Gaseous fluid vessel propulsion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

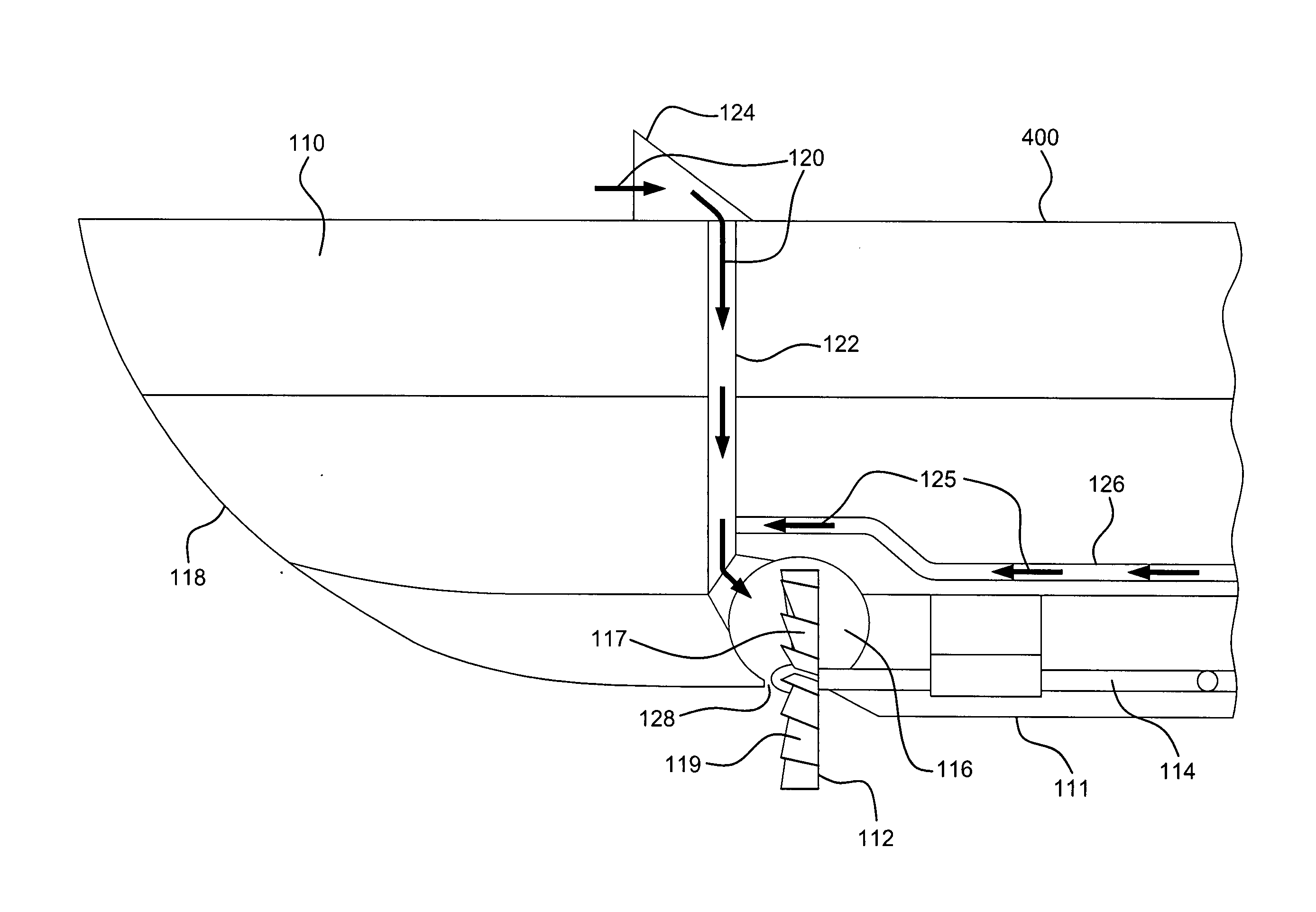

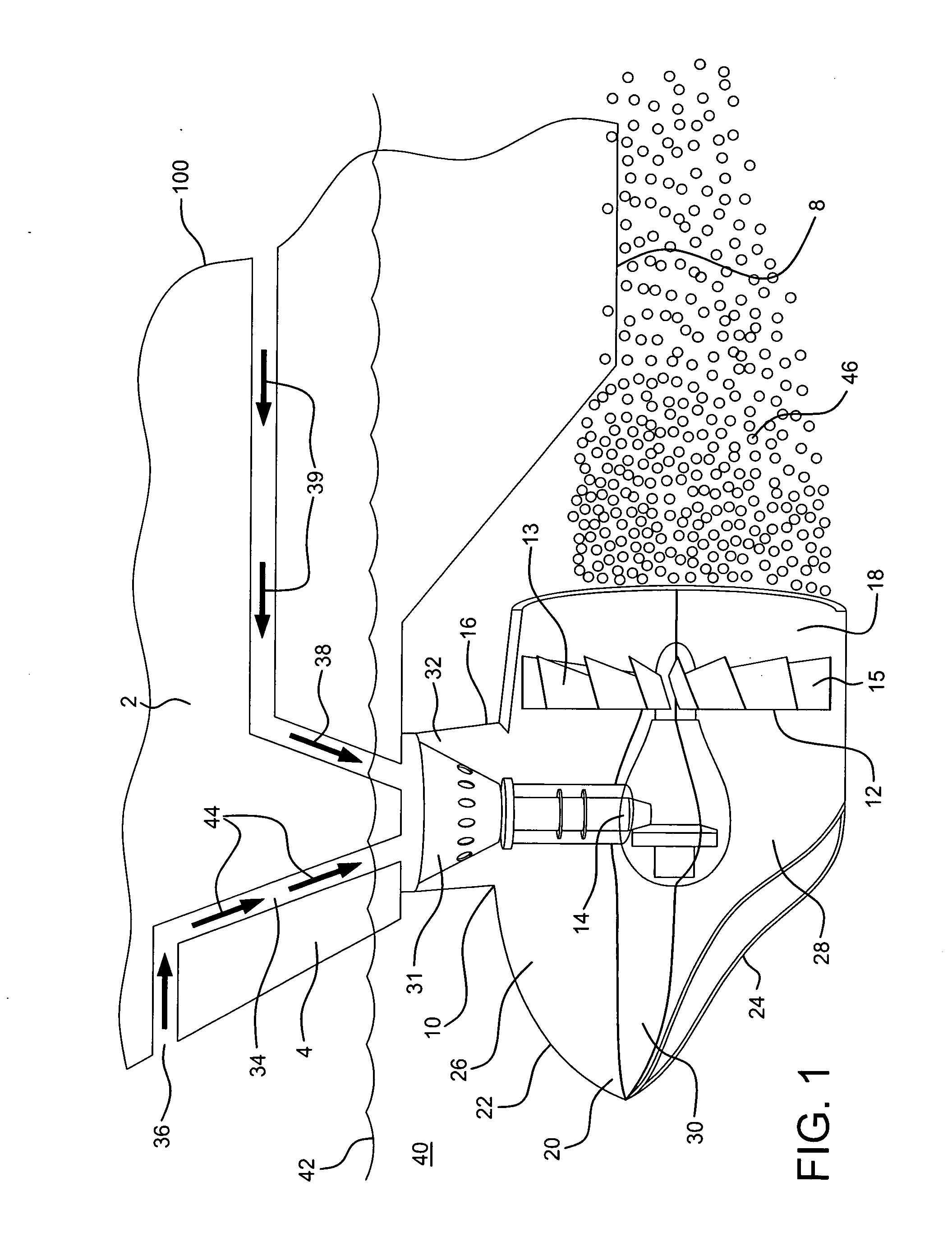

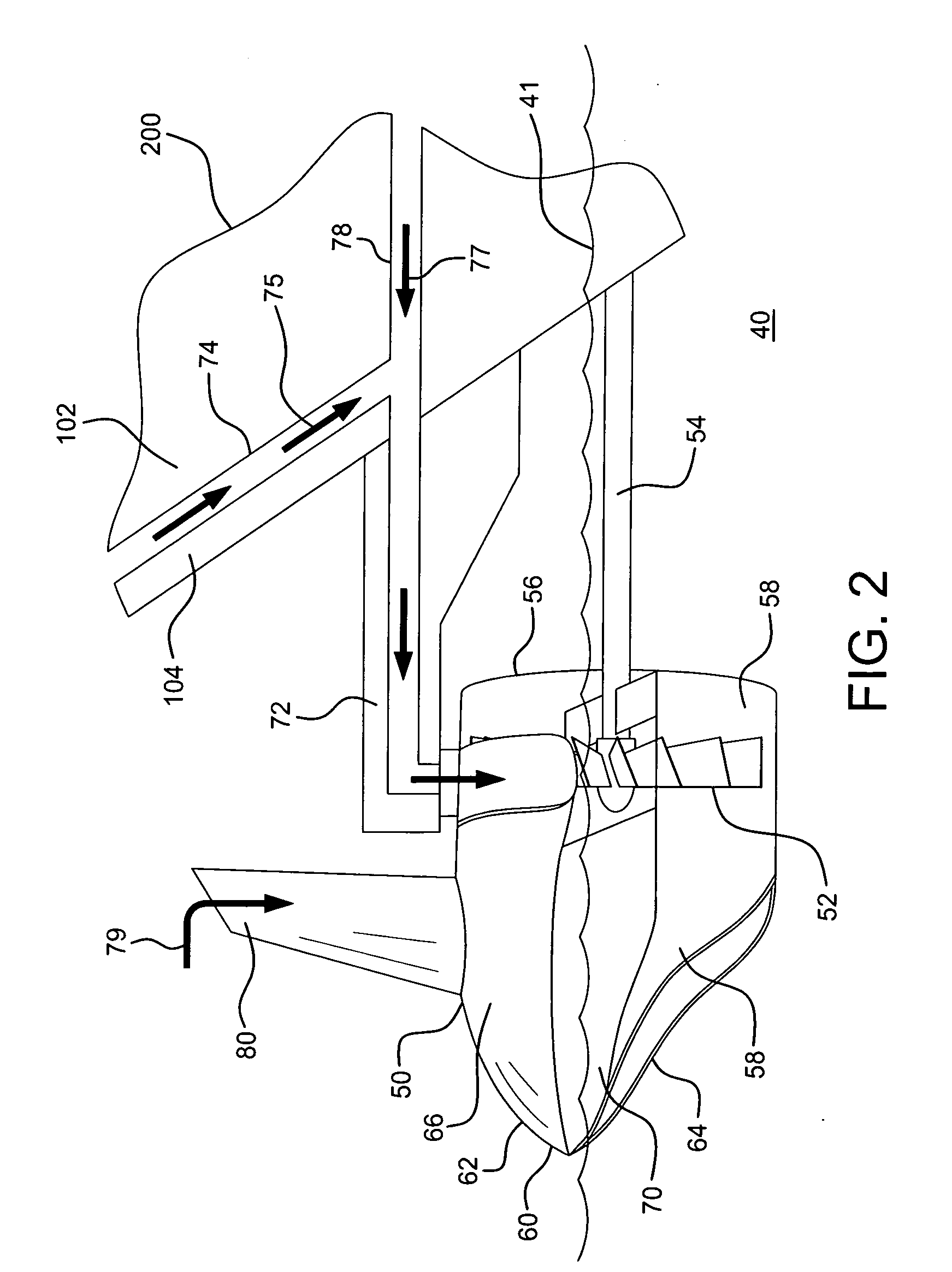

[0020]With particular reference to FIG. 1, waterborne vessel 100 comprises hull 2 having bow 4, stern 6, and hull bottom 8. Propulsion unit 10 extends down from bottom 8 at bow 4 of hull 2. The entire propulsion unit 10 shown in FIG. 1 is configured to be operational below waterline 42 when vessel 100 is moving in a forward direction 42 over body water 40.

[0021]Propulsion unit 10 comprises propeller 12, having a plurality of blades, operable via well known propulsion gearing 14 by the engine of vessel 100. Propeller 12 is housed or enshrouded within and circumscribed by rearward duct section 18 of propeller enclosure or duct 16. Duct 16 also comprises forward duct section 20 whose top portion 22 has a bulbous-type shape and whose bottom portion 24 gently slops downward and merges into the bottom of rearward section 18 of duct 16. Duct 16 is separated into upper duct section 26 and lower duct section 28 by transverse plate 30 which extends across the width of the duct. Duct 16 is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com