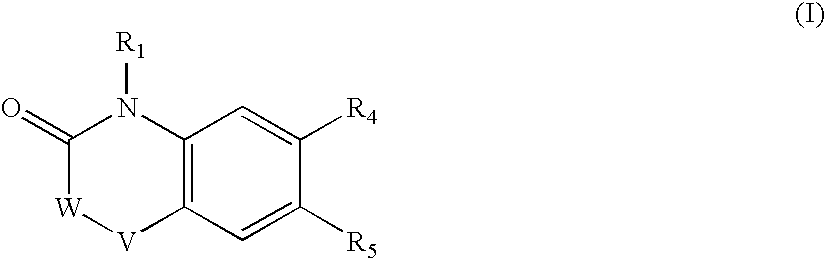

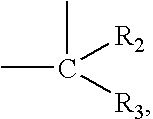

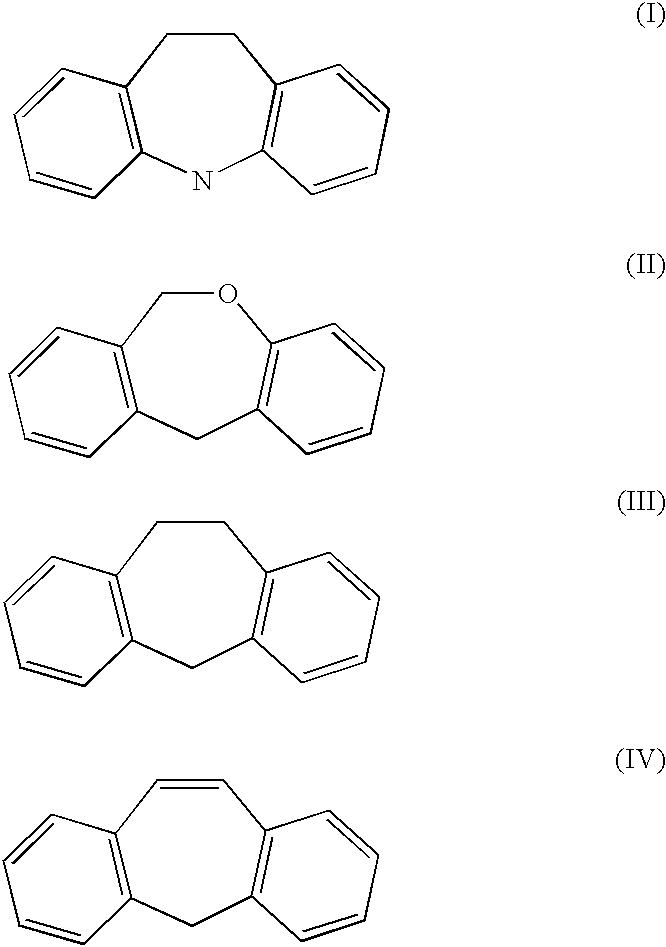

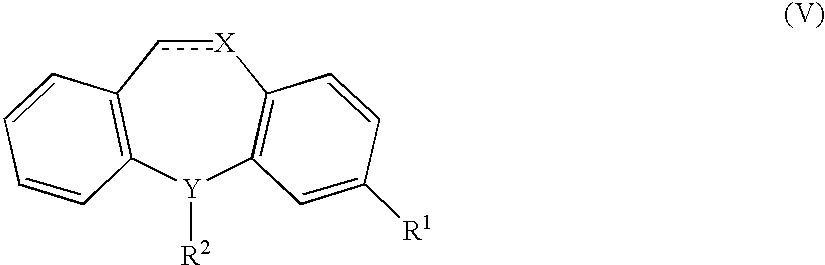

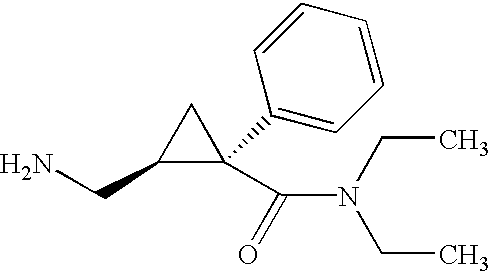

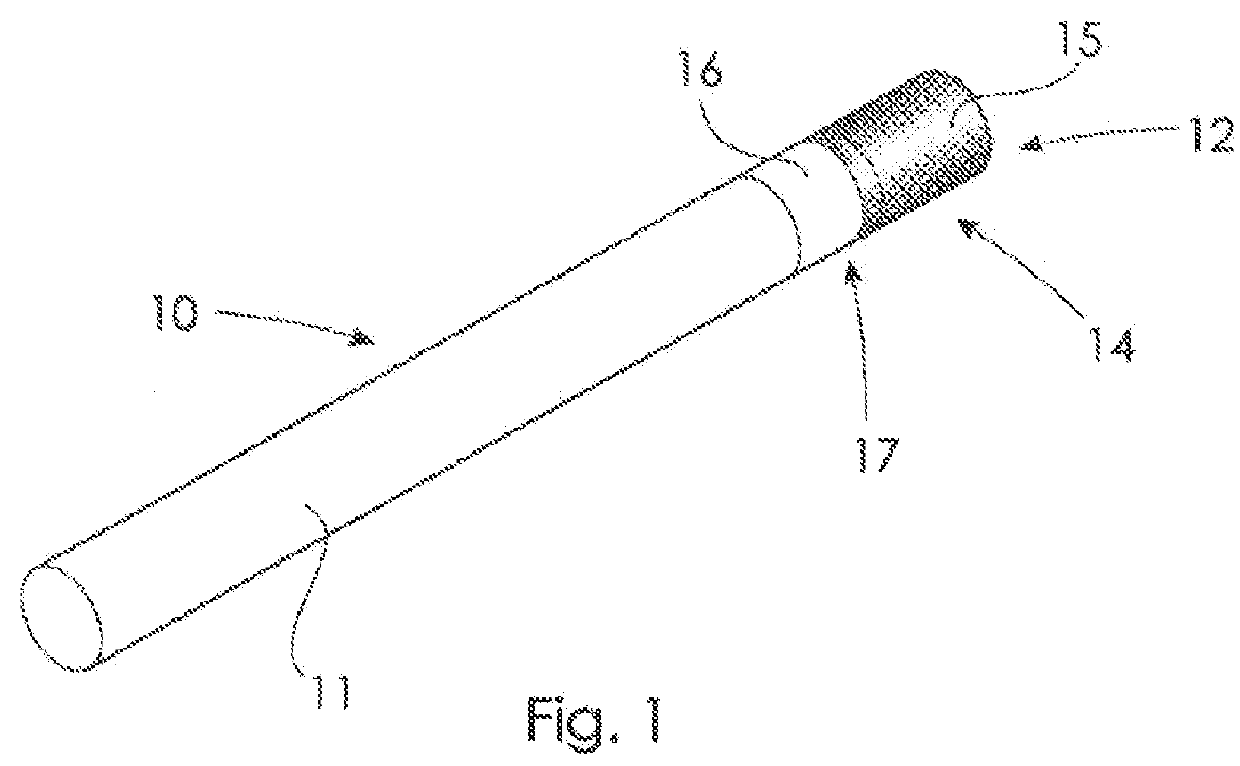

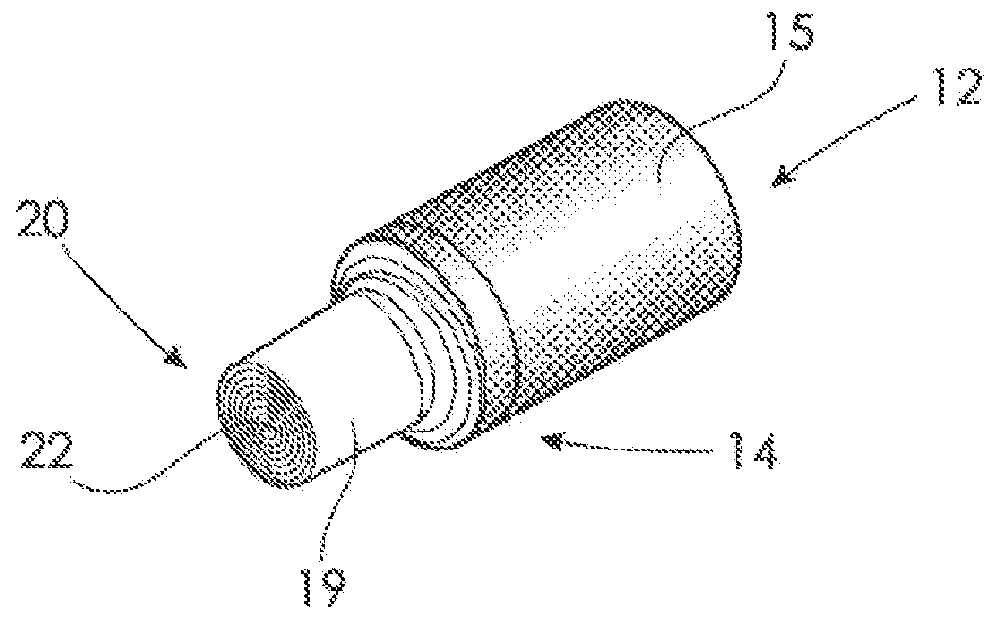

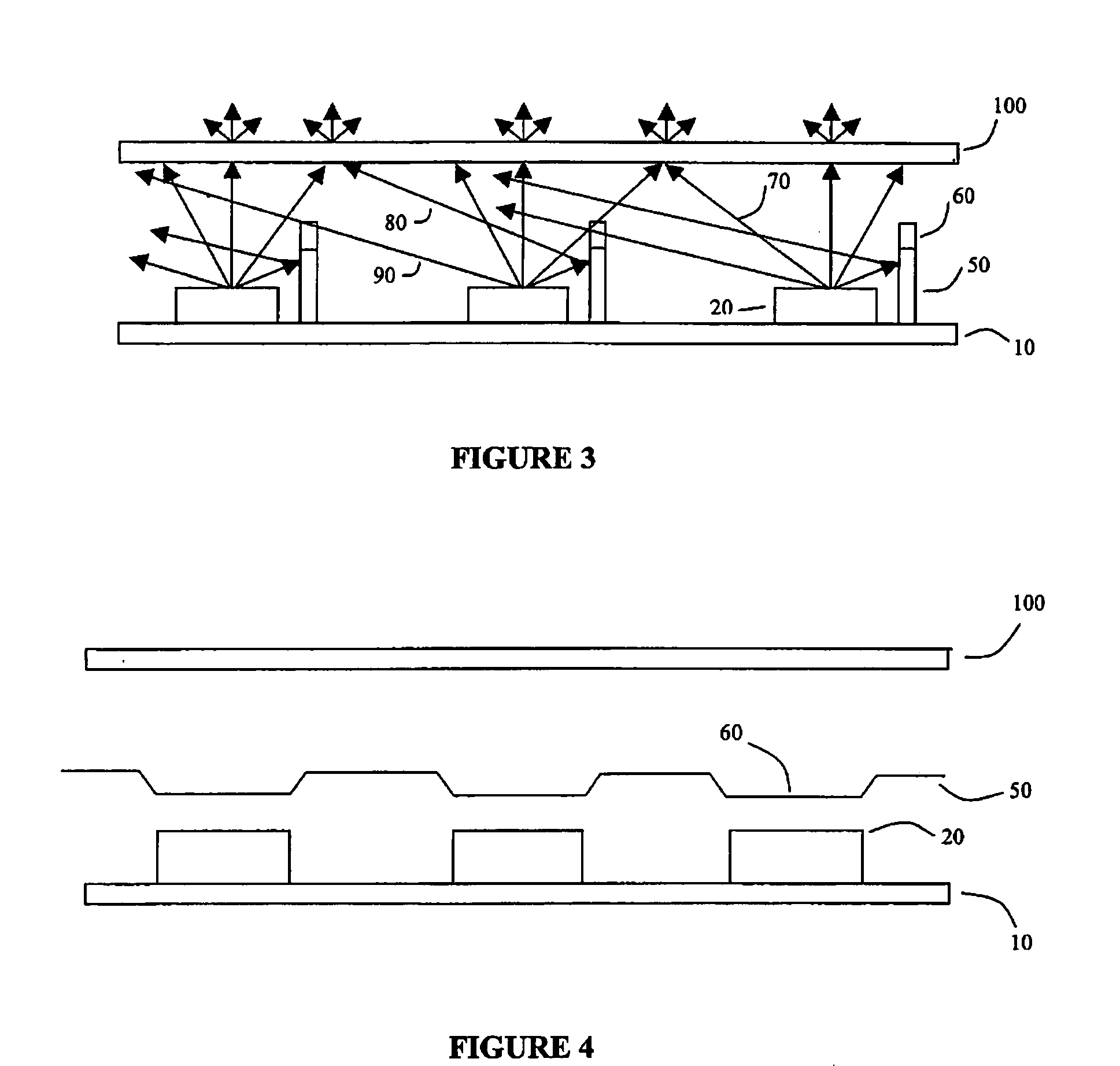

R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics

InactiveUS20060079558A1Desired effectImprove sleepingBiocideOrganic chemistryLocal anesthesiaAnesthetic

The present invention relates to the R-isomers of anesthetic compounds, the methods of treatment therewith, the compounds being useful for inducing local anesthesia, analgesia and sleep.

Owner:BRIDGE PHARMA INC

Heterocyclic amide derivatives as RXR agonists for the treatment of dyslipidemia, hypercholesterolemia and diabetes

Owner:JANSSEN PHARMA NV

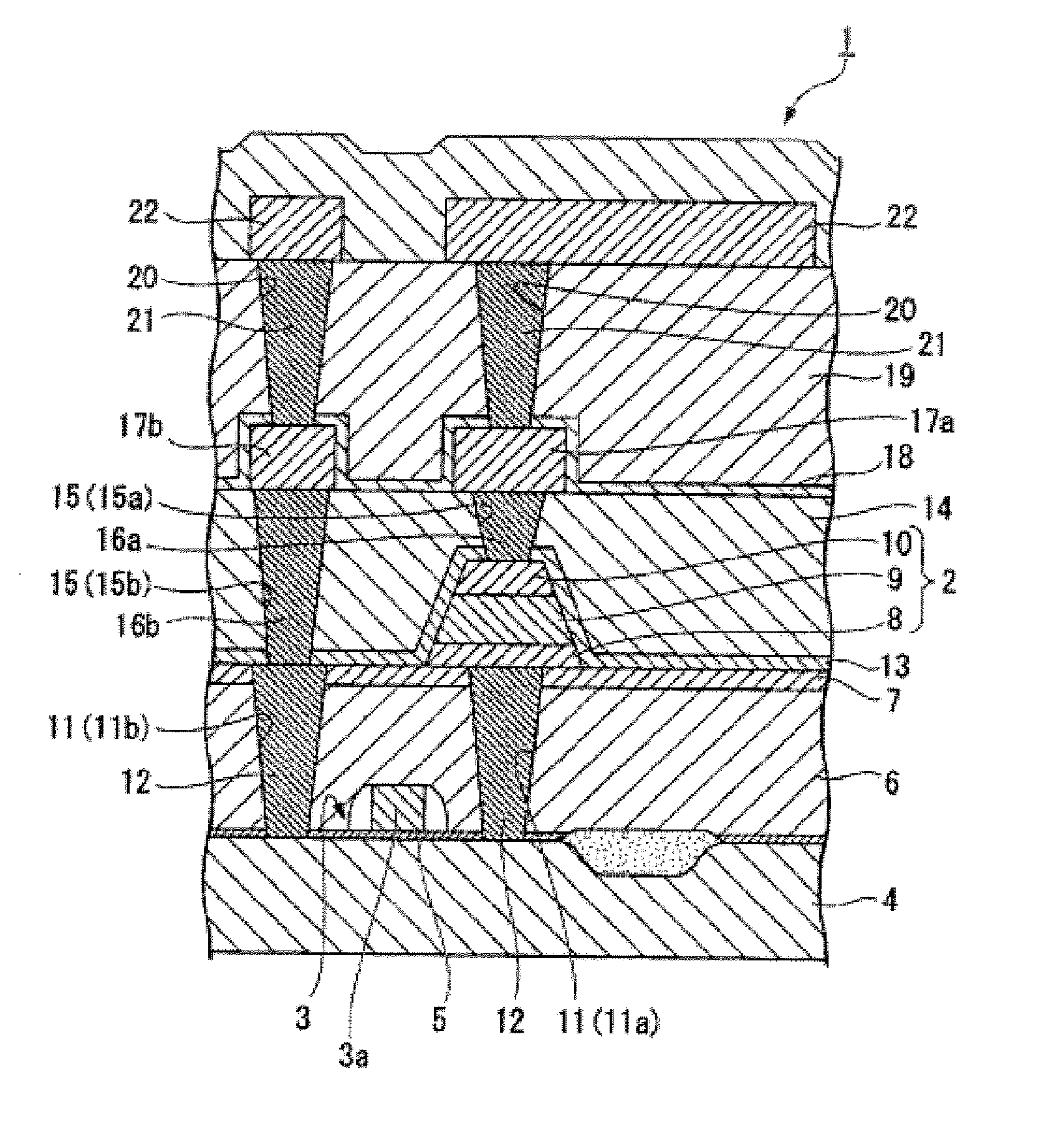

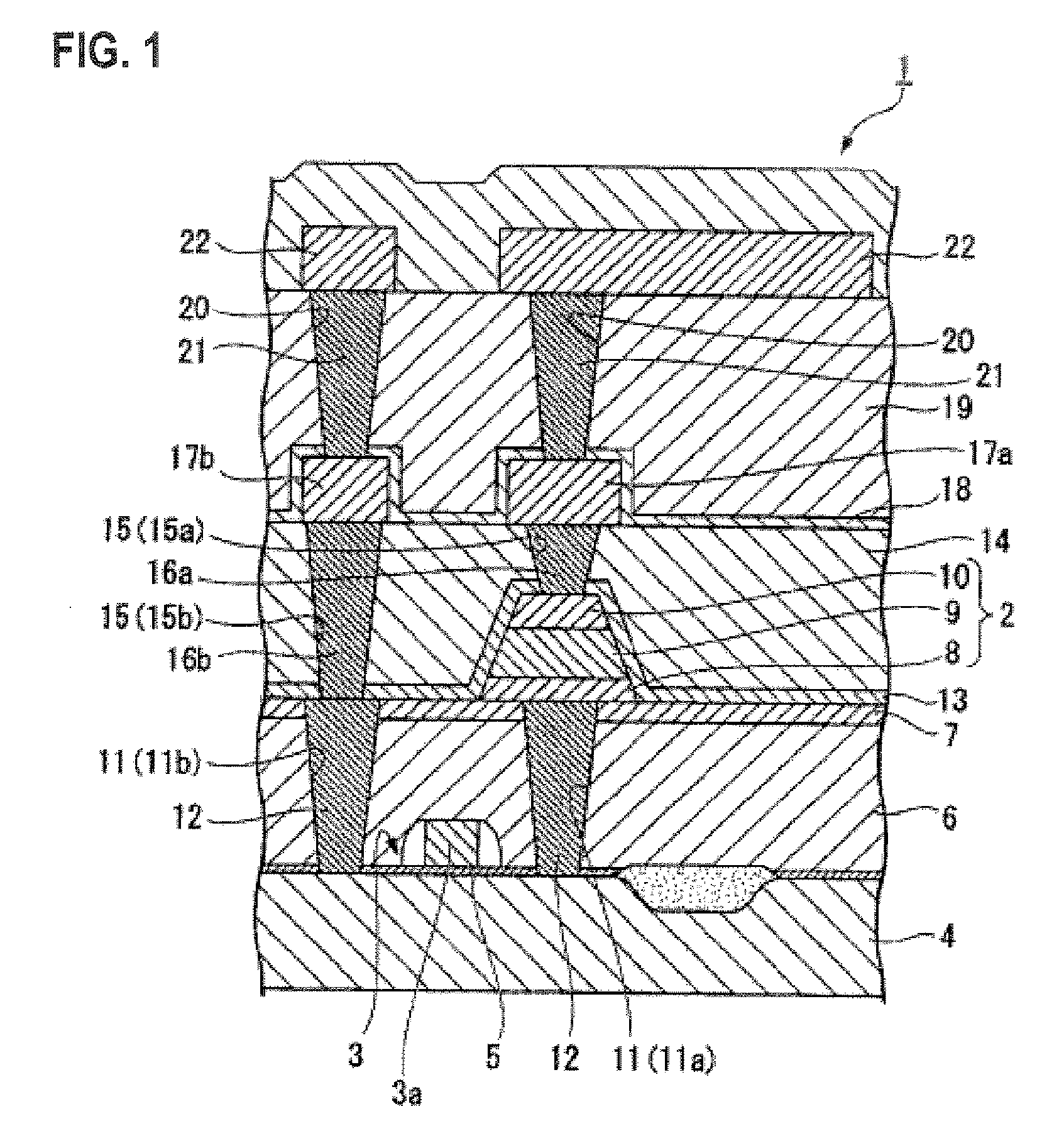

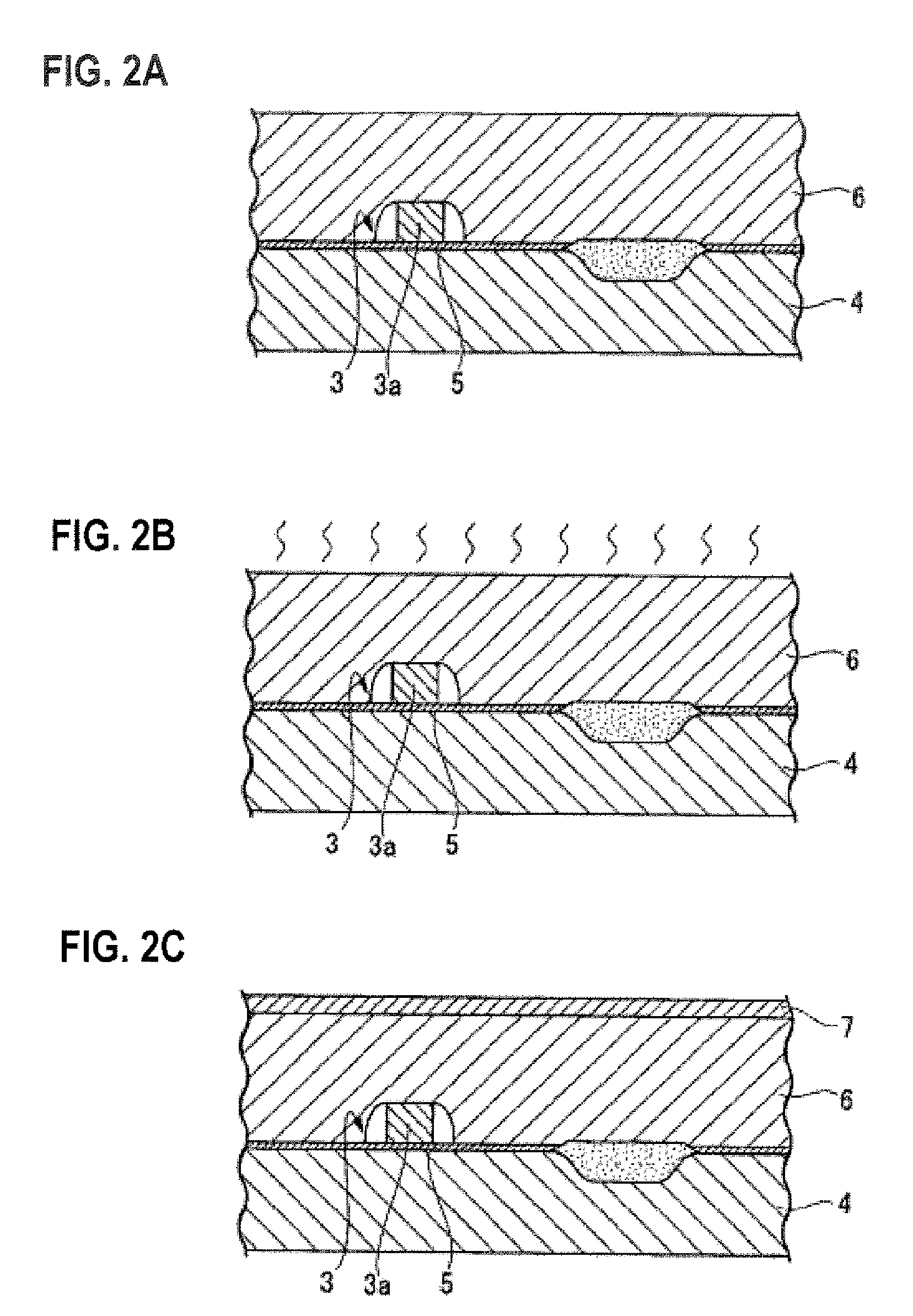

Method for Manufacturing Ferroelectric Memory

InactiveUS20070134817A1Influence layerImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDielectricEngineering

A method for manufacturing a ferroelectric memory includes the steps of forming a driving transistor on a semiconductor substrate, forming a first interlayer dielectric film that covers the driving transistor on the semiconductor substrate, forming a first hydrogen barrier film on the first interlayer dielectric film, and forming a ferroelectric capacitor electrically connected to the driving transistor on the first hydrogen barrier film, wherein hydrogen sintering treatment is conducted between the step of forming the driving transistor and the step of forming the first hydrogen barrier film.

Owner:SEIKO EPSON CORP

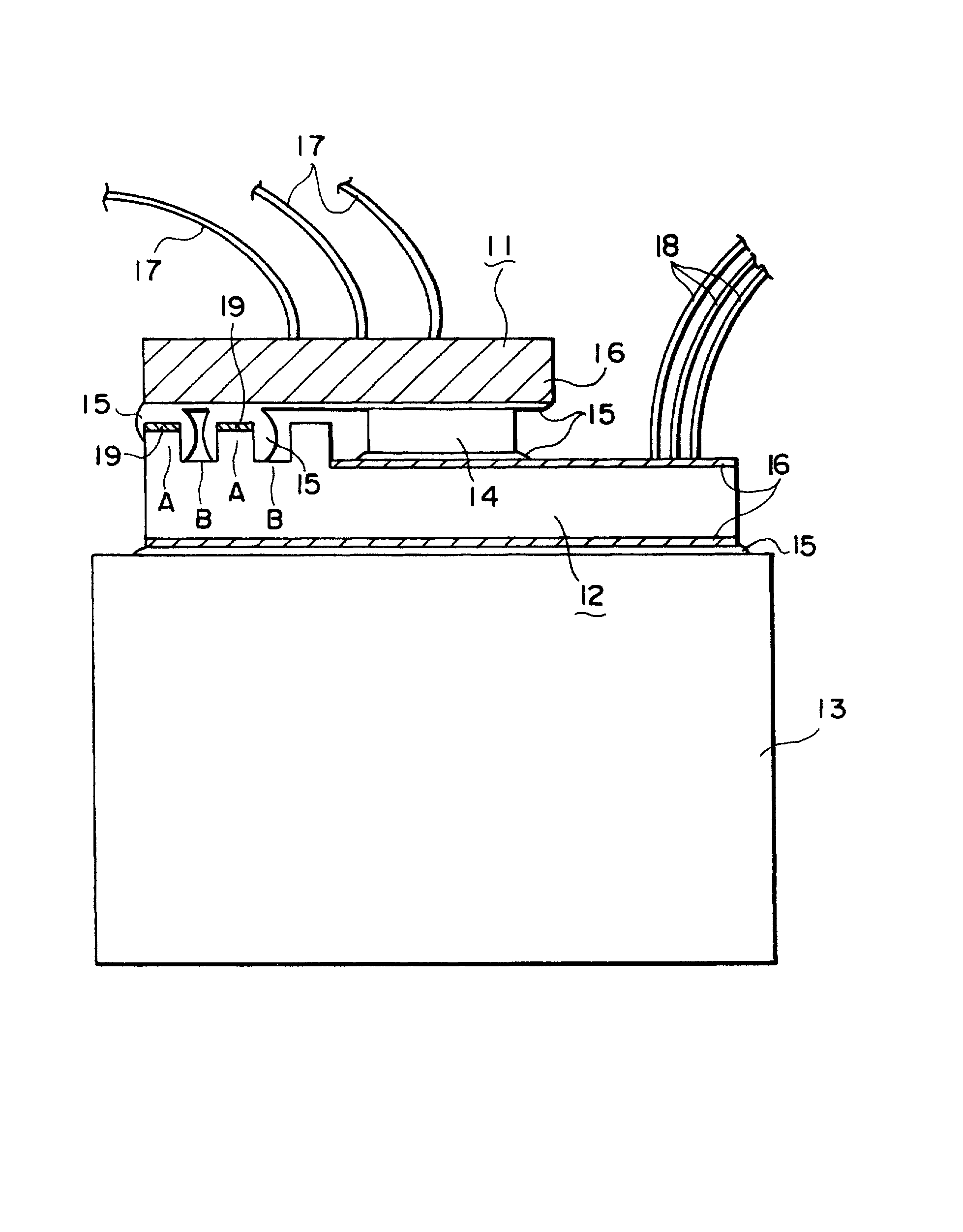

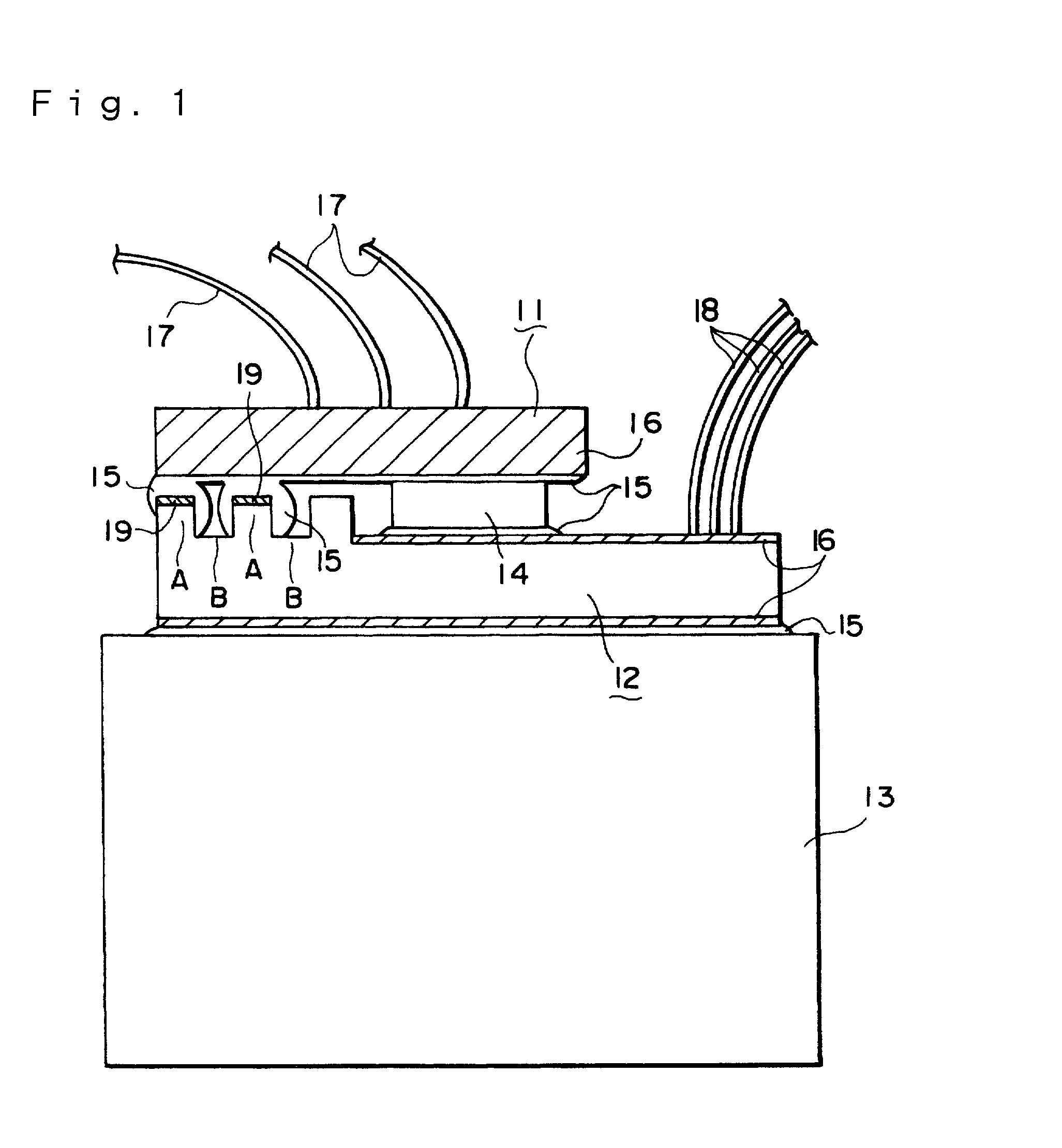

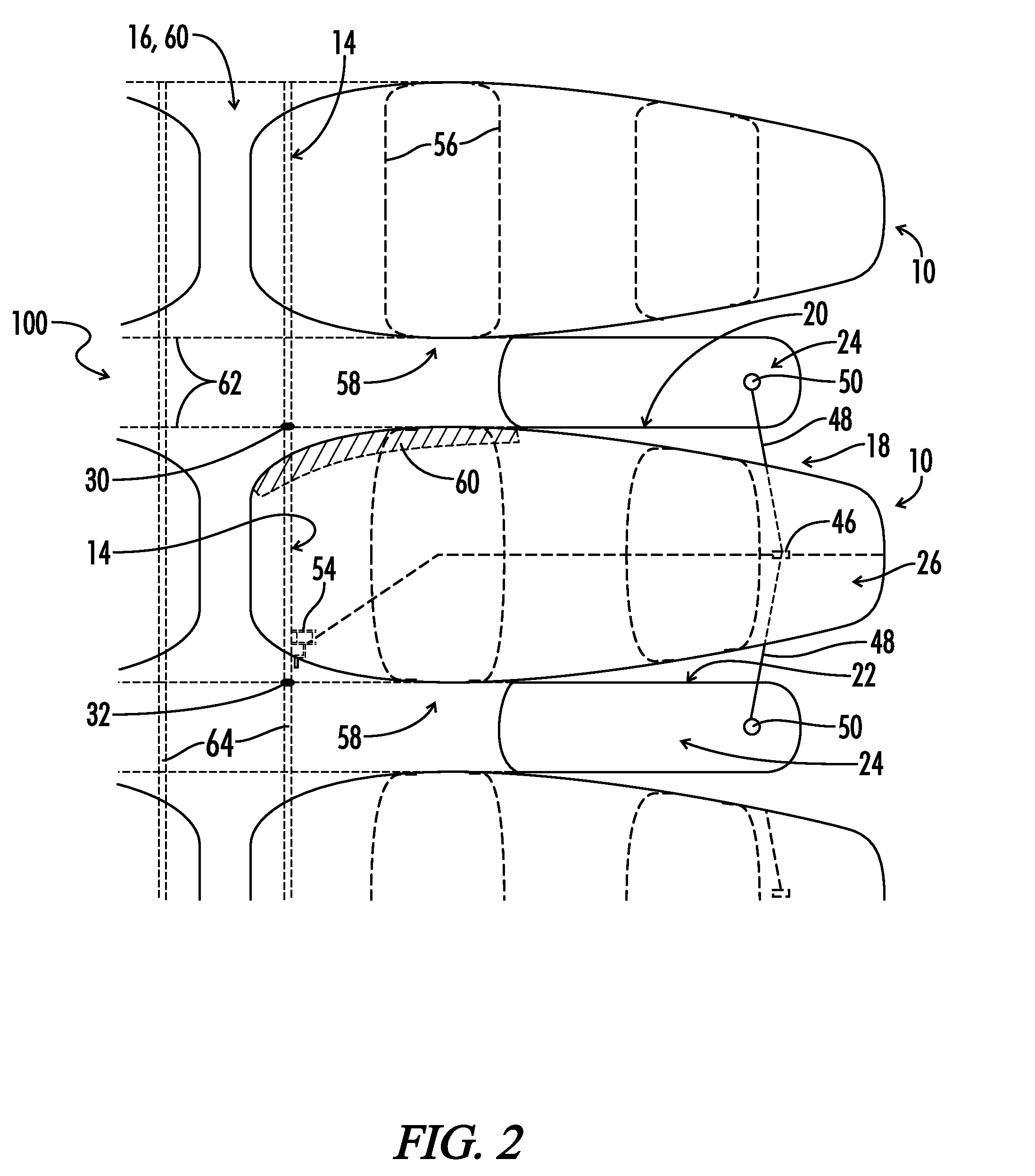

Semiconductor light emitting device

InactiveUS20020063329A1Desired effectLaser detailsSemiconductor/solid-state device detailsOptical couplingLight emitting device

The present invention discloses a semiconductor light emitting device comprising at least one semiconductor light emitting element of edge-emission type, a first heat sink and a second heat sink, wherein at least apart of an electrode for the first-conduction-type semiconductor of the semiconductor light emitting element is in contact with the first heat sink; at least a part of an electrode for the second-conduction-type semiconductor of the semiconductor light emitting element is in contact with the second heat sink; and the first heat sink and the second heat sink are in contact with each other in a junction overlooking one of the two side planes which do not compose the facets of the cavity in the semiconductor light emitting element. The semiconductor light emitting device of the present invention is characterized by having excellent heat spreading, allowing easy and reproducible assembling even if the components or the element composing the semiconductor light emitting device have dimensional errors, and allowing simple optical coupling with an optical fiber or the like.

Owner:MITSUBISHI CHEM CORP

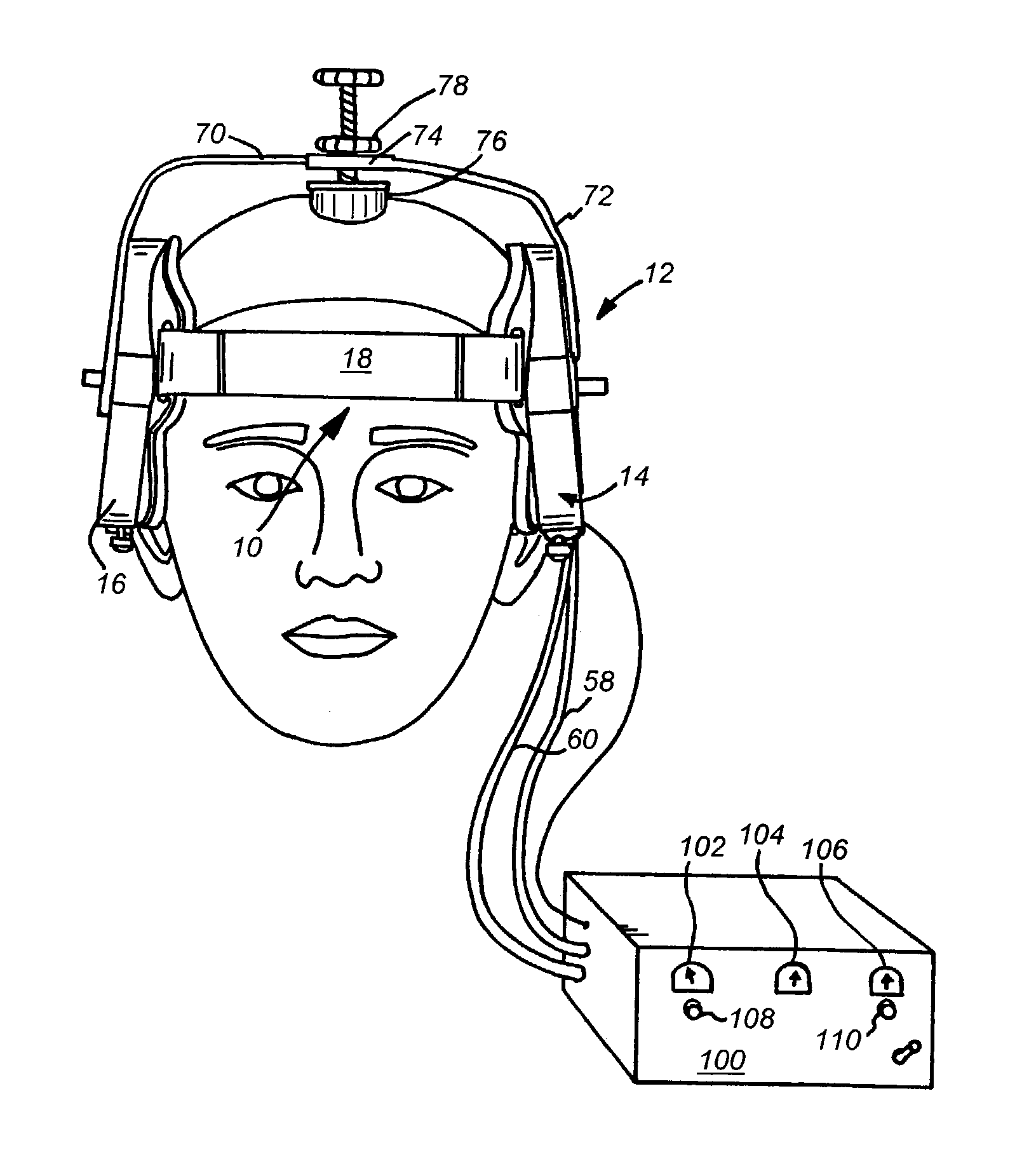

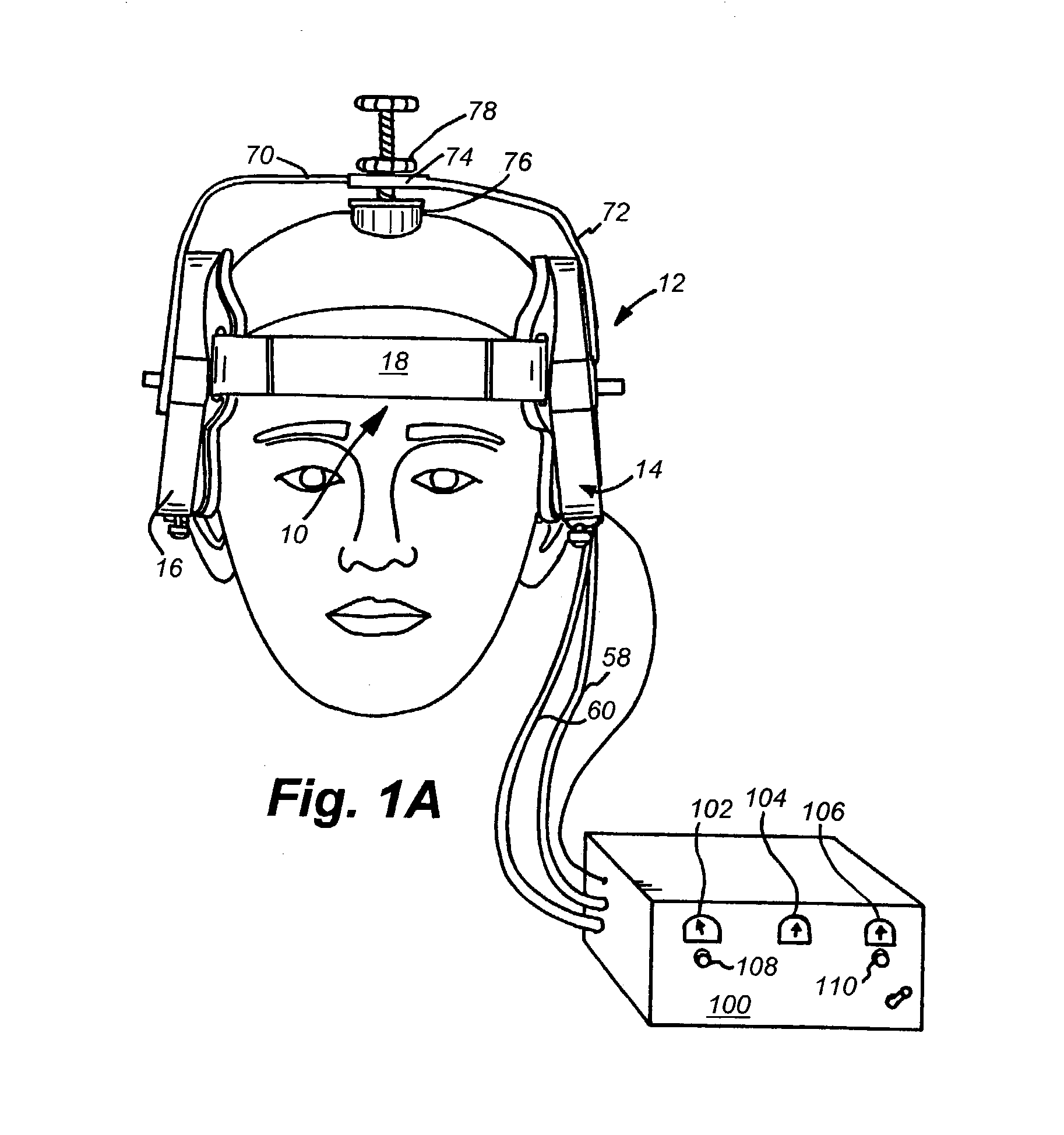

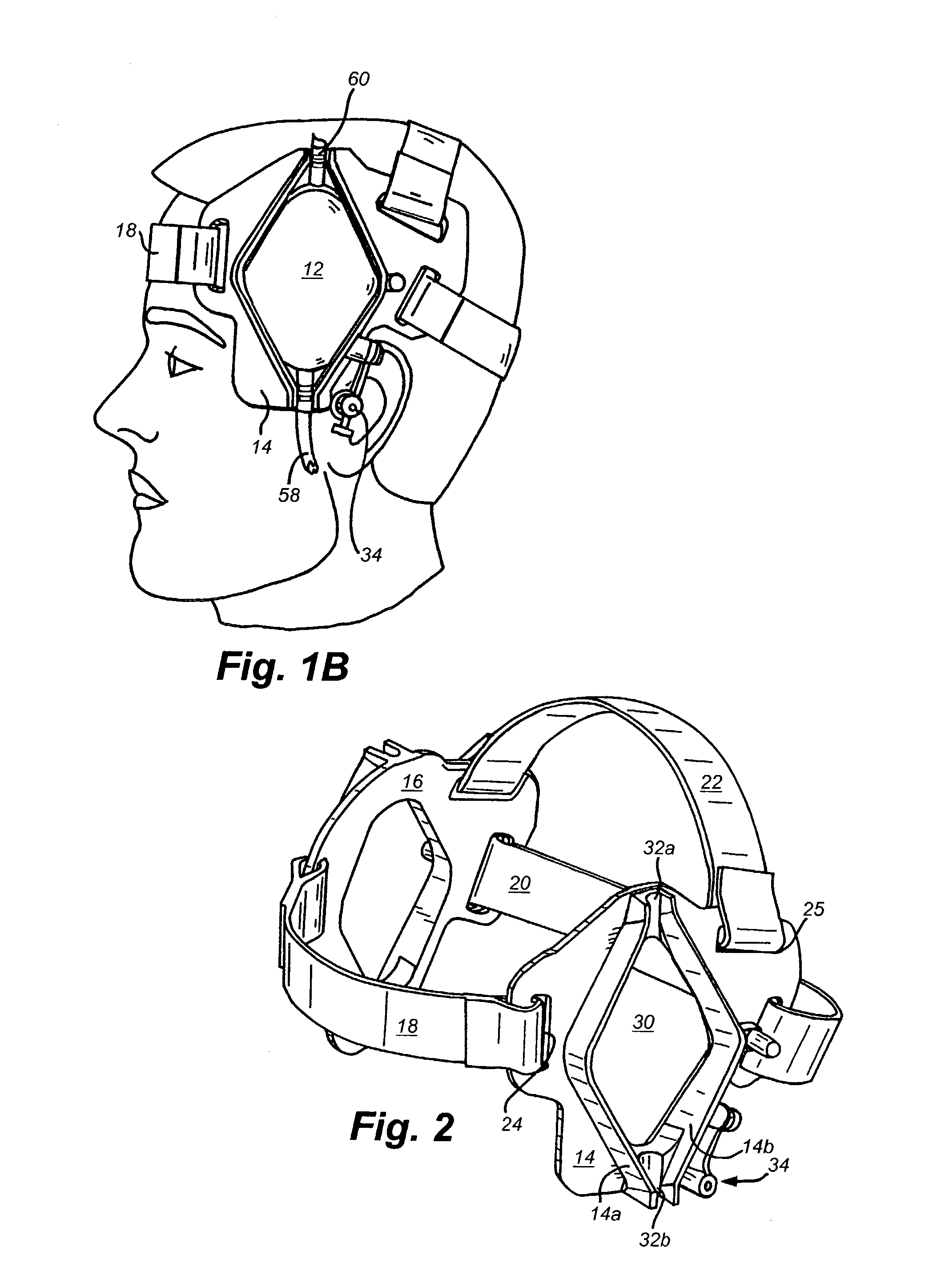

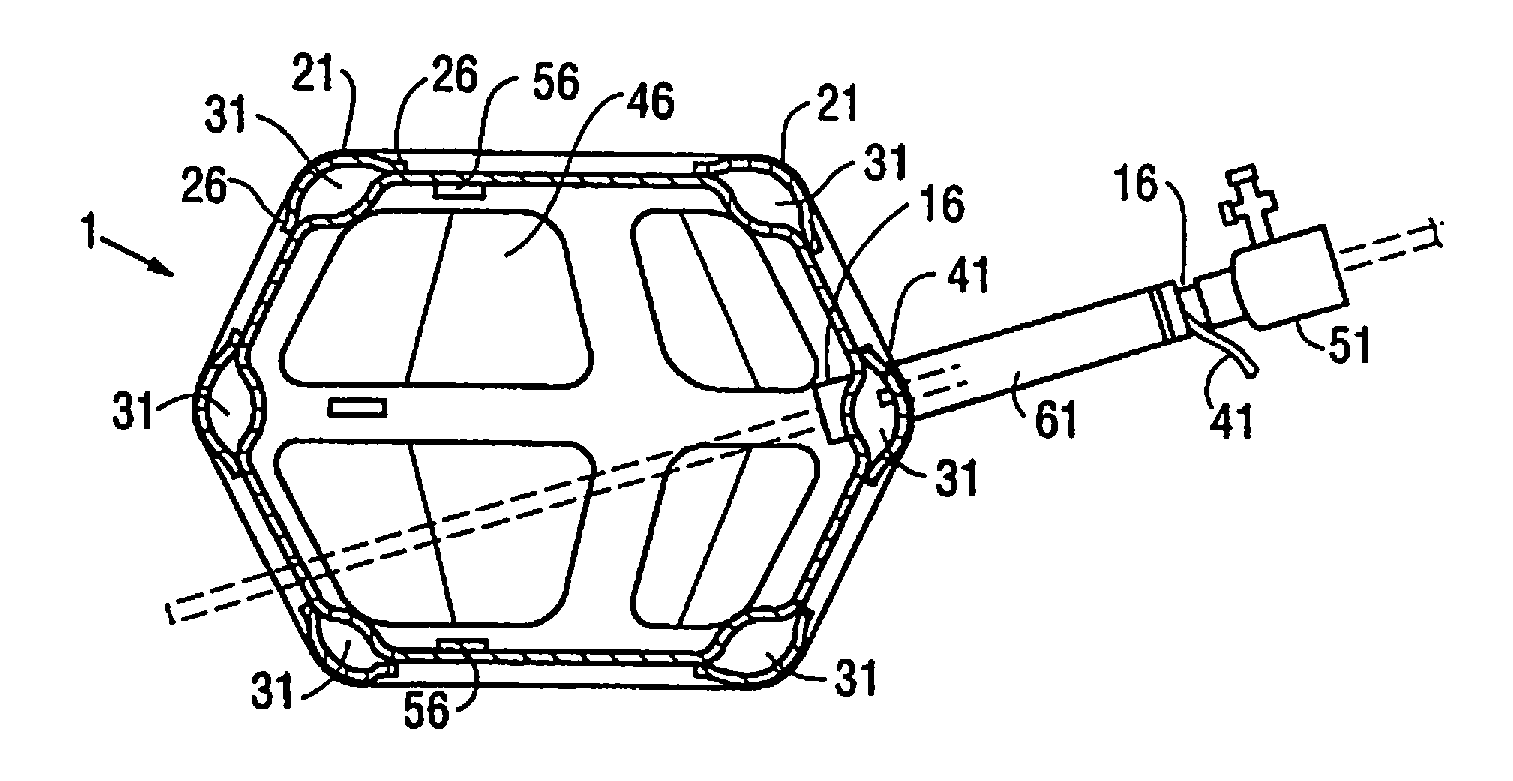

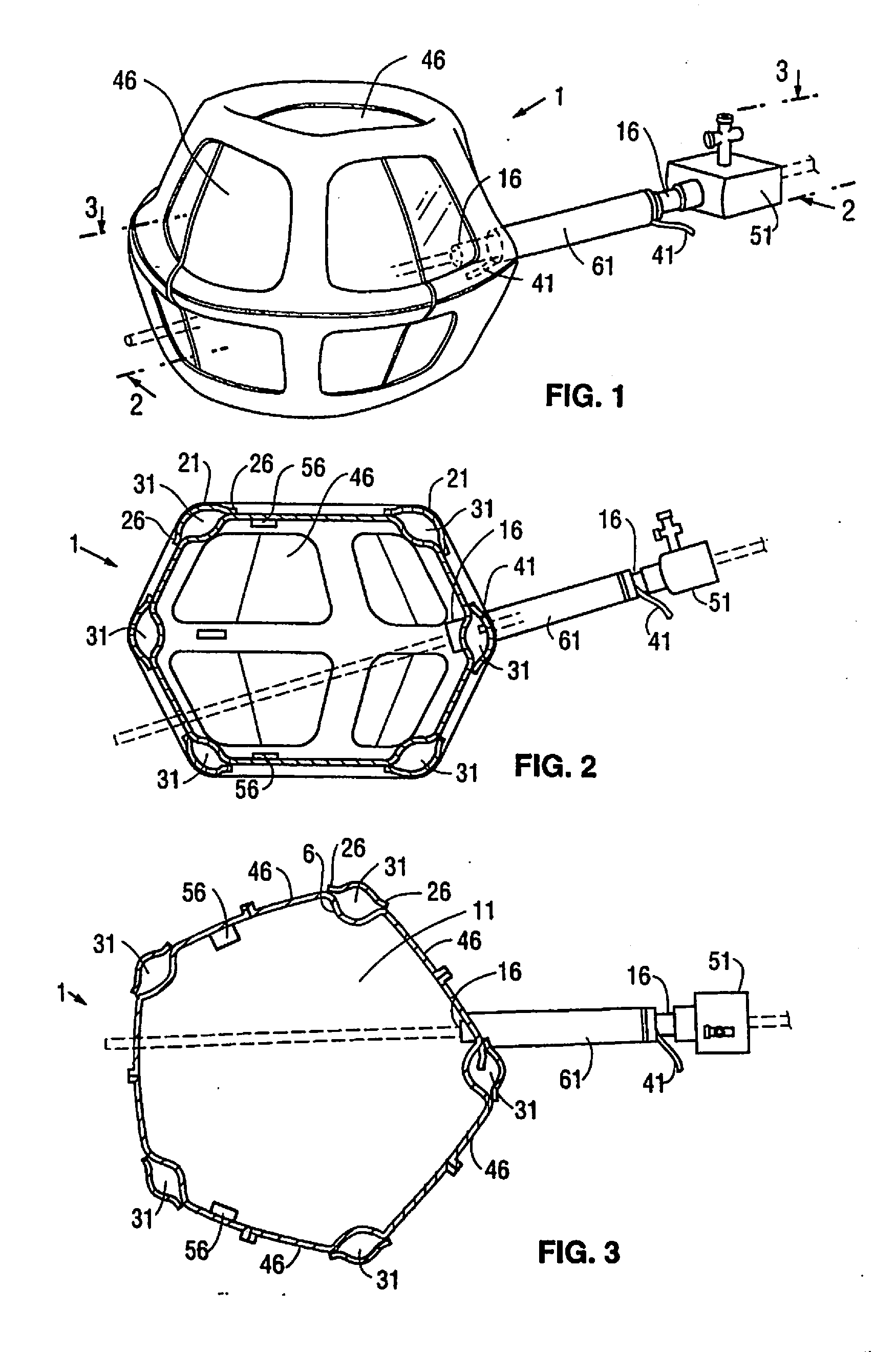

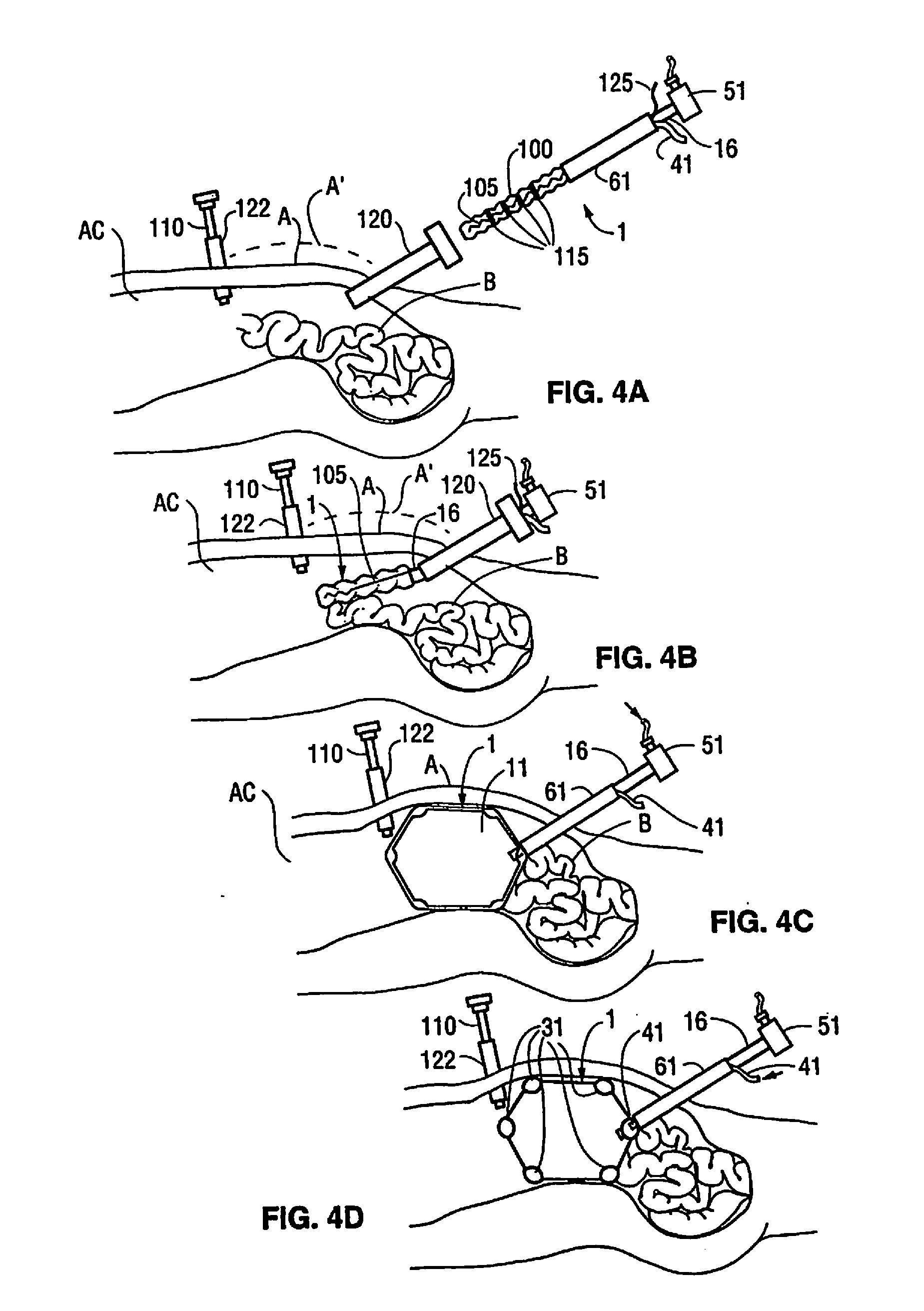

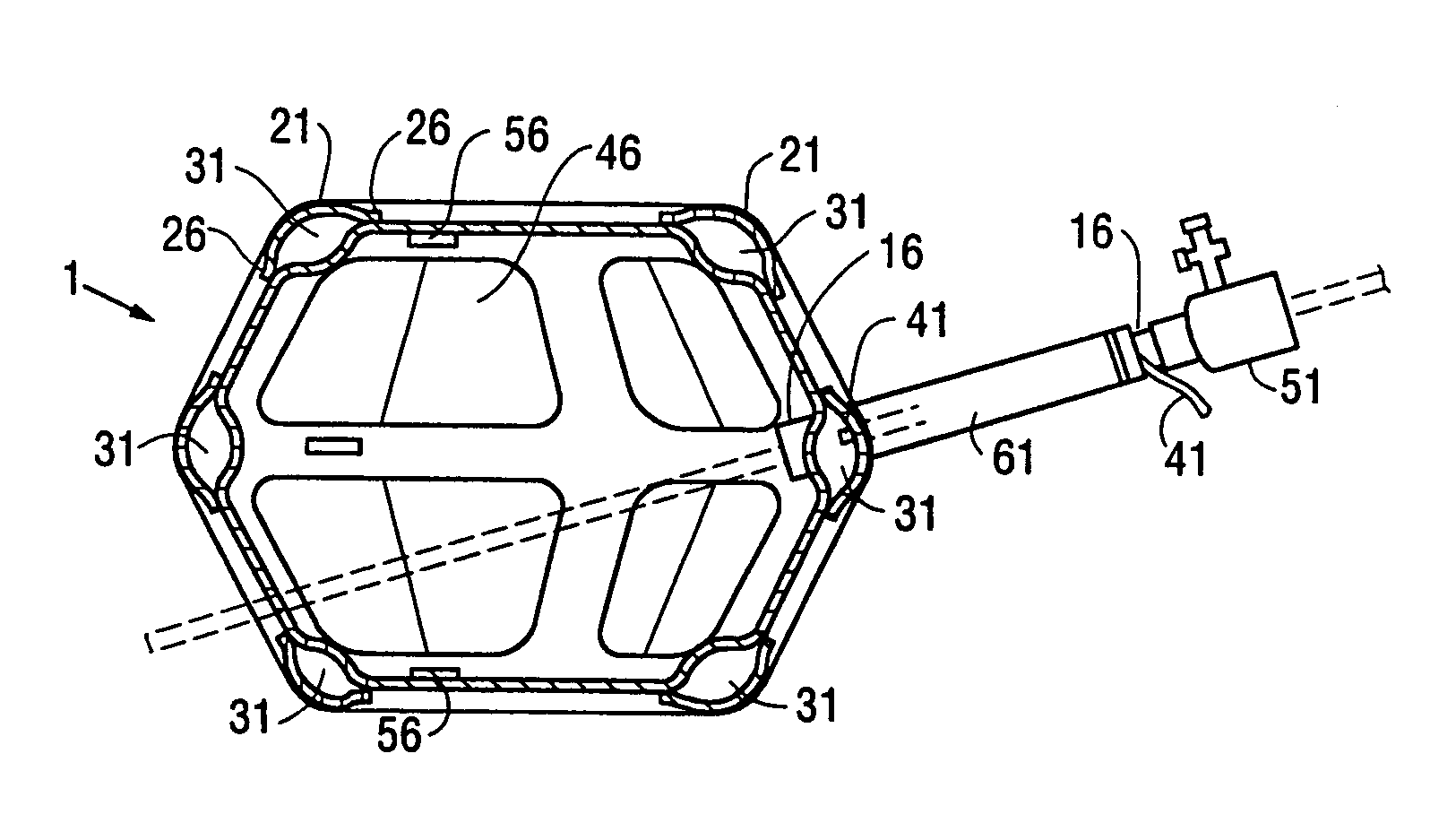

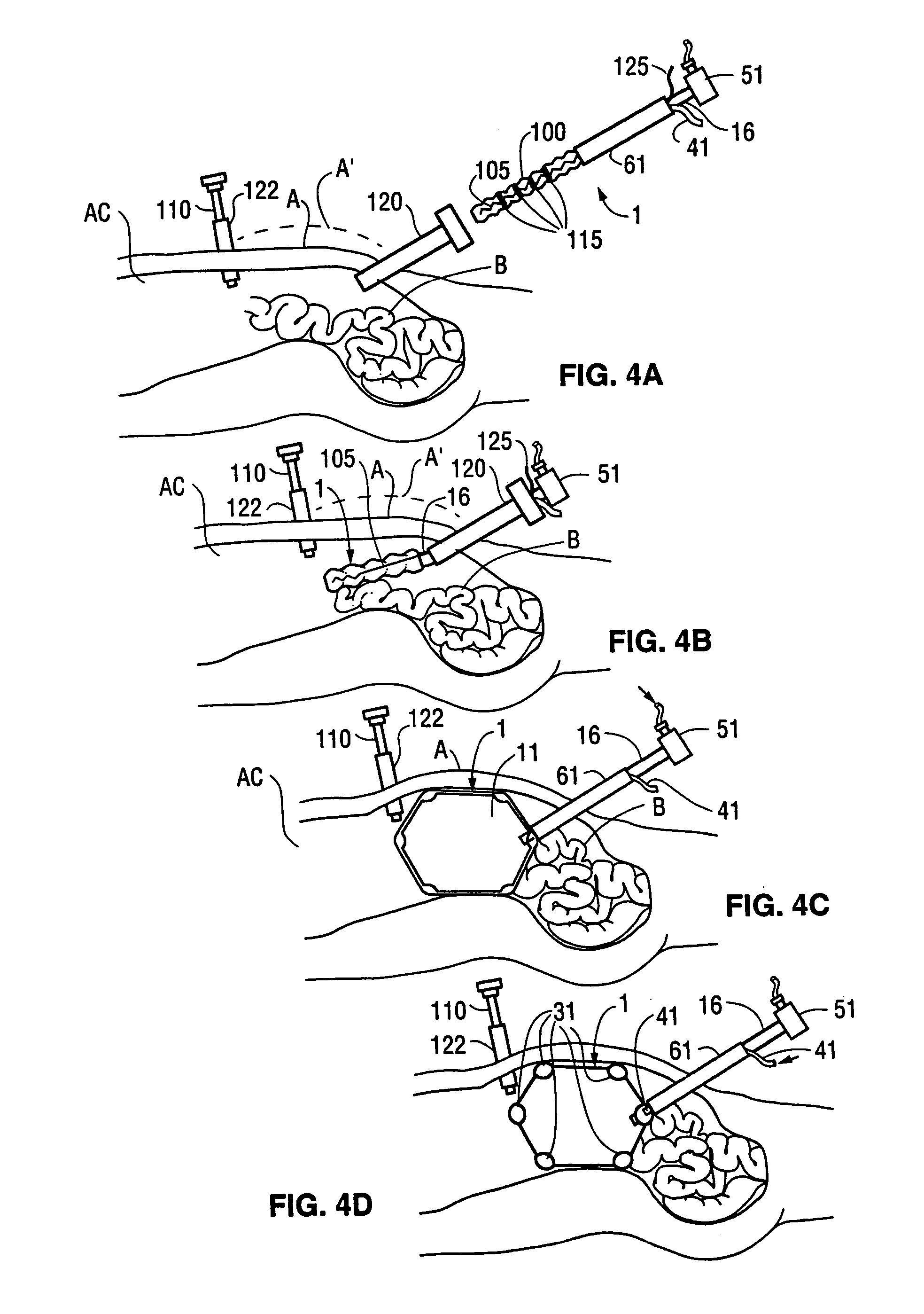

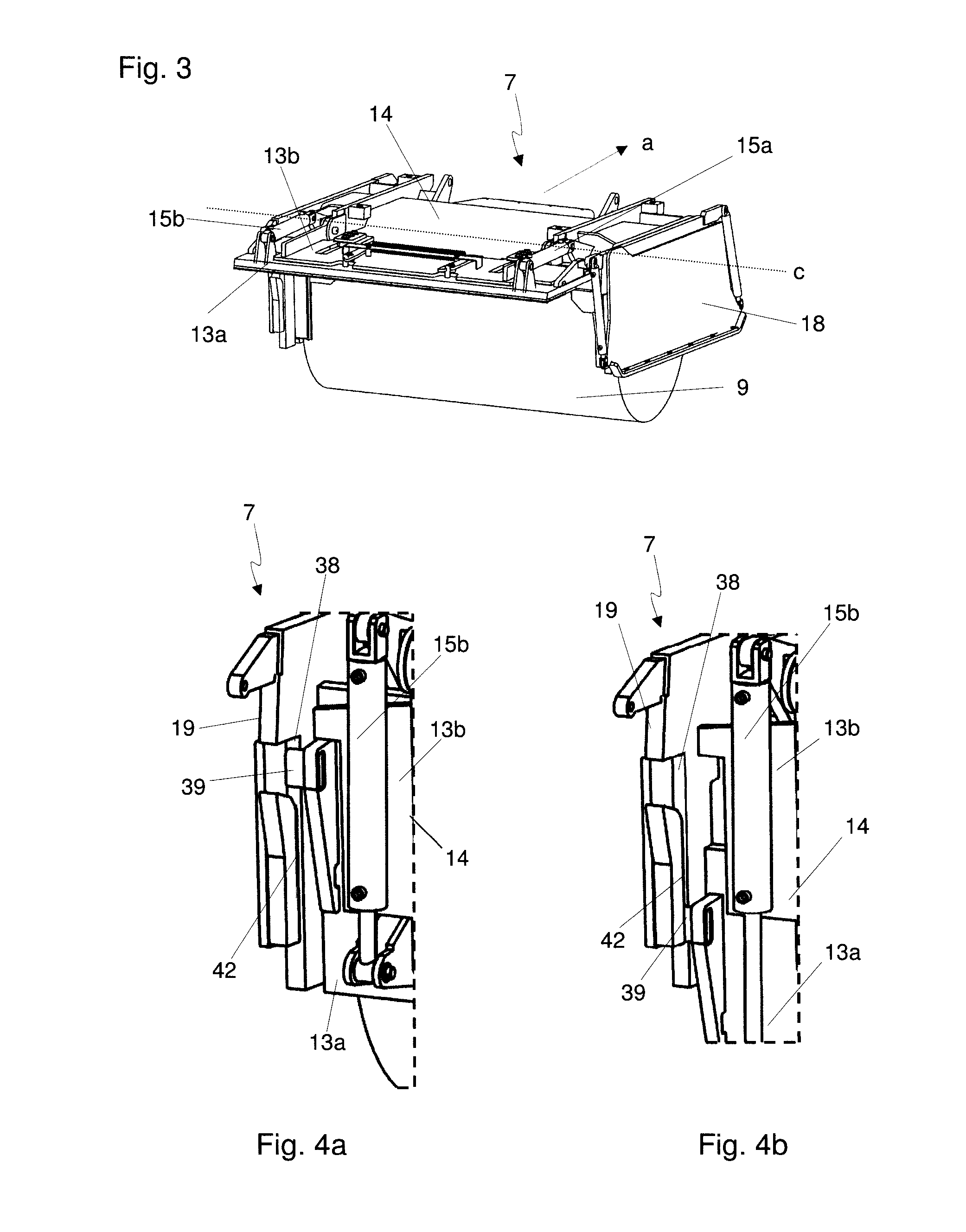

Encephalic insonication

ActiveUS8353853B1Remove heat generatedImprove transmission efficiencyUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyHuman bodyTransducer

Apparatus for encephalic insonication, comprising a transducer array configured to safely insonicate a field in a human body of a size comparable to the spatial extent of the array itself. The array comprises a plurality of acoustic transducers arranged in a polygonal configuration and energized in subsets at frequencies between 200 and 400 kHz. A relatively uniform insonication of a field comparable in size to that of significant anatomical regions of the brain is obtained by driving the transducers in each subset in opposed phase relationship during at least part of the interval during which they are active. A pulsed driving scheme enables minimization of heating effects while providing significant therapeutic treatment. The apparatus is useful both with and without additional lytic agents.

Owner:BOSTON SCI SCIMED INC

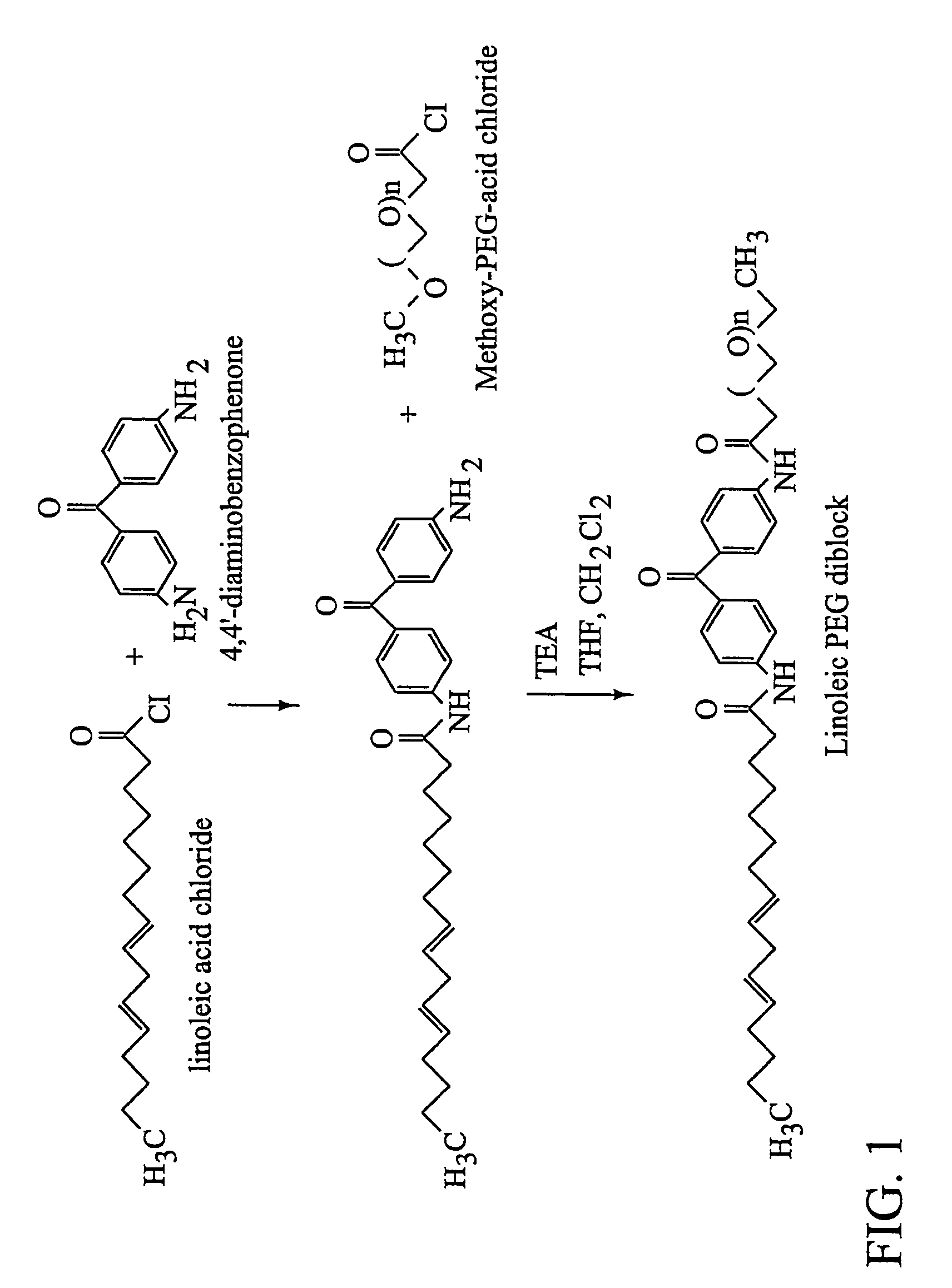

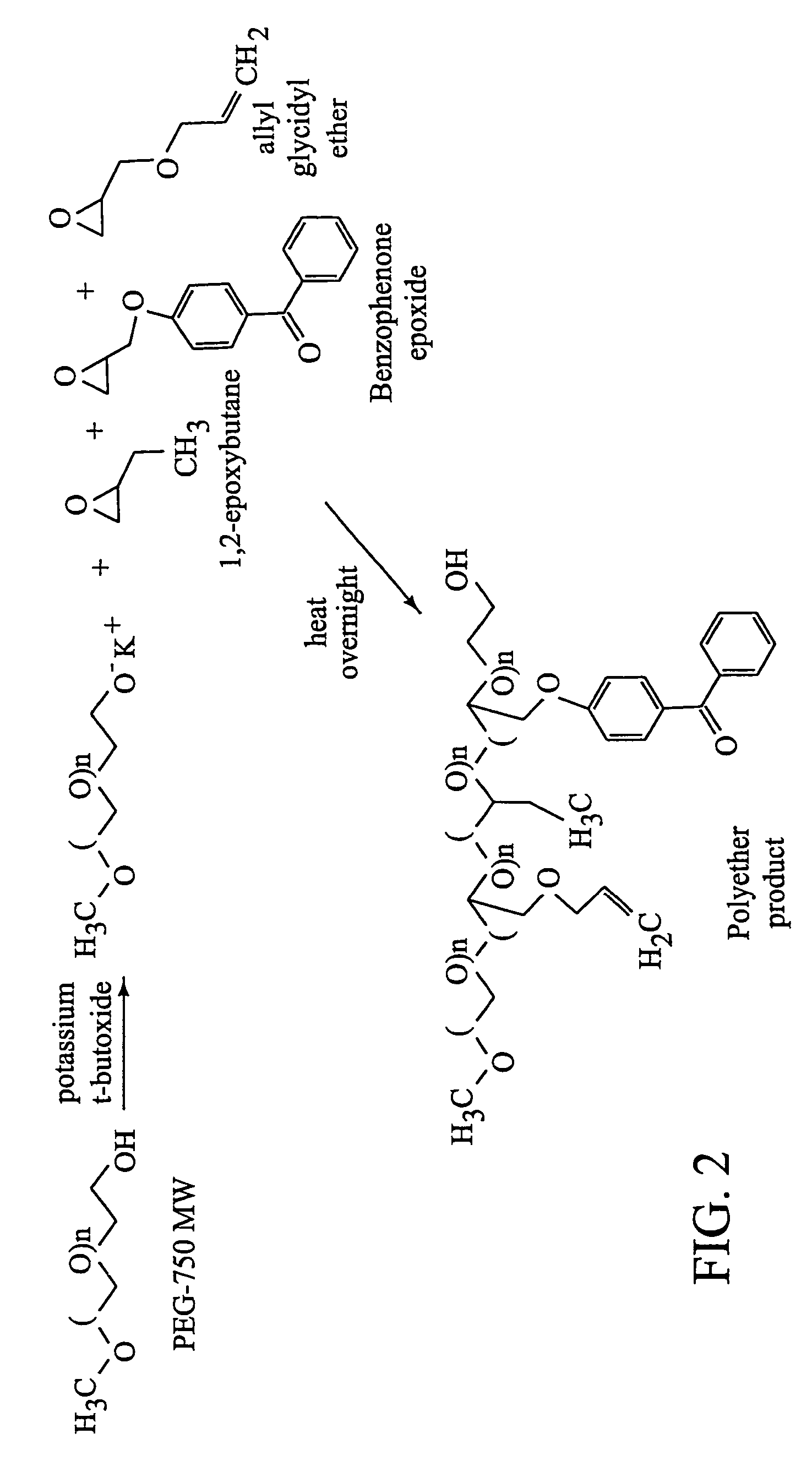

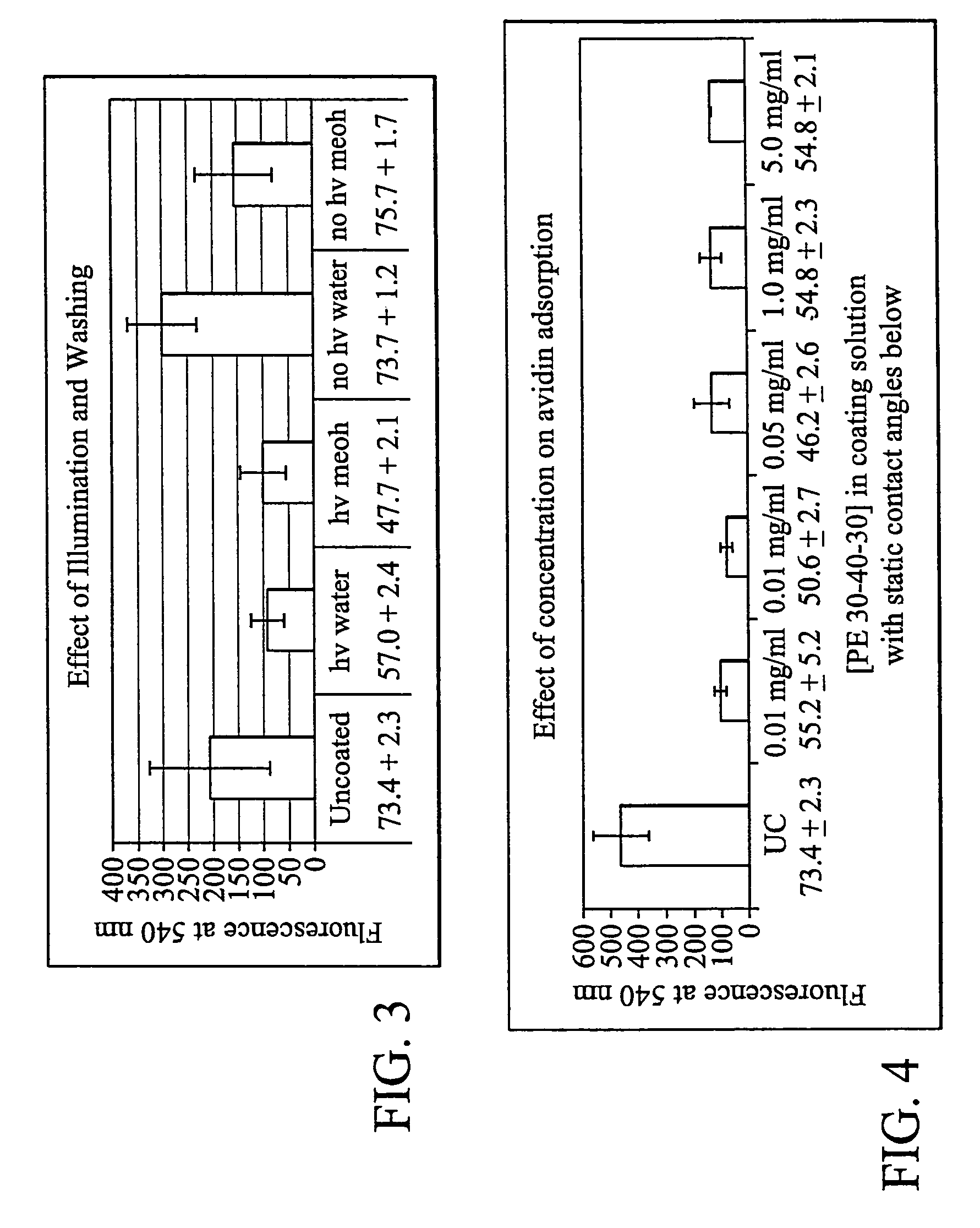

Self assembling monolayer compositions

InactiveUS7361724B2Retains and improves characteristicRetains and improves and performanceMaterial nanotechnologyPretreated surfacesSelf-assembled monolayerMedical device

A surface coating composition for providing a self-assembling monolayer, in stable form, on a material surface or at a suitable interface, as well as a method of preparing such a composition and a method of using such a composition to coat a surface, such as the surface of an implantable medical device, in order to provide the surface with desirable properties. The method provides the covalent attachment of a SAM to a surface in a manner that substantially retains or improves the characteristics and / or performance of both the SAM and the surface itself. Covalent attachment is accomplished by the use of one or more latent reactive groups, e.g., provided by either the surface and / or by the SAM-forming molecules themselves.

Owner:SURMODICS INC

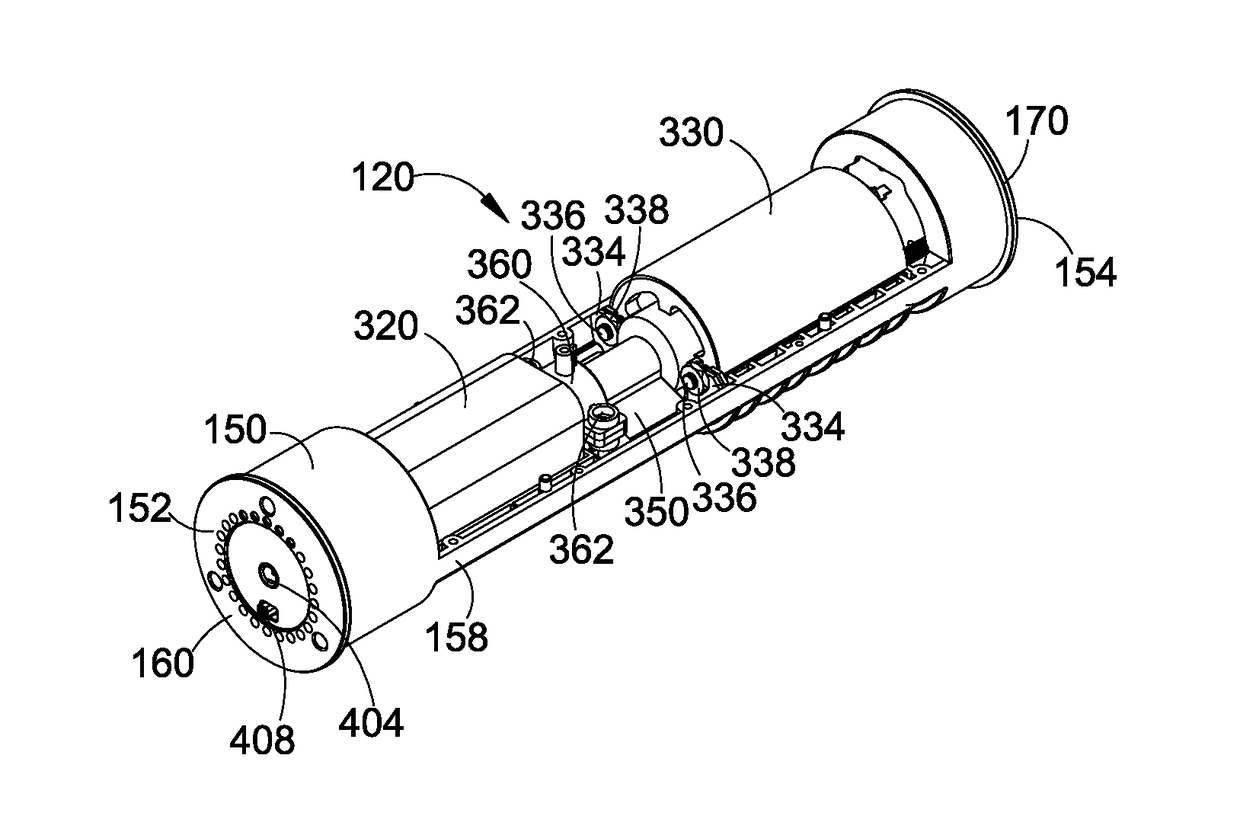

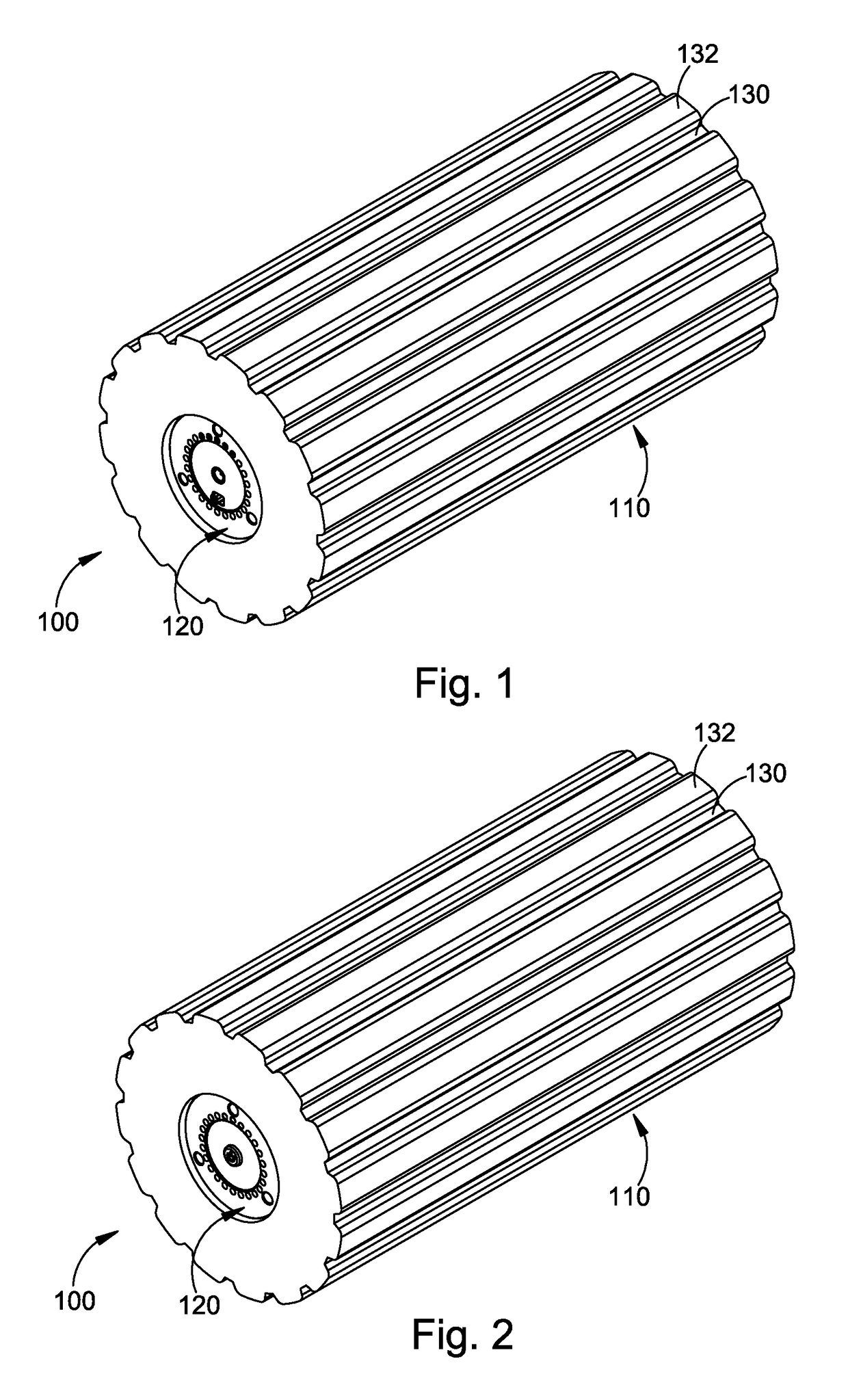

Therapeutic vibrating roller

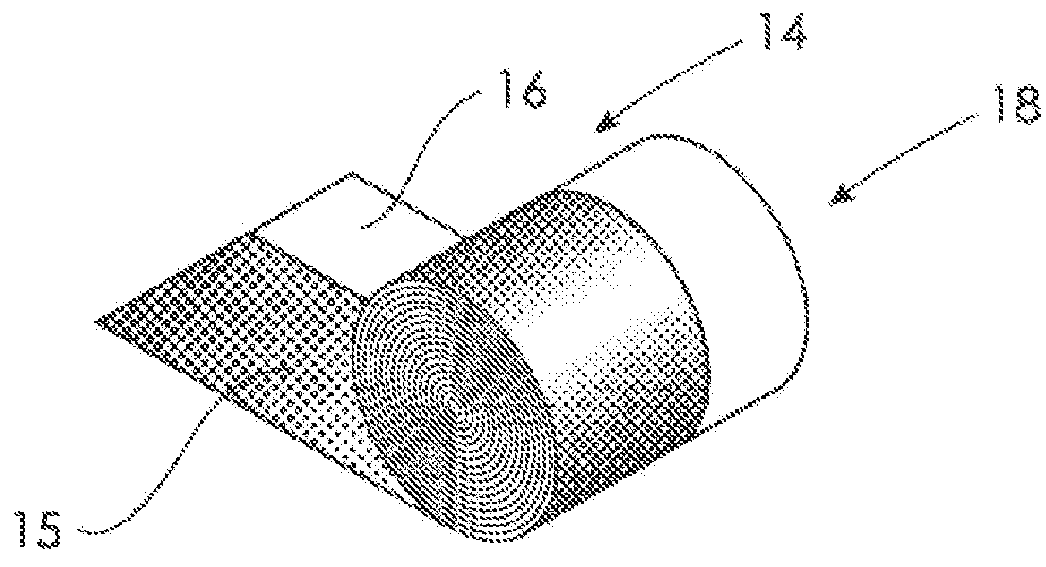

ActiveUS9968513B1Great amplitudeDesired effectVibration massageRoller massageAngular velocityElectric motor

A portable vibrating roller includes an outer roller structure having a plurality of grooves and ribs. A hollow cylindrical bore extends longitudinally through the shell. A vibration system having a first end cap and a second end cap fits within the bore. A battery positioned within the shell near one end cap provides electrical power to a motor positioned within the shell near the other end cap to cause the motor to rotate an output shaft at a plurality of angular velocities to rotate an eccentric mass located approximately midway between the two end caps. The rotating eccentric mass causes vibration. A motor control circuit receives input power from a battery and selectively provides output power to the motor in response to the operation of a switch on the first end cap. The output power is varied to control the angular velocity of the output shaft of the motor and to thereby control a frequency of vibration caused by the eccentric mass.

Owner:HYPERICE IP SUBCO LLC

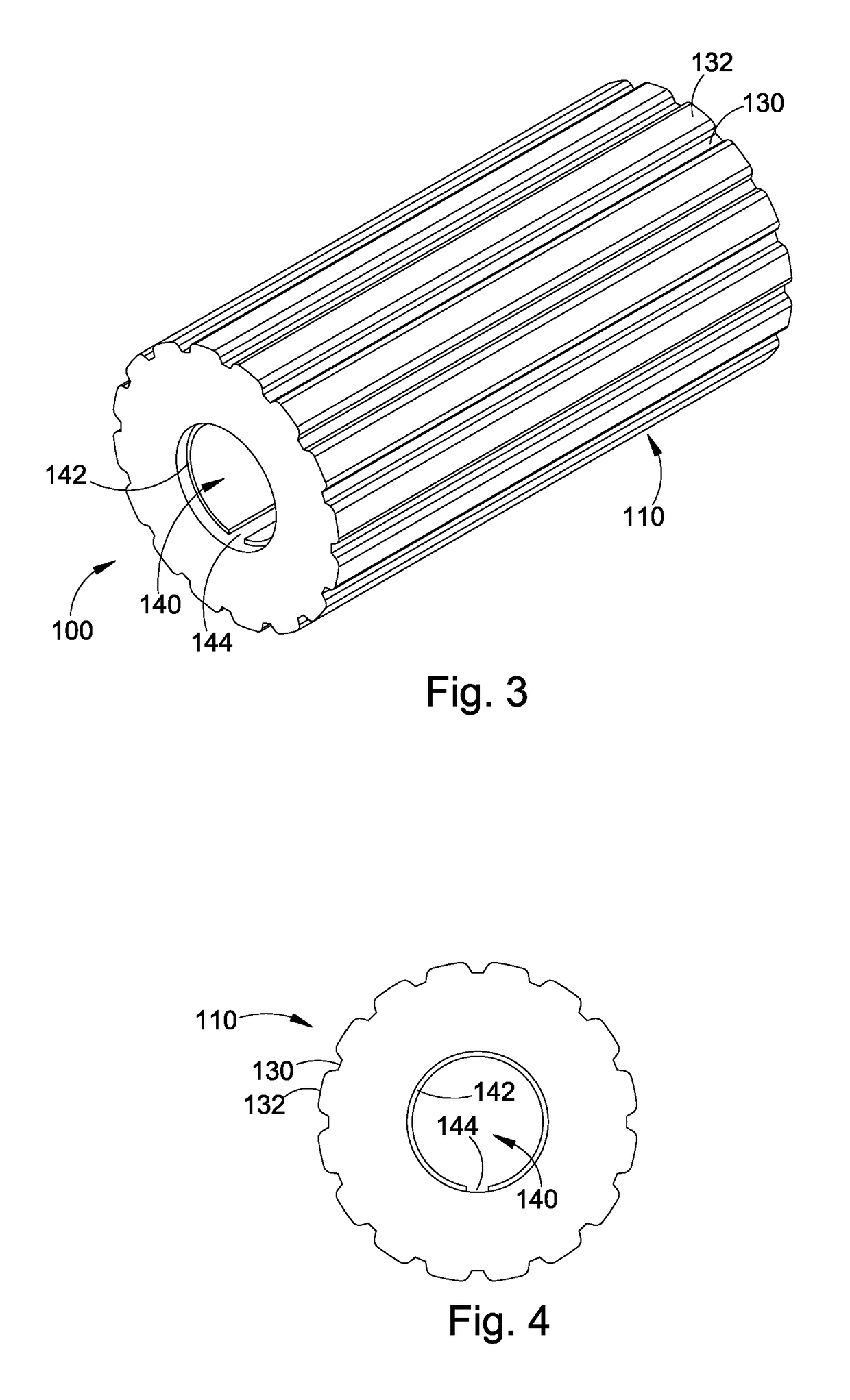

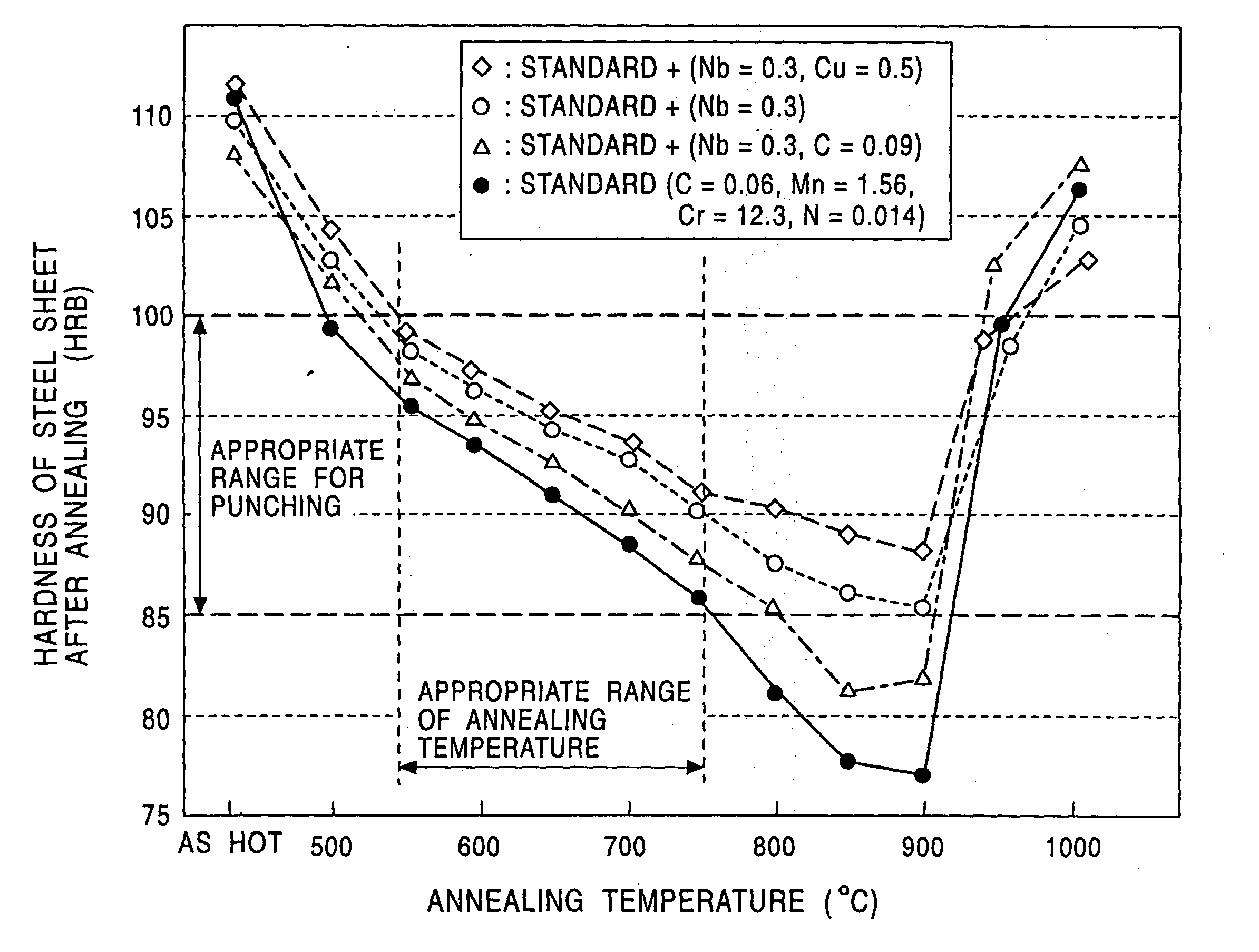

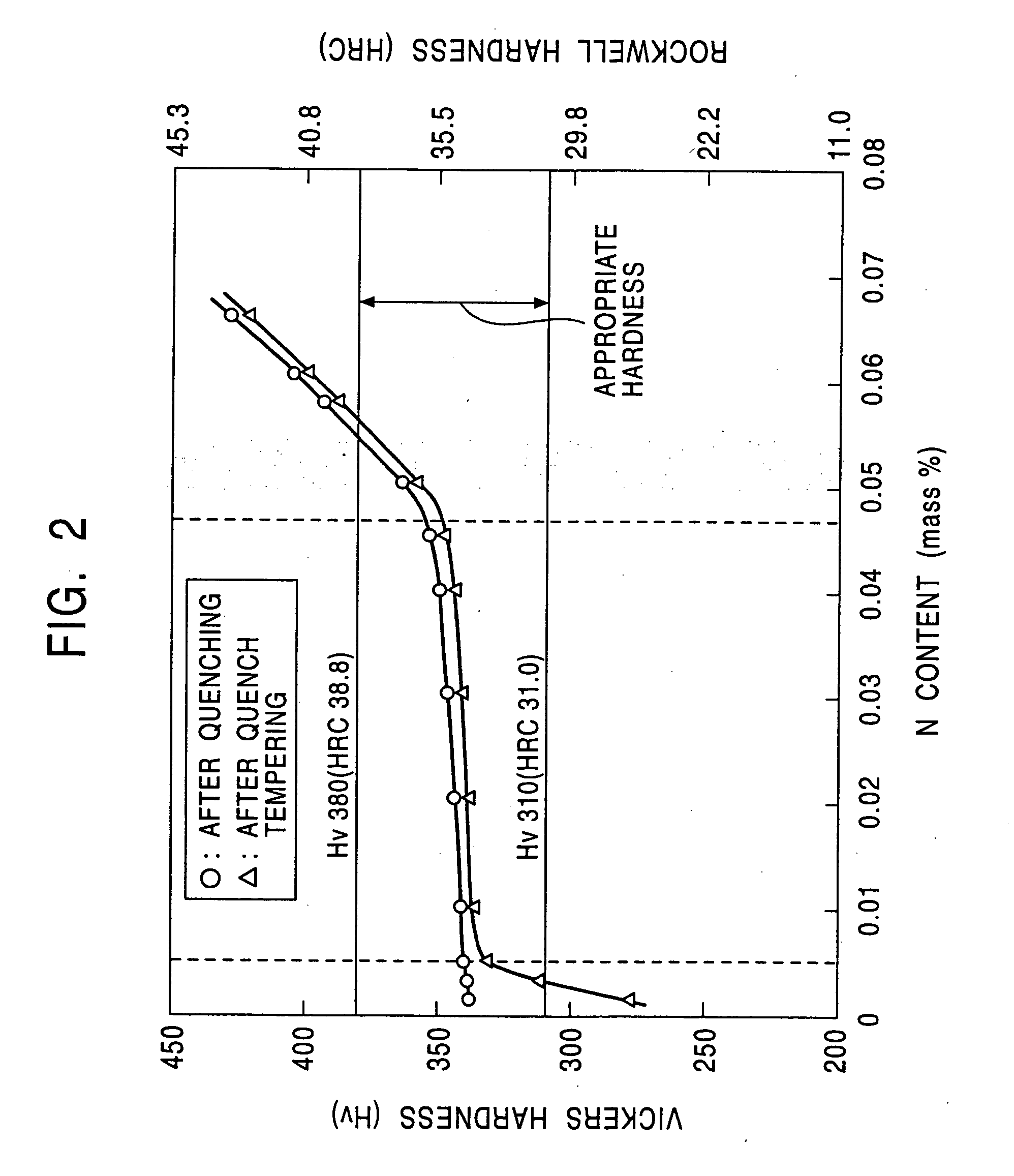

Low carbon martensitic stainless steel and method for production thereof

The present invention provides a martensitic stainless steel sheet which is hard to be softened by tempering caused by heating during the use of a disk brake, can maintain the predetermined hardness, and has excellent punching workability, bending workability before quenching, and a particularly small shear drop, and in which a predetermined hardness after quenching is constantly achieved, in a low carbon martensitic stainless steel sheet used only after quenching. Specifically, the sheet contains, on the basis of mass percent, 0.030% to 0.100% C; 0.50% or less of Si; 1.00% to 2.50% Mn; more than 10.00% to 15.00% Cr; at least one selected from the group consisting-of 0.01% to 0.50% Ti, 0.01% to 0.50% V, 0.01% to 1.00% Nb, and 0.01% to 1.00% Zr; N in an amount defined by the following expression, N: 0.005% to (Ti+V)x{fraction (14 / 50+(Nb+Zr)x{fraction (14 / 90; and the balance being Fe and incidental impurities. The sheet further contains, on the basis of mass percent, more than 0.040% to 0.100% C+N and 0.02% to 0.50% in total of at least one selected from the group consisting of 0.01% to 0.50% V, 0.01% to 0.50% Nb, 0.01% to 0.50% Ti, 0.01% to 0.50% Zr, 0.50% or less of Ta, and 0.50% or less of Hf, and further contains Mo, B, Co, W, Ca, and Mg according to needs. The martensitic stainless steel having the above composition is formed into a hot-rolled steel sheet having an HRB hardness of 85 to 100 after annealing in the range of 550° C. to 750° C.

Owner:JFE STEEL CORP

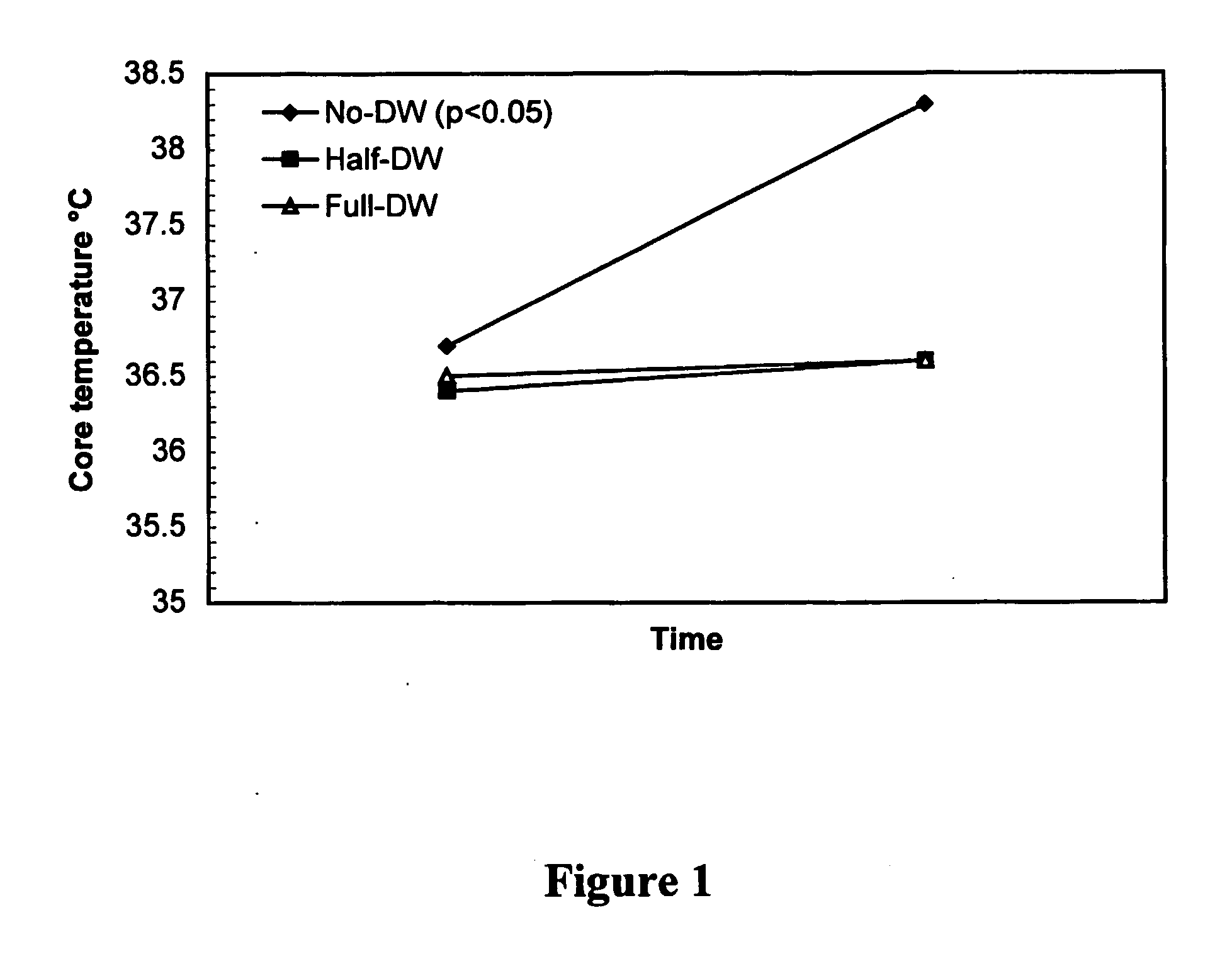

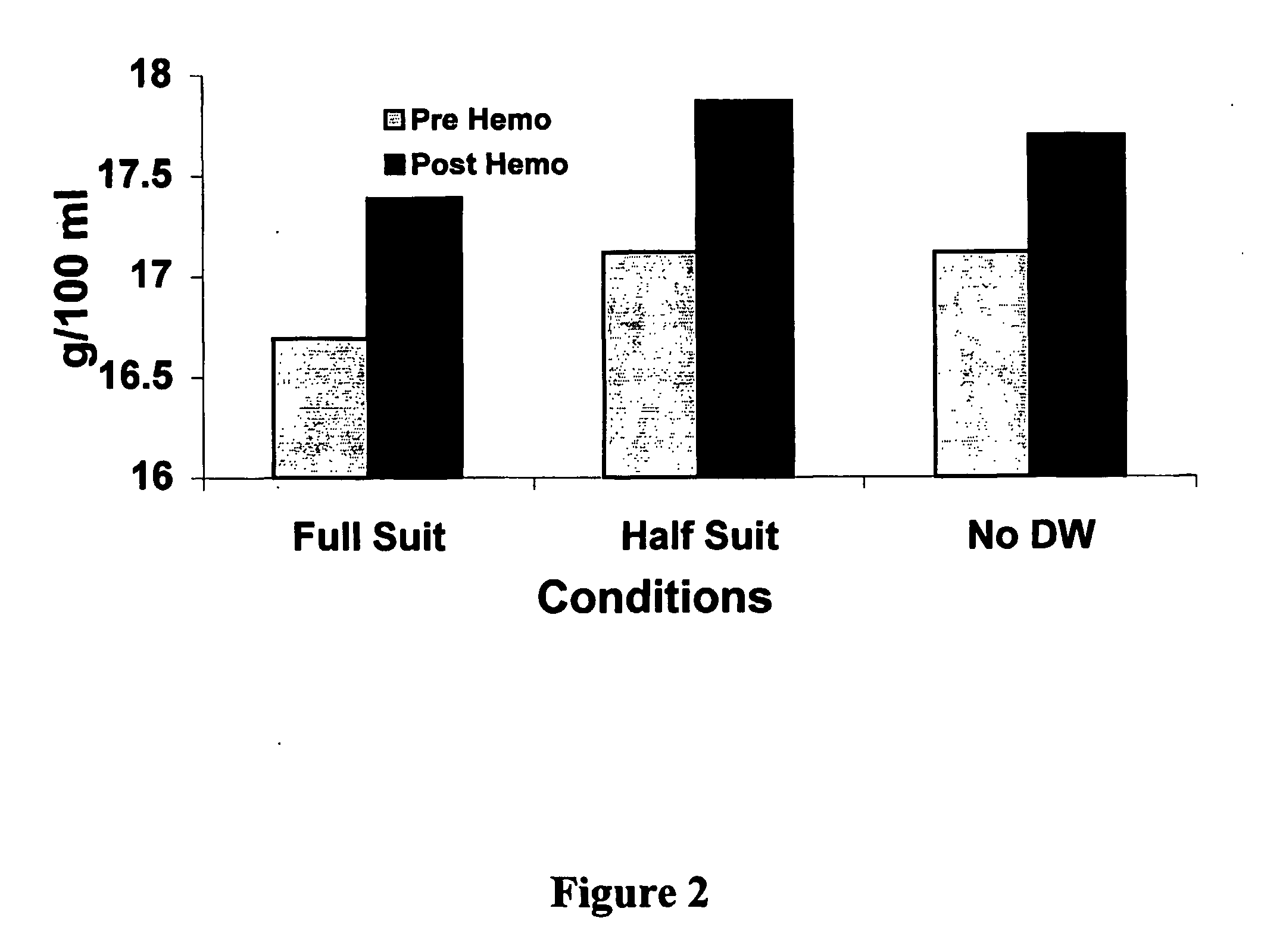

Use of thermoregulatory material to improve exercise performance

The use of a thermoregulating composition of matter, such as DRiWATER®, to help thermoregulate a subject user is disclosed. In preferred embodiments, the composition can be situated over significant surface area portions of the user's body (such as by garment-like coverage of substantial portions of the user, on the torso, arms, legs, head, etc., for example) or it can be situated at discrete locations (such as by packs or packets of the material at strategic, heat-intensive areas of the user, for example). Additionally, the composition can be delivered by a variety of means (e.g., directly or indirectly, contained within packets made of either breathable or closed cell material, etc.) to provide the thermoregulatory effects, according to preferred embodiments of the present invention.

Owner:PATERNOSTER JOSEPH

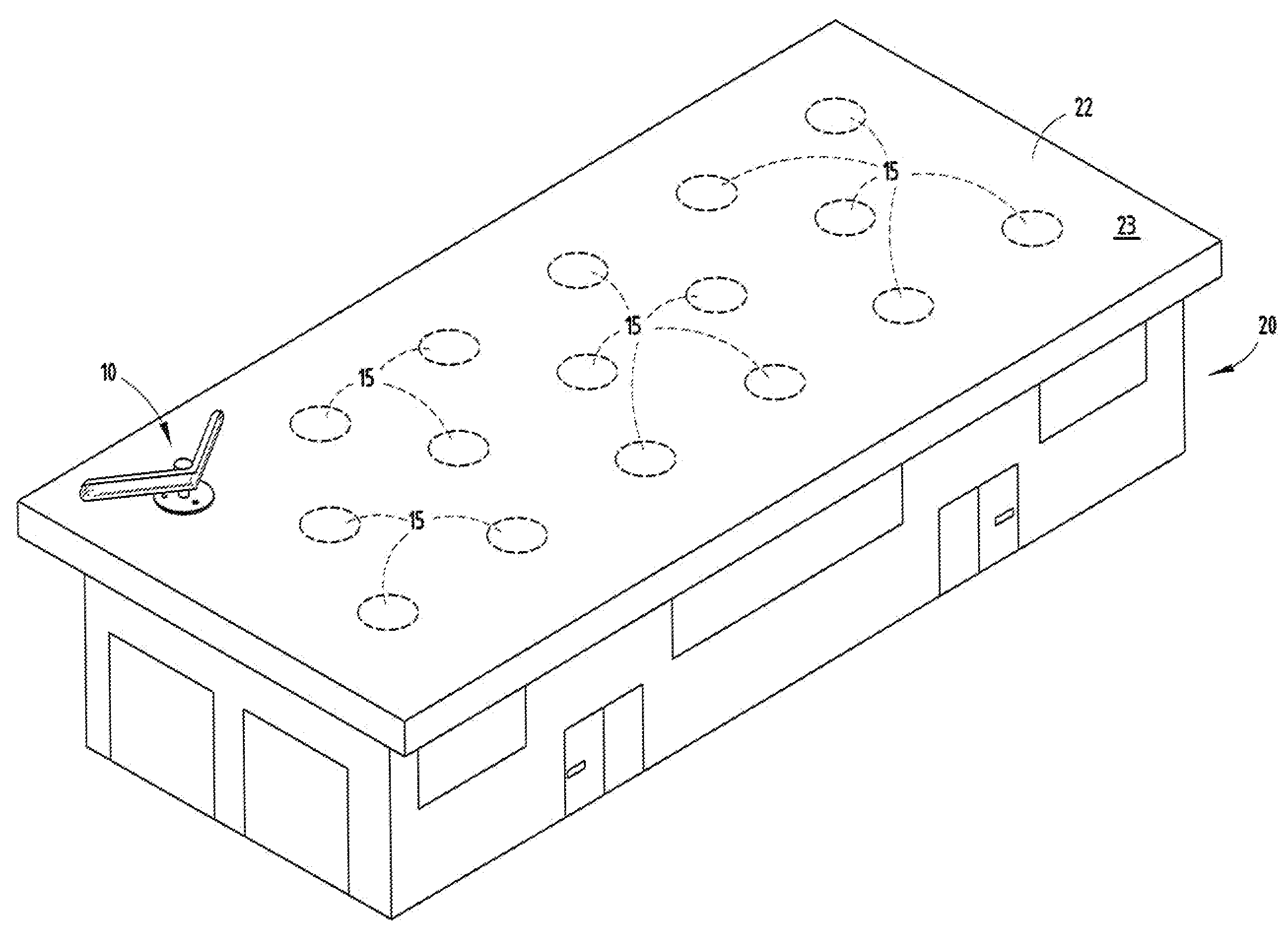

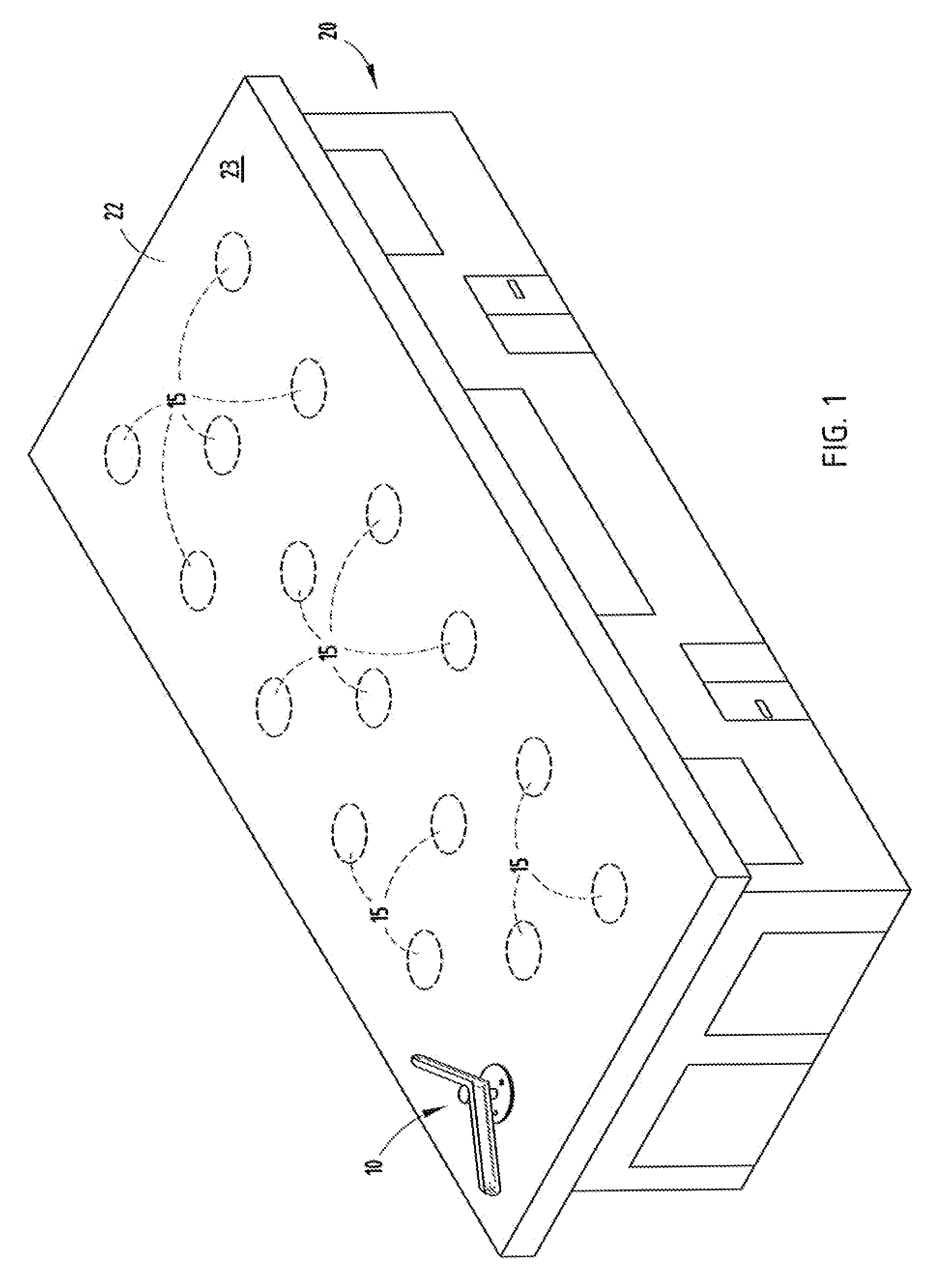

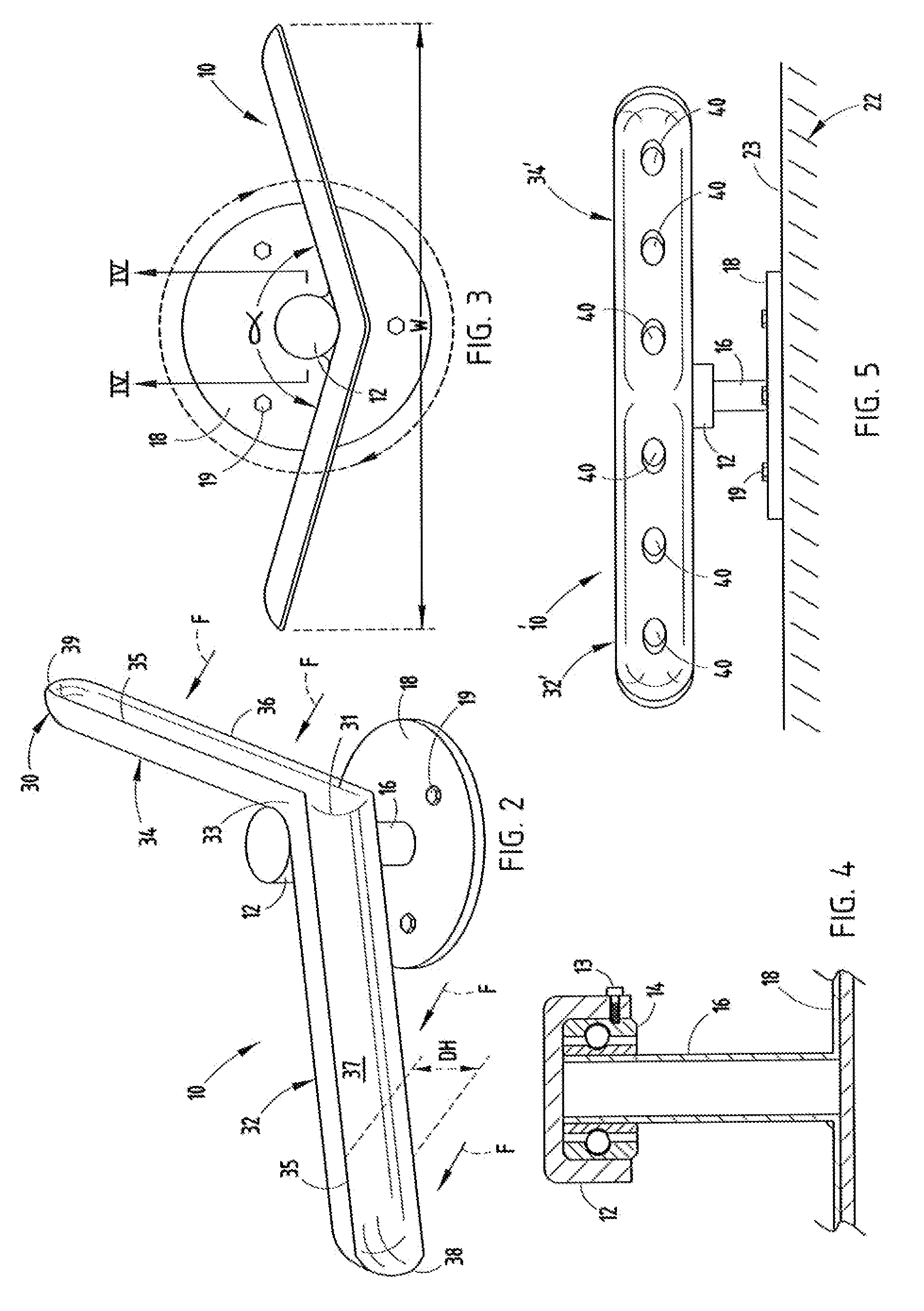

Aerodynamic roof lift-prevention device

InactiveUS20070193135A1Avoid it happening againHigh windRoof covering using slabs/sheetsBuilding roofsAerodynamicsMarine engineering

Owner:VANDENBERG CHARLES J

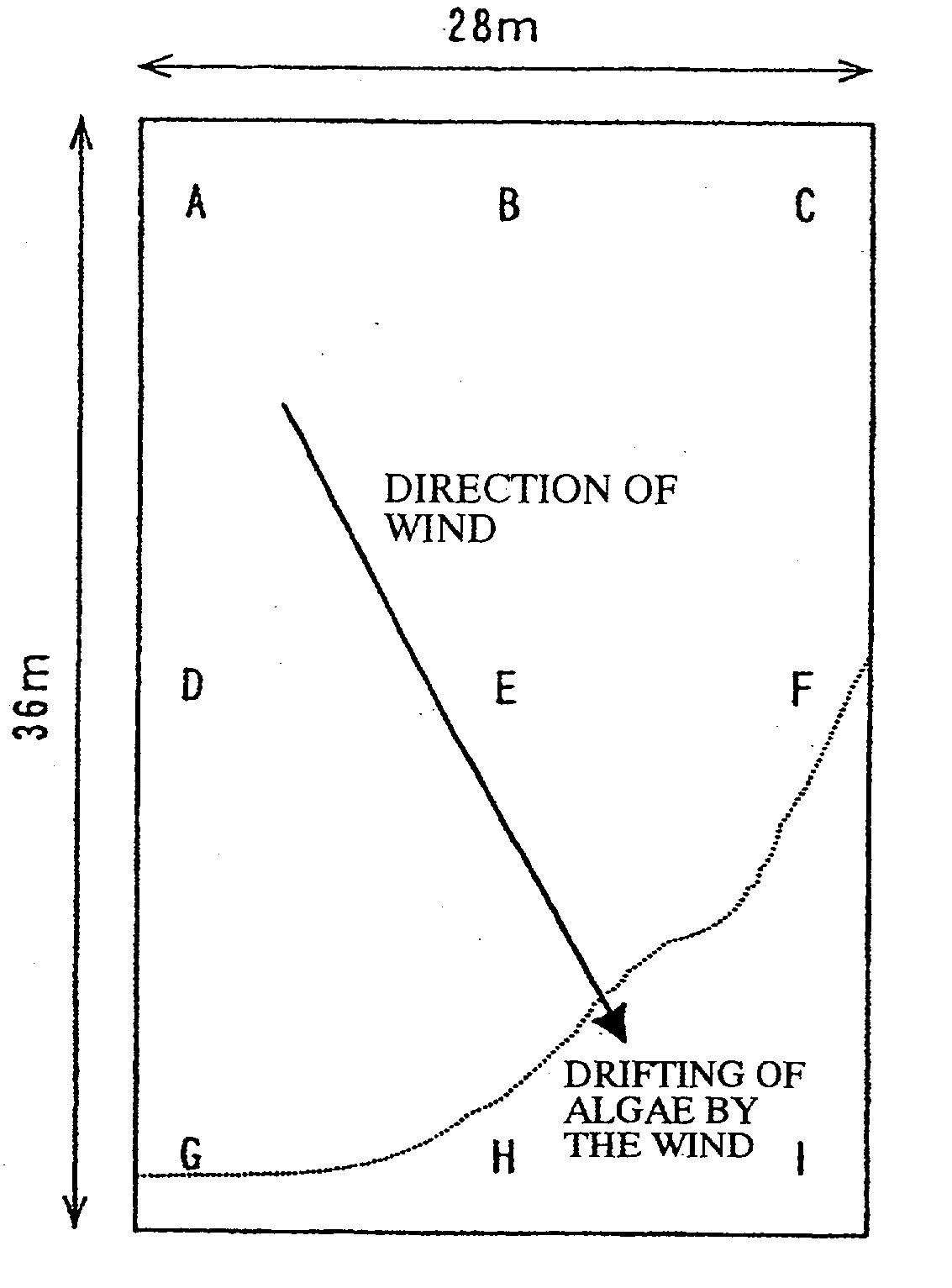

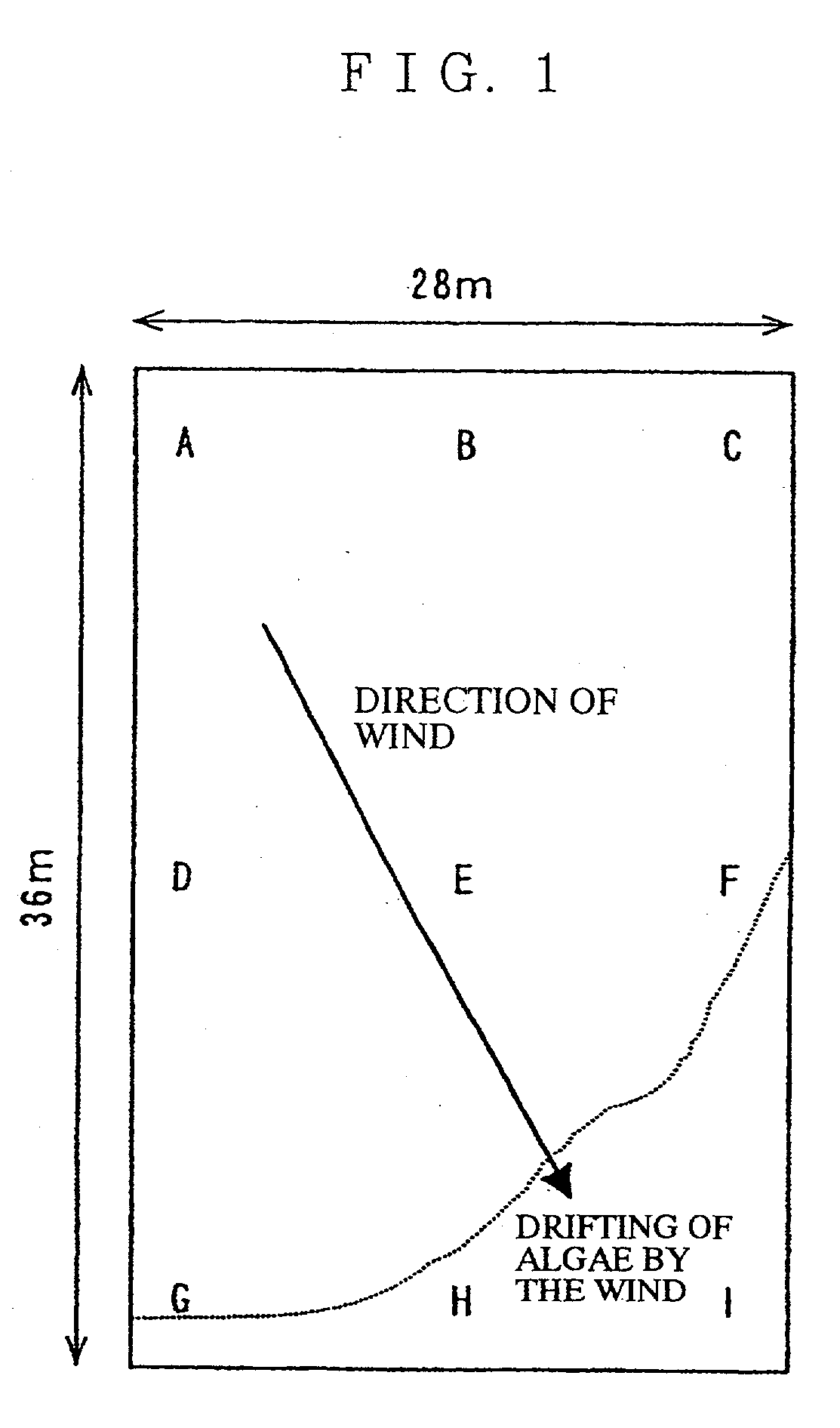

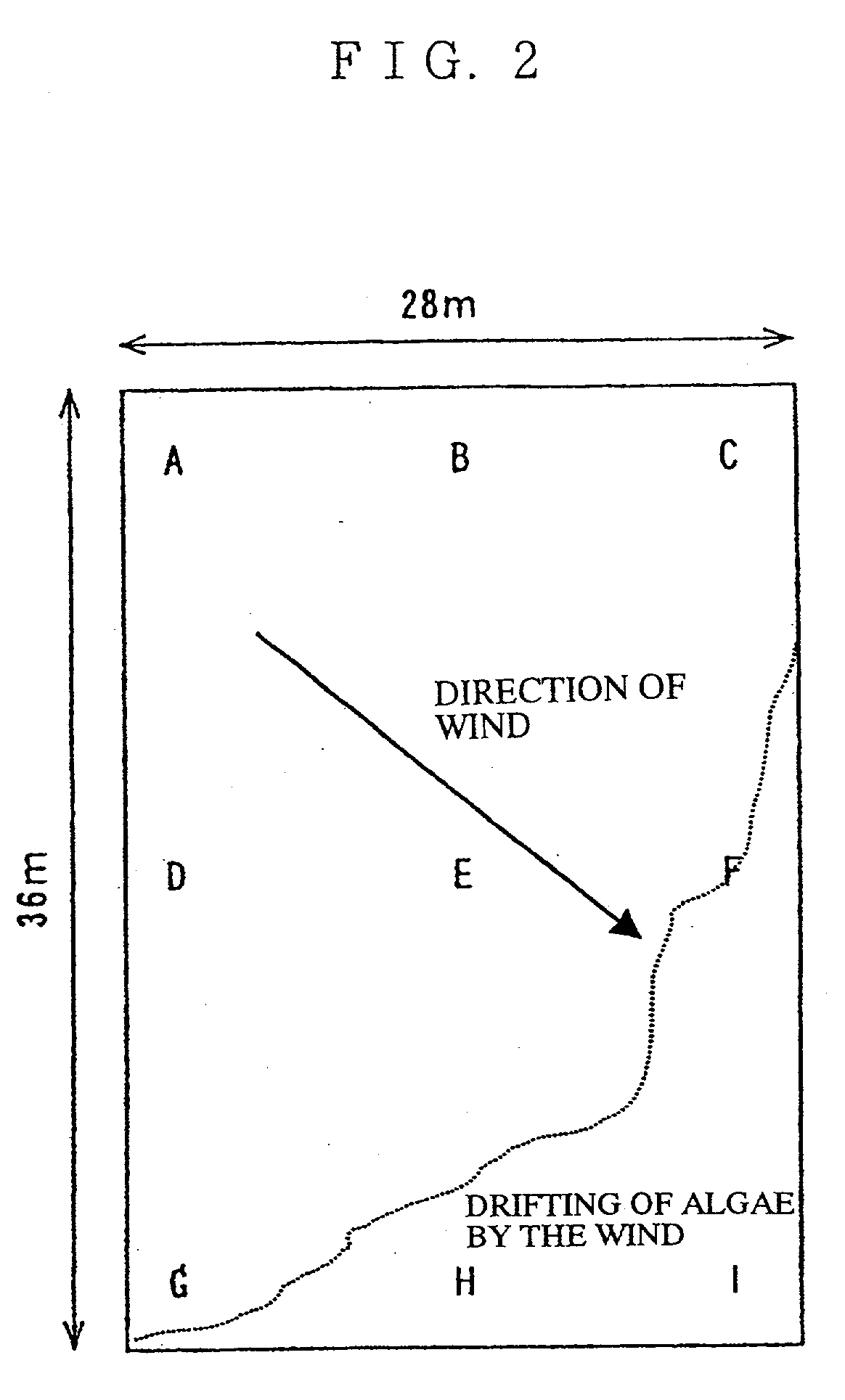

Uniformly spreadable granular agricultural chemicals formulation and method for scattering (applying) thereof

InactiveUS20040011262A1Good spreadabilityDesired effectBiocideFertiliser distributersTreatment effectBULK ACTIVE INGREDIENT

An object of the present invention is to provide a uniformly spreadable granular agricultural chemical formulation and to establish a method of scattering (applying) the formulation under the assumption that the spreadability of the agrochemically active ingredient is satisfactory so that the expected treatment effect of the agricultural chemicals can be obtained by local application even when algae are drifted by the wind and cover the surface of the water of the paddy field. A uniformly spreadable granular agricultural chemicals formulation which contains an agrochemically active ingredient, has a particle-size distribution such that 80% or more of the granules have a particle diameter of 3 mm or more, and has floatability on the water surface, and breaks down on the water surface within 30 minutes is obtained, and a method of scattering (applying) the above formulation on 5% to 50% of the total area of the paddy field applied from a levee at a distance of 1 m or more.

Owner:KUMIAI CHEM IND CO LTD

Endoscopic inflatable retraction device, method of using, and method of making

InactiveUS20100174149A1Avoid accessIncrease surface areaCannulasDiagnosticsSurgical deviceGeneral surgery

A method of providing access to tissue for a surgical instrument through a body wall is provided. The method includes providing an expandable retractor having a flexible sheath, the retractor being in a collapsed state; introducing the retractor into the body and placing the retractor adjacent the tissue; expanding the retractor; deploying the flexible sheath by engaging the flexible sheath with a tool and driving the flexible sheath through the body wall with the tool; and inserting the surgical instrument from outside the body through the flexible sheath to provide access to the tissue by the surgical instrument.

Owner:COVIDIEN AG

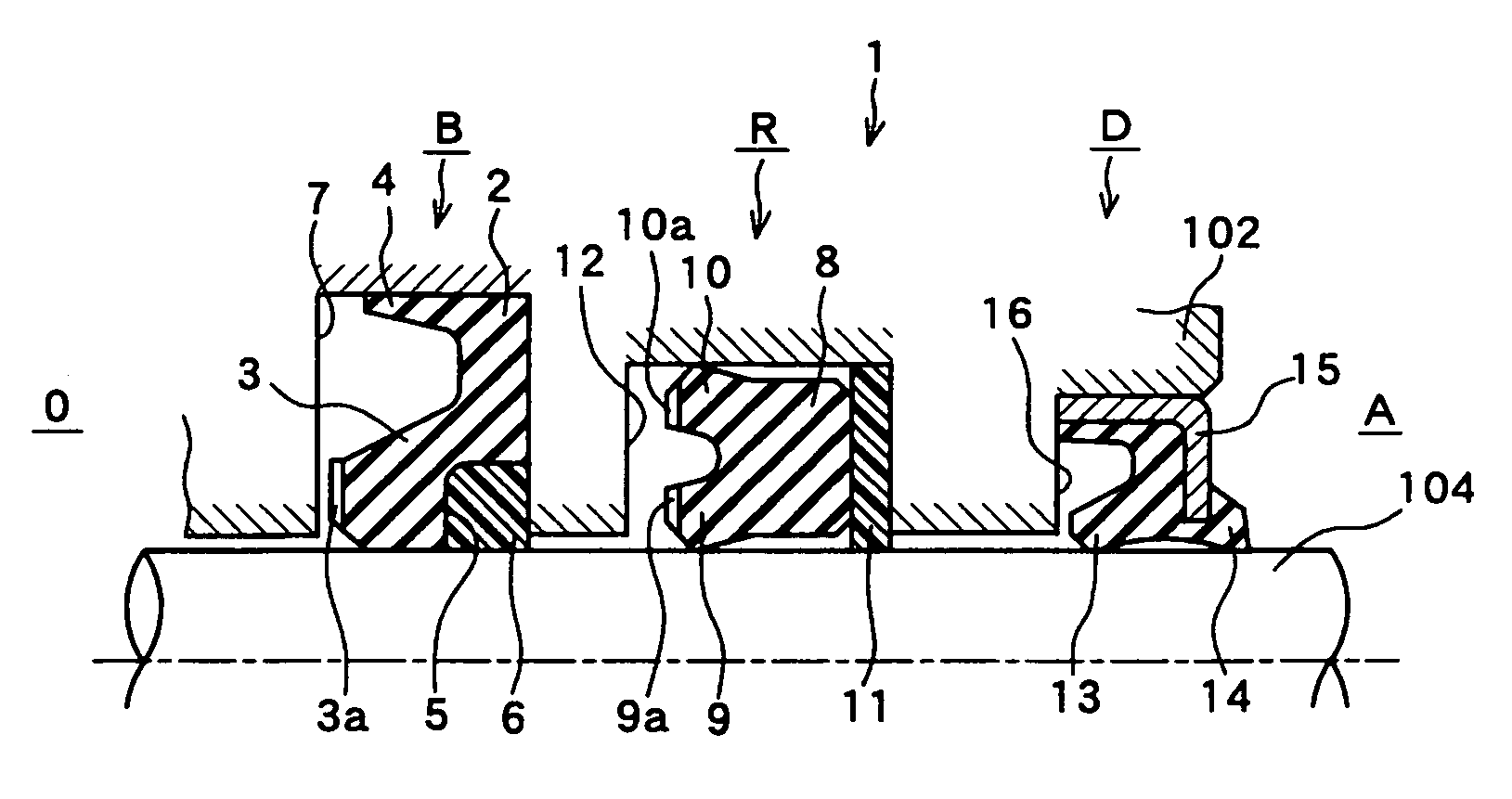

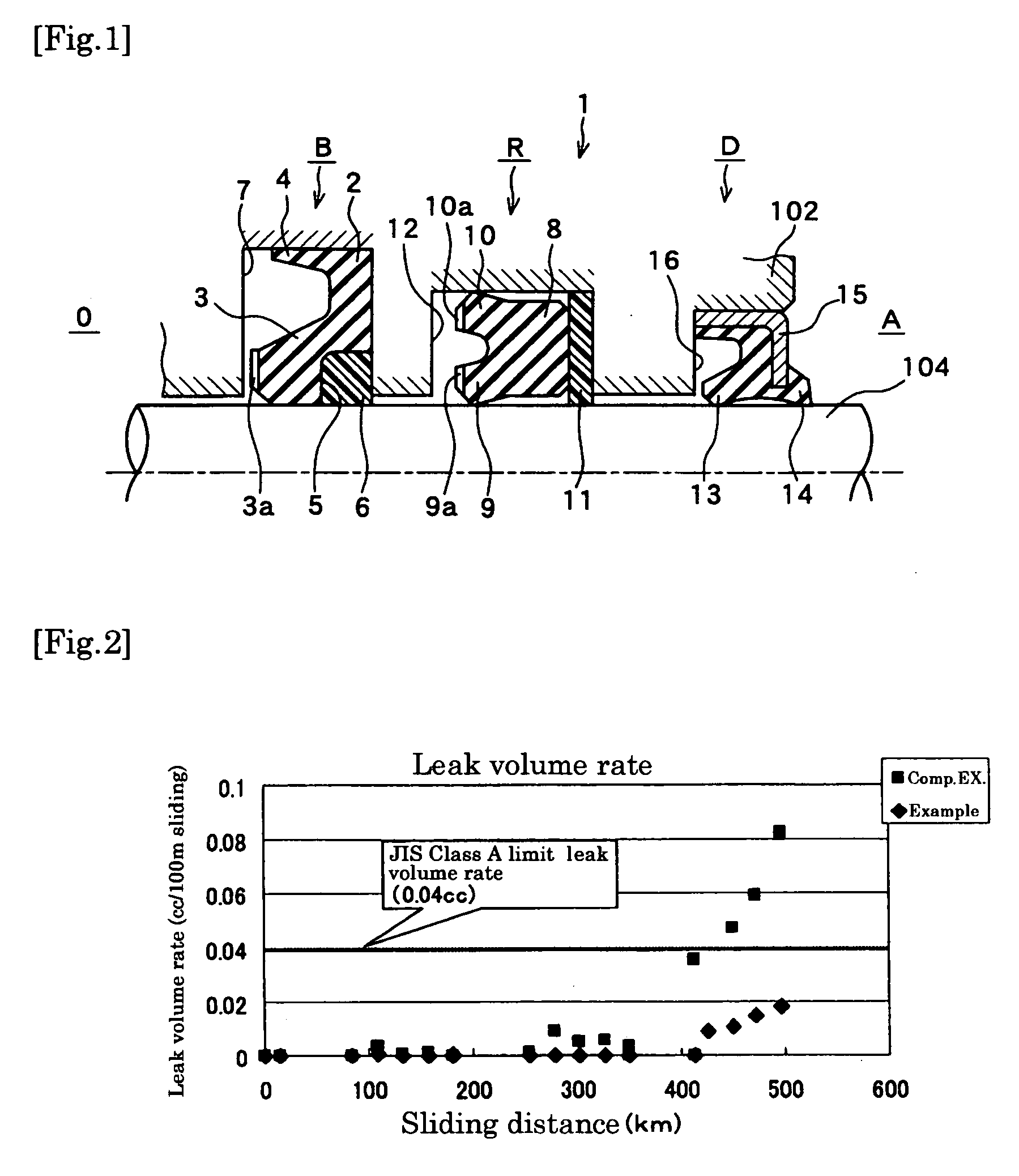

Rod Sealing System

ActiveUS20090166984A1High heat resistanceHigh compression set characteristicEngine sealsPiston ringsPolymer scienceReciprocating motion

In a rod sealing system, which comprises a buffer ring, a rod seal, and a dust seal, provided successively in this order from a fluid hydraulic side toward the outside in an annular clearance between two members in reciprocating motion, the buffer ring is made up of a thermoplastic polyurethane molding product obtained by subjecting a thermoplastic polyurethane molding product prepared by reaction of (A) a high molecular weight polycarbonatediol having a number average molecular weight Mn of 500-6,000, (B) an aromatic diisocyanate, and (C) a low molecular weight diol as a chain elongation agent in an NCO / OH ratio of 0.95-1.20, to heat treatment under conditions that a glass transition point (Tg) of hard phases becomes 170° C. or higher, preferably 170-230° C., and an endothermic peak area (ΔH) at Tg becomes 5 J / g or more, by differential scanning calorimetry. The buffer ring made up of the thermoplastic polyurethane molding product has a distinguished heat resistance capable of withstanding the service environmental temperature, particularly maximum 120° C., compression set characteristics, follow-up to eccentricity, etc.

Owner:UNIMATEC CO LTD +1

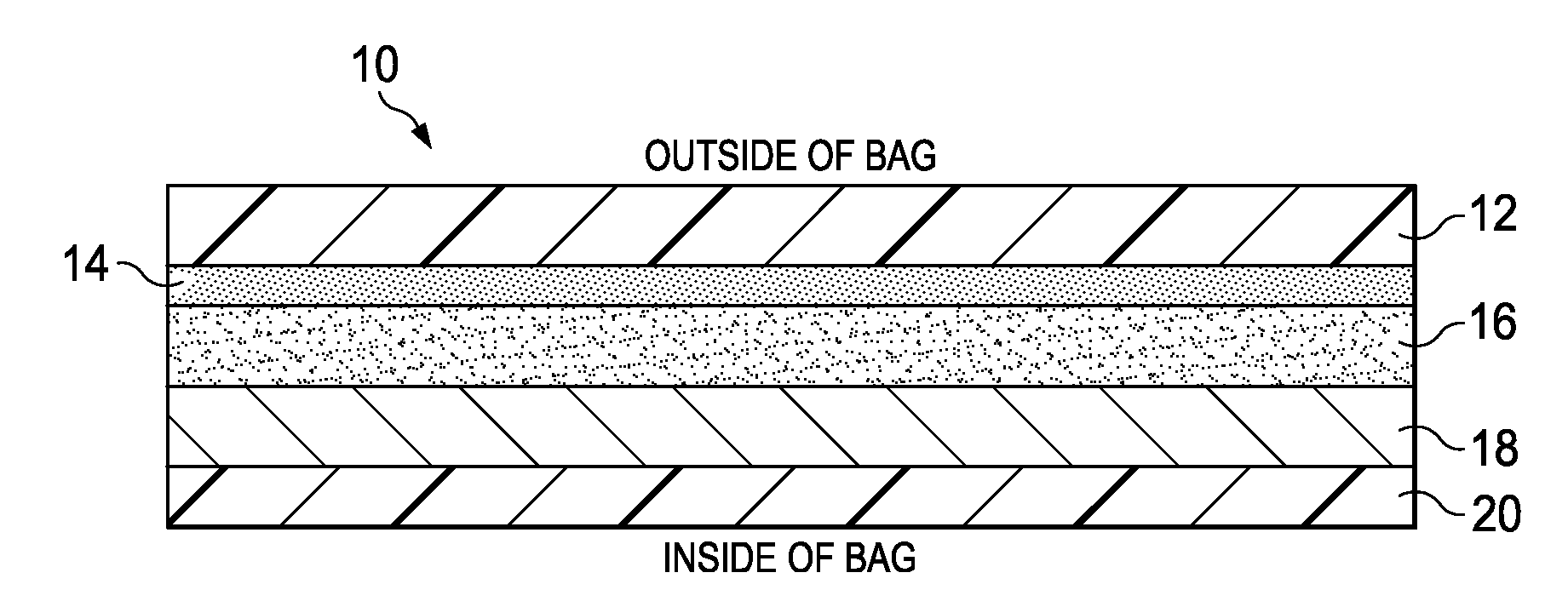

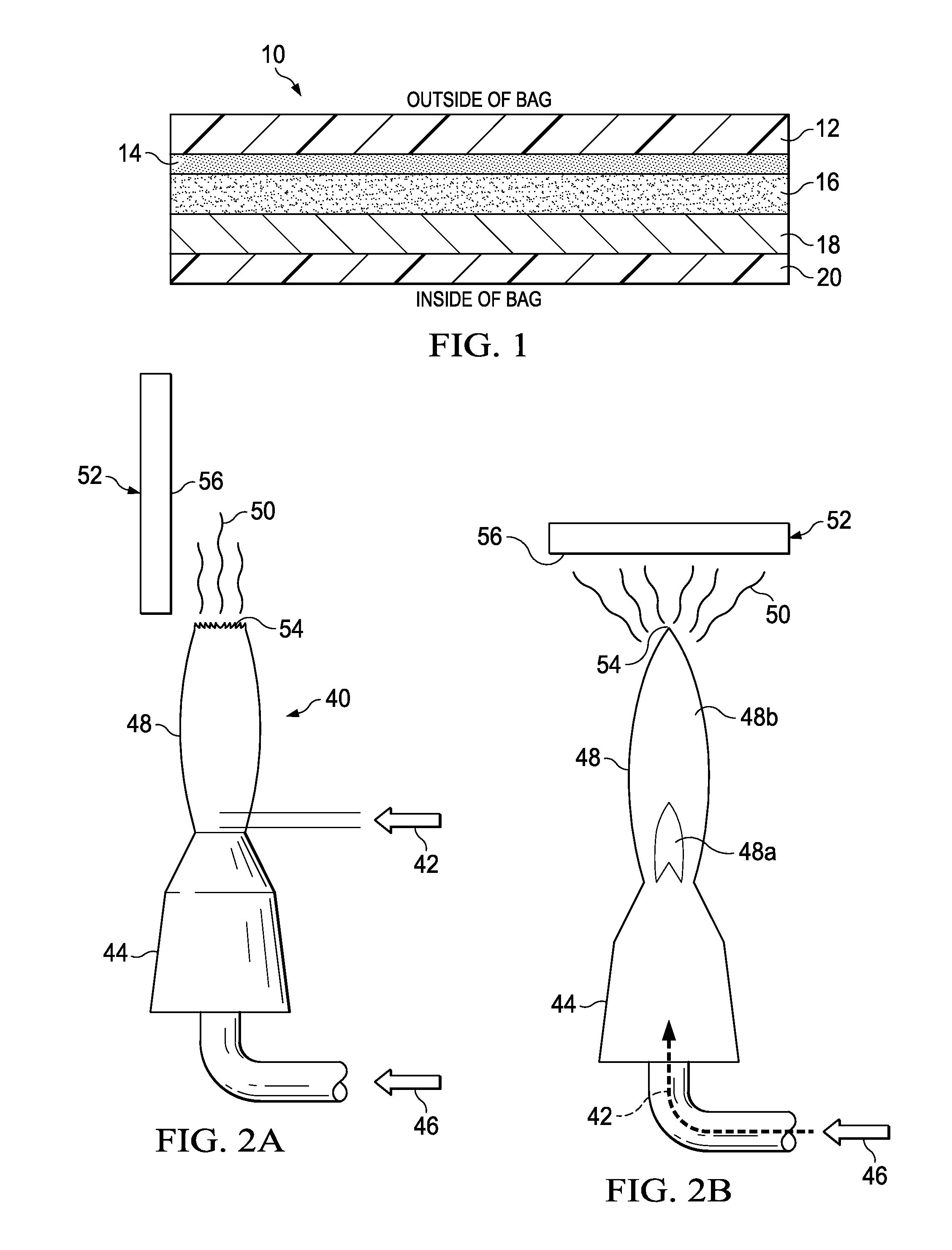

Inorganic nanocoating primed organic film

ActiveUS20130034667A1Avoid weldingDesired effectFibre treatmentVacuum evaporation coatingSurface energyNanometre

An inorganic nanolayer surface coated polymer film product is disclosed with enhancements such as improved metallization capability, low cost, low polymer additives and modifiers, improved recyclability, and good web properties. Also method for priming a flexible film substrate to enhance the reactivity or wettability of the substrate for metallization is disclosed. A substrate film is coated with one or more nanolayers of a metal or metal oxide applied by CCVD and / or PECVD at open atmosphere. The deposited coating acts to enhance the surface energy of the film substrate and to and reduce the surface gauge variation of the substrate or supporting film, thereby enhancing the wettability of the film substrate for metallization and / or to improve the anti-block characteristics of the film. The deposited coatings may also act as a barrier layer for lowering the permeability of light, gas and vapor transmission through the substrate.

Owner:PEPSICO INC +1

Endoscopic inflatable retraction device, method of using, and method of making

InactiveUS7766823B2Avoid accessIncrease surface areaBronchoscopesLaryngoscopesSurgical deviceSurgical instrument

A method of providing access to tissue for a surgical instrument through a body wall is provided. The method includes providing an expandable retractor having a flexible sheath, the retractor being in a collapsed state; introducing the retractor into the body and placing the retractor adjacent the tissue; expanding the retractor; deploying the flexible sheath by engaging the flexible sheath with a tool and driving the flexible sheath through the body wall with the tool; and inserting the surgical instrument from outside the body through the flexible sheath to provide access to the tissue by the surgical instrument.

Owner:COVIDIEN AG

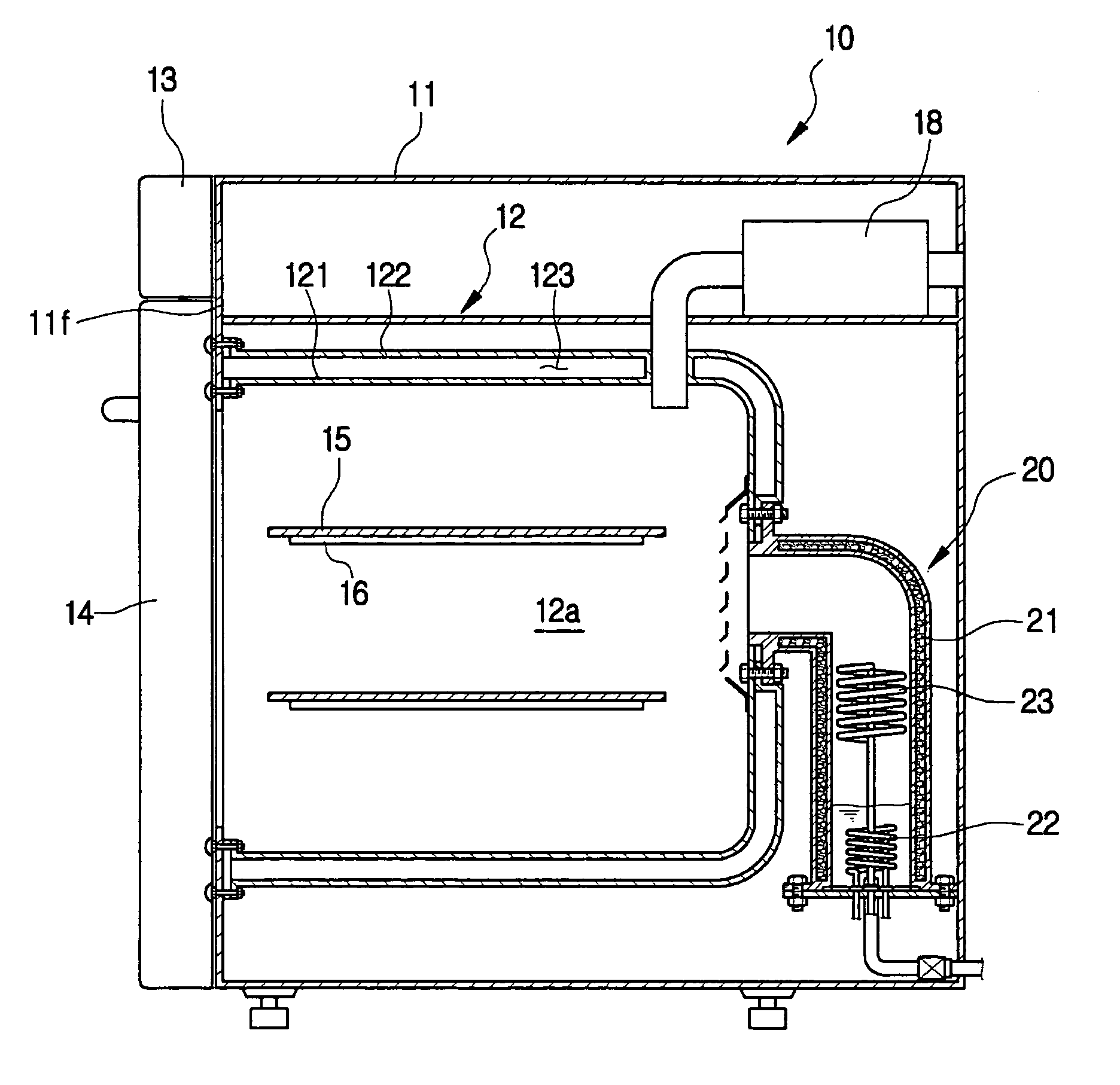

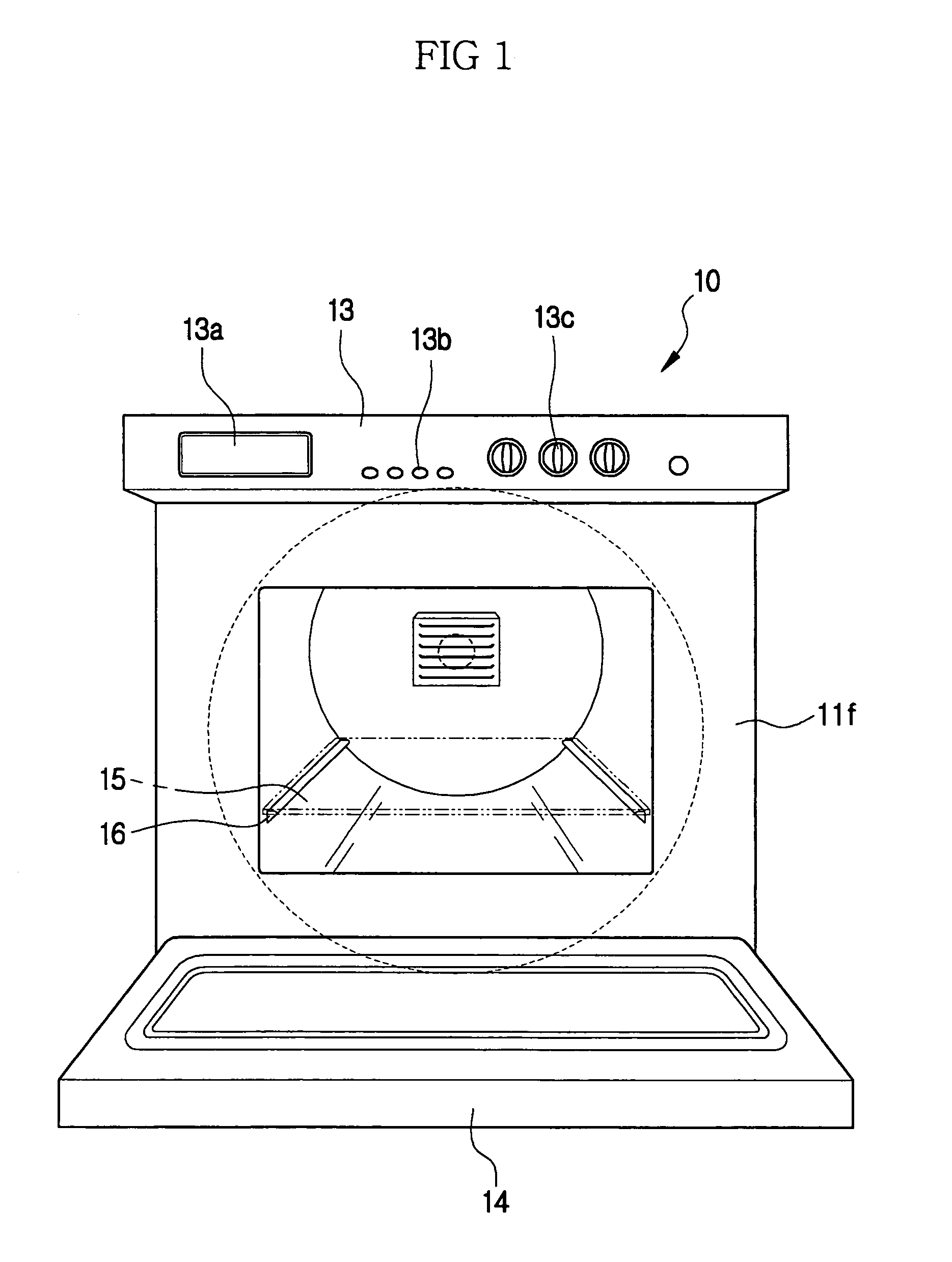

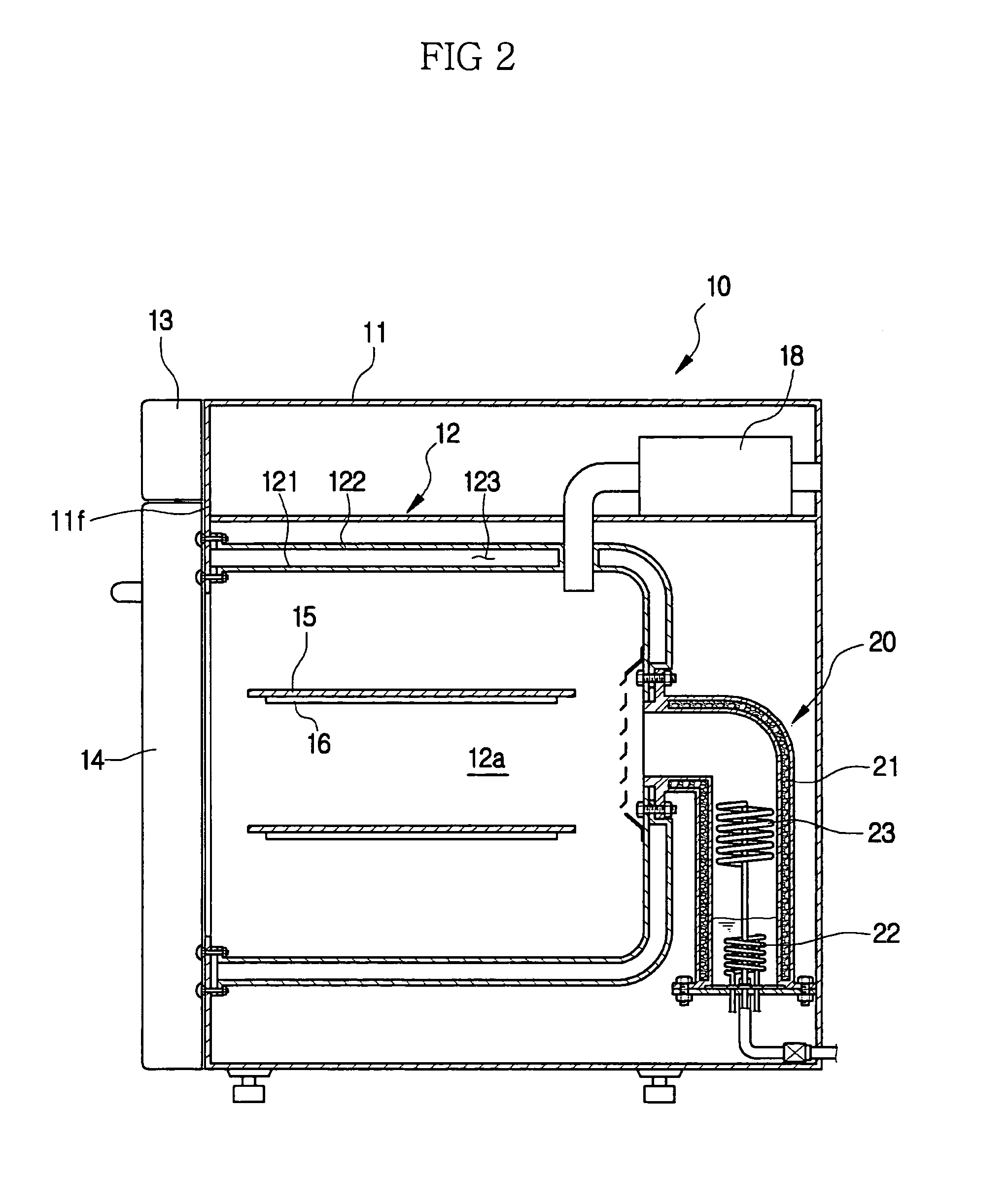

Steam oven having an inner casing including a vacuum

InactiveUS6992268B2Desired effectDomestic stoves or rangesOven air-treatment devicesEngineeringConvective heat transfer

A steam oven including an outer casing to define an appearance of the steam oven, an inner casing provided in the outer casing to define a cooking cavity to cook food therein. The inner casing includes an inner wall and an outer wall, with a space defined between the inner wall and the outer wall and maintained in a vacuum state, thus insulating the cooking cavity from an outside of the inner casing. The steam oven further includes a steam generator to supply steam into the inner casing. Therefore, the steam oven accomplishes the desired insulating effect without using any insulating material while the space defined between the inner wall and the outer wall reduces conductive and convective heat transfer.

Owner:SAMSUNG ELECTRONICS CO LTD

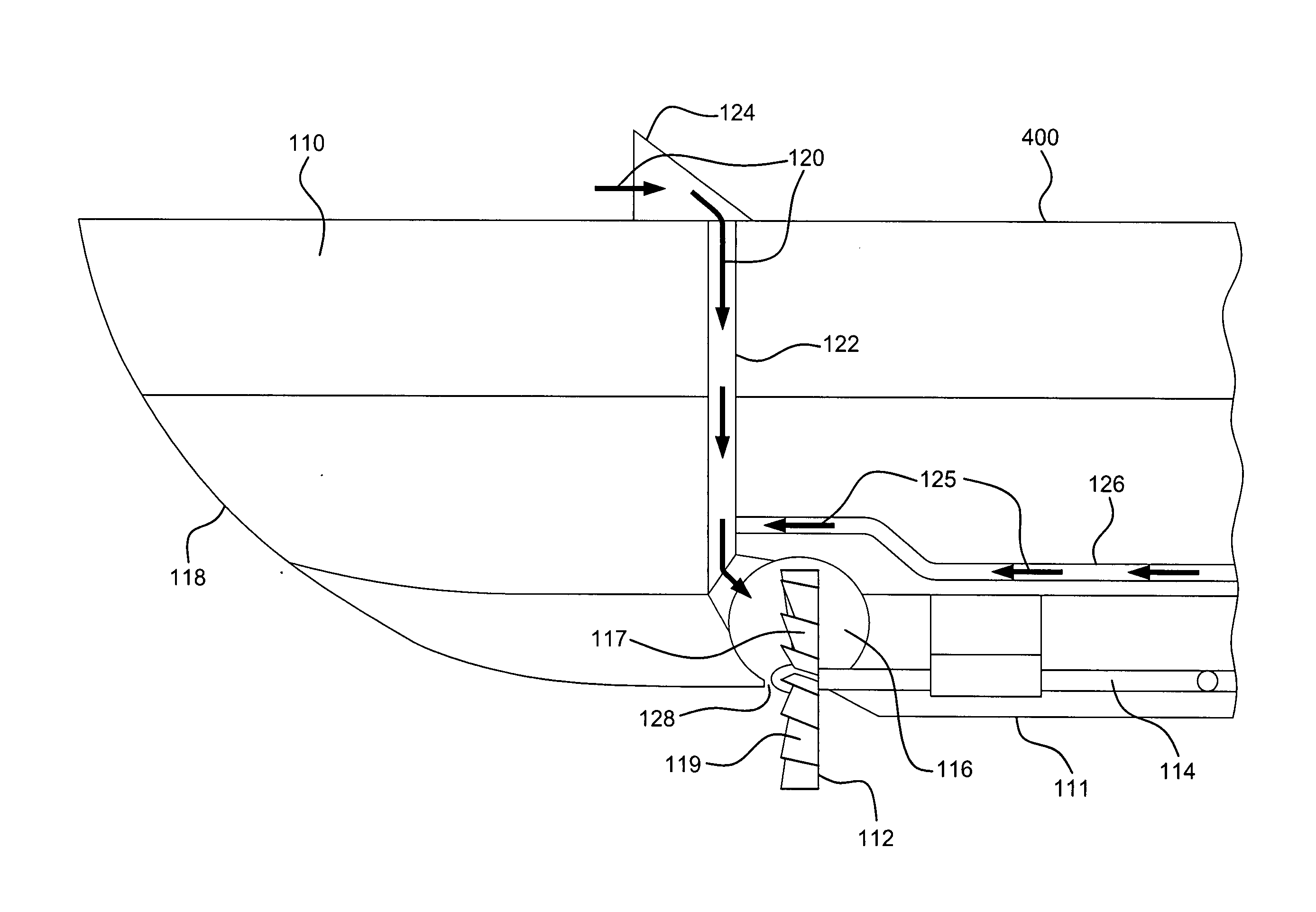

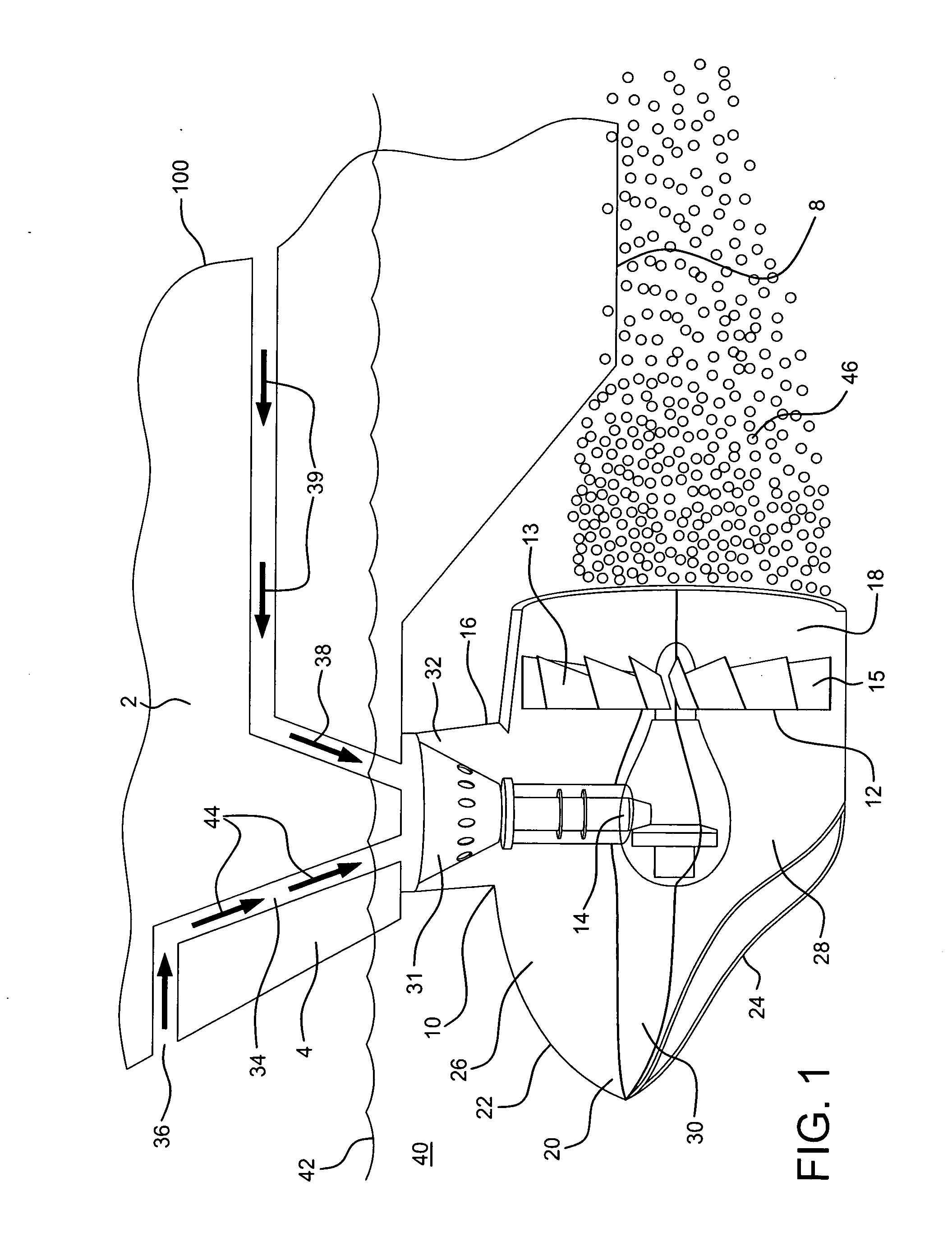

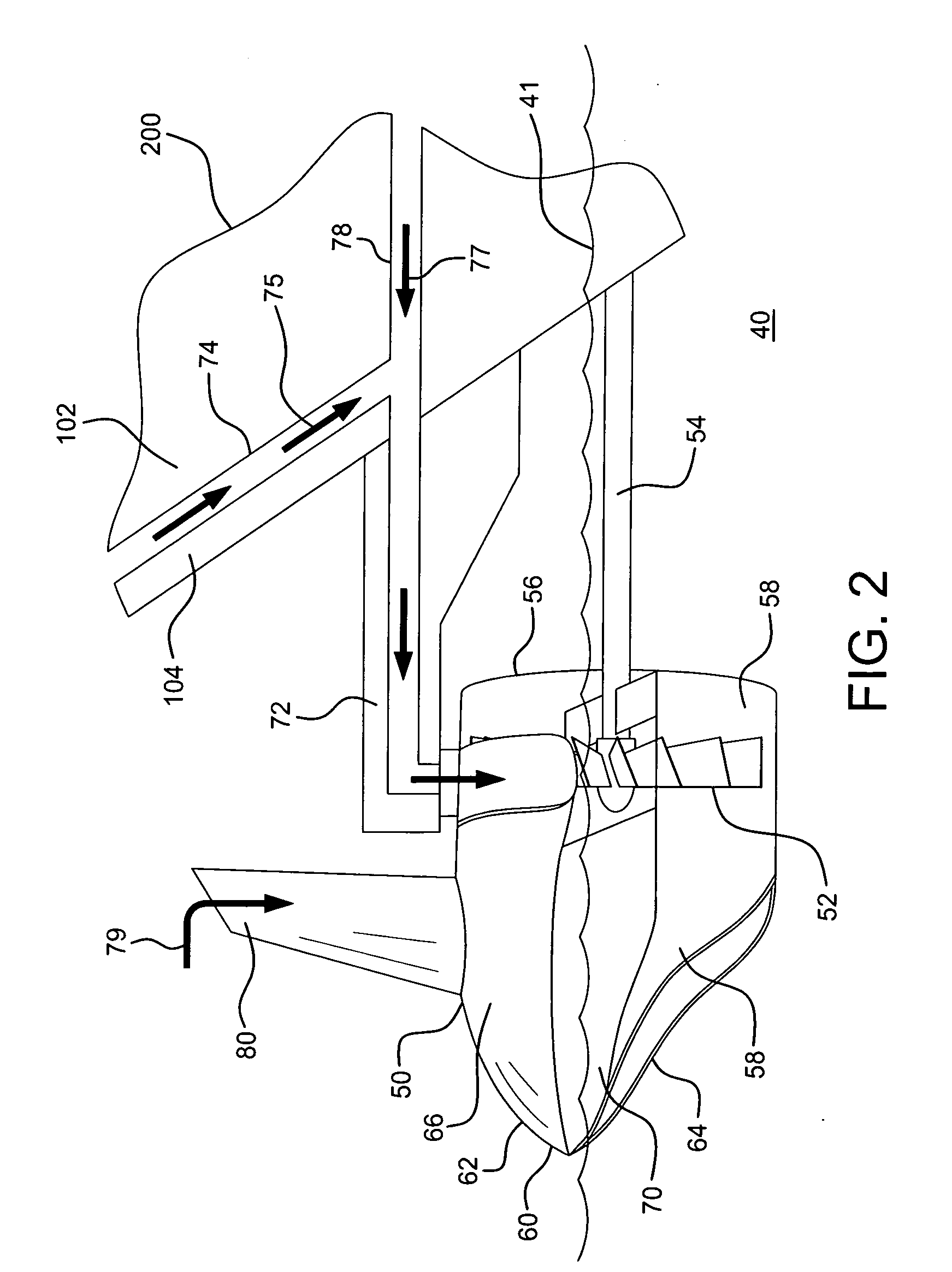

Gaseous fluid vessel propulsion system

InactiveUS20110263168A1Effectively streamliningOffset drag effectRotary propellersWatercraft hull designPropellerAmbient air

A bow mounted gaseous fluid vessel propulsion system provides for the introduction of gaseous fluids, e.g. ambient air and / or exhaust fluid gas from the vessel's engine, into the enclosure or duct which houses or circumscribes the propeller. Air and other fluid gases are drawn down into the upper section of the enclosure or duct to allow the propeller to operate in a half submerged, or water surface-piercing condition, while the vessel is moving forward through the water. The beneficial effects of water surface-piercing propeller operation is thereby obtained within a self-contained unit which continually maintains the top of the propeller out of the water during normal forward vessel operation.

Owner:ADAMS ROBERT D

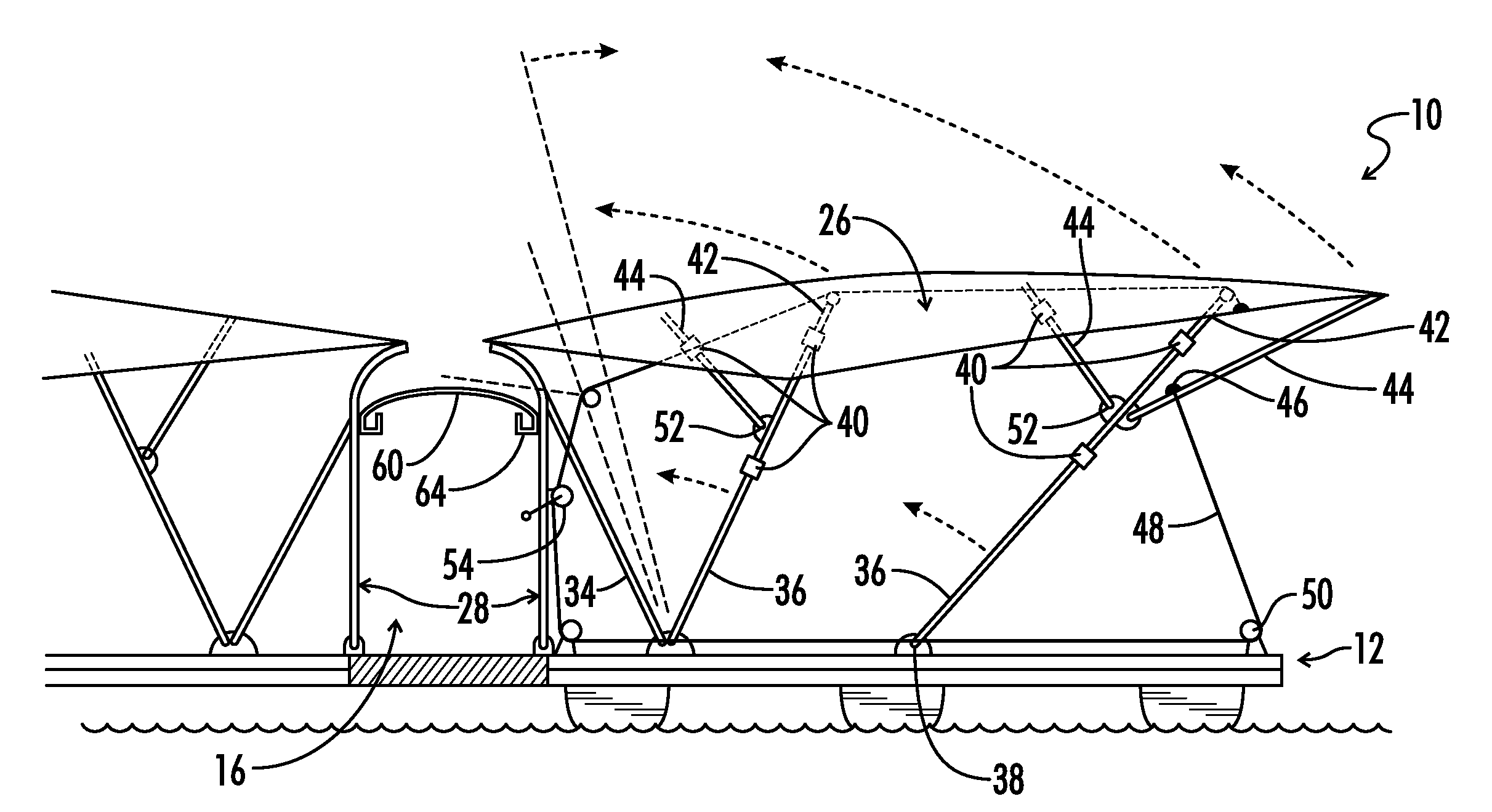

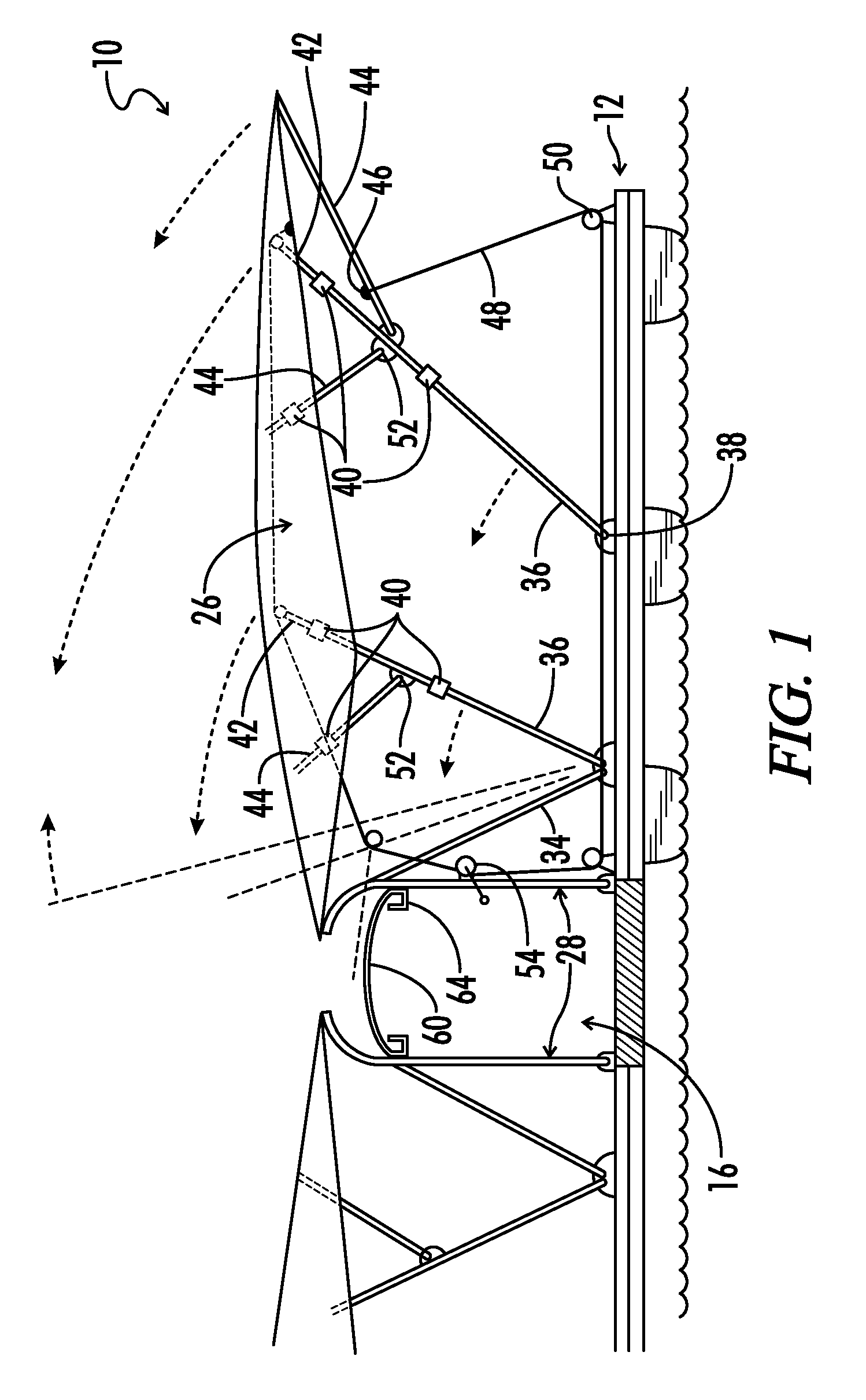

Retractable boat slip cover

InactiveUS8286651B1Easy to take backImprove featuresTents/canopiesVessel partsCovering systemEngineering

Boat slip cover systems are provided for affixing to piers having a plurality of slips with closed and open ends, and first and second sides. Each boat slip cover includes a flexible canopy. Fixed supports for a first end of the canopy are disposed about the closed end of the slip, at least one extending upward from and perpendicular to the pier surface, and at least one extending upward from and angular to the pier surface. Rotating supports are disposed along each side of the slip and extend upward from the pier. Telescoping joints are disposed along each rotating support for their extension or retraction. A winch device is further provided for manual positioning. A convertible pier cover includes various retractable boat slip covers, valley portions extending between adjacent boat slip covers and forming an attachment on each side to an adjacent boat canopy, and a central aisle canopy.

Owner:MAFFETT WILLIAM C

Implants using ultrasonic communication for modulating splenic nerve activity

PendingUS20190321640A1Desired effectReduce concentrationSpinal electrodesCircuit arrangementsTreatment hypertensionMedical treatment

Described herein are methods for monitoring or modulating an immune system in a subject; treating, reducing or monitoring inflammation; monitoring blood pressure; treating hypertension; or administering or adjusting a therapy for inflammation or hypertension in a patient by electrically stimulating the splenic nerve or detecting splenic nerve activity using an implanted medical device. Also described herein are implantable medical devices for performing such methods. The implanted medical device includes an ultrasonic transducer configured to receive ultrasonic waves and convert energy from the ultrasonic waves into an electrical energy that powers the device, two or more electrodes in electrical communication with the ultrasonic transducer that are configured to electrically stimulate a splenic nerve or detect a splenic nerve activity, and optionally a splenic nerve attachment member.

Owner:IOTA BIOSCI INC

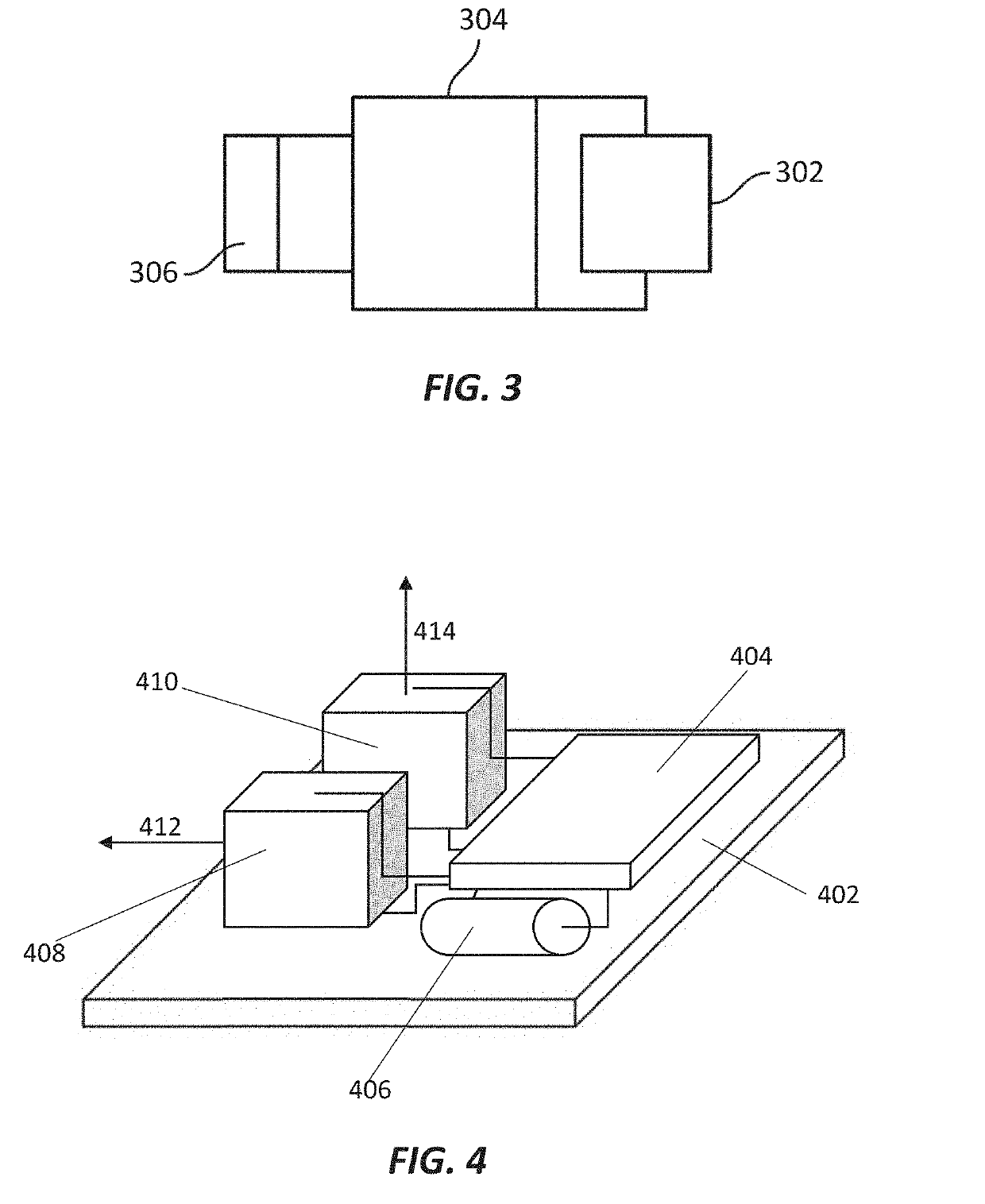

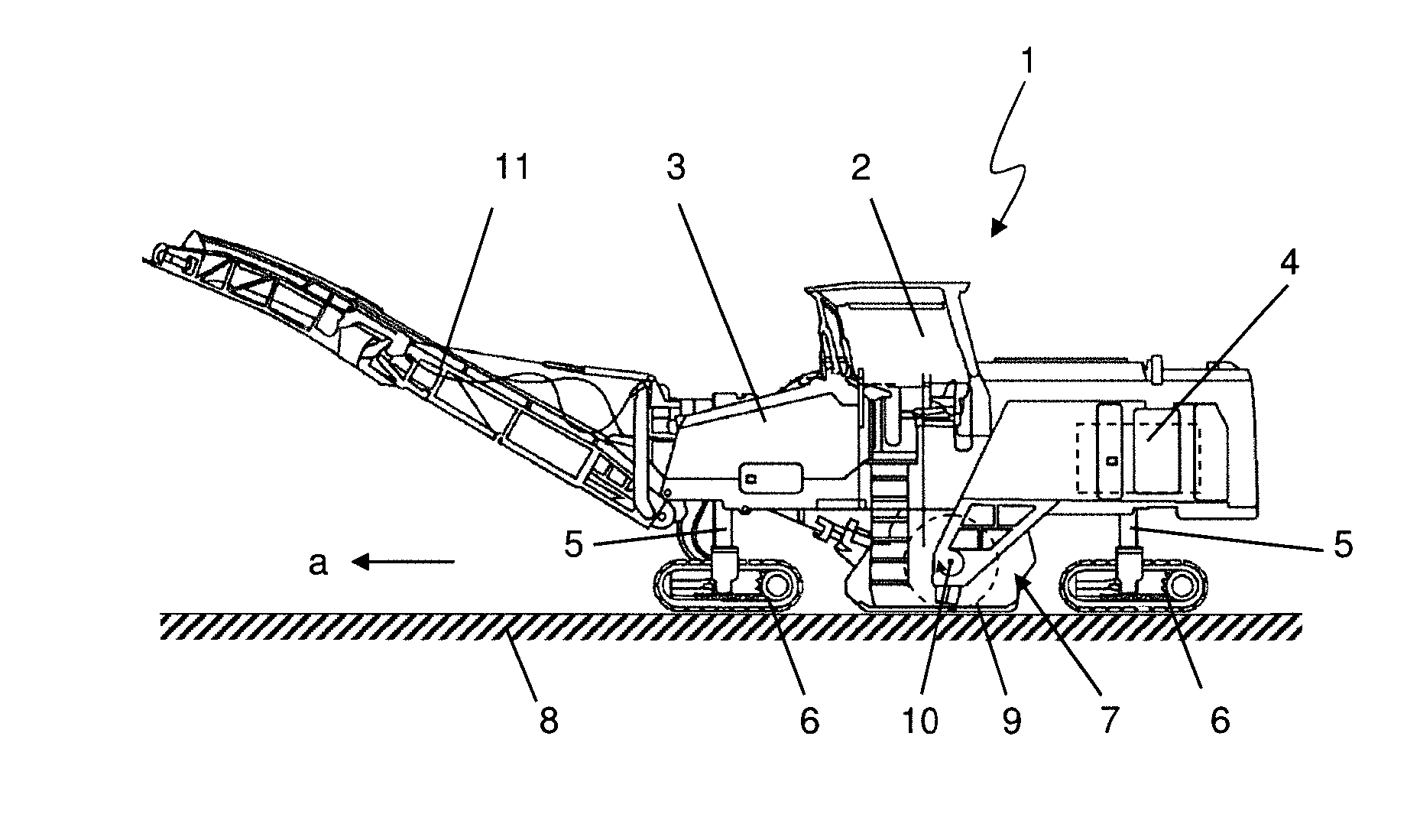

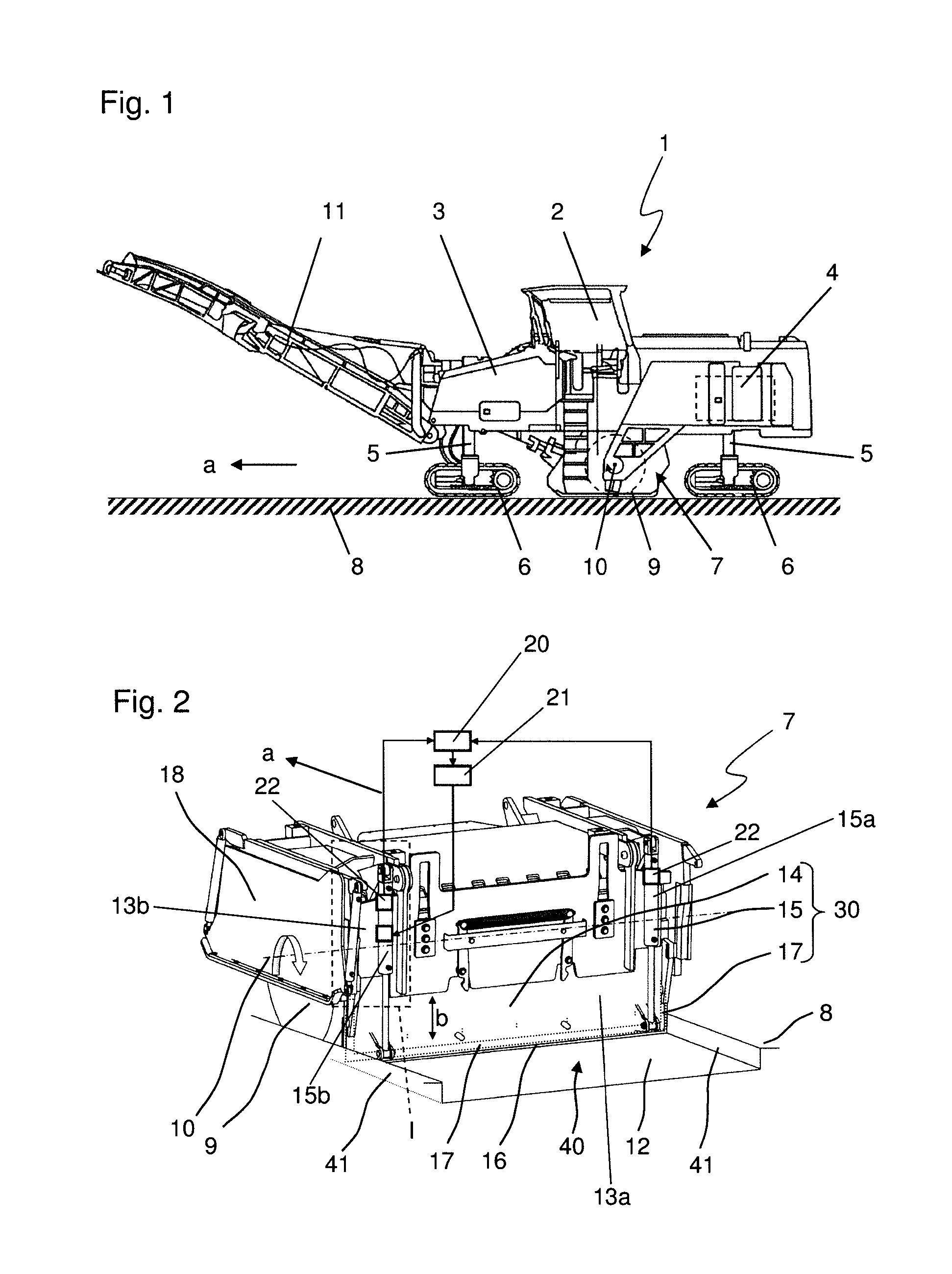

Ground Milling Machine And Method For Adjusting The Stripping Plate Of A Ground Milling Machine

ActiveUS20160186391A1Improve method performanceEasy to handleProgramme controlSlitting machinesRoad surfaceActuator

The present invention relates to a ground milling machine, particularly a road milling machine, comprising a machine frame supported by travelling devices, a drive engine and a milling device arranged in a milling drum box, the milling drum box comprising a stripping plate which is height-adjustable by means of at least a first and a second actuator. Further, the present invention relates to a method for adjusting a stripping plate of a milling drum box of a ground milling machine, particularly a road milling machine. For the purpose of a reliable adjustment of the stripping plate, the present invention proposes using a monitoring device for detecting the adjustment of a first actuator and a control device for controlling the adjustment of a second actuator depending on the adjustment of the first actuator.

Owner:BOMAG

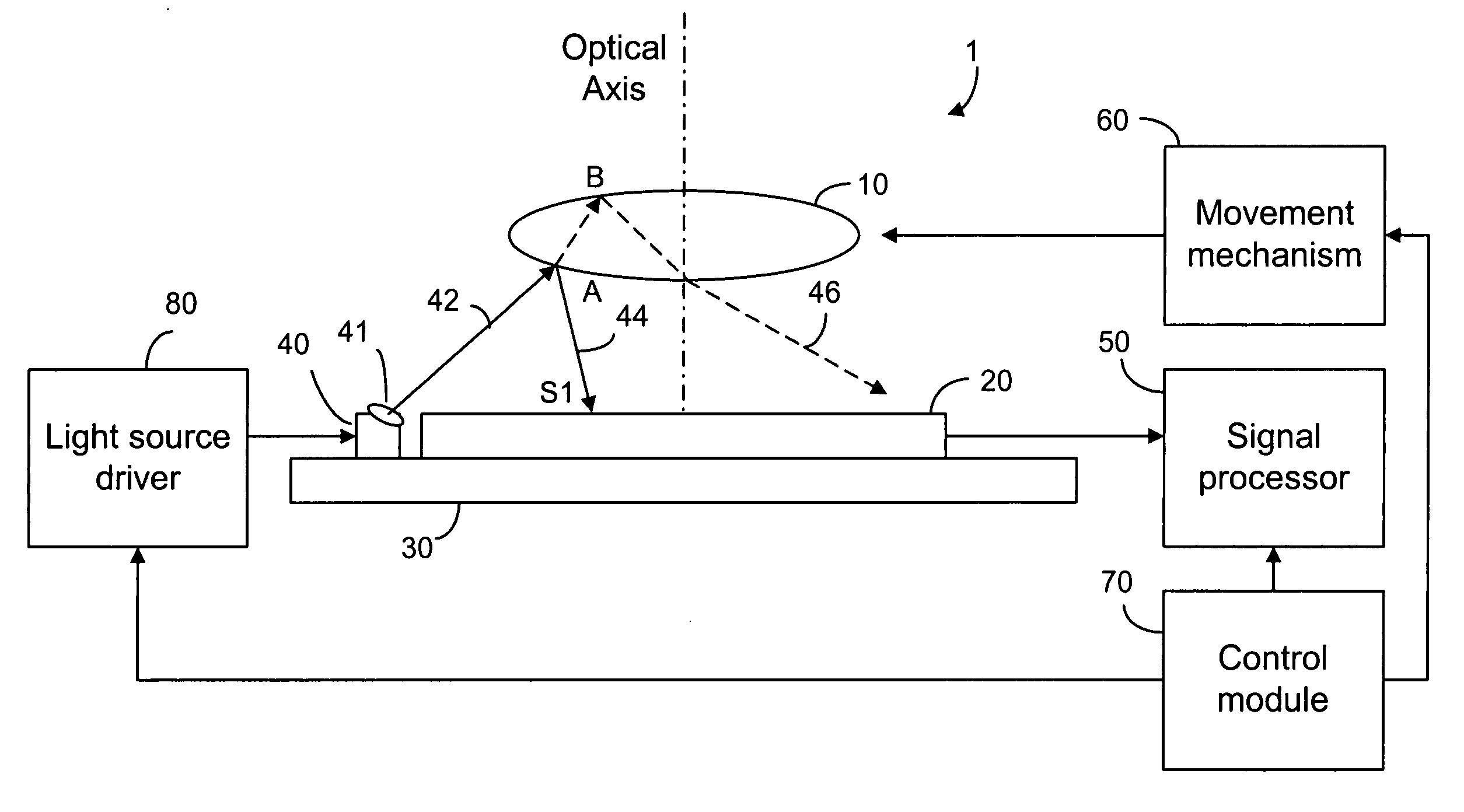

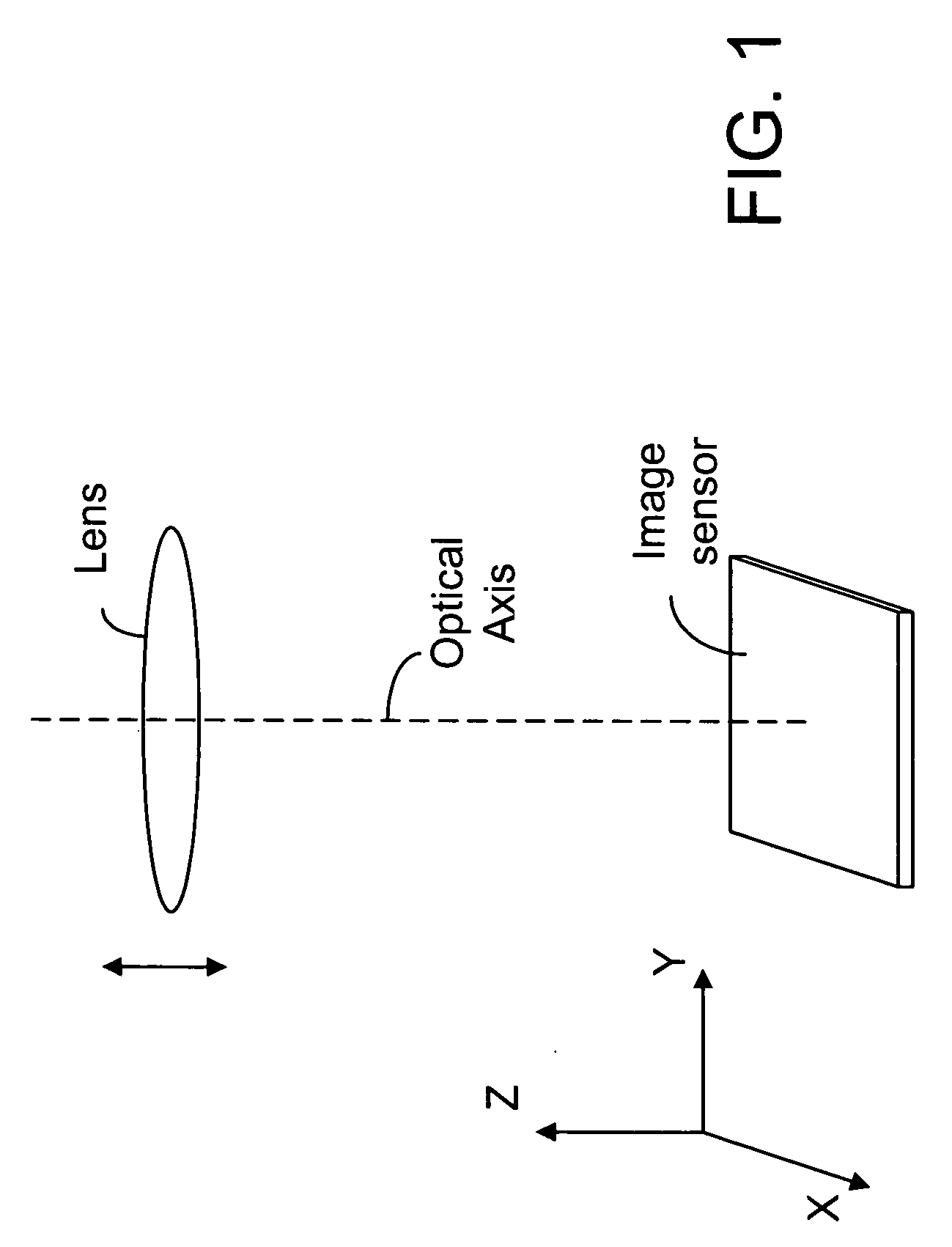

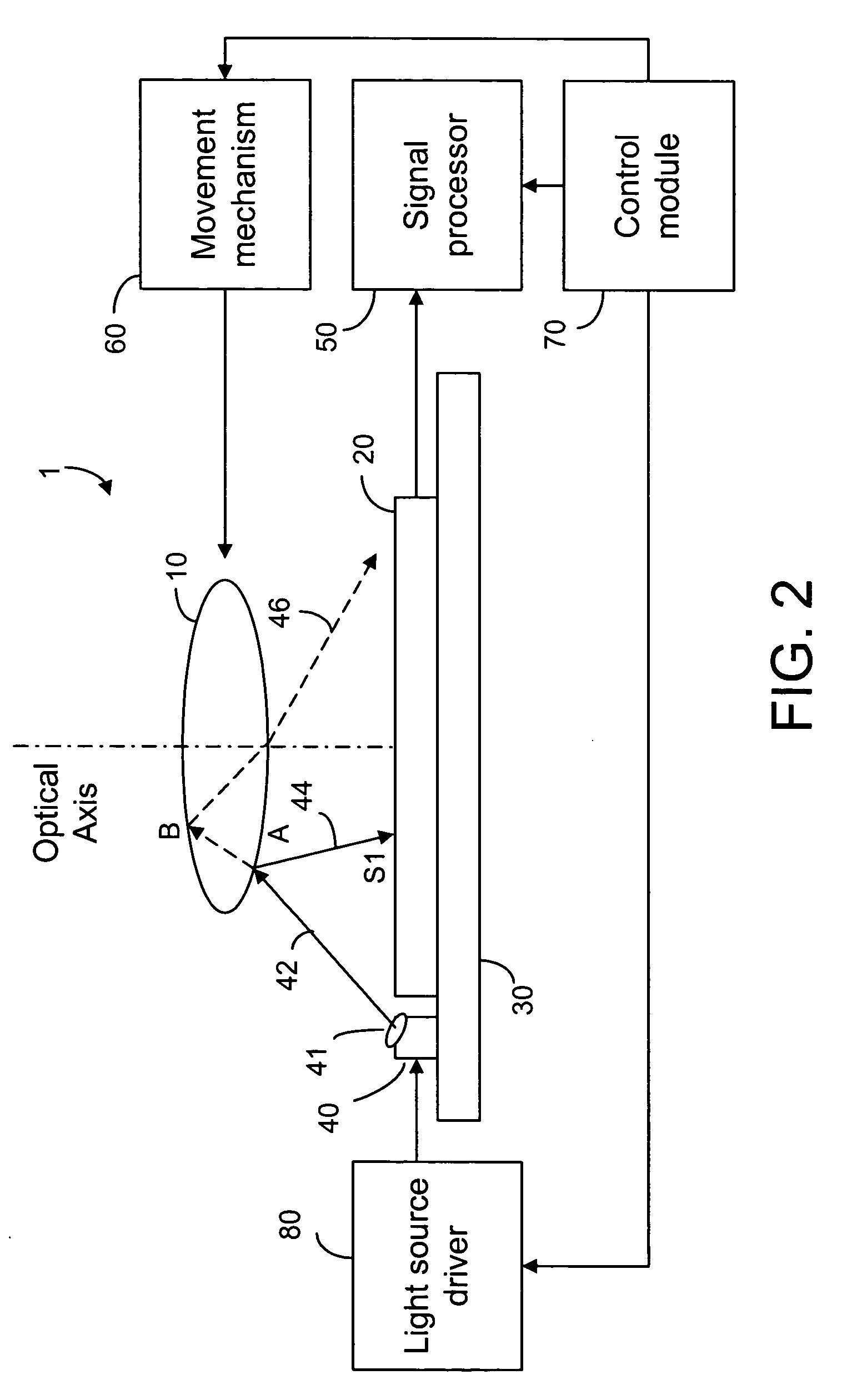

Method and device for position sensing of an optical component in an imaging system

ActiveUS20070279610A1Desired effectMaterial analysis by optical meansCamera focusing arrangementOptical axisLight beam

A light beam is used to illuminate a spot on a lens element which is shifted along the optical axis of an imaging system for auto-focus or optical zoom purposes. The light beam is arranged such that the reflected light beam from the lens element encounters a spot on the image sensor. The spot location on the image sensor is determined by a signal processor. As the lens element is shifted along the optical axis, the spot location changes accordingly. Based on the moving distance of the spot, the signal processor determines the shifting distance of the lens element and hence the position of the lens element. Based on the shifting distance of the lens element, a control module is used to adjust the lens position along the optical axis to achieve the desired focusing or zooming effects.

Owner:NOKIA TECHNOLOGLES OY

Low Normal Force Retracting Device Comprising a Microtextured Surface

Retraction of one or more three-dimensional or planar amorphous objects is provided to gain access for a procedure where the retracted elements are easily damaged by application of normal forces. For example, a surgical instrument to provide access to an organ or tissue plane. Microtextured surfaces are provided that provide immobilization of amorphous objects, the immobilization of which is characterized by low normal forces and high shear or in plane forces. The retraction device is comprised of microstructured surfaces on one or more arms. Preferably these arms are soft and flexible to minimize damage to retracted objects. In some instances, these arms resemble and are used as a nonslip tape. Alternatively, parts or whole arms of the retraction device are rigid to provide a supportive aspect. These arms may be configured around a handle. Furthermore, the microtextured aspect may be further augmented with conventional gripping surfaces, such as a sticky surface, or a surface comprised of one or more hooks or barbs. The handle means may be distributed over the retraction device, for example, holes distributed along the arms through which anchoring means are tied. The retraction device is particularly well suited for grasping wet, oily, slimy or living surfaces by applying a small nondestructive normal force.

Owner:BVW HLDG

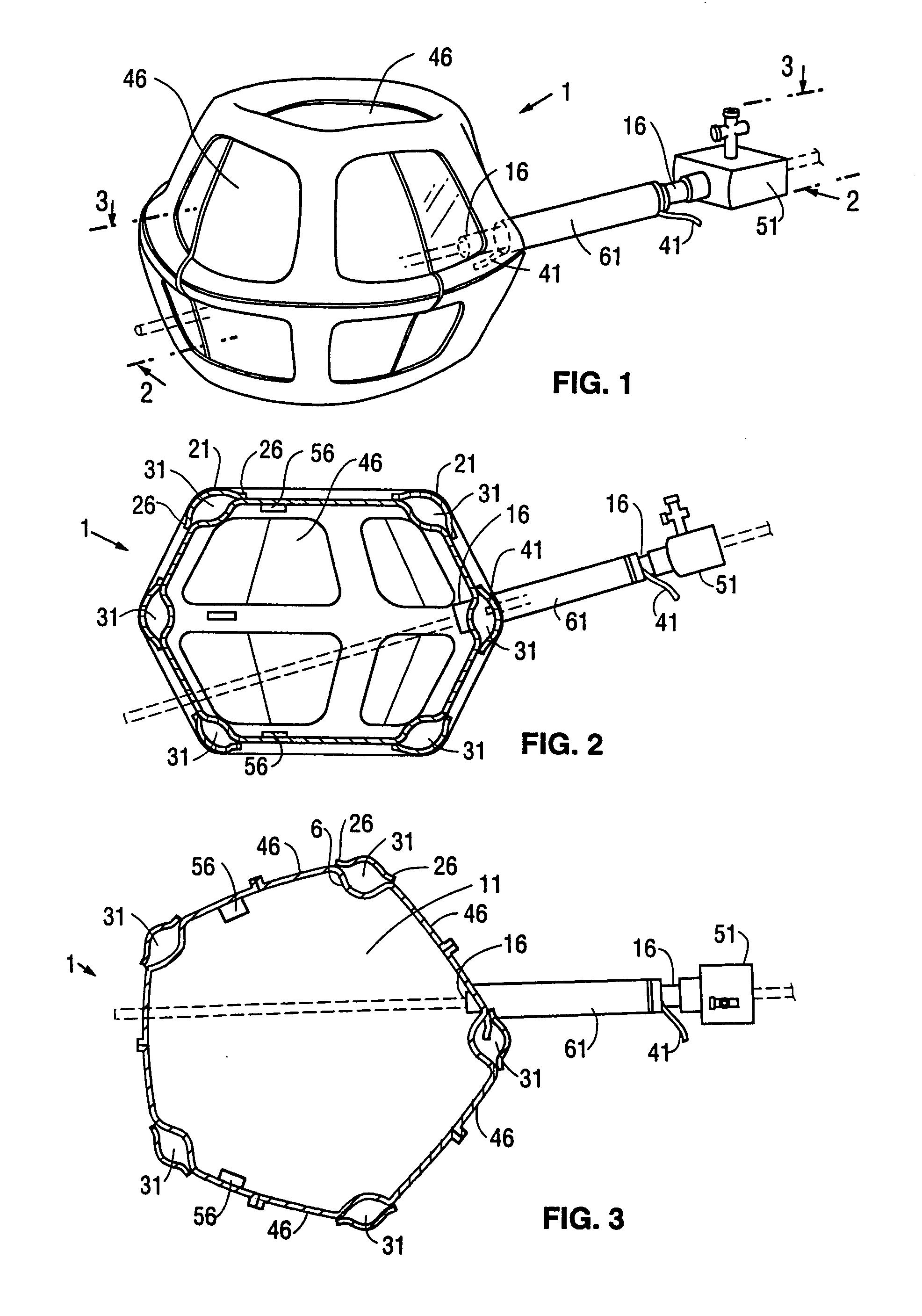

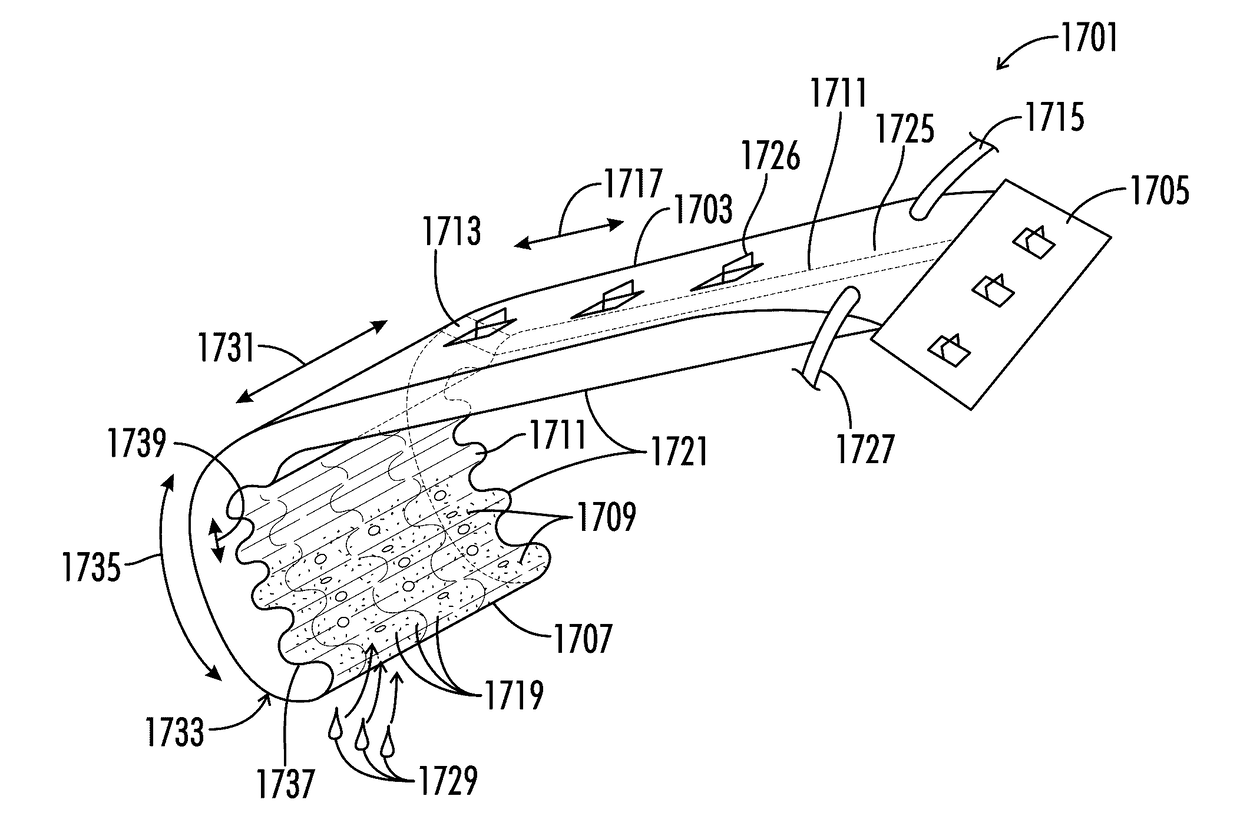

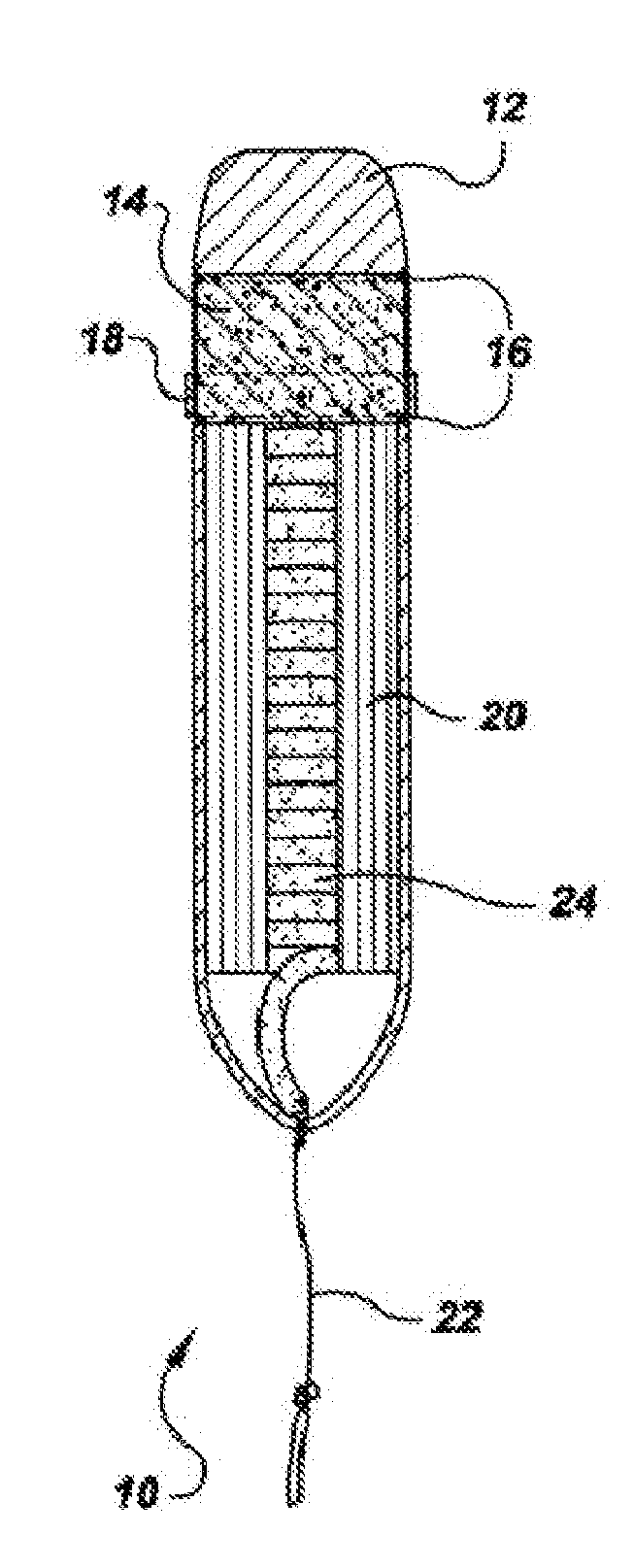

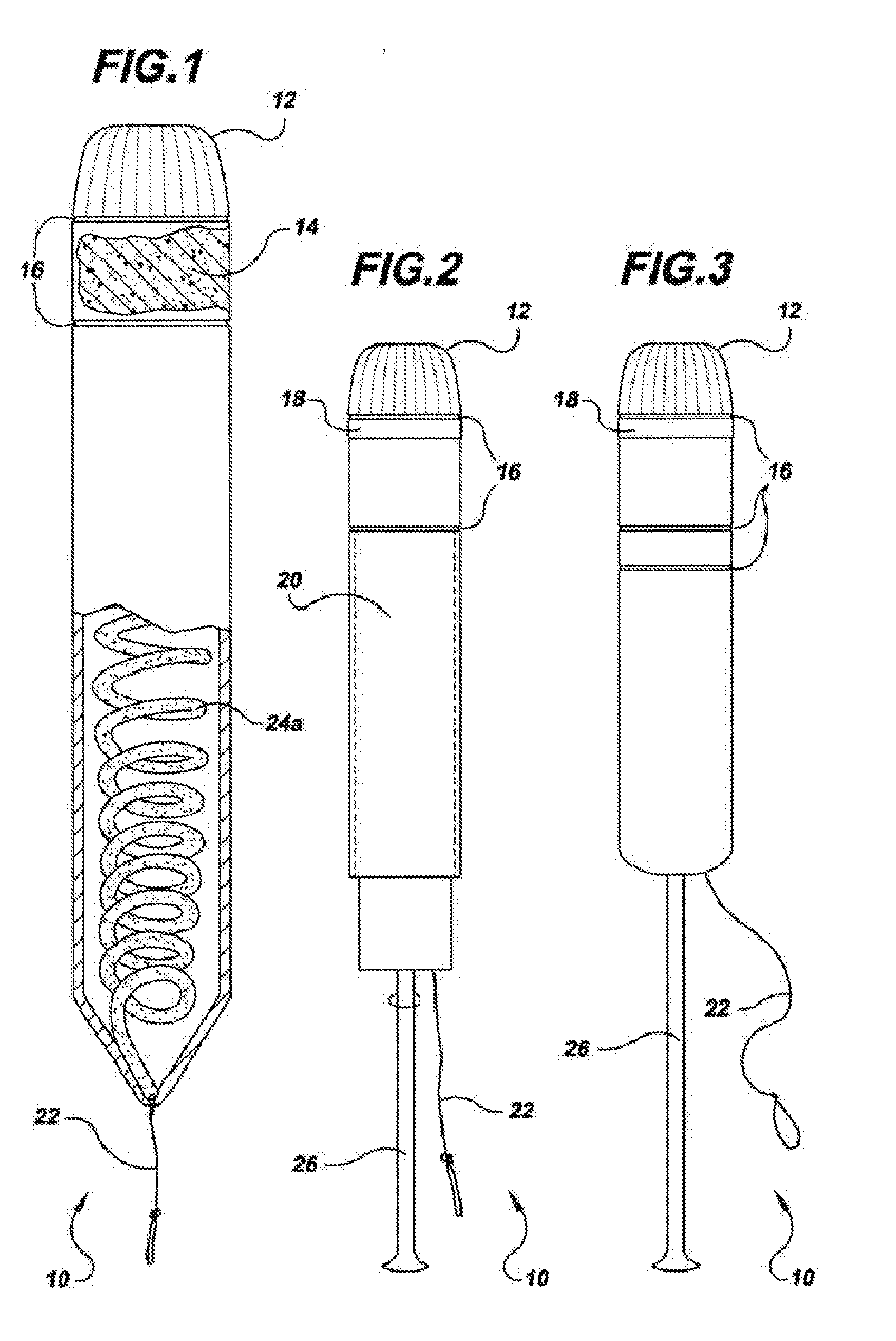

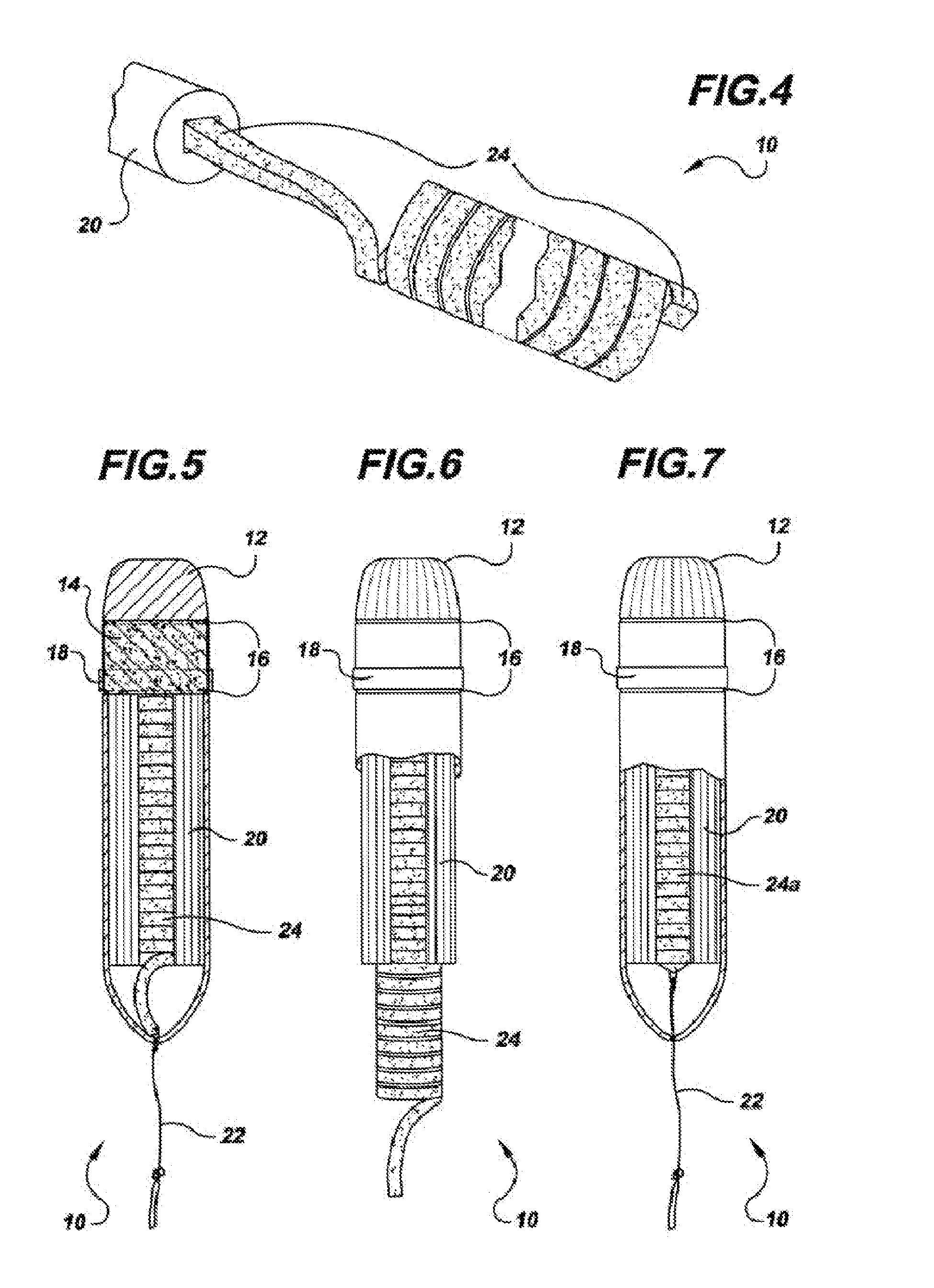

Wound penetrating hemostatic device impregnated with coagulant, antibiotic and/or anesthetic

InactiveUS20100036308A1Desired effectHighly visible and rapid and effectiveNon-adhesive dressingsDiagnosticsEmulsionTamponade

A tampon assembly used for penetration injuries to provide hemostasis and simultaneous broad spectrum antibiotic / anesthetic application. The tampon includes a helically-wound absorbent member impregnated with coagulant, covered with biodegradable or plastic accordion-pleated sheath including a bioluminescent tape outer marker. The device would also contain a measured dose of antibiotic / anesthetic suspension sealed within the confines of the outer sheath. The outer sheath would preferably have a perforated petal-shaped tip to enable wound insertion followed by through passage of the contained wound packing and treatment liquids / emulsions, etc. A radio opaque cotton withdrawal string would attach to the absorbent member at the end facing the wound opening. An insertion stick / plunger is used for tampon deposition within the wound. Manual pressure on the plunger would cause seal rupture and expulsion of the wound packing and treatment through the ruptured tip of the sheath. The tampon device may be of various sizes or shapes to conform to various injuries. It may be used intra-operatively during surgery as well.

Owner:OTTUSO PATRICK +1

Method of treating chronic fatigue syndrome

InactiveUS20030139476A1Achieve benefitsEffective amount for useBiocideNervous disorderDepressantTyrosine

The present invention provides a method of treating fibromyalgia syndrome (FMS), chronic fatigue syndrome (CFS), and pain in an animal subject comprising administering a therapeutically effective amount of a dual serotonin norepinephrine reuptake inhibitor compound or a pharmaceutically acceptable salt thereof, wherein said dual serotonin norepinephrine reuptake inhibitor compound is characterized by a non-tricyclic structure and a greater inhibition of norepinephrine reuptake than serotonin reuptake, and wherein said compound is not administered adjunctively with phenylalanine or tyrosine. In particular, the use of milnacipran to treat FMS, CFS, and pain is disclosed.

Owner:FOREST LAB HLDG LTD

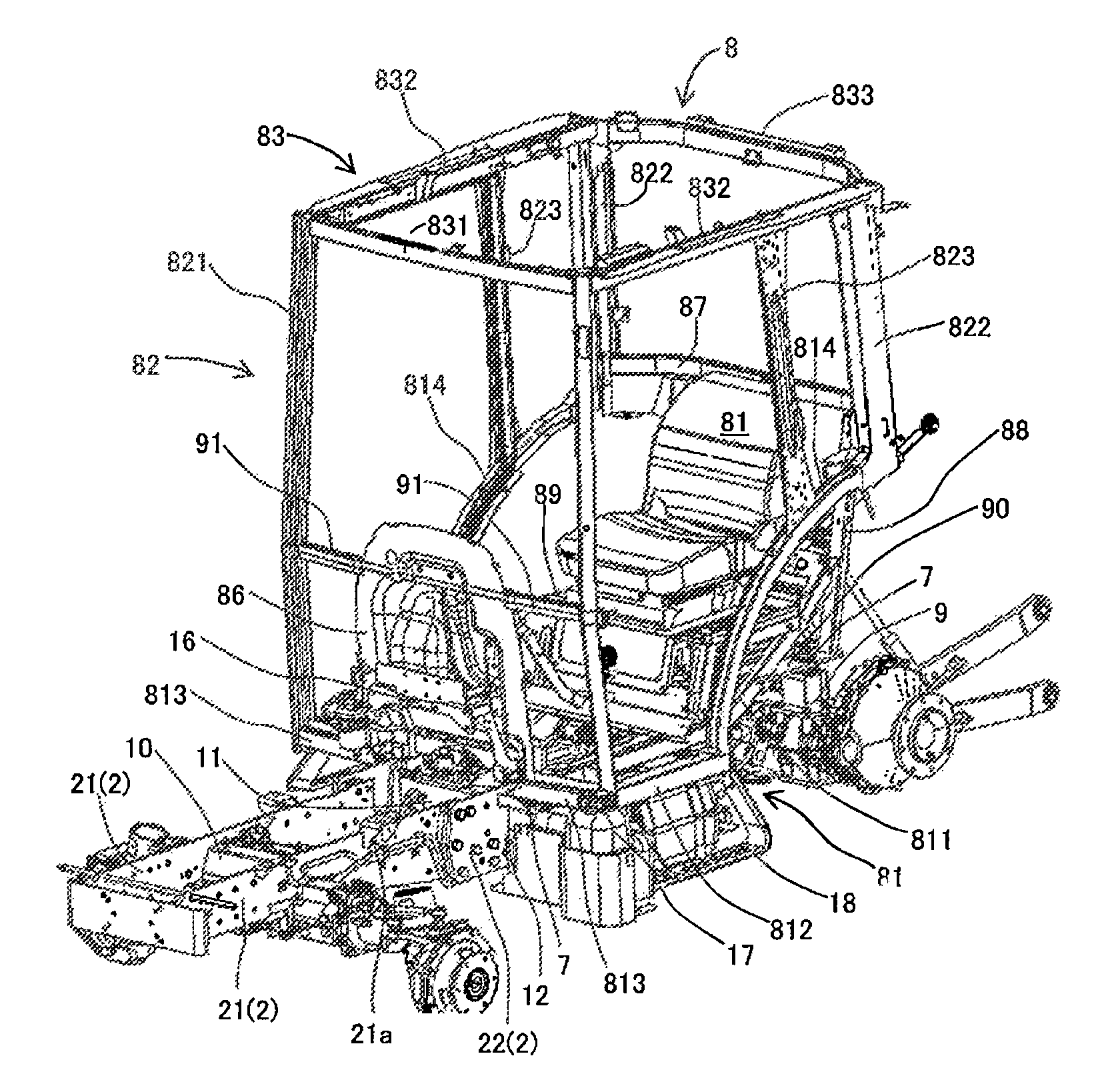

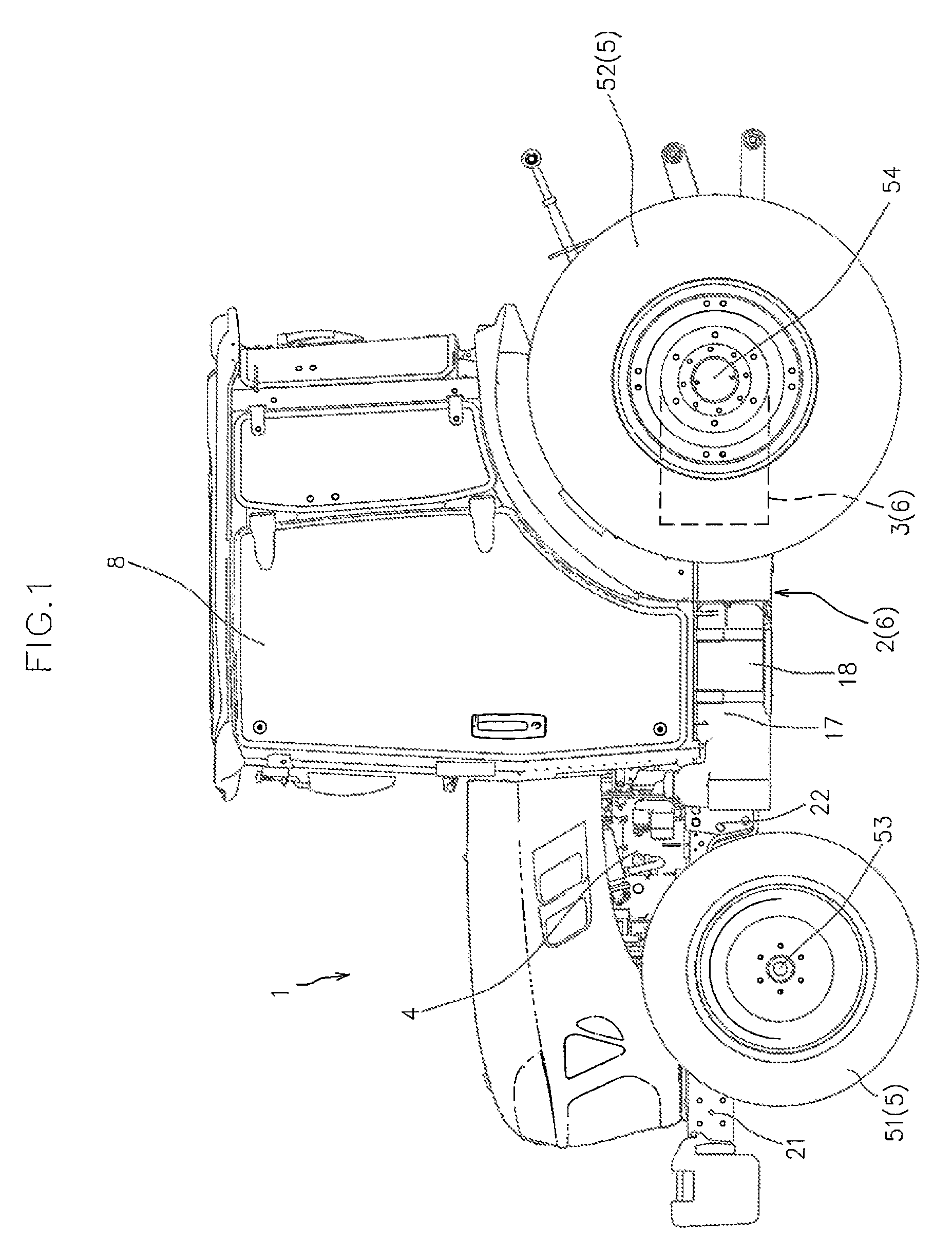

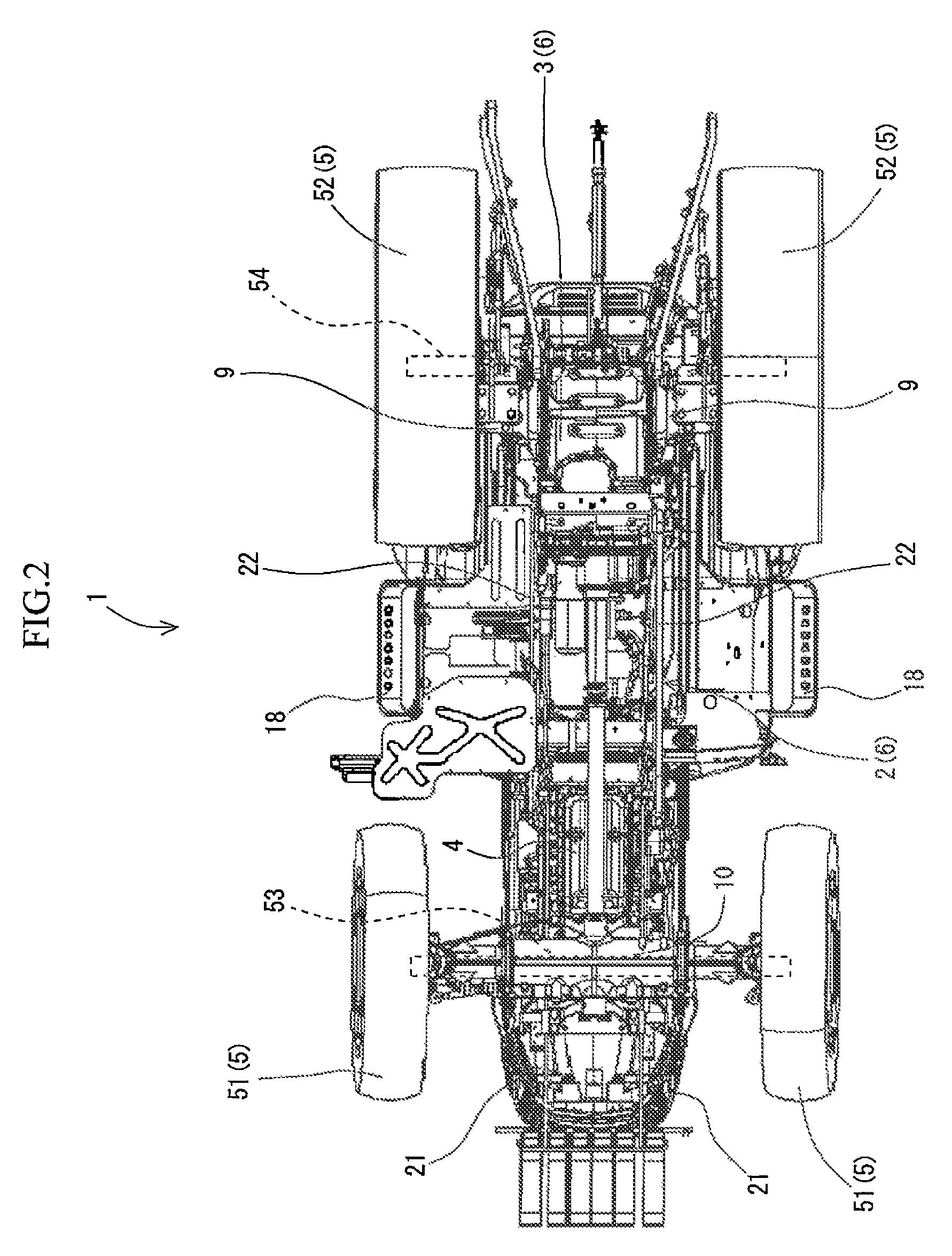

Working vehicle with cabin

ActiveUS8312955B2Simple structureImprove balanceVehicle body-frame connectionsUnderstructuresVibration isolationMechanical engineering

A working vehicle according to the present invention includes a pair of front frames and a pair of main frames that are detachably connected to each other, a reinforcing member coupling the pair of main frames while being overlapped therewith in a side view, a pair of attachment stays fixedly attached to outer side surfaces of the pair of main frames so as to be at least partially overlapped with the reinforcing member in a side view. A cabin is supported in a vibration-isolation manner at no less than four positions including the pair of attachment stays and right and left supporting positions that are provided at a pair of rear axle cases or a transmission case. The working vehicle can enhance stabilization of support of the cabin while simplifying a structure.

Owner:YANMAR POWER TECHNOLOGY CO LTD

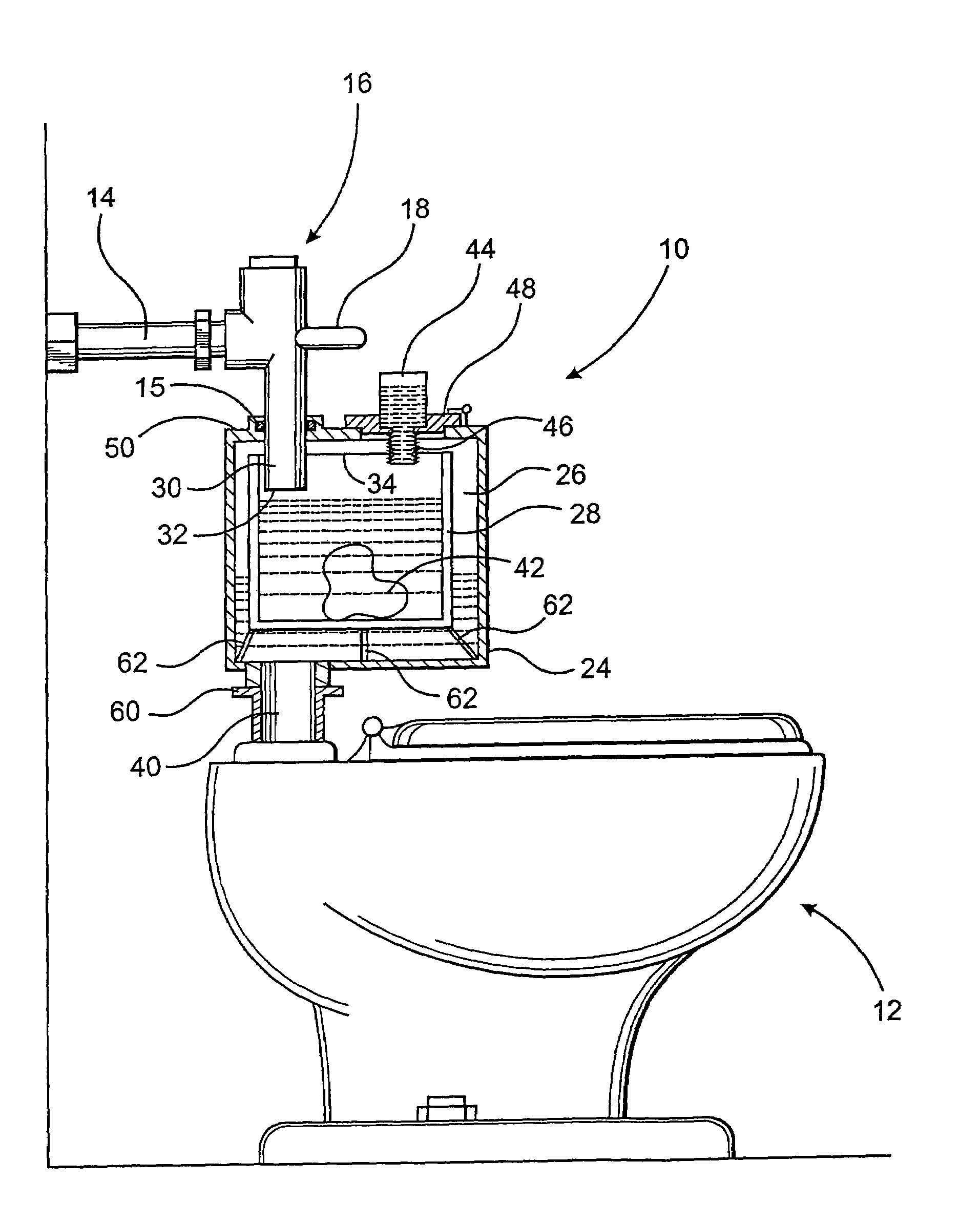

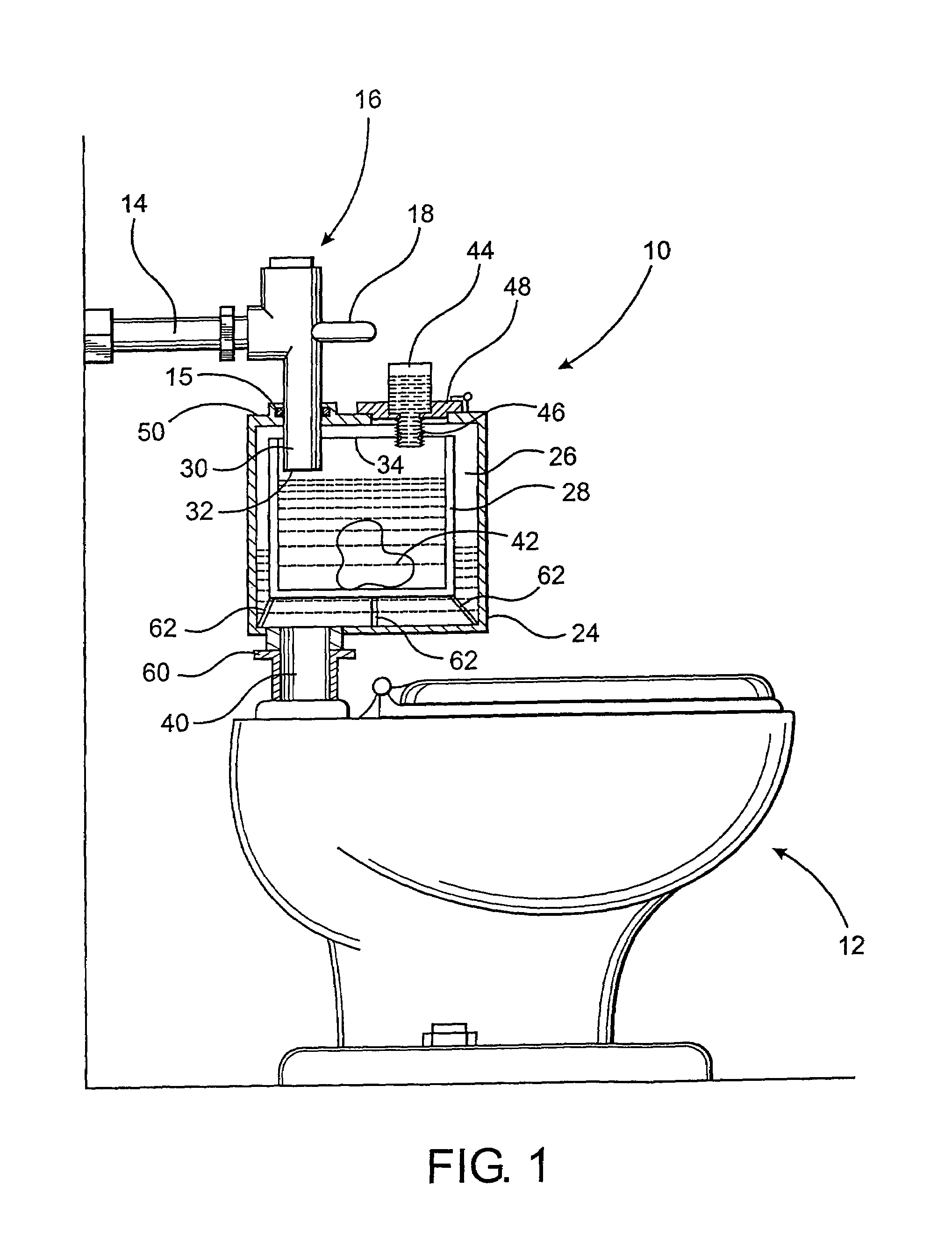

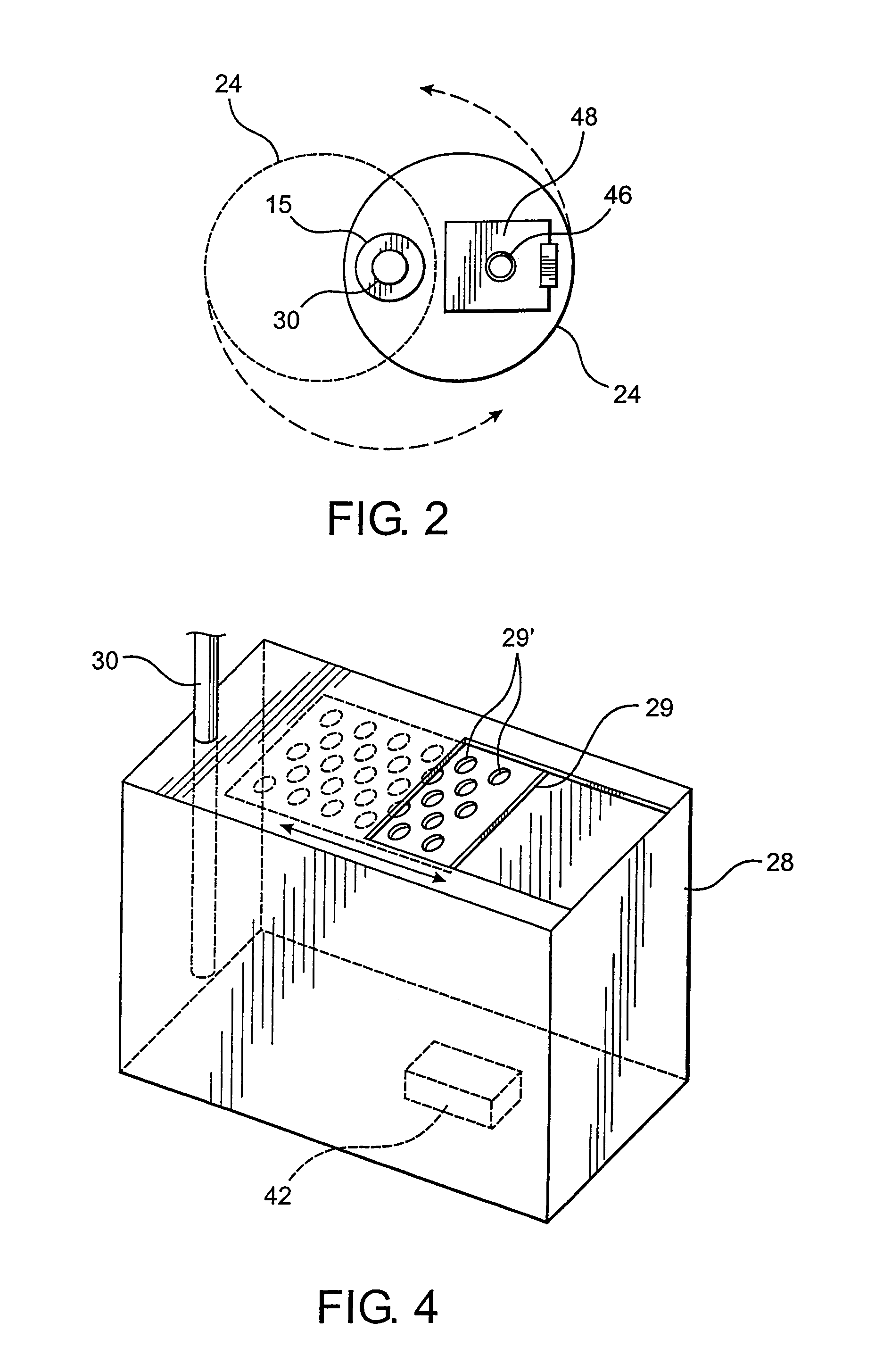

Automatic additive dispensing assembly

A dispensing assembly structured to automatically add or dispense cleanser, deodorant, disinfectant and / or like additive to a toilet bowl or urinal, particularly of the type used in commercial applications which are normally connected to a pressurized water supply for flushing without the presence of an accessible flush tank, as is present in most domestic toilet fixtures. The assembly comprising a retention chamber disposed in fluid communication between a pressurized water supply pipe and the toilet bowl or urinal and structured to retain the additive in contact with at least a first portion of the flush water. The outlet of the pressurized water supply pipe is structured to discharge a second portion of the flush water into the retention chamber thereby displacing the first portion of the flush water from the retention chamber into the toilet bowl or urinal and providing the additional water necessary during a flushing operation.

Owner:KORF RABBI ABRAHAM

Cigarettes and their construction

ActiveUS20160029692A1Rapidly extinguishedFully compressedNon-fibrous pulp additionNatural cellulose pulp/paperCigarette buttProcess engineering

A cigarette is provided with the tobacco column portion adjacent the filter assembly encased by a heat shrink material whereby as the burn approaches the butt the heat shrink material begins to contract radially and compress the encased tobacco column restricting the air flow therethrough. This reduces the diameter of burning column adjacent the filter assembly and thus extinguishes or at least confines the remaining tobacco in the cigarette.

Owner:TOTALLY NEW TECH PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics](https://images-eureka.patsnap.com/patent_img/75863e11-eb15-4fac-b728-e31a43c24920/US20060079558A1-20060413-D00001.png)

![R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics](https://images-eureka.patsnap.com/patent_img/75863e11-eb15-4fac-b728-e31a43c24920/US20060079558A1-20060413-C00001.png)

![R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics R-isomer of 2-{2[N-(2-indanyl)-N-phenylamino]ethyl}piperidine and other dermal anesthetics](https://images-eureka.patsnap.com/patent_img/75863e11-eb15-4fac-b728-e31a43c24920/US20060079558A1-20060413-C00002.png)